8.

2 Design of Tubular Reactors 229

the velocity profile be flat as one traverses the tube diam- that is used in a batch reactor. Although this analogy is

eter. Each plug of fluid is assumed to be uniform in tem- often useful, it may on occasion be misleading. Batch reac-

perature, composition, and pressure, which is equivalent to tors are almost invariably operated under the constraint of

assuming that radial mixing is infinitely rapid. However, constant volume, whereas in a tubular reactor, each plug

there may well be variations in composition, temperature, of fluid more nearly approximates constant pressure con-

pressure, and fluid velocity as one moves in the longitu- ditions. For liquid phase reactions constraints of constant

dinal direction. With respect to these variations, however, volume and constant pressure may effectively be satisfied

the model requires that mass transport via diffusion or tur- simultaneously, and the same is true of isothermal gas phase

bulent mixing processes be negligible. The plugs of mate- reactions that do not involve a change in the number of gas

rial do, however, interact with one another with respect to phase moles on reaction. However, when there is a change

both transmission of the hydrodynamic forces giving rise in temperature or in the number of molecules contained

to the fluid motion and transfer of thermal energy from one within the plug, the volume of the plug can change by an

plug to another if the plugs differ in temperature. Some of appreciable fraction. To maintain a constant mass velocity

the aforementioned requirements may be removed in more at various points along a uniform-diameter tube in cases

complex mathematical models of tubular reactors. In the where there is an increase in the number of moles on reac-

present chapter, however, we limit our discussion to the tion (an increase in plug volume), an increase in the vol-

simplest possible model: the plug flow model. Nonetheless, umetric flow rate must accompany the reaction. Instead of

when we attempt to compare the results predicted by the giving rise to the pressure increase that would take place in

model with what we observe in the real world, we should a constant volume batch reactor, the change in the number

keep in mind that the model can only reflect the idealiza- of moles on reaction causes the fluid to accelerate. Thus,

tions built into it and that deviations from ideal behavior the residence time of the plug in the reactor will be less

can fall into three categories. than that which would have been observed if the volume of

1. There will be velocity gradients in the radial direction, the plug remained unchanged. We turn now to the problem

so all fluid elements will not have the same residence of developing fundamental design relationships that allow

time in the reactor. Under turbulent flow conditions in for such effects.

reactors with large length/diameter ratios, any dispari- Consider the segment of tubular reactor shown in

ties between values observed and model predictions Figure 8.3. Because the fluid composition varies with

arising from this factor should be small. For short longitudinal position, we must write our material balance

reactors and/or laminar flow conditions, the disparities for a reactant species over a different element of reactor

can be appreciable. Some of the techniques used in (dVR ). Moreover, since plug flow reactors are usually oper-

the analysis of isothermal tubular reactors that deviate ated at steady state except during startup and shutdown

from plug flow are treated in Chapter 11. procedures, the relations of major interest are those in

2. There will be an interchange of material between fluid which the accumulation term is missing from equation

elements at different axial positions by virtue of ordi- (8.0.1). Thus,

nary molecular diffusion and eddy diffusion processes rate of flow Rate of flow of

arising from turbulence and/or the influence of any of reactant into = reactant out of

packing in the bed. Convective mixing arising from volume element volume element

thermal gradients in the reactor may also contribute

to the exchange of matter between different fluid rate of disappearance

elements. of reactants by chemical

+ (8.2.1)

reactions within the

3. There may be radial temperature gradients in the reac-

volume element

tor that arise from the interaction between the energy

released by reaction, heat transfer through the walls of If the molal flow rate of reactant A into the volume ele-

the tube, and convective transport of energy. This factor ment is designated as FA , and the molal flow rate out of

is the greatest potential source of disparities between the volume element is represented by FA + dFA , equation

the predictions of the model and the behavior observed

for real systems. The deviations are most significant in

nonisothermal packed-bed reactors.

The tubular reactor is a convenient means of approach-

ing the performance characteristics of a batch reactor on a

continuous basis, since the distance–pressure–temperature

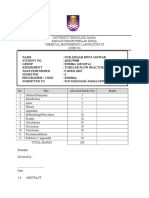

history of the various plugs as they flow through the reac- Figure 8.3 Schematic representation of differential volume element

tor corresponds to the time–pressure–temperature protocol of plug flow reactor.

�230 Chapter 8 Basic Concepts in Reactor Design and Ideal Reactor Models

(8.2.1) becomes

FA = (FA + dFA ) + (−rA ) dVR (8.2.2)

or

dFA = rA dVR (8.2.3)

At any point the molal flow rate of reactant A can be

expressed in terms of the fraction conversion fA and the

molal flow rate corresponding to zero conversion FA0 :

FA = FA0 (1 − fA ) (8.2.4)

Differentiation gives

dFA = −FA0 dfA (8.2.5)

Combination of equations (8.2.3) and (8.2.5) gives

dVR dfA

= (8.2.6)

FA0 (−rA )

which may be integrated over the entire reactor volume to

obtain

fA out

VR dfA

FA0 ∫fA in (−rA )

= (8.2.7)

This equation is a very useful relation that indicates

the reactor size necessary to accomplish a specified change Figure 8.4 Determination of VR ∕FA0 from plot of reciprocal rate

in the degree of conversion for a fixed inlet molal flow versus fraction conversion.

rate. However, it requires a knowledge of the relationship

between the reciprocal rate of reaction and the fraction

conversion. For nonisothermal systems this relationship lead to cancellation of CA0 , with a similar term appearing

can be quite complex, as we shall see in Chapter 10. in the reaction rate expression.

It should be emphasized that for ideal tubular reactors If the temperature is constant throughout the reactor

(PFRs), it is the total volume per unit of feed that deter- volume, the rate constant k may be removed from the

mines the conversion level achieved. The ratio of the length integral, and an analytic solution can often be obtained for

of the tube to its diameter is irrelevant, provided that plug the integral. At times it will be necessary to evaluate the

flow is maintained and that one uses the same flow rates and integrals in equations (8.2.7) and (8.2.9) using graphical or

pressure–temperature profiles expressed in terms of reactor numerical methods. Figure 8.4 indicates this schematically.

volume elements. For nonisothermal systems one must employ an energy

FA0 may also be written as the product of a volumet- balance in conjunction with the basic design equation to

ric flow rate and a reactant concentration where both are relate the temperature (and thus the temperature-dependent

measured at some reference temperature and pressure and terms in the rate expression) to the fraction conversion.

correspond to zero fraction conversion. Thus, The relations are such that exact analytical solutions can

VR VR rarely, if ever, be obtained (see Chapter 10).

τ

= = (8.2.8) For cases where δ = 0, equation (8.2.9) can be written

FA0 CA0 V0 CA0 in terms of concentrations:

where we have introduced the space time τ. Combining CA out

dCA

∫CA in

equations (8.2.8) and (8.2.7) gives τ=− (8.2.10)

(−rA )

fA out

VR dfA

∫fA in (−rA )

τ= = CA0 (8.2.9) but for constant density systems only. For variable density

V0

systems it is more convenient to work in terms of the frac-

Reactor inlet conditions are particularly useful as refer- tion conversion [equation (8.2.9)]. For constant-density

ence conditions for the volumetric flow rate in that they not systems either equation (8.2.9) or equation (8.2.10) is

only give physical meaning to CA0 and V0 but also usually appropriate.