Professional Documents

Culture Documents

Practical Application of Solar Tunnel Dryers

Uploaded by

trossouwOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practical Application of Solar Tunnel Dryers

Uploaded by

trossouwCopyright:

Available Formats

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Practical Application of y Solar Tunnel Dryers

Klaus Triebe, ELNATAN (Association inc. under section 21) P.O. Box 161 Calitzdorp 6660 South Africa elnatanagape@lantic.net Tel/Fax++27 44 2133 859

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Table of contents

1. 2. 3. 4. Abstract Introduction Background Project 1. Fruit Leather 1. 2. 3. 4. 5. 6. 2. Preparation of drying moulds. Preparation of fruit Grinding of fruit Mixing of fruit pulp Drying of fruit leather Storage

Fruit Juice Concentrates 1. 2. Preparation of Dryer Concentration of juices in the dryer

5.

Conclusion

Abstract

Solar Tunnel Dryers (STD) are weather protected food dehydration tunnels that dry food economically and hygienically. STD are used to dry fruits and fruit pulp as well as concentration of fruit juices, juices especially of fruits that would otherwise quickly perish perish. Fruit leather is prepared sorted and washed and fruits, which is then shredded with common Kitchen machines. The fruit pulp is mixed with preservatives and sugar and volumetrically distributed unto plastic lined mould. After drying the fruit leather is stored in a cool room until finally packed or refined with chocolate. Fruit juices are concentrated in a STD using similar drying moulds as for the fruit leather. The dryer has to be equipped with an absolute level grid to receive the moulds. Sterilised fruit juice is p j poured into moulds to a depth of 2-3 cm for p evaporation. 50% of the water content is evaporated on the first day. Thereafter the evaporation slows down until the final stage of the concentrate is reached, depending on the requirement of the final product. (E.g. Juice Concentrate, Paste, or Juice Leather)

Back to TOC

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Introduction

ELNATAN is a non-profitable organisation with a Christian background. ELNATANs main purpose is to create jobs and to train adults in basic skills. ELNATAN t j b d t t i d lt i b i kill has a solar engineering section which has built a 10 m2 Scheffler Reflector, a Solar Tunnel Dryer and mass produces the Lazola box cookers. ELNATAN has a fruit drying and processing plant where the Solar Tunnel dryer is used. Raw materials are processed into fruit leathers which are refined with chocolate and yoghurt. We also produce fruit juice concentrates. All these products are sold to the public in our own shop. ELNATAN has a further section where standard building work is executed in our district.

Back to TOC previous next

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Back to TOC

previous

next

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Background

a) b) c) d) e) f) Our Solar Drying Plant is situated in the south of South Africa in the Cape Province. We are approx. 100km from the Coast. On average we have 300 sunny days per year year. Our average maximum Summer Temperature is 44 C. Average winter minimum Temperature is 2.6 C. We have a very dry climate. We do have frost in the winter that qualifies to grow fruit from the prunes family like apricots, peaches, plums and nectarines but also grapes and quinces as well as citrus fruits. Our fruit has a short fresh life time and is many times available at low cost, especially when the normal market is unable to absorb the excess fruit at short notice. Weather changes also make necessary to harvest fruit quickly. Some producers are far away from the fresh fruit market and have no other option than to dry their products.

g)

Back to TOC

previous

next

Background (continue)

h) In our area people have dried fruits for the last 150 years and have also produced fruit leather. Excessive grape juice was cooked until it became a heavy syrup which was used in the winter as a sugar substitute. Our company is specialised to manufacture fruit leathers and to a lesser extent grape juice concentrate. Through Heike Hoedt and Wolfgang Scheffler we were introduced to the paper, Solar Tunnel Dryer for Fruit - by Albert Esper and Solar Werner Muehlbauer from the Institute for Agriculture Engineering in the Tropics and Sub-Tropics at the University of Hohenheim Sub(Germany) (Germany). In order to produce products free of insects bird droppings and insects, dust we chose their tunnel dryer.

i) j)

k)

Back to TOC

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Background (continue)

We changed their design to suit our purpose, but the basic design criteria we kept, 2m wide and 20m long. We have b ilt one of th W h built f these d dryers 6 years ago and are d very much satisfied. m) The dryer has been built in 4 sections and can be dismantled and transported to any other location. n) One third of the dryer is used as an air heater section and 2thirds are used for drying. o) The tunnel is covered with standard tunnel plastic UV protected and lasts approx 3 seasons The tunnel can approx. seasons. be opened and closed by 3 people. The tunnel is equipped with 4 fans with a total capacity from 800 1000m3 per hour, powered by one solar panel 80W. l)

Back to TOC

previous

next

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Project

Fruit Leather

Preparation of drying moulds Preparation of fruit Grinding of fruit Mixing of fruit pulp Drying of fruit leather Storage Preparation of Dryer Concentration of juices in the dryer

Fruit Juice Concentrates

Back to TOC

previous

next

Fruit Leather

Standard fruit leather in our area is made from a pulp g ground in a liquidiser type of grinder. Normally this type q yp g y yp of pulp is cooked before drying. We have changed the recipe by not grinding the fruit but shredding it and not cooking but drying it raw. This helps to retain the flavour. During the drying process the flavour evaporates first before the water evaporates. By shredding the fruit we are maintaining small individual pieces of fruit. These pieces retain the flavour in the fibre fruit structure which makes our product more attractive and tasty.

Back to Project

Back to TOC

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Preparation of drying moulds

We have chosen to make our moulds out of 6mm super wood (in Germany MDF) with the sizes of 600mm length and 400 d 400mm width. idth The edge of our moulds have got a 15mm high wooden square bar. These moulds are light and handy to work. The moulds are lined with a thin layer of plastic (45 micron) which is strong enough that it can be removed easily from the finished product without tearing it. For one dryer you should have at least 2 sets of moulds. If the dryer is packed without the use of the air heater section (full length) the dryer will take 120 moulds that means you require 240 moulds. When weather conditions permit (high ambient temperatures like 35 C), we do not use the air heater section.

Back to Project Back to TOC previous next

previous

next

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Preparation of fruit

The fruit is of good quality, fresh and firm. The fruit is sorted and washed early in the morning, It is y g, good to start when it is still dark, because you need to finish the whole process of cutting the fruit and packing the dryer before 11am, that you have 2/3 of a day for the first drying process. The quality of your finished product is best when you can load the dryer early in the morning. Then the fruit has no chance to deteriorate. 30 40% of our excess moisture should evaporates on the first day otherwise the product is loosing on colour and texture. It is important that you have at least 2 days of full sunshine to create a good product. The final drying process can be in semi cloudy weather.

Back to Project Back to TOC previous next

previous

next

10

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

Grinding of fruit

We shred our fruit with normal household shredders which work on a batch system with other words we are y grinding approx. 800gr. of fruit into a container then stop the machine, empty the container and start again. We have found that industrial shredders which work continuously into a big bucket are extremely expensive and the output does not justify the extra cost. We use these household machines for 1 - 2 years before we have to replace them. This has enabled us to start our them production without a big capital layout. For our production we use 3-4 machines simultaneously.

Back to Project

Back to TOC

previous

next

11

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

Mixing of fruit pulp

The shredded fruit is now immediately mixed with a preservative (sulphur dioxide powder) to prevent oxidation and fermentation fermentation. The preservative quantity is kept to a minimum to prevent the destruction of the fruit until is dry. After drying the sugar and the low water content will preserve the fruit. The quantity of the preservative is so low, that most of the people do not realise that it has been used. The quantity of preservative depends on the type of fruit which you want to dry. After adding the preservative you have a little time as the texture of the fruit is not deteriorating anymore. Add only sugar just before you are spreading the mixture into the mould then the sugar has no time to extract moisture from the fruit before it is poured into the moulds.

Back to Project Back to TOC previous next

12

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

Drying of fruit leather

The fruit-sugar mixture is measured volumetric into the plastic lined moulds and spreaded evenly with a plastic spatula. It is important that the fruit-sugar mixture is accurately measured and spread for consistency. i Uneven spread fruit give unequal drying time and create problems when weighing and packing. The drying time is approx. 3 days, depending on weather conditions. We have temperatures from 35 C to 44 C in our area in South Africa during normal summer conditions. We do not need the air heater section in summer and fill the dryer completely to avoid too high temperatures. High temperatures (above 55 C) destroy the flavour of the product. After the drying process the moulds are taken out of the dryer and stored in an airy room criss-cross wise. criss cross wise The moisture of the product has to be equalised (in the beginning the surface of the product is the most dry). After a day we check all moulds dryness - moulds are returned to the dryer to finish the drying process if not completed. One drying mould will be loaded with an average mixture of 0.47kg sugar and 2.21kg fruit pulp which gives a total of 2.68kg. The finished product weighs 0.92kg

Back to Project Back to TOC previous next

13

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

14

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

15

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

16

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

17

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Storage

The finished dried product is taken to a concealed chamber where the product is exposed to a gas (Phostoxin), it has an active ingredient of aluminium phosphate which will kill any eggs of moths in case of contamination during the drying process. We pack 6 layers of the fruit leather with the original liner plastic still attached to the leather on top of each other and wrap this package in plastic and seal it properly with tape. Make sure that the packing from the fumigator to the cold store goes within a few hours that there is no more contamination possible. All products which are not packed/sold immediately are stored in a cool room at temperatures between 12 C and 14 C. Our finished products are packed into rolls or in flat sheets or small snips. Part of our products are cut to size and covered in chocolate or yoghurt and sold as a delicatessen - this is keeping our people busy during the rest of the year.

Back to Project

Back to TOC

previous

next

previous

next

18

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

19

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

20

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

21

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

Fruit Juice Concentrates

We have in South Africa a special grape which originates from the Muscadel family, we call these Grapes Hanepoot. G H t These grapes have a special strong muscadel flavour and are used mainly for table grapes of for drying to raisins. In past times the juice of these grapes was concentrated by cooking until it had a honey like consistency. Naturally most of the flavour was lost. With our solar dryer we can produce a product which retains most of the flavour and vitamins. We also make concentrates from other fruit juices like quince jelly (diabetics purchase mostly). Small quantities are produced, but it is a beginning.

Back to Project Back to TOC previous next

22

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Preparation of Dryer

The dryer has to be absolutely flat, as you can guess otherwise the liquid will th i th li id ill run to one side. In order to minimise this problem we use similar moulds as for the leather, except that the rim for the moulds have to be higher (35mm high).

Back to Project

Back to TOC

previous

next

previous

next

23

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

Concentration of juices in the dryer

In order to prevent fermentation, the fruit juice has to be sterilised and is poured hot into the lined moulds to depth f 20 30 t a d th of 20-30mm. 40 to 50% of the water content is evaporated on the first day. Thereafter the evaporation slows down until the final stage of the concentrate is reached. Some of the concentrate can be used as a jam; some like the quince jelly becomes leather. We have not fully utilised all the possibilities which there are but new products are developed all the are, time. Important is to utilise valuable fruit juice which otherwise would have been wasted. The concentrate can be stored and used later as required.

Back to Project Back to TOC previous next

24

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

previous

next

25

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

previous

next

Conclusion

Solar Tunnel Dryers are ideally suitable to preserve fruit which would otherwise perish by p p y producing fruit leathers g and fruit juice concentrates. These two products can conveniently be stored and transported as needed. Fruit leather has got a very popular market and can be profitably sold. Fruit leather also can be transformed further into a more valuable product by using chocolate or yoghurt coating. There is a great unexplored market to be developed and it is proven, that this can be developed in-expensive and economically viable.

Back to TOC

previous

next

26

International Solar Food Processing Conference 2009

India, Indore 14 16 January 2009

Back to TOC

previous

27

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Samal Architecture: I. Economic ActivitiesDocument6 pagesSamal Architecture: I. Economic ActivitiesYen DaNo ratings yet

- Challenges and Opportunities For Nepal'S Small and Medium Forest Enterprises (Smfes)Document103 pagesChallenges and Opportunities For Nepal'S Small and Medium Forest Enterprises (Smfes)Anusha BhattaraiNo ratings yet

- T.K Group of Industries: "Wooden Floor & Wooden Tiles"Document8 pagesT.K Group of Industries: "Wooden Floor & Wooden Tiles"Aminul Haque PavelNo ratings yet

- Mounting OrchidsDocument8 pagesMounting OrchidsJacksiel Rivas RivasNo ratings yet

- Cactus ReviewDocument20 pagesCactus ReviewLinx_ANo ratings yet

- Pulp and Paper IndustryDocument21 pagesPulp and Paper IndustryRishabh GulalkariNo ratings yet

- Cinderella's Drink MenuDocument1 pageCinderella's Drink MenuEater BostonNo ratings yet

- Impact Assessment of NGPDocument100 pagesImpact Assessment of NGPElsa Alabado-OrtegaNo ratings yet

- PFS2006 Forestry StatisticsDocument255 pagesPFS2006 Forestry StatisticsRudy LangiNo ratings yet

- Sample 3Document30 pagesSample 3vvyshak100% (8)

- Seed Selection PDFDocument4 pagesSeed Selection PDF小次郎 佐々木No ratings yet

- Chapter 4Document30 pagesChapter 4limuelNo ratings yet

- Mean Wood ExperimentationDocument30 pagesMean Wood Experimentationconfused597No ratings yet

- The Legend of The Coconut Tree (Edited)Document2 pagesThe Legend of The Coconut Tree (Edited)Erik WeeksNo ratings yet

- Inter CroppingDocument1 pageInter CroppingGrignionNo ratings yet

- Gunung Stong State Park BrochureDocument2 pagesGunung Stong State Park BrochureAmincyber NikNo ratings yet

- Tree AtlasDocument28 pagesTree AtlasAxyNo ratings yet

- Proposed Rule: Endangered and Threatened Species: Findings On Petitions, Etc.— California Spotted OwlDocument8 pagesProposed Rule: Endangered and Threatened Species: Findings On Petitions, Etc.— California Spotted OwlJustia.comNo ratings yet

- Climate Pt2 - Equatorial ClimateDocument15 pagesClimate Pt2 - Equatorial ClimateChristle NgoveNo ratings yet

- Framing Guidelines PDFDocument9 pagesFraming Guidelines PDFJase72HR100% (3)

- Chronicles of DanversDocument416 pagesChronicles of Danversgibson150100% (1)

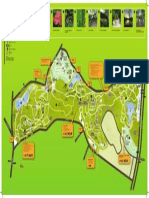

- Jardi BotànicDocument1 pageJardi BotànicMireya FernandezNo ratings yet

- Final ReportDocument61 pagesFinal ReportPrashant GopiNo ratings yet

- Sowing Light Fluffy SeedsDocument10 pagesSowing Light Fluffy SeedsRobert NorthwayNo ratings yet

- Urban Tree Risk MGM NTDocument204 pagesUrban Tree Risk MGM NTJonathan German AlacioNo ratings yet

- LysaghtArchitecturalDetailingManualRoofWallFlashingApril14 PDFDocument40 pagesLysaghtArchitecturalDetailingManualRoofWallFlashingApril14 PDFthailanNo ratings yet

- Bonsai00shar PDFDocument148 pagesBonsai00shar PDFBrian-Marti Boatright100% (1)

- Cebu Provincial Agricultural Profile PDFDocument74 pagesCebu Provincial Agricultural Profile PDFJonathan Filoteo100% (1)

- Class:10 Important Questions (Natural Vegetation) Very ShortDocument1 pageClass:10 Important Questions (Natural Vegetation) Very ShortVriti GuptaNo ratings yet

- Invasive Species in Ecological Habitats of National Parks in BhutanDocument56 pagesInvasive Species in Ecological Habitats of National Parks in BhutanYigphel100% (5)