Professional Documents

Culture Documents

Williams - Válvulas Compuerta Globo Cheque Bola Fundidas API 600

Uploaded by

espanolasaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Williams - Válvulas Compuerta Globo Cheque Bola Fundidas API 600

Uploaded by

espanolasaCopyright:

Available Formats

Will- 8.. E.... _..__ ms_ Willi a .........

Cast Steel Va:lves

Gate Globe Angle Check Ball

Introduction

For over seventy years WiIliam E. Williams Valve Corporation has been manufacturing quality valves. As with all our valves, the Williams Steel Valve Line is a reflection of a commitment to a standard of excellence and product innovation. AUWilliams valves are designed, engineered, manufactured and tested to meet or exceed all applicable industry standards including ASTM, ANSI and API. In addition to quality,Williams takes pride in its customer service and delivery, P Williams is a flexible manufacturer and remains one of the few companies. willing to help customers meet unique or special applications. Whether your needs are for standard products from our weUstocked inventories throughout the U.S. or custom modifications, remember to specify WILLIAMS.

Index

.. . General Specifications ...••..•...•.....•....••.....• How to Order •.............•••. ' ..•.•.•..••... Figure No..Pref.ix

End Connection Code Trim Code Suffix Casting Chart

Page 3 " ..• '." 4

Valve Ccimparison Charts . • • • • . . . . . . •. . . . . • • . • . .... Figure Number Equivalents

Trim Comparison Charts

Gate Valves/150 Lb..••...•••......•....••••..••... 6 Gate Valves/300 Lb•.••••...••... ' •. ' •.... ' .•••.•••.... 7 Gate Valvesl600Lb •.•.••..••......•...... ' •• , ,.. 8 Gate Valves/900 LbA500 Lb. . •......•....•. ,.' ,. 9 NRS Gate Valvesl150 Lb•.....••... ' ...••..••..... , .•.. 10 NRS Gate Valves/300 Lb. . ..........••..•••.....•.. 11 Globe & Angle Valves/150 Lb•.•..... , .......•.....••. 12 Globe & Angle Valves/300 Lb..••......•...•••....••. 13 Globe Valves/BOO.Lb•..•............ ' .••..•••....••. 14 Globe Valves/900 Lb.~1500Lb•••....... '....•........ 15 Swing Check Valvesl150 Lb•.........••.....•....••. 16 Swing Check Valves/300 Lb.,.•••••...••....••..••.•. 17 Swing Check Valves/GOOLb....•.•.•........•.....•.. 18 Swing Check Valvesl900Lb. 1500 Lb. . .•....••.....•. 19 Reduced Port~Ball Valvesl150 Lb.~300 Lb. . ...••....••. 20 Full Port-Ball Valves/150 Lb.-300 Lb......•...•••. , ...• 21 . Pressure Temperature Ratings., •••.....•...••......• 22 Steel Pipe Schedule Chart •...•••.... , .. , ...•••...... 23 Conversion Data ••. ," " •• '.. '. " .. ' ....•.••... " •.23 Flange Dimensions •...•••....•. '.....•....•••....• 24 Inch to Millimeter .•....••...•••......•...••.....• 25 Temperature Conversion °C _OF •••••....•.....••....... 26 Valve Actuation, Accessori.es & Modifications ...•..... 27 Bosses & Drain Tappings: Locations of Tapped Holes 27 Warranty ••• " ... " ••. '..•.....•••.....•...•• '. '. ' 27

.2

General Specifications

GATE VALVES are designed to offer minimum pressure drop in the fully open position. Not intended for throttling; they serve as efficient shut-off valves for flow in either direction. They are dependable for use in steam, water, oil, vapor and other high pressure services. Rising stem designs employ a tee-head stem connection to the onepiece flexible wedge. Position of the valve is readily visible. Nonrising stem design is offered for minimal space or buried services. In both cases the wedges are guided throughout their travel to assure true alignment and proper seating. GLOBE VALVES are efficient for throttling when pressure drop is about 20% of inlet pressure. They are effective stop valves and are suitable for regulating the liquid flow. Our valves incorporate a bolted bonnet design with a rising stem and handwheel. Williams GLOBE VALVES can be supplied as screw-down stop checks. The stop check valve is installed with pressure under the disc. The disc is raised from its seat by the pressure of upward fluid flow. The disc is reseated by gravity when flow is stopped or reversed. Alignment of the disc is maintained through its travel by an extended disc nut and/or a guided seat ring. ANGLE VALVES are essentially GLOBE VALVES with inlet and outlet connections at right angles. Like GLOBE VALVES, ANGLES are used for throttling service and offer less resistance to flow. The rightangle form of the body reduces pipe joints. These valves are also adaptable to stop check configuration. SWING CHECKS are self-contained and prevent the reversal of flow through the line. The pressure of the flowing fluid opens the valve. The weight of the disc assembly and reversal of flow closes it. SWING CHECK VALVES are best used on services with low fluid velocities and where flow reversals are infrequent. SWING CHECKS are automatic in operation and offer minimum resistance to flow. BALL VALVES are used mainly for on/off non-throttling services. WILLIAMS offers a FULL PORT VALVE with a split body configuration and a REDUCED PORT VALVE having a two piece, end entry design. The bore of FULL PORT VALVES is equal to the inside diameter of the pipe. In REDUCED PORT VALVES the bore is typically one size smaller than the nominal pipe size. Both styles offer reinforced teflon seats, 316 stainless steel stem and balls. In selecting BALL VALVES consideration is to be given to the temperature and pressure-resisting characteristics of the seat materials. The advantages of BALL VALVES are ease of operation, low maintainence, compact geometry and appreciable weight savings. They are readily adapted to automation using either pneumatic, hydraulic, or electric forms of operators.

SPECIAL NOTE: As product improvement is a continuous process at William E. Williams Valve Corp. Specifications and dimensions are subject to change at anytime without notice.

How to Order

This Wil'liams catalog bas been published to give you an overview of our product When transmitting orders or in" quiries, rt is important that complete specifications be given so the proper valve may be identified. Normally, intorrnation would include: quantity, size, type and figure number. Also, when other than standard conditions exist, tt is desirable that working conditions be furnished; l.e., pressure and temperature ranges, nature of fluid to be handled, and any other unusual conditions such as: cerroslon, shock. or abrasion likely to be present. For choosing .approprlats figure number, select size, ligure number prefix loll owed with end connection code leiter and trim code suffix. Standard casting material is A216 WGB Carbon Steel, il other material is required add appropriate ASTM Spec. & Grade to valve figure number.

Example: Figure number 30F2 is a 300 lb. RF flanged carbon steel gate valve with V2 Hardfaced trim of A216 Gr WCB construction,

Figure Number Prefix

VALVE TYPE

Gate Globe Angle Cheek Ball (Reduced Port) BaH (Full Port)

CLASS 150 LB.

15 152 153 151 C16 G17

CLASS 300 LB.

30 302 303 301 C36 G37

CLASS 600 LB.

60 602 603 601

CLASS 900 LB.

90 902 903 901

CLASS 1500 LB.

150 1502 1503 1501

.....",_

End Connection Code

The letter that fol·lows above figure number indicates-end connection F:. Flanged, W: Butlweld, RTJ: Ring Type JOint type:

Trim Code Suffix

TRIM, FIG. NO. SUffiX SEATING SURFACES

13% Chromium (AI

STEM MATERIAL SERVICERECOMMENDAnONS/UMITATIONS

'For unrefined oil to 8500 F. For oil, oil vapor or steam to 11000 F Steam service limited to Globe, Angle and Check Valves: Not 13% CR {Al , recommended for Gate or Ball valves. Limited to maximum operating conditions per ANSI pressure class. 130/0CR (Al For steam, gas and general service: to 1000" F. limited to maximum operating conditions per ANSI pressure class, an excellent universal trim. , For severe service: to 1200" F., including corrosion and erosive steam, oil, or oil vapor 1011000 F. Limited to maximum operating conditions per ANSI pressure class. For water, oil or gas: up to 4000 FExcelient for brine and seawater service. Limited to maximum operating conditions per ANSI pressure class. For corrosive service: Acids, alkalies, sal! solutions, etc. to 450" F. maximum. Limited to maximum operating conditions per ANSI pressure class.

2 3

13% Chromium {Al To Hard Facing (13) {Y~ HFl Hardfacing {HF} Bronze (8)

13% CR. (A)

Brass

Monel

Monel

6 7

316 SS

316 SS

For corrosive service: Acids, etc. to 850" F. maximum and corrosive oils a! high and low temperatures. Limited to maximum operating conditions per ANSI pressure class.

For extremely tight shutoff, to 400" F. maxi mum. TEE soft seat is used in conjunction with other trims, l.e., trim 7/6: TFE/316SS For steam, water, gas and other non-corrosive fluids: to 850" F. maximum. Limited to maximum operating conditions per ANSI pressure class.

TFE Seat . 13% Chromium To Monel (A)

·NA· 13% CR (A)

NOTES: (A) 13% chromium Is 410 SST ('8) Hardfacing IS weld deposited Cobaltbased aHoy.

Casting Chart

Mm.. ASTM CLASS. SPEC.

I

C

0.30 0.20

Mn

1.00 0.50·0.80

P

0.04 0.04

S

.045 .045 .045 .045 .045

SI

0.60 0.60 0.60 0.75 0.60

Cr

040 1.00·1.50 2.00·2.75 4.00-6.50

-

Mo

0.25 0.45·0.65 0.90·1.20 0.45-0.65

-

HI

0.50 0.50

SERVICE RECOMMENDmONSI

UMIm10NS

NOTES

, (1)(4)

Carbon A216WCB Steel tV. CR. VzMO. A217WC6

211. CR·

Steam, water, oil, oil vapor. g:asand genafal services at temps. -200 to 1000° F.

1'MO.

A217WC9 A217WC5 A352LCB

0.18· 0.40>0.70 0.04 0.20 0.30 0.40>0.70 0.04 1.00 0.04

Steam, water, oil,oil vapor, gas & , general services at temps. ~20° to 0.50 11.00"F. 0.50 Corrosive& Erosi ve ref nery serv,; e e at -200 F. to 1000° F Low temperat u tEl servi ee to' - 50° F. n 01 10 r use above 6500 F.

(3)(4)

r---(3)(4)

5CRVzMO. Low Icarbon Steel

(2)(4)

(4)

NorES: (1) Permissible, but not recommended for prolonged usage above 800· F. (3) NO!!O be used over 1100· F. Flangad end ratings lerm/tlare a/IOOO· F. (2) Not 10 b6 ussd wer 1050· F. Flanged end ratings termmal<! a/1000· F. (4) A/I values forelemems shown above at9 maximum.

Valve Comparison Charts

Figure Number Equivalents

Gate Valves

PRESSURECL

150# 300# 600# 900# 1500#

W1WAMS

15F 30F 60F 90F 150F

CRANE

47 33 76 83 87

WALWORTH

5202F 5206F 5232F 5247F 5262F

POWELL

1503 3003 6003 9003 1303

VELAN

F*-Q-054C-02 F*-1-054C-02 F*-2-054C-02 F*- 7-054C-02 F*-3-054C-02

PACIFIC

150 350 650 950 1550

STOCKHAM

150F 300F 600F

WNKEN HEINER

1512*· 3012** 6012"*

Globe Valves

150# 300# 600# 900# 1500# 152F 302F 602F 902F 1502F 143 151 171 183 189 5275F 5281F 5295F 5301F 5308F 1531 3031 6031 9031 1331 F*-0-074C-02 F*-1-074C-02 F*-2-074C-02 F*- 7 -07 4C-02 F*-3-074C-02 160 360 660 15G 30G

-

15A 30A

1532** 3032** 6032*'*

Angle Valves

150# 300# 600# 900# 1500# 153F 303F 603F 903F 1503F 145 153 173 185 190 5278F 5283F 5297F 5303F 531 OF 1533 3033 6033 9033 1333 F*-Q-075C-02 F*-1-075C-02 F*-2-075C-02 F*-7-075C-02 F"-3-075C-02 170 370

1552"" 3052*· 6052*·

Check Valves

150# 300# 600# 900# 1500# 151F 301F 601F 901F 1501F 147 169 175 187 199 5341F 5344F 5350F 5353F 5356F

NO. 2 TRIM.

1561 3061 6061 9061 1361

F*-Q-114C-02 F*-1-114C-02 F*-2-114C-02 F*-7-l14C-02 F*-3-114C-02

180 380 680

155F 305F 600F

1572** 3072** 6072**

"MFR'S SIZE CODE. ··AVAll.JlBLE

ONLY IN TRIM EQUAl.. TO WIWAMS

Trim Comparison Chart

MATERIALS

SEAT

CR13 HARD FACED HARD FACED BRONZE MONEL

DISC

STEM

CR13 CR13

WIWAMS 1

2

CRANE X

XU

WALWORTH AA

UT

POWELL P-l40

P-140-15

VElAN

PACIFIC

1 2

STOCKHAM

1 UOR 11

cs rs

CR13

TY

HARD FACED BRONZE MONEL

CR13

HF

P-l00

TS

(316SS STEM)'

11

BRONZE MONEL

4 5

.H

A

H A

P87 P168

5 8

6

8

XV

(HFSEA7)"

316SS TEFLON RINGS CR13

316SS CR13

316SS CR13

6 7

l8-8M

P173

SX

12 BLOCK & BLEED 3

12

XR

AM

VELAN F*-O-054C-02TY,

XV

(MONEL STEM)*

MONEL

CR13

EXAMPLE: CRANE 47XU, WALWORTH 5202FUT, POWELL 1505-P140, LUNKENHEIMER 1512 ARE EQUAL TO WILUAMS RGURE No. 15f2.

PACJRC 150-2, STOCKHAM

150F-U or 11 and

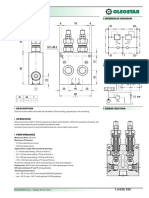

Cast Steel Gate Valves

FIG. No. 15F-FLANGED FIG. No. 15W-BUnwEL,D

FEATURES

• • • • • • Rising stem-OS& Y, Bolted Bonnet Solid wedge (Plain or flexible) Renewable seat rings (Threaded or welded) Back seat bushing allows repacking under pressure Bosses for taps, drains, bypass Ground wedges, fully guided

DIMENSIONS

SIZES 11h" 2" 2V,· 3" 3\'1" 4·· 5" ·6" 8" 10" 12" 14" 16" 18"

MATERIAL SPECIFICAT.IONS

PART

BODY BONNET WEDGE SEAT FliNG GLAND FLANGE : PACKING GLAND SHM STEM NUT BACKSEAT BUSHING YOKE NUT HANOWHEEL NUT BONNET NUT BONNET STUD HANDWHEH EYEBOLT EYE ,EYEBO PIN LT . PACKING GASKET , SET SCREW GHEASE NIPPLf

FACE

in. 7 7l1: 8 8Y, 9 liD 6'('

BeE TO

END CENTER DIA TO TOP HANDTO END(BW) OPEN WHEEL In. I•• IR.

-

MATERIAL

ASTM A211i GR WCB ASTM A216 Gil WCB SEE TIIIM CHART" SEe TRIM CHART' ASTM A105 STEEL CHROME PLATED SEE TRIM CHART' ASTM A43R GR 02C OR ALUMINUM BRONZE ASTM A182 GR F6 ASTM A47 Gil. 32510 ASTM. A47 GR 3251 0 ASTM ,1,1'94GHZH ASTM Al93 GRB7 ASTM A197 OR ASTM A21.6 GRWCB ASTM AJ07 GFI B ASTM AJD7 Gil B STEEL ' NON-ASBESTOS SOfT IRON STEEL STEEl

13 14l1: 17 18

lB';'

7 8 8 8'/, 8*, 11 12". 14 14 18 20 21'h

8't.

9V.

11% -

12 15 15% 16Y, 18 190/.

22 28 30

38V,

tov,

ltV. 13 14 15 16

17

46 55V,

22V,

24 26 2S 32 38 44

60

74*, 79 87'h

105

24

27

20"

24" 30" 36"

18 20 24 28

28

31Y, 43 51

130 162

App.licable Standards

Steel Gate Valves, API 600 (11/:/'-24") Steel Valves, ANSI B16.34, Std. CL Face-to-Face, End-to-End, ANSI B16.1 0 End Flanges,ANSIB16.5 End .Flanges (30" and 36"), MSS-SP-44 Weld Ends, ANSI 816.25

• SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

MAXIMUM ALLOWABLE NON-sHOCK WORKING PRESSURE IN PStG

TEMPERATURE

INDEGREESF

·20 TO 100 200 300 400 500 600 650 700 750 800 850 900 950 1000

IAJ·Permiosable. bul not "",ommended above approxlmately 800'1'.

150 LB.

CLASS

285 PSIG 260

__

Tests

API 598 Shell: 450 PSIG Hydrostatic Seat: 315 PSIG Hydrostatic 80PSIGAir Other testing available upon request

230

200 170 140 125 110

95

80 65 50 35 20

lor prolOn ged usage

WILLIAM E.

~I

6

l::"tAJ'" s

(B)-Ci1 BJ1 dep ICISrallr>gs lor ASTM, A216 G r WCB. for other materials refer to Pressure Temperature Chart on page 22.

38-52 Review Avenue, Long Island City, NY 11101 Telephone: 718-392-1660 1-800-221-1115 Fax: 718-729-5106

FIG. No. 3OF-FLANGED FIG. No. 30W-BUTTWELD FEATURES

• • • • • • Rising stem-OS&Y, Bolted Bonnet Solid wedge (Plain or flexible) Renewable seat rings (Threaded or welded) Back seat bushing allows repacking under pressure Bosses for taps, drains, bypass Ground wedges, fully guided

300LB

..

CLASS

DIMENSIONS

FACE SIZES 2"

2\7" 3" 4" 5" 6"

MATERIAL SPECIFICATIONS

PART

1I0DY liON NET WEDGE SEAT RING GLAND FLANGE PACKING GLAND STE..M STEM NUT II.ACKSEAT .BUSHING YOKE NlIT HANDWHEEl 1I0NNET NUT 1I0NNET STUD HANDWHEEL EYEIIOLT NUT

FACE In. 8112 9~

111'. 12 15 15% 16\'2 18 19'A

TO

CENTER In.

16 17% 19% 23% 27% 32'1s

DIA TO TOP HANDOPEN WHEel

MATERIAL

ASTM A216 GR WCB ASTM A216 GR WCII SEE TRIM CHART' SeE TRIM CHART' ASTM Al05 STEEL CHROME PLATE.D SEE TRIM CHAAr ASTM A439 GA D2C OR ALUMINUM BRONZE ASTM A182 GR Ffi ASTM M7 GR 32510 ASTM A47 GR 32510 ASTM A194 GR2H ASTM Al93 GRII7 ASTM A197 OR ASTM A216 GR WCB ASTM A307 GA B • ASTM A307 GR B

,

in. 71/,

7% 8%

9%

12\',

14

15% 17% 20 22 25 28 35'h 43 51 63

8" 10"

12" 14" 16" 18" 20" 24"

41

48% 57 62'h 69 801'2 91 120~ 143 163

30

33

36

39 45 55

30" 36"

68

EYE

EYEIIOLT PIN PACKING GASKET SET SCREW

STEEL

NON-ASBESTOS SOFT IRON STEEL

,

Applicable Standards

Steel Gale Valves, API 600 (2"-24") Steel Valves, ANSI B16.34, Std. CL. Face-to-Face, End-te-End, ANSI B 16.10 End Flanges,ANSI B16.5 End Flanges (30" and 36"), MSS-SP-44 Weld Ends, ANSI B 16.25

GREASE NIPPLE STEEL • SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

MAXIMUM ALLOWABLE NON-5HOCK WORKING PRESSURE IN PSaG TEMPERATURE INDEGREESF

300 LB.

CLASS

---Tests---------API 598 Shell: 815 PSIG Hydrostatic Seat: 1125 PSIG Hydrostatic 80PSIGAir Other testing available upon request.

·20TO 100

200 300 400 500 600

740PSlG 675 655 635

600

650 700 750

800

550 535 535

505

WILLIAM E.

850

I.LLIAMS

VALVE CORPORATION

(BI-Chart malerials

900 950 1000

(AI-Permissable, but not recornrnenoed above approximately BOO° F.

410 270 170 105 50

lor prolonged usage

38-52 Review Avenue, Long Island City, NY 11101 Telephone: 718-392-1660 1·800-221·1115 Fax: 718·729·5106

depicts mUng" lor ASTM. A216 Gr reler 10 Pressure Tempernlure

eMIl

weB, [or otrn.on page 22.

Cast Steel Gate Valves

FIG. No. &OF-FLANGED FIG. No. 6OW ..BUTTWELD FEATURES

• Rising stem-OS& Y, Bolted Bonnet • Solid wedge (Plain or flexible) • Renewable seat rings (Threaded or welded) • Back seat bushing allows repacking under pressure • Bosses for taps, drains, bypass • Ground wedges, fully guided

DIMENSIONS

FACE TO

SIZES 2~t 2W' 311

MATE.RIAL SPECIFICATIONS

PART

BODY BONNET WEDGE SEAT RING GlAfjD FlANGE

FACE In. 11'h 13 14

17

4"

5"

6" 8"

10" 12" 14" 1:6" 18" 20" 24" 30" 36"

20 22 26 31

33

CENTER DIA TO TOP HAND· OPEN WHEEL In. In. 16'12 7'11 18 8'11 20Ye 9'1a 14 25 15% 301'2 170/, 33% 42%

MAteRIAL

ASTM A216 GR.weB

49

681'2

35

39

43

59 74 84'1. 93'12 140 170

20 25 27 3111, 35'12

43

47 55 65

77

no

51 51

ASTM A216 GR WCB SEE TfI.IM CHART" SEEmlM CHART' ASTM Al0S PACKING GLAND STEEL CHROME.PLATED SJE.M SEe TflIM CHART"" STEM NlJT ASTM A439 GR D2C OR.ALUMINUM BRONZE BACKSEATBUSHING ASTM A182GRf6 YOKE NlJT ASTM A47 GR 32.510 tlANDWHEEL NlJT ASTM. A47 G.R32510 BO.NNETNlIT .ASTM Al94 GR2H BONNET STUD ASTM Al93 GRB7 HANDWHEEL ASTM A197 OR ASTM A216 GR weB EY.EBOLT . .ASTM .A307 GR B EYE ASTMA3(17 GR B EYEBOLTPIN PACKING GASKET SET SCREW GREASE NIPPLE BEARINGS STEEL NON·ASBESTOS RING JOINT·IRON STEEL STEEL STEEL

Applicable Standards

Steel Gate Valves, API 600 (2"~24") Steel Valves, ANSIB 16.34, Std. CL Fac~to-Face, End-to·End, ANSI B 16.1 0 End Flanges, ANSI B16.5 End Flanges (30" and 36"), MSS'SP-44 Weld Ends,.ANSI B16.25

• SEE TRIM NOTES ON PAGE 4 FOR OPTiONAL TRIM MATERIALS.

__

Tests

API 598 SheU:2250 PSIG Hydrostatic Seat: 1630 PSIG Hydrostatic 80PSIGAir Other testing available upon request.

MAXJMUM Au.oWABLE NON'SHOCK WORKING PRESSURE IN PSI.G TEMPERATURE INDEGREESF

GOOLS.

CLASS

·20TO 100 200 300

400

500

600

650 700 750

BOO

1480PSIG 1350 1315 1270 1200 1095 1075 1965 101'0

825

.~

rIMll LL I A MS

VALVE

WILLIAM E.

850

900

535

345

CORPORATION

950 1000

205

105

usage

38·52 R.eview Avenue. Long' Island City. NY 11101 Telephone: 718·392·1660 1·800-221·111'5 Fax: 718·729·5106

(A,. Permissable·. but no1 reoom mended tor prolonged above approximately SOO·F.

(6,Chart depict. rati ngs tor ASTM. A2 16 G r WOB. for other male~a.ls reter to Pre!;1lure Tempe,a'ure Chart on page 22.

Cast Steel Gate Valves

FLAN ..GE.D FIG. No •.9O.F.·. CLASS FIG. N..• 150F ... : o BUTTWELD: FIG No .•90W 900 .Lb FIG•.No.150W

1500 Lb

CLASS.

FEATURES

• Rising stem-OS&Y, 80.lted Bonnet • Solid wedge (Plain or flexible) • Renewable seat rings (Threaded or welded) • Back seat bushing allows repacking under pressure • Bosses for taps. drains, bypass • Ground wedges, fully guided

900 PSI CAST STEEL GATE VALES

FACE TO FACE ih.

15 18 24 29 33 38

DIMENSIONS

MATERIAL SPECIFICATIONS

PART

BODY BONNET WEDGE SEAT RING GLAND FLANGE PACKING GLAND STEM STEM NUT B.AC.K SEAT BUSHING YOKE NUT HANDWHEEl BONNET NUT BONNET STUD HANDWHEfL GLAND EYE PACKING GASKET NUT

SIZES

3" 4" 6"

DIA CENTER TO TOP HAND· OPEN WHEEL in. in. 11112 26% 30 14 40'% 20

51 61 69~ 77 24 27 31~

MATERIAL

ASTM A216 GR WCB ASTM A2l6 GR WeB

SEe TRIM CHART' S.EETllIM CHART'

ASTM Al05 ASTM A182GR F6

11

10" 12" 14" 16"

SEe TllIM CIiART'

ASTM 8148 GA 9D ASTM A182 GAF6 CARBON STEEL CARBON STEfl ASTM A194 GR2H ASTM Al93 GR B7 C.ARBON STEEL OR NODULAR IRON

40'12

44~

35'12

43

82%

1500 PSI CAST STEEL GATE VALES

FACE TO FACE In.

14\12 CENTER

roTOP in.

SIZES

2" 3" 4" 6" 8" 10"

OPEN

21\12 27\16

D1A HAND" WHEEL in.

111,1,

sou

ASTM A307 GR B ASTM AJ07 GRB NON' ASBESTOS ARMCO IRON STEEL STEEL ' STEEL

GLAND EYE BOLT NUT

18V,

21Y,

1'4 20 2.4 27 35\1, 43 51

31'12

45 53\1, 65 74

Applicable Standards

Steel Gate Valves, API 600 (.2"".24") Steel.Valves, ANSI B 16.34, Std. CL Face-to"Face, End"to--End, ANSI 816.10 End. Flanges, ANSI 816.5 Weld Ends, ANSI 816 .. 5 2

27%

32% 39

SET SCREW

G.REESE NIPPLE BEARl N.GS

12"

14" 16"

MV, 39'h 541'2

• SEE TRIM NOTES ON PAGE 4 FOR OPilONAL TRIM MATERIALS.

83V,

88

03

MAXIMUM ALLOWABLE NON·SHOCK WORKING PRESSURE IN PSlG TEMPERATURE INDEGREESF

__

Tests

API 598 Class 900 Lb. Shell: 3350 PSIG Seat: 2450 PSIG 80PSIG Class 1500 Lb. Shell: 5575 PSIG (Hydrostatic) 4080 PSIG (Hydrostatic) 80 PSIG (Air)

900 LB.

CLASS

1500 LB.

CLASS

-20TO 100

200

300

400

500

600

Other testing available upon request.

r.

WILLIAM E.

650 700 750

800

850

2220P$IG 2025 1:970 1900 1795 1640 1610 1600 1510 1235

805

3705 PSIG 3375 3280 3170

2995

2735 2685 2665 2520 2060

1340

860

1 L

I::VEt~J~s

900

950 1000

515 310 155

515 260

USl!(Ie ollJer

(Ar Permlssable. b!J I no! recom mended for prolooged above appro~imalel.y600·F.

(BrChart rnaterlala deplctsratl "g" '''' ASTM, A2': 6 Or

38-52 Review Avenue, long Island City, NY 111m Telephone: 718-392-':6601·800-221-11;15 Fax: 718·729·5106

mler to Pressum Temperatare Chart on page 22.

we B. lor

Cast Steel __ RS Gate Valves

FIG. No. N15F-FLANGED FIG. No•.N15W-BUn"WELD

• Non·Rising Stem-NRS • Solid wedge renewable seat rings • Bosses for drains or bypasses • Operating nuts available

150Lb

CLASS

FEATURES ......

------.

D.IMENSIONS

SIZES FACE TO FACE in. 7

MATERIAL SPECIFICATIONS

.PART.

BODY WEDGE SEAT RIN.G BONNET STEM PACKER BOX GLAND FLANGE HANDWHEEL WASHER HANDWHEEL NIJT GLAHD BOLT PACKER ,BOX BOLT GLAND BOLTNIJTS PACKER BOX BOLT NUTS , STUOS NIITS

211 2W' 3 4"

1i

DIA CENTER HAND· TO TOP WHEEl

in. In.

MATERIAL

ASTM A21'6 GF! WC.B SEE TRiM CHART" SEE TRIM CHART* ASTM A216 GR WCB SEE TRIM CHART" ASTM A216 GR WCB ASTM A216 GR WCB CARBON STEEL OR NODULAR IRON CARBON STEEL CARBON STEEL BRASS ASTM M07 GRB BRASS BRASS AST.M AJ07 GR. B ASTM A194 GR 2H SOFT IRON BRONZE NON·ASBESTOS BRASS

12'14

13!h

1'h 8

9

7 7 1% 8'1a

12'h

15 17% 23 27

31% 35%

6" 8" 1'0" 12" 14" 16" 18" 20"

101'2

11'h

13 14 15 16

11

41

43%

12\1, 14 15~ 17'14 19%

:1

47'{, 52

22

24%

18

GASK.ET

BEARING PACKING GLAN.D

Applicable Standards

Steel Valves, ANSI B 16.34, Std. CL Face-to~Face,.End..to-End, ANSI B 16.10 End Flanges, ANSI B 16..5 . Weld Ends, ANSI 816.25

WEDGENIIT IBRON.ZE • SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALE.

MAXIMUM ALlOWABLE NON·SHOCK WORKING PRESSURE IN PSlG

---Tests

API 598 Shell: 450 PSIG Hydrostatic Seat 315 PSIG Hydrostatic 80 PSIG Air Other testing available upon request

TEMPERATURE IN DEGREES F

150 LB.

CLASS

·20TO 100 200

300 400

500 600

285 PSIG 260

230

200

170

140

650 700 750 800 850 900 950

125

110 95 80 65 50 35 20

lor prolonged usage

1000

(A)-Permjssable, but oot recommenced above app,oxImately 800· F.

materials .,etto" to Pr_,,'e

(B)·Chart depicts

rallngs

lor ASTM, A21 6 G, WCB.la, oll1er Temperatura Ct.art on pa,ge 22.

38~52 Review Avenue, Telephone: 718-392'1660

Long

Island City, NY 11101 1·800·221·1115 Fax: 718·729·5106

10

Cast Steel NRS Gate Valves

FIG..No. N30F ... FLANGED FIG •.No.N30W ..BUnwELD FEATURES

• • • • Non-Rising Stem-NRS Solid wedge Square operating nuts Handwheels available jf required

300LB

'

CLASS

DIMEN.SIONS

FACE

MATERIAL SPECIFICATIONS

in.

TO FACE

in.

CENTEA

TOroP

13

14% 17'1.

SIZES

PART BODY

BONNET WEDGE STEM GLAND FOllDWER BUSHING THRUSH WASHER GLAND FlANGE PACKING GLAND BOLTS GLAND NUTS SQUARE NUT WASHER NUT NUTS , STEM BUSHING

MATERIAL

ASTM A216 GR WeB ASTM A216 GR weB SEe TRIM CHART' SEE TlI.IM CHARI' ASTM B62 ASTM A18.2 GRF6

211 3"

31'.·4"

8'12 11'18 12

157/a 161'2 18 19%

6" 8" 10"

12"

21Y. 26'12

32

36 42 46 51

53

ASTM 8124

ASTM 8148GR ASTM B12.4 ASTM B124 955

TEfLON CHEVRON

14"

16" 18"

30

33 36 39

MAllEABLE CAST IRON

STEEL

20"

N01ES. t. VALVES CAN BE SUPPUED WITH HANDWHEELS OR SQlJAfiE OPERATING NUTS. 2. VAL.VESCAN 8E SUPPUEO wrTH 8IfffWELD

ASTM A194GR 2H

ASTM A194 GR 2H

oos.

STEM ASTM 8148 GR. 955

SOfT-IRON ASTM A193 GR B7 ASTM. A.19 GR 2H ASTM .B62

GASKET

STUDS NUTS BUSHING

• SEE TRIM NOTES ON PAGE 4 FOR OPT/ONAL TRIM MATfRIALS.

AppUcable Standards

Steel Valves, ANSI B16.34,. Std. CL. Face-to-face, End-fa-End, ANSI B 16.10 End Flanges, ANSI 816.5 Weld Ends, ANSI 816.25

MAXIMUM AlLOWABLE NON-$HOCK WORKING PRESSURE IN PSG TEMPERATURE INDEGREESF

-.20 TO 100

300 LB.

CLASS

740PSIG 675 655 635 600

__

Tests

API 598 Shell: 815 PSIG Hydrostatic Seat 1125 PSIG Hydrostatic 80 PSIG Air Other testing available upon request

200

300

400

500

600

550

535 535 505 410

650

700

750 800

850 900 950 l~OOO

270 170 105 50

tor Pfolonged~sage

rM

(A)-Permissal;>le., but not recommended above approximately 600 OF.

ILLIAMS

VALVE CORPORATlON

(B)-Chart materials

reter to Pres""re

depiClS ratings

!of ASTM •.11216 G, WeB, to< other

Temperature Chart on page 22.

38-52 Review Avenue, long Isiand City, NY 11101 Telephone: 718-392-1660 1-800-.221-1115 Fax: 718-729-51;06

11

Cast Steel Globe & Angle Valves

GLOBE

FIG. No. 152F-FLANGED FIG. No. 153F-FLANGED FIG. No. 152W-BUTTWELD FIG. No. 153W-BUTT'WELD

I ANGLE

150 Lb

CLASS

FEATURES--• • • Rising Handwheel, Bolted Bonnet-OS& Y Renewable seat rings (Threaded or welded) Back seat bushing allows repacking under pressure Bossed for bypass Stop-check design-optional

DIMENSIONS

~

FACE C EJfTER CENTER DIA TD TD TDTDP HAND· FACE FACE DPEN WHEEl In. 11I!IQ1es) In In. In. 2" 2112" 3' 3V." 4' 5" 6' 8" 10" 12" 14" B B'h 9'12 lOY, 11\'1" 14 16 19'12 2411. 27,/, 31 36

4

MATERIAL SPECIFICATIONS

PART

BODY BONNET DISC STEM HANDWHEEl SEAT RING BACKSEAT BUSHING PACKING GLAND GLAND FlANGE YOKE BUSHING BOHNET BOLT BONNET NUT HINGE BOLT HINGE NUT HINGE PIN LOCK NUT WASHER HANDLI: NUT PACKING GASKET

MATERIAl..

ASTM A216 GR WeB ASTM A216 GR WCB SEE TRIM CHART' SEE TRIM CHART· ASTM A197 SEE TRIM CHART'

13'11. 14'12 16V. 17% 19 24

24

B!I. BV.

11'/. 11'/.

4Y. 4'\4 5Y.

5*

7 8 90/. 12'1. 13'11 15'1, 18

12'1. 12'¥.

17'1.

ASTM A479·410

STEEl CHROME PLATED

ASTM A105

26'1. 30

21% 30 30 31'1. 35V,

ASTM A439 GR D2C or

ALUMINUM BRONZE

33'1.

56 54

ASTM Al93 GRB7 ASTM Al94 GR2H

ASTM A307 GR B ASTM A307 GR B STEEL CHROME PLATED ASTM A479-410 STEEL ASTM A307 GR B NON-ASBESTOS

n-1-,-J I " I LI-t .J.__ _!____

\\

16"

SOFT IRON

Ap.plicable Standards

Steel Valves, ANSI B16.34, Std. CL Face-to-Face, End-to-End, ANSI B 16.10 End Flanges, ANSI B 16.5 Weld Ends, ANSI B 16.25

, SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

MAXIMUMALLOWABLE NON·SHOCK WORKING PRESSURE IN PSIG

___

.Yests

API 598 Shell: 450 PSIG Hydrostatic Seat: 315 PSIG Hydrostatic 80 PSIG Air Other testing available upon request

TEMPERATURE INDEGREESF

-20 TO 100 200 300 400 500 600 650 700 750 600 650 900 950 1000 8l:>O>oe approximately

(Ar~mlssable, but not recommended

150LB, ClASS

265 PSIG 260 230 200 170 140 125 110 95

eo

65 50 35 20

lor prolonged usage

WILLIAM

E,

8OO·F.

LLI

VAlVE CORPORATION

(BrChan depicts rallngs lor ASTM, A216 Gr WCB, 10<other materials raler 10 Pressure Temperature ChaJ1 on page 22.

38·52 Review Avenue, Long Island City, NY 11101 Telephone: 718·392·1660 1-800-221-1115 Fax: 718-729-5106

12

Ie Valves

GLOBE

F.IG •.No. 302F-FLANGED FI.G.No. 303.·. F~FLAN. _GED . FIG. No. 302W-BUTTWELD . FIG. No. 303W-BUTTWELD

I ANGLE

FEATURES

300 Lb . . __

•

CLASS

• Rising Handwheel, Bolted Bannet-OS& Y • Renewable seat rings (Threaded or welded) • Back seat bushing allows repacking under pressure • Bossedfor bypass • Stop-check design-optional

DIMENSIONS

SIZES 2" 2W' ·3" 4" 5"

6"

MATERIAL SPECIFI.CATIONS

PART

BODY BONNET DISC STEM HANDWHEEL SEAT RING BA.CKSEATBUSHING PACKING GLAND GLAND FLANGE YOKE BUSHING BONNET BOLT BONNET NUT HINGE BOLT HINGE NUT HINGE PIN LOCK NUT WASHER

fACE TD fACE

In.

lOY, 11'1, 121': 14 15'1>" 171/, 22 24 V, 28 31 34

CENTER CENTER DIA YO YO TOP HANOFACE OPEN WHEEl In. IBrIJIeSJ in. In. 51', 13% 9 5'/.1 61'< 7 7'!8 15'10 161'1 19'10 211'1 24'10

31%

MATERIAL

ASTM AZ16 GR.WCB ASTM AZ16GR WeB SEE TRI M CHART' SEE TRIM CHART' WM A191 SEE TRIM. CHARY' ASTM M79-410 STEEL CHROME PLATED ASTM A105 ASTM A439 GRD2C or AlUMINUM BRONZE ASTM A193 GR.B7 ASTM A1!14 GR2H ASTM A307 GR B . ASTM A307 GR 8 STEEL CHROME PLATED . ASTM M7!1-410 SrEEL ASTM A301 GR B NON·ASBESTOS

9 13 14 15'" 17>,1 22

8'"

11 12Y<

14

8" 10" 12"· 14" 16"

15'" 17

'GEAR AG11JATOR RECOMME.NDED

· · · ·

· · · ·

HANDLE NUT

PACKING

Applicable Standards

Steel Valves, ANSI 816.34, Std. CL Face-to-Face, End-to-End, ANSI 816.1 End Flanges, ANSI 816.5 Weld Ends, ANSI 816.25

GASKET SOFT IRON • SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

a _

MAXIMUM ALLOWABLE NON-sHOCK WORKING PRESSURE INPSlG TEMPERATURE IN DEGREES F -20 TO tOO

200

300

300 1:.8. CLASS 740 PSIG 675

655 6::;S

600

__

::Tests

API 598 Shell; 1125 PSIO Hydrostatic Seat: 815 PSIG. Hydrostatic 80PSIGAir Other testing available upon request.

400

500

600

650

700

550

5::;5 535 505

750

BOO

410

270 170

850

900 950

1000 (A}-Permlssable.

t05

50

above approxlmal"'y 800' F.

but not reoom mended for prolong.ed usage

(B)-Chart depicts ratings for ASTM. A216 Or wee. for rnaterlals refer to Pressure Temperature eha~ on page

other

22.

38·52 Review Avenue. long Island City. NY 11101 Telephone: 718'392-1660 1-800-221-1115 Fax: 718-729,5106

13

Cast Steel Globe Vaves

FIG. No. 602F·FLANGED FIG. No. 602W·BUTTWELD FEATURES

• Rising Handwheel, Bolted Bonnet-OS& Y • Renewable seat rings (Threaded or welded) • Back seat bushing allows repacking under pressure • Bossed for bypass • Stop-check design-optional

DIME.NSIONS

FACE TO FACE SIZES

MATERIAL SPECIFICATIONS

PART

BODY BONNET DISC STEM HANDWHEEL SEAT RING BACKSEAT BUSHING PACKING GLAND GLAND FlANGE YOKE BUSHING BONNET BOLT BONNET NUT HINGE BOLT HINGE NUT HINGE PIN LOCK NUT WASHER HANDLE NUT PACK.ING GASKET

In.

CENTER D1A TO TOP HAttDOPEN WHEEl.

MATERIAL

ASYM A216 GR WCB ASTM .A216 GR WCB SEE mIMCHAHY" SEE TllIM CHARY' ASYM A197 SEE mlM CHARY' ASYMA479·4·1Q STEEL CHROME PLATED ASYM .Al05 ASTM M39 GR D2C OR ALUMINUM BRONZE ASTM A193 GRBl ASTM Al94 GR2H ASTM A307 GR B ASYM A307 GR B STEEL CHROME PLATED ASYM M79-410 STEEL ASYM A307GR NO.N.·ASBESTOS RING JOINT-IRON B

,

2"· 2\1:>" 3"

4"

It'h 13

14

In. 15)'; 17 19 21 25

in. 11 13

14

9'h

5" 6"

8" 10"

17 20

22

26%

26

31 33

12"

.. .

20

15%

'GEAR ACTUATOR RECOMMENDED

Applicable Sta.ndards

Sleel Valves, ANSI B16.34, Std. CL. Face-to-Face, End-to-End, ANSI B16.10 End Flanges, ANSI B16.5 Weld Ends, ANSI B16.25

• SEE TRIM NarES ON PAGE 4 fOR OPTIONAL TRIM MATERIALS.

MAXIMUM ALLOWABLE NON-SHOCK WORKING PRESSURE IN PSlG

__

Tests

API 598 Shell: 2.250 PSIG Hydrostatic Seat 1630 PSIG Hydrostatic 80 PSIG Air Other testing available upon request

TEMPERATURE INDEGREESF

-20TO 100 200

600 LB. CLASS

1480PSIG 1350 1315 1270 1200 1095 1·075 1965 1010 825 535 345

300

400

SOO

600 650 700 750 800 850 900

WILLIAM E

rMill LLI A MS

VALVE CORPORATION

950 1:000

IA1·Perm;ssa~te. out no! recommended above approximatety 8OO'F.

205

105

for prolonged uS<O{jJl

lSI' Chan dep lets rallngs for ASTM, M1l6 Gr weB. lor omer mat"riats refer to Pressure Tempera1ure· CI1an on page 22.

38·52 Review Avenue. Long Island City, NY 11101 Telephone: 718-392-1660 1-800-221! -1115 Fax: 718-729-5106

14

Cast Steel Globe Valves

FLANGED: FIG. No. 902F BUTTWELD: FIG.No.902W

CLASS 900 Lb

I FIG. No.1502F

FIG. No. 1502W

CLASS 1500 Lb

FEATURES

• • • • • Rising Handwheel, Bolted Bonnet-OS&Y Renewable seat rings (Threaded or welded) Back seat bushing allows repacking under pressure Bossed for bypass Stop-check design-optional

DIMENSIONS

900 PSI CAST STEEL GLOBE VALVES fl\CE CENTER

SIZES TO FACE In. 15 18 24

WHEEL

MATERIAL SPECIFICATIONS

PART

BODY SEAT RING DISC STEM BONNET STUD BONNET NUT BONNET GASKET BONNET BACK SEAT BUSHING STEM PACKING GLAND EYE BOLT GLAND GLAND FLANGE GLAND EYE BOLT NUT STEM NUT HANDWHEEL

MATERIAL

ASTM A216 GR WCB SEE mlM CHART" SEE TRIM CHART" SEE TRIM CHART· ASTM A193 GR B7 ASTM A194 GR2H ARMCO IRON ASTM A216 GR WCB ASTM A182 GR F6 NON-ASBESTOS ASTM A307 GR B ASTM A182 GA F6 ASTM A105 ASTM A307 GR B ASTM 8148 GR 90 CARBON STEEL OR NODULAR IRON

DIA TO TOP HANDOPEN WHEEL In. In. 22% 14 2111, 20·

3"

4"

6"

'HAMMERBLOW

26'12 36

1500 PSI CAST STEEL GLOBE VALVES CENTER DIA fl\CE

SIZES 2" 3" 4" 6"

'HAMMERBLOW

TO FACE In. 14Y,

TOTOP OPEN In. 24

WHEEL In.

Iwm·

lW.

18 26 20·

18'12

21'1> 27%

WHEEL

26

28 37'1>

HANDWHEEL NUT CARBON STEEL • SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

Applicab.le Standards

Steel Valves, ANSI B16.34, Std. CL. Face-to-Face, End-to-End, ANSI B 16.10 End Flanges, ANSI B 16.5 Weld Ends, ANSI B16.25

MAXIMUM ALLOWABlE NON-SHOCK WORKING PRESSURE IN PSIG TEMPERATURE INDEGREESF 9OOLB. CLASS 1500 LB. CLASS

-20TO 100

......Te~

API59S Class 900 Lb. Shell: 3350 PSIG Seat: 2450 PSIG 80 PSIG

_

Class 1500 Lb. Shell: 5575 PSIG (Hydrostatic) 4080 PSIG (Hydrostatic) SO PSIG (Air)

200

300

400 500 600

650

700

750

800

Other testing available upon request.

850

900

950 1000

2220PSIG 2025 1970 1900 1795 1640 1610 1600 1510 1235 805 515 310 155

lor prolonged

3705PSIG 3375 3280 3170 2995 2735 2685 2665 2520 2060 1340

860

515 260

usage

(A}-Perm,ssable, but not recommended above approximately BOO·F.

LIAMS

VALVE CORPORATION

(B)-Chart deolcts ratings to< ASTM, 11216Gr WCB, 10<other materialS ret", to Pressure Temperature Chart on page 22.

38-52 Review Avenue, Long Island Crty, NY 11101 Telephone: 718-392'1660 1-800-221-1115 Fax: 718-729-5106

15

Cast Steel Swing Check Valves

FIG. No. 151F-FLANGED FIG. No. 151 W-BUTTWELD

FEATURES·

• • • • Renewable seat rings (Threaded or welded) Bolted cover Optional lever and wei.ght or spring Bosses for bypass

150Lb

•

CLASS

DIMENSIONS

SIZES

2" 2\1i" 3" 4"

MATERIAL SPECIFICATIONS

CENTER TOroP In. 5'12 61'. 6¥a 8'/8

9

FACE TO FACE In.

8

PART

MATERIAL

ASTM A216 GR WCB ASTM .A21.6 GR WCB SEE TRIM CHART' SEE mlM CHART' ASTM A216 GR. WCB

BODY

COVER

D.ISC

81':. 91':.

'11'1

SEAT RING

HANGER . D.ISCNUT WASHER

5" ·6"

8" 10" 12" 14"

13

14

9'1~

11% 13 14% 15% 181'. 22 24

ASTM M07 GR B . STEEL

.ASTM A58DGR 304 ASTM. A.l93 GIlB 7

SPLIT PIN • COVER STUD , COVER NUT

HINGE PIN

19'h

241':. 27Y2 31 34 381':. 38Y2 51 60 77

ASTM Al94 GRZH ASTM A479 410 SOFT IRON ASTM M01 GR.B

16"

18" 20" 24"

GASKET

,SIDE PLUG

• SEE TRIM NOTES ON PAGE 4 FOR opnONAL TRIM MATERIALS.

28'h

32 34

30" 36"

MAXIMUM AlLOWABlE NON-SHOCK WORKING. PRESSURE INPSlG TEMPERATURE IN DEGREES F -20 TO 100 200 300 400 500 600 650 700 750 800 850 900 950

1000

(A}Permissable. !tILIl no! recommended 800' F.

150 LB. CLASS

285P$IG 260 230 200 170 140 125 110 95 8Cl 65 SO 35 20

lor prolonged usa,g.e

Applicable Standards

Steel Valves, ANSI B 16.34, Std. CL Face-to-Face, End-to-End, ANSI 816.10 End Flanges, ANSI B 16.5 End Flanges (30" and 36"), MSS-SP-44 Weld Ends, ANSI B 16.25

__

Tests

API 598 SheH:450 PSIG Hydrostatic Seat: 315 PSIG Hydrostatic BO PSIG Air Other testing available upon request.

above approximalely

{B}Ci1ar1depIClS ,.,.llngs lor ASTM •.A21 s Or malenals rele< 10 Pr=e Temper;ilure Chart on

wea

page 22.

IQI.O\Iwr

__ LLIAMS

VALVECORPORATION 38-52 Revfew Avenue, long Island Oity, NY 11101 Telephone: 718-392-1660 1-800-221-1115 Fax: 718-729-5106

16

Check Valves

FIG. No. 301F-FLANGED FIG. No. 301W-BUTTWELD FEATURES

• • • • Renewable seat rings (Threaded or welded) Bolted cover Optional lever and weight or spring Bosses for bypass

300Lb

•

CLASS

DIMENSIONS

FACE

,sIZES 2" 2'1::."

3"

MATERIAL SPECIFICATIONS

PART

BODY COVER DISC SEAT RING HANGER DISC NUT WASHER SPLIT PIN COVER STUD COVER NUT HINGE PIN GASKET SIDE. PLUG.

FACE

In.

TO

CENTER fn.

MATERIAL

ASTM A216 GR WCB ASTM A216 GR WeB SEE TRIM CHART" SEE TRIM CHART" ASTM A216 GR WCB ASTM A301 GR B STEEL ASTM A5BO GR304 ASTM Al93 G.RB1 ASTM Al94 GR2H ASTM. A479 410 SOFT IRON ASTM AS01 GRB

TO TOP

6% 7'h 7'1. 9

10'1::. 111',

12'h

4"

6" 8"

14

IT'h

11

12% 15

21

24'h

·',0" 12" 14" 16" 18" 20" 24"

28

33 34 38'h

17'k 20

2OY,

22'1::. 25 29

40 53

• SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

MAXIMUM ALLOWABLE NON-SHOCK WORKING PRESSURE IN PSlG TEMPERATURE INDEGREESF

300 La.

CLASS

·20TO 100

200

Applicable Standards

Steel Valves, ANSI 816.34,. Std. CL. Face-to"Face,.End-to-End, ANSI B 16.10 End Flanges, ANSI B16.5 Weld Ends, ANSI B 16.25

300

400

500

600

650 700 750

800

___

Tests

API 598 Shell: 1125 PSIG Hydrostatic Seat: 815 PSIG Hydrostatic 80PSIGAir Other testing available upon request

850

900

950

1000

(A)-Permlssable,buln.ot recommended, abO", appro.lmalely 800°F.

740PSIG 675 655 635 600 550 535 535 505 410 270 170 105 50

for prolonged usa.ge

(B)-Chan depicts ratings for ASTM. 1\.:216 Gr WCB, for other matertals ref"'lo Pressure Tsrnperalure Oharton page 22.

••

ILLIAMS

VALVE CORPORA1l0N

38-52 Review Avenue. Long Island City. NY 11101 Telephone: 718-392-1660 1,800-22Hl15 Fax: 718-729-5106

17

Cast Steel Swing Check Valves

FIG. No. 601 F·FLANGED FIG. No. 601W·BUnwEL.D FEATURES

• • • • Bolted cover Renewable seat rings (threaded or welded) Bosses for drains or bypasses Outside lever and weight or spring available

..

DIMENSIONS

FACE SIZES

2" 2'h."

MATERIAL SP.ECIFICATIONS

CENTER TDTDP in. 7% 7'/1

8\4 10'1. 13 17

FACE In.

111'! 13 14 17 22 26 31 33 35 39

TO

PART

BODY COVER DISC SEAT RING HANGEfl DISC NUT WASHER SPLIT PIN COVER STUD COVER NIJT HINGE PIN GASKET SIDE PLUG

MATERIAL

ASTM A216 GR WCB ASTM A2UiGR WeB SE.E TRIM CHART" SEE TRIM CHART" ASTM A216GR WCB ASTM A307 GR B

3" 4l'

6"

SUEL

ASTM A580 GR304 ASTM A193 GR 117 ASTM. Al94 GR. 2H ASTM A479 410 RING JOINT·IRON ASTM A307 GR B

8"

10"

19

20

12"

14" 16"

221'2

26 28 31 34

18"

20" 24"

43

47

55

• SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

MAXIMUM ALLOWABLE NON-SHOCK WORKING PRESSURE IN PSlG TEMPERATlJRE INDEGREESF ·20 TO 100 200 300 400 500

600

600 LB.

CLASS 1480PSIG 1350 1315 1270 1200 1095 1075 1965 1010 825 535 345 205 105

usage

Applicable Standards

Steel Valves, ANSI B 1. 6.34, Std. CL. Face-to-Face, End-to-End, ANSI B 16.10 End Flanges, ANSI B16.5 Weld Ends, ANSI B 16.25

___

Tests----------

API 598 Shell: 2250 PSIG Hydrostatic Seat 1630 PSIG Hydrostatic 80 PSIG Air Other testing available upon request.

650 700 750 800 850 900 950 1000

(A)-!'etm ,ss:able. but oot reoom mended lor prolonged above appro,,; mat"ly 800' F.

(B)-Chart d~pict. ra~ngs lor ASTM, A216 Gr WCB. fur other materials reler to Pres1lure Temperature Chart on page 22.

_1

WILLIAM E.

18

2L

-=~tATI!" s

38·52 Review A\lenue, Long Island City, NY 111.01 Telephone: 718·392·1660 1·800·221-1115 Fax: 718·729·5106

Cast Steel Swing Check Valves

FLANGED: FIG. No. 901F BUTTWELD: FIG. No. 901W

900 Lb.. FIG.

CL.ASS I FIG. No. 1501F

No. 1501W

1500 Lb

CLASS

FEATURES-----• • • • Bolted cover Renewable seat rings (threaded or welded) Bosses for drains or bypasses Outside lever and weight or spring available

DI.MENSIONS

900 PSI CAST STEEL SWING CHECK. VALVES

FACE TO FACE CENTER TO TOP In.

MATERIAL SPECIFICATIONS

PART

BODY COVER DISC SEAT RING HANGER DISC NUT WASHER SPLIT PIN COV.ER STUD COVER NUT HINGE PIN GASKET SIDE PLUG

MATERIAL

ASTM A216 GR WCB ASTM A216 GR. WCB SEE TRIM CHART' SEE TllIM CHARTASTM A216 6R WCB ASTM AJ01 GR B STEEL ASTM A5BO GR304 ASTM A.l93 GR B7 ASTM Al94 GR 2H ASTM A479410 RING JOINT-IRON ASTM A307 GI'I8

SIZES 3" 4"

in.

15

9'/, 11 1331.

6"

18 24

1500 PSI CAST STEEL SWING CHECK. VALVES FACE

In. 14'h FACE. TO CENTER TO TOP In.

SIZES 2"

8%

9V. 11 13%

3"·

4" 6"

1811, 21'h

27%

.• SEE TRIM NOTES ON PAGE 4 FOR OPTIONAL TRIM MATERIALS.

MAXIMUM ALlOWABLE NON-SHOCK WO.RKlNG PRESSURE IN PSlG TEMPERATURE INDEGREESF

9OOLS.

CLASS

1500 LB.

CLASS

-20TO 100 200

Applicable Standards

Steel Valves, ANSI 816.34, Std. CL. Face-to-Face, End-to-End, ANSI 816.1 0 End Flanges, ANSI 816.5 Weld Ends,. ANSI 816.25

300 400

500

600

650 700 750

800

----Tests

API 598 Class 900 Lb. Shell: 3350 PSIG Seat 2450 PSIG 80PSIG Other testing

_

Class 1 500 Lb. Shell: 5575 PSIG (Hydrostatic) 4080 PSIG (Hydrostatic) 80 PSIG (Air) upon request.

{B)-Chart

850

900

2220PSIG 2025 1970 1900 1.795 1640 1610 1600 1510 1235 805 515

310

950

1000

155

3705 PSIG 3375 3280 31'70 2995 2735 2685 2665 2520 2060 1340 860 515 260

usage

(A}-PermISsabi<>, but not recorn mended for prolonged above approximalefy BOO'F.

depicts .rati ng. lor ASTM, A216 Gr we s, for other mater·lal. refer to Pressore Temperatura Cha~. on page 22.

available

WILLIAM

E.

_.

L -='Et~"ON. S

19

38-52 Review Avenue, Long Island City, NY 111.01 Telephone: 718-392-1660 '-800-221-1115 Fax: 718-729-5106

Cast Steel Reduced

FLANGED: FIG. No. C16F6RT

ortBal1 Valves

300Lb

CLASS

FEATURE.S

• Blow-out proof stem • Anti-static grounding • 10" and 12" valves are trunion mounted design

150 PSI CAST STEEL REDUCED PORT BALL VALVES

FACE

DIMENSIONS

MATERIAL SPECIFICATIONS

PART

BODY RETAINER BAlL STEM COVER lEVERIIOSS LEVER OF

MATERIAL

ASTM Al16 GR WCB ASTM Al16 OR WCB ASTM A351 GR CF8M ASTM A182 GRF316 ASTM Al16 GR WCII ASTM A351 G.R CF8M ,o,sTM .A120 (PIPE)' REINFORCED TEFLON ,o,sTM A182 GR FJ16 ASTM A276 GR F316 . ASTM A276 GR 1'316 .o.sTM A276 GR F316 TE.FLON TEFLON ·TEFLON STAINLE.SSSTEEL

TO

7

CENTER In.

LENGTH

in. 9

SIZES

FACE In.

T010P UVER· 4%

2" 2'12"

--++~----+------~H--+-

3" 4" 6" 8" 10"

7'12 8

9

4:v.

51'. 6'1. 7% 11 12'li 15'12

to \I;

11'12 13 14

11 1.4 16 .20 24

30

SEAT

GLANOR.ING GLAND BOLT JOINT 1I0l1 WASHER WASHER PACKING GASKET SPRING

12"

36

300 PSI CA.ST STEEL REDUCED PO.RT BALL VALVE.S

FACE SIZES FACE In.

TO

CENTER

LENGTH

OF LEYEfI. In.

TO TOP

In. 4% 4'ti

"GEAR OPERAmRS ARE RECOMMENDED FOR SIZES 8" AND LARGER. MAXIMUM ALLOWABLE

2"

2\1;"

8'12

9\1;

6

11 14

WORKING PRESSURE IN PSIG

150 LB. CLASS

285 PSIG 260 230

NON-stfOCK 3OOLB. CLASS

740PSIG

3"

4"

111'. 12

15'1a

5'1. 61',

7%

16

20 24

30

TEMPERATURE INDEGREESF

·20 TO 100

Applicable Standards

Shell & Wall thickness: ANSI 816.34, Std. CL Face-to-Face: ANSI 816.10 Flange Dimensions: ANSI 816.5

6"

8"

lEW.

18

11

12% 15\1;

200 300

400

(ArTempernture PTFE materials.

10" 12"

200

rallng.lor

675 655 635

TFE and

19"{.

36

lim~ed: 10 maximum

___

Tests

APIS9S Glass 150 Lb. Shell: 450 PSIG Seat: 80 PSIG

_

Class 300 Lb. Shell: 1125 PSIG (Hydrostatic) Seat: 80 PSIG (Air)

Optional high pressure test per 598 available upon request

rIMllLLIAMS

~ VALVE CORPORATION

WILLIAM E.

38-5.2 Review Avenue, Long Island City, NY 11101 Telephone: 718·392·1660 1-800· 221·1115 Fax: 718·729·5106

20

Cast Steel Full Port Ball Valves

FLANGED:

Fig. No~C37F6RT

FEATURES

• Blow-out proof stem • Anti-static grounding • 10" and 12" valves are trunion mounted design

150 PSI CAST STEEL FULL PORT B.ALL VALVES

fACE TO mE In.

4y., 4%

DIMENSIONS

MATERIAL SPECIFICATIONS

PART

BODY BONNET

BALl

MATERIAL

ASTM ASTM ASTM ' ASTM ASTM A216 A216 .A35l M1S A182 GR WCB GR WCB G.R CF8M GR.WCB Gft F316

I

SIZES

'11"

3fio" t"

11+---~

LENGTH CENTER OF TO TOP LEVER· In. In. 5 3 3'1. 5

3% 4% 4% 6% 9 11 14 16 18 24 30 40

+ --~

H~" 2" 2'11" 3" 4" 6" 8"

5 6'12

7

I,

1'12

B 9 15% 18 21 24

5'1,

1%

8'11

12% 15% 17l\i 18".

YOKE STEM LEVER GIM 0 FLAN GE GLAND RING STOPPER BALL SEAT THRUST WASHER 80NNET STUO BONNET NlJT SNAP RING PACKING GASKET SPRING

ASTM A216 6R WCB' ASTM A216 GR WCB ASTM A182 GRF316 STAINLESS STEEL REINFORCED TEFLON VIRGIN TEFLON ASTM Al93 GR B7 ASTMAl94 6R 2H STEEL CHROME PlATm TEFLON TEFLON STAINLESS STEEL

10"

12"

48

300 PSI CAST STEEL FULL PORT BALL VALVES

FACE TO BeE In, 5'12

6

'GEAR OPERATORS .ARE RECOMMENDED FOR SIZES 6" AND LARGER. MAXIMUM AlJ..OWABLE NON-SHOCK WORKING PRESSURE IN PSIG

SIZES '12"

Applicable Standards

Shell & Wall Thickness: ANSI 816.34, Std. CL Face-to-Face: ANSI 816.10 Flange Dimensions: ANSI B 16.5

'to" 1" lW' 2" 2W'

LENGTH OF CENTER TO TOP LEVERIn. In. 5 3 5 3l\i 3% 4'1.

4% 5Y, 1%

TEMPERATURE

-2010100 200 300 400

IN DEGREES F

150LB. CLASS

285PSIG 260 230 200

3OOLB. CLASS

740 PSiG 675 655 635

6'1, 7'12 8'h 9'h

11'/a 12 15% 1.9'/.0 2.2%

6 6

11 14

(Ar Temperature lim~.ed to maximum notin9 lor TFE and PTFE. materials.

___

Tests

API 598 Glass 150 Lb. Shell: 450 PSIG Seat: 80 PSJG

_

Class 300 Lb. SheH.:1125 PSIG (Hydrostatic) 80 PSIG (Air)

1l

4"

8'h

12),. 15% 17'1. 18'1.

16 1.8

24 30

6"

8"

10"

12"

25'12

40 48

Optional high pressure test per 598 available upon request.

WILLIAM E.

VALVE

CORPORATION

AMS

21

38-52 Review Avenue, Long Island City, NY 11101 Telephone: 718F392'1660 '·8()()"221-1115 Fax: 718-729-5106

Pressure Temperature Ratings

(COMPLY WITH ANSI B16.34~1981-STD

WORKING

CLASS TEMP

CLASS VALVES)

PRESSURE (PSIG)

A217

(3)

WORKING

(4) A352 CLASS TEMP

PRESSURE (PSIG)

A217

(3)

OF

(2) (1) A218 A217 WCB C5

wee wee

290 260 230 200 170 140 125 110 95 80 65 50 35 20 750 710 675 660 640 605 590 570

530

A217

(3)

(4) A352

LeB

Le3 290 260 230 200 170 140 125 -

OF

(2) (1) A2HI A217 WCB C5

wee

A2t7

(3)

WCe 1135 1065 1015 975 900 755 535 2250 2150 2030 1945 1920 1815 1765 1705 1595 1525 1460 1350 1130 805

(4) A352

LCB

(4) A352

Le3

-2010100 200 300 400 500

600

285 260 230 200 170 140 125 110 95

80

290 260 230 200 170 140 125 110 95 80 65 50 35 20 750 750 730 705 665 605 590 570

530 500

290 260 230 200 170 140 125 110 95 80 65

265 250 230 200 170 140 125

-

700 750

800

1065 1010 825 535 345 205 105 2200 2025 1970

1900

1135 1065 995 880 705 520 385 2250 2250 2185 2115 1995 1815 1765 1705 1595 1490 1315 1060 780 575 3750 3750 3640 3530 3325 3025 2940 2840 2660 2485 2195 1765 1305 960

1135 1065 1015 975 900 755

445

600

850 900 950 1000 ·2010100 200 300 400

500

150

650 700 750

800

2085 1970 1915 18SO 1745 1600 1570

2250 2135 2020 1975 1925 1815 1765 1705 1595 1525 1460 1350 1130 670 3750

3560

2250 2250 2185 2115 1995 1815 1765

850 900 950 1000 -2010300 200 300 400 500 600

65 50 35 20 740 675 655 635 600 550 535 535 505 410 270 170 105 50 1480 1350 1315 1270 1200 1095 1075

so

35 20 750 715 675 650 640 605 590 570

530

1840 1640 1610

1600

750 750 730 705 665 605 590

600

900

650

695 655 640 620 585 535 525

700 750 800 850 900 950 1000 -2010100 200 300

400

1510 1235 805 510 310 155 3705 3375 3280 3170 2995 2735 2685 2665 2520 2060 1340 860 515 260

300

650 700 750

800

3470 3280 3190 3085 2910 2665 2615

3750

3580

3750 3750 3640 3530 3325 3025 2940

-

510 485 450 380 225 1500 1425 1345 1315 1285 1210 1175

510 485 450 380 270 1500 1430 1355 1295 1280 1210 1175

650

900

440, 355 260 190 1500 1500 1455 1410 1330 1210 1175

950 1000 -2010600 200

1390 1315 1275 1235 1165 1065 1045

1500 1500 1455 1410 1330 1210 1175

3365 3290 3210 3025 2940 2840 2660 2540 2435 2245 1685 1115

3385 3240 3200 3025 2940 2840 2660 2540 2435 2.245 1885 1340

500

600

1500

650 700 750

800

600

300 400 500 600 650

850 900 950 1000

NOTES: (1) PERMISSIBLE, BIJTNOT (2) NOT TO BE USED OVER (3) NOT TO BE USED OVER (4) NOT TO BE USED OVER

RECOMMENDED FOR PROLONGED USAGE ABOVE ABOIJT 800' F. 1050' F.FlANGED END RATINGS TERMINATE AT 1000· F1100' F.FLANGED END RATINGS TERMINATE AT 1000· F. 650· F.

WILUAM E.

~

22

IL

-="t~mN

38-52 Review Avenue, Long Island City, NY 11101 Telephone: 718-392-1660 1-800-221-1115 Fax: 718-729-5106

Steel Pipe Schedule Chart

Carbon and Alloy Steel Pipe Dimensions in Inches

Nominal Pipe Size 2 2Y~ 3 3Ya 4 5 6 8 10 12 14 16 18 20 24 30 36 Outside Dia. 2.375 2,875. 3.500 4,000 4,500 5,563 6.625 8.. 25 6 10.750 12.750 NOMINAL Sch. 10 Sth. 20 Sch. WA L L THICK.NESS

30

-

Std. Wall

Sch.

40

Sch.

80

-

0.154 0.154 0,203 0.203 0.216 0.216 0.226 0,226 0.237 0,237 0,258 0,258

Sch. 80 0.218 0.218 0.270 0,270 0.300 0.300 0,318 0,318 0.. 37 0.337 3 0,375 0.375

Extra Strong

Sch. lOO

Sch.

120

Sch. 140

8ch.

0.438 0.500

180

Strong

XX

~ ~

0.343 0.436 0,375 0,552 0.438 0,600 - 0,636 0,531 0,674 0.625 0.750

0.280 0.280 - 0.432 0.432 0.562 0.718 0.864 0.250 0.2.77 0.322 0.322 .0.40.6 0.500 0.500 0.593 0.. 19 0.812 0.906 0.875 7 0.250 0.307 0.365, 0.365 0.500 0.500 0.593 0.718 0.844 1.000 1.125 0.250 0.330 0.375 0.406 0.562 0.500 0.687 0.843 1.000 1.125 1,312

14.000 0.250 0.312 0.375 0.. 75 0.438 0.593 0.500 0..750 0.937 1.094 1.. 50 1.406 3 2 16.000 0.250 0.312 0.375 0.375 0,500 0.656 0.500 0.848 1.031 1.219 1.438 1.593 18.000 0.250 0.312 '0.438 0.375 0.562 0.750 0.500 0.937 1.156 1.375 1,562 1.781 20.000 0.250 0.375 0.500 0.375 0.593 0.812 0.. 00 1.031 1.281 1.500 1.750 1.968 5 24.000 0.250 0.. 75 0.562 0,375 0.688 0,968 0.500 3 30.000 0.312 0.500 0.625 0.375 - 0.500 - 0.312 0,500 0.625 0.375 0.750 - 0.500 1.218 1.531 1.812 2.. 62 2.343 0

Conversion Data

Power

1 horsepower = 33,000 It. lb. per min. I horsepower", 550 ft. lb. per sec. 1 horsepower » 2,546.5 BT.u. per hr. I horsepower = 745.7 watts 1 watt = 0,00134 horsepower 1 wall '" 44.26 It. lbs, per min.

Pressure

, in. of water == 0.03613 lb. per sq. in. 1 in. of water = 0.07355 in. of Hg. 1 fl. of water", 0.4335 lb. per sq. in. 1 f1.01 water = 0.88265 in. of Hg. 1 in. of mercury « 0.49116 lb. per sq. in. 1 in. of mercury = 13.596 in. 01 water 1 in. of mercury", 1.13299 ft. of water 1 atmosphere'" 14.696 lb. per sq. in. 1 atmosphere '" 760 mm. of Hg. 1 atmosphere = 29.921 in. of Hg. 1 atmosphere (metriclkg/O) '" 14.22 P.S.1. 1 atrnospbere « 33.899 fl. of water 1 lb. per sq. in. = 27.70 in. of water 1 lb. per sq. in. '" 2.036 in. of Hg. 1 lb. per sq ..in. = .0703066 kg. per sq. cm. 1 kg per sq. ern. '" 14.233 lb. per sq. In. 1 dyne per sq. ern. = .0000145 lb. per sq. in, 1 rntcron » ,00001943 lb. per sq. in.

Density

1 lb. per cu. ft. =16.018 kg. per cu. meter 1 lb. per cu. ft. = .00057B7 lb. per cu. in. j kg. per cu. rneter e 0.06243 lb. per cu. 11. 1 g. per cu. ern, => 0.03613 lb. per cu. in.

Energy

1 BTU '" m.97 It. lbs, 1 erg'" 9.4805 x 10-11 B.T.U 1 erg == 7.3756 x 10-8 It. Ibs. 1 kilowatt hour", 2.655 x 105 ft. lbs, 1 kilowatt hour = 1.3410 h.p, hr. . 1 kg ..calorie '" 3.968 BT.U.

:Flow

1 CU. 11.per sec. '" 448.83 gal. per min. 1 cu. 11.per sec. '" 1699.3 liters per min. 1 US. gal. per min, '" 0.002228 cu. It. per sec, 1 US. gal. per min. '" 0.06308 liters per sec. 1 cu. cm. per sec. = 0.0021186 cu. ft. per min.

Volume

1 cu. in. 1 cu. ft. 1 cu. ft. 1 cu. ft. 1 cu. ft.

1 1 1 1 1 1 1 1 1 '" 16.387 cu. ern. = 1728 cu .. in. = 7.4805 US. gal. = 6.229 British gal. = 28.3171ilers U.S. gal. '" 0.1337 cu. II U.S. gal. '" 231 cu. in. U.S. gal. '" 3.785 liters British gal. = 1.20094 US. gal. British gal. '" 2n.3 cu. in. British gal. = 4..546 liters liter'" 61.023 cu. in. liter", 0.03531 cu. 11. liter '" 0.2642 U.s. gal.

Weight

1 ounce avo '" .28.35 g. lib. avo = 453.59 g. 1 gram = 0.03527 oz. avo , kg. '" 2.205 lb. avo 1 cu. It. of water", 62.425 lb. 1 U.S. gal. of water = 8.33 lb. 1 cu. in. of water '" 0.0361 lb. 1 British gal. 01 water = 10.04 lb. 1 cu. It. of air at 32°f, & tatrn '" 0.080728 lb.

Velocity

1 II. per sec. = 30.48 ern, per sec. 1 cm. per sec. = .03280811. per sec.

Viscosity

1 Centipoise", .000672 lb. per fl. sec. 1 Centistoke '" .00001076 sq. II. per sec.

Heat Transfer

1 1 1 1 1 BT.U. per sq. fl. '" ,2712 g. cal. per sq. ern, g. calorie per sq. ern, = 3.687 BT.u. per sq. ft. B.T.U per hr. per sq. 11.per oF. = 4.88 kg. cal. per hr. per sq. rn, per 0C kg. cal. per hr. per sq. m. per cC. '" .205 B.T.U. per hr. per sq. 11.per OF Boiler Horsepower = 33479 B:rU per hr.

Temperature

Temperature Fahrenheit (F) '" 915 Centigrade (C) + 32 = 914 Re + 32 Temperature Centigrade (C) = 519 (Fahrenheit (F) - 32) '" 5/4 Ae Temperature Reaumur (Re) '" 4/9 (Fahrenheit (F) - 32) = 415 C Absolute Temperature Centigrade or Kelvin (K). '" Degrees C + 273.1.6 Absolute Temperature Fahrenheit or Rankine (R)= Degrees F + 459.69

23

lange Dimensions

oJ ~1f I

0

Wfo-t;

0 SLlP·ON

;~

0

~1T ~-

[]J

0 LAP·JOINT

~nrc~ pv~ ,

..... l

BL'INO

WELDING

NEeI':

THREADED

Nom. Pip. Sill.

0

3'{ 4Y4%

C<D

150 LB. I=LANGES yID

W.ld SlIpO, Thrd. H"k 1'1" 2% LapJoint

No.and Bolt Sin of Chel, Hal .. i'{

0

3"1,

4'/0

Ca:

01".

"/,

300 LB. FLANGE'S Y<D

W.ld N.ek 2';'.

400 LB. FLANGES

No.and Slip 0" Lap~ Bolt Siz. of Clrell Halos Thrd. JoInt 1

0

4'10 4',,"

C<i

9;"

W.ld Noek

Slip On LopThrd. Joint 1 1 '1,. 1'/0

y®

Nom. Pip. Na.onc:! Bolt Siz. of Size Clrel, Hoi ••

1'1,

1 III,.

~ ~

3'1,

2 2'1, J 3'1, 4 5

6

6 7 7>-"; 9 10

11

111" 'J" '10

"I"

'I,

'I,_ '1, "I".

2'1" 2'1,.

2'1,.

2'1:, 2';' 2% 2tJ;,. 3 3'/,. 3'!,_

4

%'. 1 1'/0 1't.

ul,

"4.

'I, 'I,

"I,.

% I 1'1,

2'1,

3';'

4.%

4.'1,

''I"

3%

3'6

4-'1"

40/"

'/0

4.'1,

8'1,

"1,.

"f,.

131,. 1 1'/0

1'1,. 1'1,.

1'1,.

1'1'

1"" 1 1,.

8 10 12 14 16 18 20 2~ 30 36

13'/, 16 19 21 25 27'/,

32

1'1,.•

1't. 1%

la

4';'

5 5'/,

2"/,_

2';'

23'1,

1'1.. 1"1".

I"/,

1'1, ..

Ja'/. 46

ill

"1,.• 111,

~11,. Slil, 2'1,'

5%

5'10

3't. 3'1:, 3';'

1~ I 11'1. 1 /,. 14% 2 '1,. 17 18% J~ 3 21't. 3' /,. 22'1, 4'1.. 25 29'1, 4% 36

'"1,. ,

l'l,~

1't. I'Ii,

5'1, 6 7

4'1,

7'" gi!,_

9'!,

4.'/0 4-';' 4};' 4.% 8-';'

.91, 6Y,

0/.." %

"I"

6'1, 7'1, 9 10 11

8'1.

1,

42'1,

12.1 12.1 12.1'/0 16-1% 16.1 V. 20.1 Y. 20.1% 28-1% 32-1'1,

8.% 8-'1, 8.'/0 8-';'

20'1,

15 17'1,

12'1,

23 25';' 28 30'!,_ 36 43 50

1'1, 1'/0 2 2'/0 2';' 2Y,

I'li.

1%

1 1'/0 1';'. 1%

2'1,. 2"1" 2'1.

2';'.

2'1,

'I"

I';'. IV,

1'/,.

,';,.

1'1,.

I 1'1,.

,

1'1" 1%

1'./1.

1'(,

1'1".

2% 3'/,

3'1,

4.>;'

4-% 4.%

3'1,

J't.

l.if,

1';'\ 1'1, 2 2'/" 2% 2%

J

l,f;,.

1'10 2

3'1, 4';.

4% 5'10

3% 3'1,

3'1,.

5'1, 6'1,

7'i\

4'1, 5

3'1,

4.'1. 4.'1.

6'1,

6'1, 7'1,

5'1.

"I,.

'!,

1

t~/1.6

'I,

2'1" 21,. i'1, 2'1, 2'1,

2;-

'I,

B-';' B-'/o 8-'/0 8.%

1'1,

8-'1, 8.'1, 12-'10

16.1V. 20-1% 24.1% 12.1

2'1,.

2'1,.

4

3'1.;

2'1,.

10"4 13 1.9;' 17'1.

9Y.

16.1'1,

.?Io

2'1,

2'1.

6'1,

6%

3:'/0 4'1,

6'1, gil. 9'/,

3'1, 4"1,. 9'1,

gil.

3';'; 3'1:,

4'10

4% 5'/0 !lY, 6

20';'

27 32 46

24'1,

22'1;

20·1'1,

24.1'1,

24-1'1,

1% 1ll,

39'1.

32-2';'

2B-ll;

20Y, 23 25Y, 28 30'!, 36 43

17'1,

9 10 11 12'!,_ 15

Sy.

1'1,

1'1. 1%

1'1,

3Y,

4

3Y. 3%

3'/0

I'_{ 1 "1,. 1 "Ii, 2 2V. 2% 3'10

1'1. 1'1,.

IV, Ill.

1'1,.

'I,

2'1, 3'/, 3'1,

5

3~

4.'1, 4_'1, 4-'1, 4~'1,

4_%

1"/1. 2

1"1"

1:~. 1'10

4'1,

5'1, 7'1. 7'1, 9'1.

6%

s-%

8.' 8-1 12-1 12.1'4

B~',," 8·%

8.'

I 1'1. 1';' 2 2'1, 3 3'1, 4

6

1%

1'!,_ 1'/0

4'/,

2'/0

.2';'

2'1. 4 4';' 4'1, 5 .9/0 5% 6'1.

-

SO

2% 2% 3 4 4'4

2';' 2'1. 2'1, 2'1,

4'1,

5';. 5'1. 6 6'/,

4%

2"1\. , 2"1,.

10"/0 13

15'f.

20y'

16.1'1.. 10

:f?, 3'1,.

4

17'1,

6'1, 6'1,

3'/0

4'1,

24% 27 32 46

.22'1,

S"I,

9'1,

8-'1,

9'1.

39'1.

16.1',~ 12 20.1?' 14 2o.1~ 16 24.1~ 18 24_1' 20 24.1' .24 28-2'! 30 32.2'1. 36

600 LB. FLANGES

'!,_ 1'1, 1'1, 2 2Y, 3 3Y,. 4 5 6 8 10 12 14 16 18 20 24 30 36

900 LB. FLANGES

2'1,. 3';' 3'1, 3'1. 4'1, 5 5';' 4-';'

'I..

3'1.

4'1, 4'!,.

2'/ .. 2'ti,

2';'

2'1.

6'1, 7'1, 10'1. 16'1, 23'1.

32

5'1.

6'!,_ 8't. 9

ul,.

1 I'!,. 1"

'10

'I,

2'1.

IV.

1'1.

1'1,

1'1,

1'1,

13 14

1'1, 1'1, 2'f,

2'/1. 2'10 3 3%

2'10 3';8 3% 3% 4 4'1, 4';. 6

1 ;"

"

1'1,

1'/0 1't. I /1. 1'1, 2';' 2';'

1'11.

4-'1, 4-'1. 4.'1, 4_'1,

8.'/0 8.1 8·1

6%

7

4'1. .91, 5'1,

IV.

'I,

2%

2'1,

8.'1.

8Y,

2'!,

1::;'. 1 1".

1'%

3

1"1,

6'/0

8'!,

1Y.

8·'4

9'/0 9'!,_

1% 1'1. 1'!,_ 1%

2'1.

IV. 1'10

3Y.

4

1'1, 1'1.

3V. 4 4'41 4 4V, 5 6'1,

-

2'/0

1'1,

1'1, 1'1. 2'1, 2';'

,'1,

J'!,

4.'1, 4.'1,

4.1 4_1

4% 5'10 7

Ill..

1%

4'1, 7Y,

4'10

4-1'1,

a.1 8-1'/0 8-1

,

5'1, 6'1.

IV.

1'1,;

1'1,

'I,

1500 LB. FLANGES 2'1, IV. 1'1.

2%

2'1.

2'1.

2'1. 2'/,

2';'

6Y,

20 2~

5'1.

27 29',{ 37 441< 51'/.

3'1,

6Y, 7 7';'

6'/0

2'/0 2'1, 3 3'1, 3'1, 3"1". 4%

5

2';.

4'1, 4'1,

5 5Y, 6

10'1, 11'1, 13'1.. 17

19'1.

8·1V. 12-1'1, 15 12-1't. 18'1, 16.1'1, ~1V,

20.1'1, 20-1V, 20.1'1, 20-1'1, 24-2 24 27'1. 31 41 4e'!,

11';, 13%

2'1. 3"1,

4% 5'/0 5'1. 6 6y' 8 3'1,. 4

2 2"1i, 2'~

5'1,

2'1, 3'-1,

7¥.

1'1,

4'1,

3'1, 4'/,

5

2'1. 3'1,

I

7V,

9'1.

11 12'1:, 1 5'1, 21

10'/,

12'(,

a" 9'1,

8-1~~ 12·n~

11, 1%

1;'

1'r.

2'10

3'1.

4 4'1,

4'1,

1'10 1'1,. 1% 1'1. 2Y. 2'1;

1'1, I'/.,

3't.

1'1.

2y' 2'"

1%

4 4% 4'10 7'1:, 8

3'h

4_1

4.'1, 4.'1. 4.1 4-1'1,

8-1 8-1%

'I,

1 1'1.

'I,

1'1,

6'1;

8.1%

14'1.

2'1, 2'1,

3'1. 4'4 4~;'

2%

2'1, 3'1,. 4'1. 4,rli•

5'1, 7 8'10

4';'

5'1, I 6'1, 7>-";

8'1. 10'1, 6'1,1

18'1,

4'1,.

5'1,

20'1, 2gil, 33 40';' 47

4 4V, 4%

1'1,

B

(1'1; 7"

23'1, 25"1.

25'1.

24.1'1.'

33"1, 57'1,

11'1;

9'1.

11'1,

9'1,

I'

"

3% 3Y, 4 4.'4 sV,

8% gil, 9

22 24'1.

11 V,

>"4

28.t;. 28-2'10

5'1,

12'1.

14%

12):;

14'1.

27 29";', 35Y, 42';' 50%

20.1'1, 20.1% 2().VI" 2().2

12.' 'I, 16-1'1,

IS'!, 19 23 26'1:,

6'1.

3'1,

6'1. 8'1,

3"/1. 4'!.

10

11'1,

5'1, 6X

7'{

4,JIi•

9'1, '1'1,

12'!, 19

15'1, 22'1,

25 27%

20.2'1,

6';'

20-2'/0 20-3';'

32'oS 5';' 36 6'10 38% ·7 46 8

29'1, 511.

11'1, 12'1.

12%

14

16

9'1,

11'1:.

13 -

10'1. 10'1,

30'1,

32% 39

-

20-3'1,

2 2'!, B.I'/~ 3 - 3'1, 4 8-1% 8-1'1, 5 12.1'1, 6 12.1'1. 8 1"2.2 10 16-2'1, 12 16-2';' 14 16.2'/0 16 16.2'/0 18 16.3'~ 20 16.3':. 24 - 30 - 36

Nom.

Pip. SI&e

2500 LB. FLANGES

0

5'1.

sV, 8

1~

CID

1'1,.

1% 1% 1'1, 2 2't. 2% 3 3'/. 4% 5 6'1,

y®

W.lcI Neck SllpOn Thtd. 19~. 1 'I" LapJoin'

Bolt Clrcl.

'I,

1 1% lV, 2 2'1, 3 4 5 6 8 10 12

2'Is

6'1. 7'1. 9'1.

3'1s

11 1,.. 2% 2';' 3';. 3% 4% 6 7 9 10

19?~

No. ancl Size of Hal ..

:w,

5"10 5'1.

3';' 4'1.

4·'1s

4~'I.

4.1

3'1,

1%

16'1, 26'1,

30 19 21%

12 14

4% 5 5% 6% 7'1, 9 10% 12'1,

3%

1% 2'1", 2'10

2% 3% 6 7 9 10

1'1, 2'1".

4.1'1,.

4.1'!.

3%

4'1. 5';'

6%

a.lv,:

a.I';' 8.1% B-l%

5'10

12'1.

7% 9 10%

7't,

la'l.

16'1,

21Y., 24%

m~

14'1:,

8·1'10 a:2'1,

12-2';,; 12-2%

WILLIAM E.

12·2'10

IL L I A M S

VALVE CORPORATlON

(j) Includas 1/16"

reised foce in 150 lb. ond 300 lb. standards. Does not include 1/4" rclsed Ieee· in 400 lb. and hecvler stondords.

38-52 Review Avenue, Long Island City. NY 11101 Telephone: 718-392-1660 1-800·221-1115 Fax: 718-729-5106

24

Inch to Millimeter

inch to millimeter (1 inch

Inch 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 0 0.0 25.4 50.8 76.2 101.6 127.0 152.4 177.8 203.2 228,6 254.0 279.4 304.8 330.2 355.6

406,4

= 25,4 mm)

3/16

4.8 30.2 55.6 81.0 106.4 131..8 157.2 182.6 208.0 233.4 258.8 284.2 309.6 335.0

360A

1/16

1.6 27.0 52.4 77.8 103.2 128.. 6 154.0 179.4 204.8 230.2 255.6 281.0 306.4 331.8 357.2 382.6 408.0 433.4 458..8 484.2 509.6 535.0 560.4 585.8 611.2 636.6 662.0 687,4 712..8 738.2 763.6 789.0 814.4 839,8 865.2 890.6 916.0 941.4 966 .. 8 992.2 1017.6 1043.0 1068.4 1093..8 1119.2 1144.6 1170.0 1195.4 1220.8 1246.. 2 1271.6

1/8

3.2 28.6 54.0 79,4 104.8 130.2 155.6 181.0 206.4 231.8 257.2 282.6

1/4 6.4 31.8 57.2 82.6 108.0 133.4 158.8 184.. 2 209.6 235.0 260,4 285..8 311.2 336.6 362.0 387.4 412.8 438.:2 463.6 489.0 514.4 539.8 565.. 2 590.6 616.0 841.4 666.8 692.2 717.6 743.0 768.4 793.8 819..2 844.6 870.0 895.4 920.8 946 .. 2 971.6 997.0

5/16

7.9 33.3 58.7 84.1 109.5 134.9 160.. 3 185.7 211.1 236.5 261.9 287.3 312.7 338.1 363.5

3/8

9.5 34.9 60.3 85.7 111.' 136.5 161.9 187.3 212.7 238.1 363.5 288.9 314.3 339.7 365.1

7/16

11.1 36.5 61.9 87.3 112.7 138.1 163.5 188.9 214.3 239.7 265.1 290.5 315.9 341.3 366.7 392 .. ' 417.5 442.9 468.3 493.7 519.1 544.5 589.9 595.3 620.7 646.1 671.5 696.9 722.3 747.7 773.1 798.5 823.9 849.3 874.7 900.1 925.5 950.9 976.3 1001.7 1027,1 1052.5 1077.9 1103.. 3 1128.7 1154.1 1179.5 1204.9 1230.3 1.255.7 1281.1

1/2

12.7 38.1 63.5 88.. 9 114.3 139.7 165.1 190.5 215.9 241.3 266.7 292.1 317.5 342.9 368 .• 3 393 .. 7 419.1 444.5 469.9 495.3 520.7 546.. 1 571.5 596.9 622.3 647.7 673.1 698.5 723.9 749.3 774.7 800.1 825.5 850.9 876.3 901.7 927.1 952.5 977.9 1003.3 1028.7 1054.1 1079.5 1104.9 1130.3

9/16

14.3 39.7 65.1 90.5 115.9 141.3 166.7 192.1 217.5 242.9 268.3 293.7 319.1 344.5 369.9 395.3 420.7 446.1 471.5 496.9 522.3 547.7 573.1 598.5 623.9 649.3 674.7 700.1 725.5 750,9 776,3 801.7 827.1 852.5 877.9

5/8

15.9 41.3 66.7 92.1 117.5 142.9 168.3 193.. 7 .219.. 1 244.5 269.9. 295.3 320.7 346.1 371.5 396.9 422.3 447.7 473.1 498.5 523.. 9 549.3 574.7 600,1 625.5 650.9 676.3 701.7 727.1 752.5 777.9 803.3 828.7 854.1 879,5

11/16

17.5· 42.9 68.3· 93.7 119.1

3/4

19.1 44.5 69.9 95.3 120;7

13/16

20.6 46.0 71.4 96.8 122.2 147.6 173.0 198.4 223.8 249.2 274.6 300,0 325.4 350.8 376.2 401.6 427.0 452.4 477.8 503.2 528.6 554.0 579.. 4 604.8 630,2 655.6 681,0 706.4 731.8 757.. 2 782.6 808.0 833.4 858.8 884.2

i

7/8

22.2 47.6 73.0 98.4 123.8 149.2 174.6 200.0 225.4 250.8 276.2 301.6 327.0 352,4 377.8 403.2 428.6 454.0 479.4 504.8' 530.2 555.6 581.0 606.4 631,8 657.2 682.6 708.0 733.4 758.8 784.2 809.6 835.0 860.4 885.8 911.2 936.6 962.0 987.4 1012.8

15/16

23.8 49.2 74.6 100.0 125.4 150.8 176.2 201.6 227.0 252.4 277.8 303.2 32.8..6 354.0 379.4 404.8 430,2 455.6 481.0

506,4

144.5 146.1 169.9 . 171.5 195.3 196.9 220.7 222.3 246,1 247.7 271.5 296.9 322.3 347.7 373.1 398.5 423 .. 9 449.3 474.7 500.1 525.5 550.9 576.3 601.7 627.1 652.5 677.9 703.3 728,7 754.1 779.5 804.9 830.3 855.7 881.1 273.1 298.5 323.9 349,3 374.7 400.1 425.5 450.9 476.3 501.7 527.1 552.5 577.9 603.3 628..7 654.1 679.5 704.9 730,3 755.7 781.1 806.5 831.9 857.3 882.7

3OB.0

333.4 358.8 384.2 409.6 435.0 460.4 485.8 511.2 536.6 562.0 587,4 61.2.8 638.2 663.6 689.0 714.4 739.8 765.2 790.6 816.0 841.4 866.8 892.2 917.6 943.0 968,4 993.8 1019.2 1044.6 1070.0 1095.4 1120.8 1146.2 1171,6 1197.0 1.222.4 1247.8 12732

381.0 431.8 457.2 482.6 508.0 533.4 558.8 584.2 609.6

385.8 411.2 436.6 462.0 487.4 512.8 538.2 583.6 589.0 614.4 639.8 665.2 690.6 716.0

74104

388.9 390 ..5 414.3 415 .. 9 439.7 . 441 .. 3 465.1 466.7 490.5, 492.1 515.9 541.3 566.7 59.2.1 617..5 642.9 668,3 693.7 719.1 744.5 769.9 795.3 820.7 846.1 871.5 896.9 922.3 947.7 973.1 998.5 517,5 542.9 568.3 593.7 619.1

644.5

531.8 557.2 582.6 608.0 633.4 658.8 684.2 709.6 735,0 760.4 785.8 811.2 836.6 862.0 887.4 912.8 938.2 963.6 989.0 1014.4

635.0 660.4 685.8 711.2 736.6 762.0 787.4 812.8 838.2 863.6 889.0 914.4 939.8 965.2 990.6 1016.0 1041.4 1066.8 109.2.2 1117.6 1143.0 1168.4 1193.8 1219.2 1244.6 1270.0

669.9 695 .. 3 720.7 746 .. 1 771.5 796.9 822.3 847.7 873.1 898.5 923.9 949.3 974.7 1000,1

766.8 792.2 817.6 843.0 868.4 893.8 919.2 944,6 970.0 995.4

903.3 904.9 930,3 928.7 954..1 955.7 979.5 981.1 1004.9 1006.5 1030.3 1055.7 1081.1 1106.5 1131.9

906.5 908.1 909.6 931.9 933.5 935.0 957.3 958 .. 9 960.4 982.7 984.3 985.8 1008.1 1009,7 1011.2 1036.6 1062.0 1087.4 1112.8 1138.2

1020.8 1022,4 1046,2 1047.8 1071.6 1073.. 2 1097.0 1098.6 1122.4 1124.0 1147.8 1149.4 1173.2 1174.8 1198.6 1200_2 1224.0 1225.6 1249,4 1251.0 1274.8 1276,4

1023.9 1025.5 1049.3 1050.9 1074.7 1076.. 3 1100.1 1101:7 1125.5 11.27.1 1150.9 1176,3 1201..7 1227.1 1252.5 1152.5 1177.9 1203.3 12.28.7 1254.1

1031.9 1033.5 1035.1 1057.3 1058,9 1060.5 1082.7 1084.3 1085.9 1108.1 1109.7 1111.3 1133.5 1135.1 1136.7

1038.2 1039.8 1063.. 1065.2 6 1089.0 1090.6 1114.4 1116.0 1139.8 1141.4

1155.7 1157.3 1181.1 118.2.7 1206,5 1208.1 1231,9 1233.5 1257.3 1258.9 1282.7 1284.3

1158.9 1'160.5 1162.1 1163.6 1165.2 1166.S 1184.3 1185.9 1187.5 1189.0 1190.6 1192.2 1209.7 121.1.3 1212.9 1214.4 1216.0 1217,6 1235.7 1236.7 1238.3 1239.8 1241.4 1243.0 1260.5 1262.1 1263.7 1265.2 1266,8 1268.4 1285.. 9 1287.5 1289.1 1290.6 1292.2 1293.81

1277.9 1279.5

WILLIAM E.

_.

L -=VEt~,,!"I S

25

38-52 Review Avenue. Long Island City.NY 11101 Telephone: 718-392-1660 1'800-221-1115 Fax: 718·729·5106

Temperature Conversion °C-oF

-495.+0

HlO .. F

61-290

~

"F

141.8 143.6 145.4 1472 149.0 150.8 152.6 154.4 156.2 158.0 159.8 1'61.6 163.4 165.2 167.0 168.8 170.6 172.4 1742 176.0 177.8 179.6 1.81.4 183.2 185.0 186.8 188.6 190.4 1922 194.0 195.8 197.6 199.4 201.2 203.0 204.8 206.6

900-3000

II

e-273 -268 -262 -251

Fe

-459A -4SO -440 -430 -420 -410 -400

c=

-172 -16.7 -16.1 -15.6 -15.0 -14.4 -13.9 -13.3 -12.8 -122 -11.7 -11.1 -10.6 -10.0 9.4

Fe

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45

-F

33.8 35.6 37.4 392 41.0 42.8 44.6 48..4 482 50.0 51.8 53.6

55.4

c=

16.1 16.7 17.2

17..8

Fe

61 62 63 64 65 86 67 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 110 120 130 140 150 160 170 180 190 200 210 212 2.20 230 240 250 260 270 280 290

e149 154 160 166 171 177 182 188 193 199 204 210 216 221 227 232 238 243 249 254 260 266 271 277 282 288 293 299 304 310 316 321 327 332 338 343 349 354 360 366 371 377 382 393 399 404 410 416 421 427 442 438

443 3B8

Fe

300 310 320 330 340 350 360 370 380 390 400 410 420 430 440 450 460 470 480 490 500 510 520 530 540 550 560 ·570 580 590 600 610 620 630 840 650 860 670 660 690 700 710 720 730 740 750 760 770 780 790 800 810 820 830 840 850 860 870 880 890

=F

572 500

c=

48.2 488 493 499 504 510 516 521 527 532 538 549 560 571 582 593 604 616 627

Fe

900 910 920 930 940 950 960 970 960

=F

1652 1670 1688 1706 1724 1742 1760 1778 1796 1814 1832 1888 1904 1940 1976 2012 2048 2084 2120 2156 2192 2228 2264 2300 2336 2372 2462 2552 2642 2732 2822 2912 3Xl2 3:192 3182 3272 3362 3452 3542 3632 3722 3812 3902 3992 4082 4172 4262 4352 4442 2532 4622 4712 4802 4892 4982 5072 5162 5252 5342 5432

-257

-246 -240 -234 -229 -223 -218 -212 -'207 -201 -196 -190 -184 -179 -173 -169 -168

see

18,3 18.9 19.4 20.0 20.6 21.1 21.7 22.2 22.8 23.3 23.9 24.4 25.0 25.6 26.1 26.7 27.2 27.8 28.3 28.9 29.4 30.0 30.6 31.1 31:7 32.2 32.8 33.3 33.9 34.4 35.0 35.6 36.1 36.7 37.2 37.8 43

626 644

-380 -370

-390

68

662 680 698 716 734 752 770 788 806 824 842 860 878 914

990

10:::0 1020 1040 1060 1060 1100 1120 1140 1160 1;180 1200 1220 1240 1260 1280 13(X) 1350 1400 1450 1500 1550 1600 1650 1700 1750 1800 1850 1900 1950 2000 2050 2100 2150 2200 2250 2300 2350 2400 2450 2500 2550 2600 2650 2700 2750 2800 2850 2900 2950

3COO

-'360 -350 -340 -330 -320 -310

-3)(1

572 59.0 60.8 62.6 64.4 662 68.0 69..8 71.6 73.4 75.2 77D 78..8 80.6 82.4 842 86.0 87.8 89.6 91.4 93.2 95.0 96.8 98.6 100.4 1022 104.0 105..8 107.6 109.4 111.2 113.0 114..8 116.6 118.4 120.2 1.22.0 123.8 125.6 127,4 129.2 131.0 132.8 134.6 136.4 1382 140.0

-290 -280 -273 -210 -260 -250 -240 -230

-459.4 -454 -418 -400 -382

8.. 9 8.3 7.8 7:2 6.7

896

932. 950 968 986 1004 1022 1040 1058 1,076 1094 1112 1130 1148 1166 1184 1202 1220 1238 1256 1274 1.292 1310 1328 1346 1364 1382 1400 1418 1436 1454 1472 1490 1508 1526 1544 1.56.2 1580 1598 1616 1634

638

-157 -151

-162

-436

-146

-140 ~134 -129 -123 -118 -112 -107 -101 96 90

6.1 5.6 5.0 4.4 - 3.9 3.3 2.8 22 1.7. 1.1 .6 .0 .6 1.. 1 1.7 22 2..8 3,3 3..9 4.4 5.0 5.6 6.1 6.7 72 7.8 8.3 8.9 9A 10.0 10.6 11.1 11.7 12.2 12.S 13.3 13.9 14.4 15.0 15.. 6

649 660 671 682 693 704 732 760 788 816 843 871 899 927 954 882 1010 1038

-210

-220 ~2OO

-190 -180 -170 -160 -150 -140 -130

-364 -346 -328 -310 -292 -274 -256 -238 -220 -'202 -184 -166 -148 -130 -112