Professional Documents

Culture Documents

Arbor Final

Uploaded by

Aline Moser Nunes CoelhoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arbor Final

Uploaded by

Aline Moser Nunes CoelhoCopyright:

Available Formats

Arbor

Activate 3D

p m D I Y H O m E /// a r b O r

Making the Arches

1 2

The curved top pieces are made of two layers of 2 x 6 segments fastened together with screws and exterior glue. each layer is half an octagon, rotated 22.5 degrees apart so the segments overlap. to lay out the curved pieces, first make a template of the arch; a stick with a pencil hole bored in one end and a nail driven at the other works as a compass [1] . cut the mitered segments to length [2], then temporarily screw the template to each arch set [3] and trace the curve. after youve cut to the curved lines on each piece [4], screw the template to a layer of segments, spread glue and clamp a second layer to the first. Then drive the screws [5] and remove the template. although cedar is soft enough to take a screw without a pilot hole, its a good idea to bore clearance holes in the top pieces. This allows the screws to draw the pieces tightly together. When the glue is dry, sand the curved edges smooth.

step photographs by thomas klenck

p m D I Y H O m E /// a r b O r

Side Panel Construction

9 6

10

8 11

Assembling the Top

This part is tricky because the arches must be upside down to attach the arch crossties. We solved the problem by clamping 1 x 6s along the tops of two sawhorses so they were parallel to each other and 47 in. apart (the diameter of the arches).

Then, we blocked up the arches so their ends were flush with the top surfaces of the 1 x 6s and clamped them in place [6]. With the arches stabilized, screw the crossties to the arch ends [7]. Flip the assembly over and check for square. Use a piece of wood as a spacer when nailing the strips across the arches [8].

to build perfectly square side panels, we drew the post positions directly on the garage floor [9] . you could also draw on plywood. nail horizontal lattice strips at the tops and bottoms of the posts, again using a small piece of wood as a spacer [10] . Flip the assembly over and temporarily screw a diagonal strip to the opposite side to keep things square [11] . add the remaining horizontal strips, and screw the lattice crossties to the tops of the posts. nail the verticals from the inside, angling the nails so they dont poke through [12] .

12

Putting It All Together

make a template for the curved knees that brace the side corners. cut the

13

14

knees from 2 x 6 stock and screw them to the posts and crossties [13] . clamp the side panels to the arch and screw the arch and lattice crossties together [14] . Then add the beveled rain cap over the arch crosstie. This helps keep water from pooling on the crosstie surfaces. Until the arbor is in place, screw temporary braces across the bottoms of the posts to prevent flexing.

pVERSION 3Fm E1/02/07b O r m D I Y H O /// a r

ARBOR

Diagram

HALF SEGMENT ASSEMBLE WITH GLUE AND 2-1/2" DECK SCREWS FROM INSIDE FACE 19-3/4" 22-1/2 2" 23-1/2" RAD. 20" RAD. 3-1/2"

ARCH ASSEMBLY 45 45 22-1/2 40" CUT SEGMENTS FROM 2 X 6 (18 PIECES REQ'D)

ARCH SEGMENT

ARCH TEMPLATE CUT FROM PLYWOOD 6-1/16" RAIN CAP 3/4 X 3-1/2 X 30" (2 REQ'D) 1/8" 1/2"

ARCH (2 REQ'D) SEE ARCH ASSEMBLY

ARCH STRIPS 3/4 X 1-1/2 X 37-1/2" (9 REQ'D)

1/8" 3/4" OVERHANG

5/8" X 45 CHAMFER

2-1/2" DECK SCREW (TYP.) 1/4" LATTICE CROSSTIE 3/4 X 5 X 37-1/2" (2 REQ'D) 6"

ARCH CROSSTIE 3/4 X 5 X 37-1/2" (2 REQ'D)

1-5/8" DECK SCREW

KNEE CUT FROM 2 X 6 (4 REQ'D)

2" GALV. NAIL (TYP.)

6"

HORIZONTAL LATTICE 3/4 X 1-1/2 X 37-1/2" (16 REQ'D)

1-1/2" GALV. NAIL DRIVE AT ANGLE

3/4" OVERHANG VERTICAL LATTICE 3/4 X 1-1/2 X 60" (6 REQ'D) 1" 14-1/8"

i l l U s t r at i o n b y e U g e n e t h o m p s o n

POST 3-1/2 X 3-1/2 X 62" (4 REQ'D)

36"

40"

POST BRACKET (4 REQ'D) 6-1/8" 4 X 8 X 16" CONCRETE BLOCK ON GRAVEL BASE

2-1/4"

2" SQUARES

1"

KNEE PATTERN

You might also like

- CanoePlansPart1 PDFDocument20 pagesCanoePlansPart1 PDFcockybundoo80% (5)

- Shed Storage2Document9 pagesShed Storage2Bob Pouliot88% (8)

- Wood PlanesDocument6 pagesWood Planeshenrybelanger100% (1)

- Build This Boat Shaped BarDocument6 pagesBuild This Boat Shaped BarMark MihalkoNo ratings yet

- Craftman Wood ChestDocument5 pagesCraftman Wood ChestIsidro CM100% (1)

- Dog House Plans 3Document5 pagesDog House Plans 3Devika PrithiNo ratings yet

- Gazebo Shelter PlansDocument7 pagesGazebo Shelter PlansMikeNo ratings yet

- MTX - DCT1001 - Dirt Cheep Terrain - Basic SetDocument18 pagesMTX - DCT1001 - Dirt Cheep Terrain - Basic Setlup_alb_13No ratings yet

- A Christmas Memory. Lesson - AnthologyDocument24 pagesA Christmas Memory. Lesson - AnthologySherry CallisonNo ratings yet

- Ultimate WorkbenchDocument8 pagesUltimate WorkbenchEric Gruff0% (1)

- Tambour Topped BoxDocument7 pagesTambour Topped BoxTed MooreNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Ultimate Quilt Block Collection: The Step-by-Step Guide to More Than 70 Unique Blocks for Creating Hundreds of Quilt ProjectsFrom EverandUltimate Quilt Block Collection: The Step-by-Step Guide to More Than 70 Unique Blocks for Creating Hundreds of Quilt ProjectsRating: 5 out of 5 stars5/5 (1)

- Woodworking Plans - Workbench - Popular Mechanics - Hard MapleDocument7 pagesWoodworking Plans - Workbench - Popular Mechanics - Hard Maplepandearroz100% (2)

- Redwood Canoe PDFDocument6 pagesRedwood Canoe PDFpaulo_enpjNo ratings yet

- Plan Etabli UKDocument6 pagesPlan Etabli UKDimitri RogoffNo ratings yet

- Woodworking Guide - Basic JoineryDocument6 pagesWoodworking Guide - Basic JoineryMrPaulCorcoran100% (1)

- Station Wagon SkiffDocument8 pagesStation Wagon SkiffJim100% (3)

- Children's Bunkhouse LoftDocument7 pagesChildren's Bunkhouse Loft- yAy3e -100% (3)

- Make Your Own Toolbox: A Woodworker’s Guide to Building Chests, Cases & CabinetsFrom EverandMake Your Own Toolbox: A Woodworker’s Guide to Building Chests, Cases & CabinetsNo ratings yet

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- Dodec Spinning Wheel BrochureDocument5 pagesDodec Spinning Wheel BrochureKen Kline100% (2)

- Lawn Swing: IMPORTANT: Read This Before You StartDocument6 pagesLawn Swing: IMPORTANT: Read This Before You StartBill RNo ratings yet

- Sabot 8 FT Pram DinghyDocument6 pagesSabot 8 FT Pram DinghyFrenchwolf420100% (2)

- Ticket To Ride CraftingDocument15 pagesTicket To Ride Craftingapulcino42100% (1)

- The Turned Hall Tree: A Great Weekend Project To Help Build Your Woodturning SkillsDocument2 pagesThe Turned Hall Tree: A Great Weekend Project To Help Build Your Woodturning SkillsSergeiNo ratings yet

- With A Finger-Safe Hinge On The Roof, An Operabl em Exit and A Working Sign This Incredibly Cut S Busisasaf Bet For y Gift ListDocument6 pagesWith A Finger-Safe Hinge On The Roof, An Operabl em Exit and A Working Sign This Incredibly Cut S Busisasaf Bet For y Gift ListJuanRodriguezNo ratings yet

- PlayStation MagazineDocument116 pagesPlayStation MagazineFrank Costello67% (3)

- Krenov Style Hand PlaneDocument8 pagesKrenov Style Hand PlanerhinorodNo ratings yet

- Butcher BlockDocument32 pagesButcher BlockMark DingleNo ratings yet

- The DAMA Guide To The Data Management Body of Knowledge - First EditionDocument430 pagesThe DAMA Guide To The Data Management Body of Knowledge - First Editionkakarotodesu100% (10)

- Potters Kick Wheel PlansDocument4 pagesPotters Kick Wheel PlansboomixNo ratings yet

- ParacordBraceletJig PDFDocument9 pagesParacordBraceletJig PDFAnonymous vRX0OvwHNo ratings yet

- Bench - Classic Cedar Garden PDFDocument11 pagesBench - Classic Cedar Garden PDFmarianrkwNo ratings yet

- Dingbat WaterscooterDocument8 pagesDingbat WaterscooterJim100% (2)

- Bench - Classic Cedar GardenDocument11 pagesBench - Classic Cedar Gardenvdbroger100% (1)

- Cherry Dresser: How To Build A Classic 5-Drawer DresserDocument9 pagesCherry Dresser: How To Build A Classic 5-Drawer DresserriverbendfcNo ratings yet

- Wj001 Barristers BookcaseDocument7 pagesWj001 Barristers BookcasemiclarkNo ratings yet

- Total Dash8Document14 pagesTotal Dash8Luiz Fernando MibachNo ratings yet

- Tilting Mirror Stand - FH96DJADocument7 pagesTilting Mirror Stand - FH96DJAJvlValenzuelaNo ratings yet

- A Round Kitchen Classic - Bent Laminated Cherry TableDocument8 pagesA Round Kitchen Classic - Bent Laminated Cherry TableJainar BerlianaNo ratings yet

- Trestle Coffee TableDocument7 pagesTrestle Coffee Table- yAy3e -No ratings yet

- Bob's Card Models: and (Resources)Document19 pagesBob's Card Models: and (Resources)Luiz Fernando MibachNo ratings yet

- Captain's Clock: Project 12325EZDocument7 pagesCaptain's Clock: Project 12325EZBSulliNo ratings yet

- Wood Magazine - 3 in One Bed For All Ages Part 1Document4 pagesWood Magazine - 3 in One Bed For All Ages Part 1clnieto2450% (2)

- Vehículos Pesados para Hacer en MaderaDocument88 pagesVehículos Pesados para Hacer en MaderaFranco Mauricio97% (31)

- How To Build A Hexagonal Picnic TableDocument35 pagesHow To Build A Hexagonal Picnic TableMarcelo LopezNo ratings yet

- Drifter 12 L: A Small Trimaran For Paddling or SailingDocument54 pagesDrifter 12 L: A Small Trimaran For Paddling or SailingPaulo Cunha100% (1)

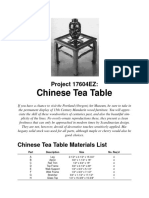

- Mesa China CarpinteriaDocument7 pagesMesa China CarpinteriaMCarrillo_1971No ratings yet

- Mesa Auxiliar Con CajonesDocument8 pagesMesa Auxiliar Con CajonesTETSUO111No ratings yet

- Tools and Materials:: Rojects Online: Building A Six-Sided GazeboDocument8 pagesTools and Materials:: Rojects Online: Building A Six-Sided GazeboMara_Traistaru_808No ratings yet

- Projetos DRIFTER14 Plans 1Document58 pagesProjetos DRIFTER14 Plans 1Joao CalinhoNo ratings yet

- Projetos DRIFTER16 Plan 1Document62 pagesProjetos DRIFTER16 Plan 1Joao CalinhoNo ratings yet

- Tool Box - Workshop ToolboxDocument6 pagesTool Box - Workshop ToolboxDaniel Lourenço100% (1)

- Circoflex Building InstructionsDocument4 pagesCircoflex Building InstructionsGiacomo Marco ToigoNo ratings yet

- Wheelbarrow Planter DIY: More in The Workshop Search FACT SHEETSDocument4 pagesWheelbarrow Planter DIY: More in The Workshop Search FACT SHEETS- yAy3e -No ratings yet

- Ukulele Kit Assembly Instructions: Getting Started Supplies ContinuedDocument10 pagesUkulele Kit Assembly Instructions: Getting Started Supplies ContinuedPablo PolettoNo ratings yet

- Toddler Bed With Built in ShelvesDocument21 pagesToddler Bed With Built in ShelvesAdnan HasanovicNo ratings yet

- Construction of A Longworth ChuckDocument10 pagesConstruction of A Longworth ChuckshopsmithmodNo ratings yet

- Timber Frame Bird House InstructionsDocument8 pagesTimber Frame Bird House InstructionsBobNo ratings yet

- General Construction Tips Dagey RocksDocument23 pagesGeneral Construction Tips Dagey Rocksbiker110No ratings yet

- Youthprograms Doghouse PlansDocument10 pagesYouthprograms Doghouse PlansNacho MowjiNo ratings yet

- REACH ArticlesDocument12 pagesREACH ArticlesChristian SugasttiNo ratings yet

- Tikkun Kisay HaShemDocument47 pagesTikkun Kisay HaShemYochananMauritzHummasti100% (1)

- VW 60330 2009 12 eDocument29 pagesVW 60330 2009 12 eAmir Borhanipour100% (1)

- Too Early! by Anton Pavlovich ChekhovDocument4 pagesToo Early! by Anton Pavlovich Chekhovapi-19787590No ratings yet

- Mum LatecityDocument14 pagesMum LatecityGkiniNo ratings yet

- Wooden Buildings: exposed to tiếp xúc với dramatic renewal sự làm mới đáng kểDocument6 pagesWooden Buildings: exposed to tiếp xúc với dramatic renewal sự làm mới đáng kểNguyễn Phạm Thảo NguyênNo ratings yet

- D e N R Process Flow of Hazardous WasteDocument2 pagesD e N R Process Flow of Hazardous WasteMaragtasInnovationsNo ratings yet

- Miri Datalogger FlyerDocument1 pageMiri Datalogger FlyerernestoveigaNo ratings yet

- NS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710Document27 pagesNS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710PHAM PHI HUNGNo ratings yet

- Cognitive Benefits of Language LearningDocument11 pagesCognitive Benefits of Language LearningIlhamdi HafizNo ratings yet

- Organizational Behavior Exam 2 Practice QuestionsDocument1 pageOrganizational Behavior Exam 2 Practice QuestionsSydney EverettNo ratings yet

- Physics 715 HW 1Document13 pagesPhysics 715 HW 1Antonildo PereiraNo ratings yet

- Tea Board of India PDFDocument18 pagesTea Board of India PDFDebasish RazNo ratings yet

- Supplier Accreditation Application-V1 - RevisedDocument8 pagesSupplier Accreditation Application-V1 - RevisedCandiceCocuaco-ChanNo ratings yet

- Ahmed 2022. Ergonomic Work From Home and Occupational Health Problems Amid COVID-19Document17 pagesAhmed 2022. Ergonomic Work From Home and Occupational Health Problems Amid COVID-19FioriAmeliaHathawayNo ratings yet

- Math 2 MakilingDocument28 pagesMath 2 MakilingAnnabelle Poniente HertezNo ratings yet

- Additional Clinical Case Study TemplatesDocument4 pagesAdditional Clinical Case Study TemplatesMikhaela Andree MarianoNo ratings yet

- Aeroacoustic Optimization of Wind Turbine Airfoils by Combining Thermographic and Acoustic Measurement DataDocument4 pagesAeroacoustic Optimization of Wind Turbine Airfoils by Combining Thermographic and Acoustic Measurement DatamoussaouiNo ratings yet

- 18TE72 - Wireless Communication Experiential Learning ReportDocument10 pages18TE72 - Wireless Communication Experiential Learning ReportRitika BakshiNo ratings yet

- Cassius Resume CVLatestDocument3 pagesCassius Resume CVLatestCaszNo ratings yet

- English The Smiles and Tears of RasoolullahDocument130 pagesEnglish The Smiles and Tears of RasoolullahwildqafNo ratings yet

- Draft Technical Notes SGLG 2023 - National OrientationDocument109 pagesDraft Technical Notes SGLG 2023 - National OrientationZane ZyneNo ratings yet

- BBC Learning English - 6 Minute English - Bitcoin - Digital Crypto-CurrencyDocument38 pagesBBC Learning English - 6 Minute English - Bitcoin - Digital Crypto-CurrencyMohamad GhafooryNo ratings yet

- TelemetryDocument8 pagesTelemetryKristin WiseNo ratings yet

- Sample CISSP ResumeDocument4 pagesSample CISSP ResumeAskia MappNo ratings yet

- Can We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsDocument15 pagesCan We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsKionara SarabellaNo ratings yet

- Inspection and Test Plan (ITP) For Spherical Storage Tanks: Dehloran Olefin PlantDocument9 pagesInspection and Test Plan (ITP) For Spherical Storage Tanks: Dehloran Olefin PlantbahmanNo ratings yet