Format No:SRLTRF/GEN

<br>

Issue No:01, Issue Date:01-04-2017

Page 1 of 2

Research Lab entures (P) Ltd. TEST REPORT

CIN:U73200DL2006PTC355024

Test Report Issued To: K211028001/K211028001-11

Test Report No:

PRABHAT AUTOMOBILES Date offIssue: 04-Nov-2023

58,K.P. KAKKAR ROAD,

ALLAHABAD, UTTAR PRADESH -211003,

INDIA

Sample Bopkíng/Receipt Date: 28-0ct-2023

Date of Start of Testing: 29-0c-2023

Date of Completion of Test: 04-Nov-2023

Customer Relationship Number 69864

Sample Description

PAINT ENAMEL SAND

Customer Reference No

LETTER DATED 04.11.2023

MR. SANJAY SINGHAL (PROP.)

Kind Attention

E-Mail: shashanksinghal18@gmail.com Contact No: 9198240085

Sample Condition: Good

Sample Quantity (Approx)

:

1- BOX

Sample Size(Approx): 1-LTR

SAMPLE NOT DRAWN BY OUR LABORATORY. THE RESULTS RELATE ONLY TO THE ITEMS TESTED

ARCHLAB

VEN

m

RRUMAR MILRA

ULR-TC784521000010278F

sssued By

Authencity of report can be verified by mail at verification@spectrolab.in

This is a Digitally Signed Report and hence doesn't require Physical Signature.

Spectro Research Lab Ventures (P) Ltd, G-3, Bajrang Bali Industrial Area, Near Panki Site-IV,Kanpur-208020(lndia)

Phone :+91-9235503984/85 || Web: www.spectroresearchlabs.com|| Email: knp@spectro.in

ISO 9001:2015, ISO 14001:2015 & ISO 45001:2018 Certified Laboratory

�<br>

Format No: SRL/TRFIGEN

ŠPECTRO5

Issue No: 01, Issue Date: 01.04.17

Research Lab Ventures (P) Ltd. TEST REPORT Report No. K211028001/K211028001-11

Page 2 of 2

CIN:U73200DL2006PTC355036

ID-K211028002-1

Discipline- Chemical Testing

Group-Paints & surface coating

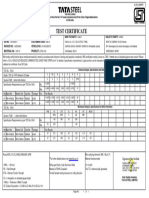

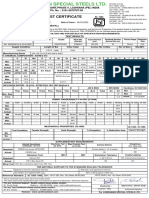

SI. Test Parameter Observed Value Specified value Test method

No. JSS-8010-78-2013

1. Drying Time

Surface Dry After 15 minutes Not Below 15 min IS:101(P-3/Sec-1)-86

ii) Hard Dry Within 2 hours Not more than 2 hours

iii) Tack Free Within 4 hours Not more than 4 hours

2. Consistency Smooth & uniform Smooth & uniform IS:101(P- I/Scc-5)-89

3. Viscosity, ford cup No.4 at 30+1°C 115 70 to 120 sec IS:101(P-1/Sec-S)-89

4. Finish Smooth & glossy Smooth & matu glossy IS:101(P-3/Sec-4)-87

5. Colour Close match to ISC 220 ISC 220 of IS:5-2007 IS:101(P.4/Sec-2)-89

(SAND) (SAND)

6. Mass in Kg/10 Liters 10.8 To be reported IS:101(P-1/Sec-7)-87

7. Scratch hardness No such scratch as to No such scratch as to IS:101(P-5/Scc-2)-88

show the bare metal show the bare metal

8. Flexibility & adhesion No visible damage or No visible damage or IS:101(P-5/Sec-2)-88

after 48h air drying (Bend test) detachment of the film detachment of the film

9. Flash Point, °C 34.5 Not blew 25°C IS:101(P-1/Scc-6)-90

10. Gloss value, specular 60 82 80 min IS:101(P-4/Sec-4)-88

11. Protection against corrosion under No sign of corrosion on No signs of corrosion IS:101(P-6/Sec-1)-88

conditions of condensation metal surface observed

12. Resistance to lubricating oil, 48h No permanent injury to film No permanent injury to film IS:101(P-7/Sec-2)-90

13. Resistance to petroleum No permanent injury to film No permanent injury to film IS:101(P-7/Sec-2)-90

hydrocarbon solvent 145/205

14. Application Shall be suitable for Suitable for application by IS:101(P-3/Sec-4)-87

application by brushing brushing

A

LAB

VEA

-- End of

Test Report -- KURE

EVSANIHETTA

ULR-TC784521000010278F UMAR MISHR

ds *

Analyst Signature TC-7845 Authorised Signatory

Spectro Research Lab Ventures (P) Ltd, G, Bajrang Bali Industrnal Area, Near Panki Site, Kanpur-208020(lndia)

Phone +919235503984/85 |Web: www.spectroresearchlabs.com]|:Email: knp@spectro.in