0% found this document useful (0 votes)

59 views4 pagesMPP1 Lab - Exp. 2

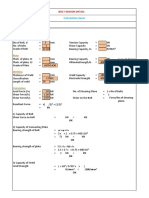

The document outlines the process of Tungsten Inert Gas (TIG) welding, detailing the aim, materials, equipment, theory, procedure, precautions, applications, advantages, and disadvantages of the technique. TIG welding utilizes a non-consumable tungsten electrode and inert gas to create strong, high-quality welds on various metals, particularly in critical applications like aerospace. While it offers benefits such as cleaner joints and versatility, it also has drawbacks including a slower process and the need for skilled operators.

Uploaded by

ahsansiam454Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

59 views4 pagesMPP1 Lab - Exp. 2

The document outlines the process of Tungsten Inert Gas (TIG) welding, detailing the aim, materials, equipment, theory, procedure, precautions, applications, advantages, and disadvantages of the technique. TIG welding utilizes a non-consumable tungsten electrode and inert gas to create strong, high-quality welds on various metals, particularly in critical applications like aerospace. While it offers benefits such as cleaner joints and versatility, it also has drawbacks including a slower process and the need for skilled operators.

Uploaded by

ahsansiam454Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd