Professional Documents

Culture Documents

Effects of Elements On Steel

Uploaded by

Karthik Karthi0 ratings0% found this document useful (0 votes)

50 views4 pagesHardness and tensile strength increases as carbon content increases. Manganese contributes to strength and hardness, but less than carbon. Phosphorus decreases ductility and notch impact toughness of steel. Higher phosphorus is specified in low-carbon free-machining steels.

Original Description:

Original Title

Effects of Elements on Steel

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHardness and tensile strength increases as carbon content increases. Manganese contributes to strength and hardness, but less than carbon. Phosphorus decreases ductility and notch impact toughness of steel. Higher phosphorus is specified in low-carbon free-machining steels.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

50 views4 pagesEffects of Elements On Steel

Uploaded by

Karthik KarthiHardness and tensile strength increases as carbon content increases. Manganese contributes to strength and hardness, but less than carbon. Phosphorus decreases ductility and notch impact toughness of steel. Higher phosphorus is specified in low-carbon free-machining steels.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 4

Effects of Elements on Steel

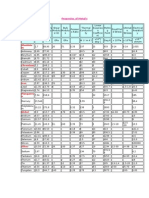

-------------------------------------------------------------------------------------------------------------------------------------------Carbon has a major effect on steel properties. Carbon is the primary

hardening element in steel. Hardness and tensile strength

increases as carbon content increases up to about 0.85% C as

shown in the figure above. Ductility and weld ability decrease with

increasing carbon.

------------------------------------------------------------------------------------------------------------------------------------------Manganese is generally beneficial to surface quality especially in

resulfurized steels. Manganese contributes to strength and hardness,

but less than carbon. The increase in strength is dependent upon the

carbon content. Increasing the manganese content decreases ductility

and weld ability, but less than carbon. Manganese has a significant

effect on the harden ability of steel.

----------------------------------------------------------------------------------------------------------------------------------------Phosphorus increases strength and hardness and decreases

ductility and notch impact toughness of steel. The adverse effects on

ductility and toughness are greater in quenched and tempered highercarbon steels. Phosphorous levels are normally controlled to low levels.

Higher phosphorus is specified in low-carbon free-machining

steels to improve mach inability.

---------------------------------------------------------------------------------------------------------------------------------------Sulphur decreases ductility and notch impact toughness especially in the

transverse direction. Weldability decreases with increasing sulfur

content. Sulfur is found primarily in the form of sulfide inclusions. Sulfur

levels are normally controlled to low levels. The only exception is freemachining steels, where sulfur is added to improve machinability.

---------------------------------------------------------------------------------------------------------------------------------------Silicon is one of the principal deoxidizers used in steelmaking. Silicon is

less effective than manganese in increasing as-rolled strength and

hardness. In low-carbon steels, silicon is generally detrimental to

surface quality.

-------------------------------------------------------------------------------------------------------------------------------------------Copper in significant amounts is detrimental to hot-working steels.

Copper negatively affects forge welding, but does not seriously affect

arc or oxyacetylene welding. Copper can be detrimental to surface

quality. Copper is beneficial to atmospheric corrosion resistance when

present in amounts exceeding 0.20%. Weathering steels are sold having

greater than 0.20% Copper.

--------------------------------------------------------------------------------------------------------------------------------------Lead is virtually insoluble in liquid or solid steel. However, lead is

sometimes added to carbon and alloy steels by means of mechanical

dispersion during pouring to improve the machinability.

-------------------------------------------------------------------------------------------------------------------------------------Boron is added to fully killed steel to improve hardenability. Borontreated steels are produced to a range of 0.0005 to 0.003%. Whenever

boron is substituted in part for other alloys, it should be done only with

hardenability in mind because the lowered alloy content may be

harmful for some applications.

-------------------------------------------------------------------------------------------------------------------------------------Chromium is commonly added to steel to increase corrosion

resistance and oxidation resistance, to increase hardenability,

or to improve high-temperature strength. As a hardening element,

Chromium is frequently used with a toughening element such as nickel

to produce superior mechanical properties. At higher temperatures,

chromium contributes increased strength. Chromium is a strong carbide

former. Complex chromium-iron carbides go into solution in austenite

slowly; therefore, sufficient heating time must be allowed for prior to

quenching.

--------------------------------------------------------------------------------------------------------------------------------------Nickel is a ferrite strengthener. Nickel does not form carbides in steel.

It remains in solution in ferrite, strengthening and toughening the ferrite

phase. Nickel increases the hardenability and impact strength of

steels.

-------------------------------------------------------------------------------------------------------------------------------------------Molybdenum increases the hardenability of steel. Molybdenum may

produce secondary hardening during the tempering of quenched

steels. It enhances the creep strength of low-alloy steels at elevated

temperatures.

------------------------------------------------------------------------------------------------------------------------------------------Aluminum is widely used as a deoxidizer. Aluminium can control

austenite grain growth in reheated steels and is therefore added to

control grain size. Aluminium is the most effective alloy in controlling

grain growth prior to quenching. Titanium, zirconium, and vanadium are

also valuable grain growth inhibitors, but there carbides are difficult to

dissolve into solution in austenite.

------------------------------------------------------------------------------------------------------------------------------------------Zirconium can be added to killed high-strength low-alloy steels to achieve

improvements in inclusion characteristics. Zirconium causes sulfide inclusions to

be globular rather than elongated thus improving toughness and ductility in

transverse bending.

------------------------------------------------------------------------------------------------------------------------------------------Niobium (Columbium) increases the yield strength and, to a lesser

degree, the tensile strength of carbon steel. The addition of small

amounts of Niobium can significantly increase the yield strength

of steels. Niobium can also have a moderate precipitation strengthening

effect. Its main contributions are to form precipitates above the

transformation temperature, and to retard the recrystallization of

austenite, thus promoting a fine-grain microstructure having improved

strength and toughness.

----------------------------------------------------------------------------------------------------------------------------------------Titanium is used to retard grain growth and thus improve toughness.

Titanium is also used to achieve improvements in inclusion characteristics.

Titanium causes sulfide inclusions to be globular rather than elongated thus

improving toughness and ductility in transverse bending.

-------------------------------------------------------------------------------------------------------------------------------------------Vanadium increases the yield strength and the tensile strength

of carbon steel. The addition of small amounts of Niobium can

significantly increase the strength of steels. Vanadium is one of the

primary contributors to precipitation strengthening in microalloyed

steels. When thermomechanical processing is properly controlled the

ferrite grain size is refined and there is a corresponding increase in

toughness. The impact transition temperature also increases when

vanadium is added.

------------------------------------------------------------------------------------------------------------------------------------------

You might also like

- Application of Plain Carbon SteelDocument39 pagesApplication of Plain Carbon SteelDivyesh Kumar0% (1)

- AAMRADocument50 pagesAAMRARona Khairol Pratama100% (1)

- COMPUTATIONDocument24 pagesCOMPUTATIONMaynard BaralNo ratings yet

- Welcome To JB SteelDocument5 pagesWelcome To JB SteelMohit BansalNo ratings yet

- Steel Material ScienceDocument15 pagesSteel Material Science04352No ratings yet

- High Strength Low Alloy SteelsDocument42 pagesHigh Strength Low Alloy SteelsDeepak PatelNo ratings yet

- Assignment #03 Non-Ferrous Metals & AlloysDocument1 pageAssignment #03 Non-Ferrous Metals & AlloysAbdo siyedNo ratings yet

- Effect of Elements On SteelDocument18 pagesEffect of Elements On SteelMohamed Ahmed MaherNo ratings yet

- Copper Alloys InfoDocument18 pagesCopper Alloys InfoPhung Tuan AnhNo ratings yet

- Welding Al CastingsDocument13 pagesWelding Al CastingsSmartNo ratings yet

- Classification of SteelsDocument9 pagesClassification of SteelsrajbhushanbhattNo ratings yet

- Ferro Silicon Calcium Cored Wire: Chemical Composition of Casi PowderDocument4 pagesFerro Silicon Calcium Cored Wire: Chemical Composition of Casi PowderVasu RajaNo ratings yet

- Steels Used in Coated Sheet Products: GalvinfonoteDocument8 pagesSteels Used in Coated Sheet Products: GalvinfonoteFabio FabregasNo ratings yet

- Cast Steel Is 1030Document4 pagesCast Steel Is 1030Shailendra SharmaNo ratings yet

- Assignment #01 Alloy SteelsDocument1 pageAssignment #01 Alloy SteelsAbdo siyedNo ratings yet

- SAE 1020 s5Document26 pagesSAE 1020 s5Nikola BoskovicNo ratings yet

- Submitted in Partial Fulfillment of The Requirements For The Award ofDocument25 pagesSubmitted in Partial Fulfillment of The Requirements For The Award ofAnuj TripathiNo ratings yet

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNo ratings yet

- Structure and PropertiedDocument43 pagesStructure and PropertiedJalaj GaurNo ratings yet

- USS PlateDocument78 pagesUSS Platepipedown456No ratings yet

- Assignment #02 Cast IronsDocument1 pageAssignment #02 Cast IronsAbdo siyedNo ratings yet

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDocument8 pagesWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNo ratings yet

- JPH04365841A Original Document 20200926111404 ADocument7 pagesJPH04365841A Original Document 20200926111404 ASteve OoiNo ratings yet

- Guide To Beryllium CopperDocument46 pagesGuide To Beryllium CopperJonson CaoNo ratings yet

- Aluminum Bronze PDFDocument37 pagesAluminum Bronze PDFTi AnnelNo ratings yet

- Steel Cleanliness ReportDocument8 pagesSteel Cleanliness ReportSiva SubramaniNo ratings yet

- Effect of Elements On SteelDocument18 pagesEffect of Elements On SteelHaytham MohamedNo ratings yet

- Brunswick Steel Reference ManualDocument79 pagesBrunswick Steel Reference ManualDarrell MayoNo ratings yet

- Lecture-1, Plain Carbon SteelsDocument40 pagesLecture-1, Plain Carbon Steelssatish chinthamNo ratings yet

- NASA Bolting Design ManualDocument98 pagesNASA Bolting Design ManualjoshhinesNo ratings yet

- UC Aluminium CatalogueDocument44 pagesUC Aluminium CatalogueGaurav AgarwalNo ratings yet

- Ebook Civil Engineering Materials 1St Edition Sivakugan Solutions Manual Full Chapter PDFDocument28 pagesEbook Civil Engineering Materials 1St Edition Sivakugan Solutions Manual Full Chapter PDFtironcolossald30y100% (10)

- Civil Engineering Materials 1st Edition Sivakugan Solutions ManualDocument7 pagesCivil Engineering Materials 1st Edition Sivakugan Solutions Manualbinhlinhh9ih100% (32)

- Fabrication Guide PDFDocument96 pagesFabrication Guide PDFbookpp100% (2)

- BL501. Learning Pack 4 - Reinforcement Bars in Concret WorksDocument5 pagesBL501. Learning Pack 4 - Reinforcement Bars in Concret WorksLaki AlgomNo ratings yet

- KB Alloys Foundrymans Guide To SR and TiBorDocument7 pagesKB Alloys Foundrymans Guide To SR and TiBorfoundryjoeNo ratings yet

- Ic 4340Document2 pagesIc 4340asfsdfsdfgdsNo ratings yet

- Chapter - 15 Boiler Metallurgy DefinitionsDocument12 pagesChapter - 15 Boiler Metallurgy DefinitionsRavi ShankarNo ratings yet

- 01 PDFDocument51 pages01 PDFantonioNo ratings yet

- Aluminum Data SheetDocument15 pagesAluminum Data Sheetabdalla el-saadaneyNo ratings yet

- FC-06-Engineering Material & Metallurgy PDFDocument431 pagesFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- FLBOEA Course Notes Welding MEM05026B-Sections 13-18Document111 pagesFLBOEA Course Notes Welding MEM05026B-Sections 13-18stanleyNo ratings yet

- Course Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineDocument63 pagesCourse Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineGopi GopinathNo ratings yet

- 1.1 Advantages of Steel As A Structural MaterialDocument11 pages1.1 Advantages of Steel As A Structural MaterialAlaa TelfahNo ratings yet

- Class 8 Science Notes Ch-1Document9 pagesClass 8 Science Notes Ch-1deepakatoliaNo ratings yet

- Calculation Sheets For Steel Structure oDocument6 pagesCalculation Sheets For Steel Structure oSaifullahNo ratings yet

- Material and PropertyDocument14 pagesMaterial and PropertyRutvikNo ratings yet

- Introduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13Document13 pagesIntroduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13luisA1923No ratings yet

- Pass 99PVDocument9 pagesPass 99PVBassam AbdelazeemNo ratings yet

- Alloy: The Institution of Automobile EngineersDocument23 pagesAlloy: The Institution of Automobile EngineersXantos YulianNo ratings yet

- Manufacturing Process For TMTDocument6 pagesManufacturing Process For TMTKratagya SinghalNo ratings yet

- Effects of Alloying ElementsDocument3 pagesEffects of Alloying Elementsdraj1875977No ratings yet

- Alloying Elements of Steels and PropertiesDocument3 pagesAlloying Elements of Steels and PropertiesdaimaheshNo ratings yet

- Aws-5 18Document42 pagesAws-5 18Nick McalpinNo ratings yet

- 3a Electro Slag WeldingDocument66 pages3a Electro Slag WeldingKathiravan MNo ratings yet

- 2012 - 2013 Final Spec. Guide Digital Version For The WebDocument80 pages2012 - 2013 Final Spec. Guide Digital Version For The Webhasan_676489616100% (1)

- Affect of Elements On SteelDocument82 pagesAffect of Elements On SteelAditya PratapNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Basic DimensionsDocument2 pagesBasic DimensionsKarthik KarthiNo ratings yet

- GE Design GuideDocument53 pagesGE Design GuideGuido Kats100% (1)

- IT Companies in CoimbatoreDocument1 pageIT Companies in Coimbatoresureshkumarmask60% (5)

- What Does A CAD Technician DoDocument1 pageWhat Does A CAD Technician DoKarthik KarthiNo ratings yet

- Properties of MetalsDocument2 pagesProperties of MetalsKarthik KarthiNo ratings yet

- Community Service Learning IdeasDocument4 pagesCommunity Service Learning IdeasMuneeb ZafarNo ratings yet

- Basics of An Model United Competition, Aippm, All India Political Parties' Meet, Mun Hrishkesh JaiswalDocument7 pagesBasics of An Model United Competition, Aippm, All India Political Parties' Meet, Mun Hrishkesh JaiswalHRISHIKESH PRAKASH JAISWAL100% (1)

- Chemical BondingDocument7 pagesChemical BondingSanaa SamkoNo ratings yet

- 059 Night of The Werewolf PDFDocument172 pages059 Night of The Werewolf PDFomar omar100% (1)

- Chapter 6 Bone Tissue 2304Document37 pagesChapter 6 Bone Tissue 2304Sav Oli100% (1)

- KB000120-MRK456-01-HR SamplingDocument15 pagesKB000120-MRK456-01-HR SamplingMiguel Zuniga MarconiNo ratings yet

- Game Theory Presentation: Big BrotherDocument11 pagesGame Theory Presentation: Big BrotherNitinNo ratings yet

- BWTS Test HazırlıklarıDocument1 pageBWTS Test HazırlıklarısabeerNo ratings yet

- Pea RubricDocument4 pagesPea Rubricapi-297637167No ratings yet

- Describe The Forms of Agency CompensationDocument2 pagesDescribe The Forms of Agency CompensationFizza HassanNo ratings yet

- Jurnal Perdata K 1Document3 pagesJurnal Perdata K 1Edi nur HandokoNo ratings yet

- Kozier Erbs Fundamentals of Nursing 8E Berman TBDocument4 pagesKozier Erbs Fundamentals of Nursing 8E Berman TBdanie_pojNo ratings yet

- Pigeon Racing PigeonDocument7 pagesPigeon Racing Pigeonsundarhicet83No ratings yet

- Simple Past and Past Continuous Notes and ExercisesDocument5 pagesSimple Past and Past Continuous Notes and ExercisesConstantina KouverianosNo ratings yet

- Hankinson - Location Branding - A Study of The Branding Practices of 12 English CitiesDocument16 pagesHankinson - Location Branding - A Study of The Branding Practices of 12 English CitiesNatalia Ney100% (1)

- Digestive System LabsheetDocument4 pagesDigestive System LabsheetKATHLEEN MAE HERMONo ratings yet

- Vickram Bahl & Anr. v. Siddhartha Bahl & Anr.: CS (OS) No. 78 of 2016 Casе AnalysisDocument17 pagesVickram Bahl & Anr. v. Siddhartha Bahl & Anr.: CS (OS) No. 78 of 2016 Casе AnalysisShabriNo ratings yet

- Medication ErrorsDocument5 pagesMedication Errorsapi-456052042No ratings yet

- Grope Assignment 1Document5 pagesGrope Assignment 1SELAM ANo ratings yet

- Pda Teachers GuideDocument2 pagesPda Teachers Guidepeasyeasy100% (2)

- Phylogenetic Tree: GlossaryDocument7 pagesPhylogenetic Tree: GlossarySab ka bada FanNo ratings yet

- LEWANDOWSKI-olso 8.11.2015 OfficialDocument24 pagesLEWANDOWSKI-olso 8.11.2015 Officialmorpheus23No ratings yet

- MagmatismDocument12 pagesMagmatismVea Patricia Angelo100% (1)

- Final Test General English TM 2021Document2 pagesFinal Test General English TM 2021Nenden FernandesNo ratings yet

- The Skylane Pilot's CompanionDocument221 pagesThe Skylane Pilot's CompanionItayefrat100% (6)

- Quiz 07Document15 pagesQuiz 07Ije Love100% (1)

- Military - British Army - Clothing & Badges of RankDocument47 pagesMilitary - British Army - Clothing & Badges of RankThe 18th Century Material Culture Resource Center94% (16)

- Ob AssignmntDocument4 pagesOb AssignmntOwais AliNo ratings yet

- Stress Corrosion Cracking Behavior of X80 PipelineDocument13 pagesStress Corrosion Cracking Behavior of X80 Pipelineaashima sharmaNo ratings yet

- Information: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIDocument2 pagesInformation: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIlossesaboundNo ratings yet