0% found this document useful (0 votes)

57 views7 pagesSOM Assignment

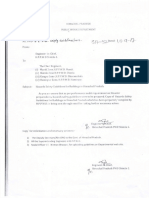

The document outlines a series of written assignment questions and case studies related to the topics of stress, strain, deformation of solids, transverse loading on beams, torsion, deflection of beams, and the behavior of thin and thick cylinders. Each question is assigned specific marks and categorized under different units, focusing on practical applications and calculations in mechanical engineering. The document is intended for students in the B.E. Mechanical Engineering program for the academic year 2023-2024.

Uploaded by

gopalakrishnanmechCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

57 views7 pagesSOM Assignment

The document outlines a series of written assignment questions and case studies related to the topics of stress, strain, deformation of solids, transverse loading on beams, torsion, deflection of beams, and the behavior of thin and thick cylinders. Each question is assigned specific marks and categorized under different units, focusing on practical applications and calculations in mechanical engineering. The document is intended for students in the B.E. Mechanical Engineering program for the academic year 2023-2024.

Uploaded by

gopalakrishnanmechCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd