0% found this document useful (0 votes)

21 views4 pagesDelta Engineering 10 Krishnakunj, 3rd Oor, 1187/23 Ghole Road, Pune +91-20-25520163 / 9422015840

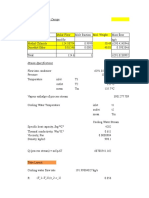

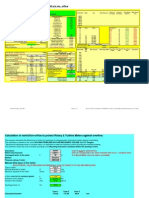

Delta Engineering acknowledges the acceptance of a purchase order from Thermo Fab Engineers for the supply of goods related to a boiler feed water and high-pressure steam project. The expected delivery timeframe is 6-8 weeks from receipt of approved drawings. Contact information for inspection and delivery is provided, along with a request to mention the order acceptance reference in future correspondence.

Uploaded by

manuchaurasiya580Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

21 views4 pagesDelta Engineering 10 Krishnakunj, 3rd Oor, 1187/23 Ghole Road, Pune +91-20-25520163 / 9422015840

Delta Engineering acknowledges the acceptance of a purchase order from Thermo Fab Engineers for the supply of goods related to a boiler feed water and high-pressure steam project. The expected delivery timeframe is 6-8 weeks from receipt of approved drawings. Contact information for inspection and delivery is provided, along with a request to mention the order acceptance reference in future correspondence.

Uploaded by

manuchaurasiya580Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd