0% found this document useful (0 votes)

23 views15 pagesControl Valve Sizing !-1

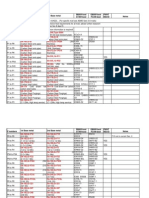

Control valves are essential for regulating flow, pressure, temperature, or liquid level in processes by adjusting the flow passage size based on control signals. Key characteristics include flow types such as linear, equal percentage, and quick opening, while sizing considerations involve parameters like flow medium, pressure-temperature ratings, and valve coefficients (Cv). The Cv value is crucial for selecting the appropriate valve size, ensuring effective control within the optimal stroke range.

Uploaded by

Hassan ElmasriCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

23 views15 pagesControl Valve Sizing !-1

Control valves are essential for regulating flow, pressure, temperature, or liquid level in processes by adjusting the flow passage size based on control signals. Key characteristics include flow types such as linear, equal percentage, and quick opening, while sizing considerations involve parameters like flow medium, pressure-temperature ratings, and valve coefficients (Cv). The Cv value is crucial for selecting the appropriate valve size, ensuring effective control within the optimal stroke range.

Uploaded by

Hassan ElmasriCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd