0% found this document useful (0 votes)

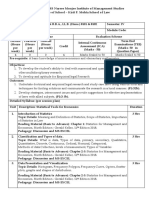

13 views23 pagesWell Completion L 4

The document outlines the well completion process, detailing the decision-making involved in determining whether to complete a well or abandon it. It discusses various completion methods, including open hole and cased hole completions, and emphasizes the importance of optimizing hydrocarbon production while ensuring safety and environmental considerations. Additionally, it covers functional requirements for well completion, such as pressure integrity and the ability to conduct downhole operations.

Uploaded by

SaadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

13 views23 pagesWell Completion L 4

The document outlines the well completion process, detailing the decision-making involved in determining whether to complete a well or abandon it. It discusses various completion methods, including open hole and cased hole completions, and emphasizes the importance of optimizing hydrocarbon production while ensuring safety and environmental considerations. Additionally, it covers functional requirements for well completion, such as pressure integrity and the ability to conduct downhole operations.

Uploaded by

SaadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd