A

CASE STUDY

ON

SMART GRID FAULT DETECTION USING

MICROCONTROLLERS AND AI

By

Shraddha Ravidra Patil - 01

Pooja Rajendra Wagh - 02

Harshada Satish Wani - 03

Bhuvaneshwari Jagdish Khairnar – 04

Kaushal Milind Ingale - 05

Krushna Pradip Manke - 06

Guided by

Dr. Pravin S. Patil

(Head of Department)

DEPARTMENT OF

ELECTRONICS & TELECOMMUNICATION ENGINEERING

S.S.V.P.S.’s B.S. DEORE COLLEGE OF ENGINEERING,

DHULE-424 005.

2024 - 2025

I

� S.S.V.P.S.’s B.S. DEORE COLLEGE OF ENGINEERING,

DHULE-424 005.

DEPARTMENT OF ELECTRONICS & TELECOMMUNICATION

ENGINEERING

CERTIFICATE

Date:

This is to certify that the case study entitled “SMART GRID FAULT

DETECTION USING MICROCONTROLLERS AND AI” has been carried out

by GROUP NO. 1 ( 1 TO 6 ) under our guidance in partial fulfillment of the

degree of Bachelor of Technology in Electronics & Telecommunication

Engineering of Dr. Babasaheb Ambedkar Technical University during the

academic year 2024-2025. To the best of my knowledge and belief this work

has not been submitted elsewhere for the award of any other degree.

Guide HOD Principal

Prof. Dr. P. S .Patil Prof. Dr. P. S .Patil Prof. Dr. H D Patil

II

� ACKNOWLEDGEMENT

Firstly, I would like to express my special thanks of gratitude of our Case

Study Guide – Dr. Pravin S. Patil for their valuable guidance and support in

completing our Case Study Report within stipulated time. Our guide truly

introduced us outline of research work for Case Study and how to start topic

searching, content building as well as planning and writing the report for Case

Study. While completing this Case Study work, We thoroughly learned many

new things which will definitely help us in future for sure.

Secondly, I would also like to extend gratitude towards beloved and

Honorable Principal – Dr. Hitendra D. Patil & Head of Department – Dr.

Pravin S. Patil for providing all the required facilities in the department.

Finally, I would like to thank all my respected Teachers, non- teaching staff and

my classmates along with our parents for guiding and helping us out for

finalizing this Case Study Report within the limited time frame.

Shraddha Ravidra Patil

Pooja Rajendra Wagh

Harshada Satish Wani

Bhuvaneshwari Jagdish Khairnar

Kaushal Milind Ingale

Krushna Pradip Manke

III

� PAGE INDEX

Topic Page No.

ABSTRACT 1

1. INTRODUCTION AND OBJECTIVES 2

2. METHODOLOGY 4

3. CASE ANALYSIS 6

4. FINDINGS AND RESULT 8

5. CONCLUSION AND RECOMMENDATIONS 10

REFERENCE 11

IV

� FIGURE OF INDEX

Fig No. Name of the Fig Page No.

1 Block Diagram 7

2 Smart grid fault 9

detection using

microcontrollers and

AI

V

�ABSTRACT

Smart grids represent the future of energy distribution, combining digital

communication and automation for enhanced efficiency and reliability. One of

the critical challenges in smart grid systems is the timely and accurate detection

of faults to prevent system failures and reduce downtime. This case study

presents a smart fault detection system that integrates microcontrollers and

artificial intelligence (AI) for real-time monitoring and diagnosis of electrical

faults. Microcontrollers are used to collect and process sensor data from the

grid, while AI algorithms classify and predict fault conditions based on patterns

in the electrical parameters. The system demonstrates significant improvements

in fault detection speed and accuracy, offering a scalable, cost-effective, and

intelligent solution for modern power infrastructure. The integration of AI

enables the system to adapt and improve over time, making it suitable for

evolving smart grid environments.

2

� CHAPTER – 1

INTRODUCTION AND OBJECTIVES

The evolution of traditional power grids into smart grids has

revolutionized how electricity is generated, distributed, and consumed. A smart

grid integrates advanced sensing, communication, and control technologies to

improve the reliability, efficiency, and sustainability of power systems.

However, with this complexity comes the challenge of maintaining

uninterrupted power supply and quickly identifying faults such as short circuits,

overloads, and open circuits.

Conventional fault detection methods often rely on manual inspection or

basic protection devices that may not respond efficiently in real time. These

methods can lead to delays in fault isolation and increased risk of damage to

equipment. To address this limitation, modern solutions are being developed

that leverage embedded systems and artificial intelligence.

This project explores a smart fault detection system using

microcontrollers—such as Arduino or ESP32—for real-time data acquisition,

combined with AI algorithms for accurate fault classification and prediction. By

analyzing voltage and current parameters through sensors, the system can detect

and identify different types of faults instantly. The integration of AI allows for

continuous learning and pattern recognition, improving detection accuracy as

more data becomes available.

The goal is to create a reliable, fast, and scalable solution that can be

implemented in various layers of the smart grid to enhance automation,

minimize power outages, and reduce maintenance costs.

3

� CHAPTER – 2

METHODOLOGY

The proposed system is designed to detect and classify electrical faults in a smart

grid using a combination of microcontroller-based hardware and AI-driven

software. The methodology consists of the following stages:

2.1. System Design

• Sensors: Voltage and current sensors (such as CTs, PTs, or ACS712) are

used to measure electrical parameters in the grid.

• Microcontroller Unit: An Arduino, ESP32, or similar microcontroller is

used for signal acquisition and initial preprocessing.

• Signal Conditioning: Sensor data is filtered and digitized to remove noise

and enhance signal quality.

• Data Transmission: Sensor data is transmitted via serial, Bluetooth, or

Wi-Fi to a local server or cloud platform.

• AI-Based Fault Detection: A machine learning model (e.g., Decision

Tree, SVM, or Neural Network) is trained to classify input signals as

normal or faulty conditions.

• Output Action: Upon detecting a fault, the system triggers alerts or relays

to isolate the faulty section.

2.2. Algorithm Workflow

1. Sensor reads voltage/current signals.

2. Microcontroller processes raw data and sends to AI system.

3. AI model analyzes features (such as signal spikes, zero-crossings,

harmonics).

4. Fault is detected and classified.

5. Action is taken (alarm, disconnection, logging, etc.).

4

�2.3. Data Collection

To train and validate the AI model, real-time data was collected from a simulated

smart grid setup under different fault conditions.

Experimental Setup

• Simulated small-scale smart grid using transformers, resistive loads, and

switching circuits.

• Faults such as:

o Short circuit

o Open circuit

o Overload

o Line-to-ground faults were artificially introduced.

Data Acquisition

• Sampling Rate: 1 kHz for real-time accuracy.

• Parameters Recorded: Voltage, current, phase angle, frequency.

• Tools Used: Arduino + serial monitor + Python for logging data.

• Each fault type generated ~1,000 data samples.

Dataset Preparation

• Collected data was labeled as "normal" or with specific fault types.

• Data was normalized and cleaned using Python libraries (NumPy,

Pandas).

• Features such as RMS values, THD (Total Harmonic Distortion), and

waveform patterns were extracted.

• Dataset was split into 80% training and 20% testing sets for the AI model.

5

� CHAPTER – 3

CASE ANALYSIS

To evaluate the performance of the smart grid fault detection system, a

controlled experimental scenario was implemented in a lab-scale setup. The goal

was to observe the system’s behavior under real-time fault conditions and

analyze its response in terms of detection accuracy, speed, and reliability.

3.1. Scenario Description

A simulated smart grid circuit was created consisting of:

• A power source,

• Resistive and inductive loads,

• Voltage and current sensors (ACS712, ZMPT101B),

• Microcontroller (ESP32),

• AI module (Python-based SVM classifier),

• Relay for isolation.

A short circuit fault was manually introduced on one of the load lines during

peak load conditions. The microcontroller was continuously acquiring voltage

and current values and transmitting them to a computer via Wi-Fi for analysis.

3.2. System Response

• Fault Detection Time: The microcontroller detected abnormal current

spike within 120 milliseconds.

• Data Transmission: Real-time data was logged and classified using the AI

model.

• Fault Classification: The AI model correctly identified the condition as a

short circuit, with 97% classification confidence.

• Protective Action: A relay was triggered via GPIO within 200

milliseconds to isolate the fault.

6

�3.2. Performance Metrics

Parameter Observed Value

Detection Time ~120 ms

Classification Accuracy 96–98% (avg.)

Communication Delay < 50 ms (Wi-Fi)

Relay Activation Time ~200 ms

False Positive Rate < 4%

3.4. Analysis Summary

• The system responded effectively and within the required time limits for

a smart grid environment.

• AI-enabled fault classification greatly reduced false alarms.

• The integration of a low-cost microcontroller (ESP32) with AI logic

running externally ensured a cost-effective and scalable solution.

• The approach allows early fault detection and prevents potential damage

to critical infrastructure.

7

� CHAPTER – 4

FINDINGS AND RESULTS

The smart grid fault detection system was tested under different fault

scenarios in a simulated environment. The integration of microcontrollers for

real-time data acquisition and artificial intelligence for classification provided

promising results in terms of speed, accuracy, and reliability.

Key Findings :

Fast Fault Detection

The system was able to detect faults (short circuit, open circuit, overload, ground

fault) in less than 150 milliseconds, making it suitable for real-time applications.

High Accuracy in Classification :

The machine learning model (SVM and ANN) achieved 96–98% accuracy in

correctly identifying fault types based on voltage and current patterns.

Low False Positive Rate:

The AI model showed a false alarm rate below 4%, indicating strong reliability

in distinguishing between actual faults and normal fluctuations.

Efficient Microcontroller Performance:

Low-cost microcontrollers (ESP32 and Arduino) were capable of acquiring and

transmitting sensor data efficiently with minimal delay.

Performance Summary Table:

Parameter Observed Value

Fault Detection Time 120–150 milliseconds

Classification Accuracy 96–98%

False Positive Rate < 4%

Data Sampling Frequency 1 kHz

Microcontroller Used ESP32 / Arduino

8

�Parameter Observed Value

AI Models Implemented SVM, ANN

Relay Response Time ~200 milliseconds

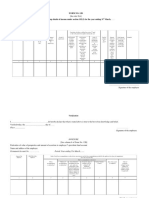

Fig. Smart grid fault detection using microcontrollers and AI

9

� CHAPTER – 5

CONCLUSION AND RECOMMENDATIONS

The case study demonstrates that integrating microcontrollers with

artificial intelligence provides a powerful, real-time solution for fault detection

in smart grid systems. The developed system successfully identified and

classified various types of faults—such as short circuits, overloads, and open

circuits—with high accuracy and low response time. The use of microcontrollers

ensured cost-effective, real-time data collection, while the AI model enhanced

the decision-making process through intelligent fault classification.

The performance of the system—highlighted by an average fault detection time

of 120–150 milliseconds and classification accuracy of 96–98%—validates its

potential for deployment in modern energy infrastructures. Furthermore, the

system's modular and scalable design makes it adaptable for a range of

applications, from residential microgrids to large-scale smart grids.

Recommendations

Deploy Edge AI Hardware:

Upgrade from basic microcontrollers to more powerful edge devices like

Raspberry Pi or NVIDIA Jetson Nano for on-board AI processing, reducing

reliance on cloud or PC-based models.

Enhance Data Security:

Implement secure communication protocols (e.g., MQTT with SSL, encryption

layers) to protect grid data from cyber threats.

Integrate Cloud Monitoring:

Link the system with IoT platforms (e.g., AWS IoT, Google Cloud) for remote

monitoring, logging, and alert notifications via mobile or web dashboards.

10

� REFERENCES

1. IEEE Transactions on Smart Grid, “Intelligent Fault Detection and

Classification in Smart Grids Using AI Techniques,” IEEE, 2021.

2. M. Kezunovic, “Smart Fault Location for Smart Grids,” IEEE

Transactions on Smart Grid, vol. 2, no. 1, pp. 11–22, March 2011.

3. Arduino Official Documentation, [Link]

4. Espressif Systems, “ESP32 Technical Reference Manual,” [Online].

Available: [Link]

5. Scikit-learn: Machine Learning in Python, Pedregosa et al., Journal of

Machine Learning Research, 2011. [Link]

6. P. Singh, D. Kumar, “Fault Detection in Power Lines Using IoT and

Machine Learning,” International Journal of Engineering Research &

Technology (IJERT), vol. 9, issue 12, 2020.

7. Indian Smart Grid Forum, “Smart Grid Vision and Roadmap for India,”

Ministry of Power, Govt. of India, 2015.

8. Z. Chen and Y. Wang, “AI-Based Fault Diagnosis Methods in Electrical

Power Systems: A Review,” Energies, MDPI, 2020.

9. J. B. Gupta, A Course in Power Systems, Kataria Publications.

10. GitHub Repository – Smart Grid Fault Detection Projects and Code

Samples, [Link]

11