Professional Documents

Culture Documents

12 Smart Steps To Building A New Hatchery

Uploaded by

tayyababOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 Smart Steps To Building A New Hatchery

Uploaded by

tayyababCopyright:

Available Formats

4 Smart steps to building a new hatchery

Step

Choose the correct site for your new hatchery

When choosing a site, look out for the following basic local requirements: A well drained site, minimum 615 sq.m. making sure there is sufficient, available space to extend your hatchery as required in the future Preferably not more than 1800 meters above sea level (unless hatching eggs are produced at the same altitude) Ideally more than 500 meters away from other poultry farms: check prevailing wind direction does not carry debris or potential pathogens from other poultry farms in the area Reliable supply of electricity for main power and heating Reliable, uninterrupted supply of water for cooling, humidifying and cleaning

Step

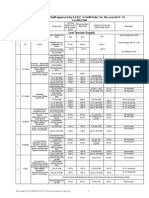

Choose your incubators

Use the following table to decide how many setters and hatchers you will need:

Incubators Setter Capacity (eggs) Width (mm) Dimensions Depth (mm) Height (mm) Ventilation (m3/h) Connection values Cooling (kW) Electricity (kW)

SmartSet 115 115,200 Incubators Hatcher Capacity (eggs)

SmartSet 77

SmartSet 38

76,800

38,400

4834

4834

4834

7271

4933

2595

2459

2459

2459

700

500

300

38.0

27.0

15.0

23.1

15.7

8.4

SmartHatch

19,200

3235

Width (mm)

Dimensions

2210

Depth (mm)

2445

Height (mm)

450

Ventilation (m3/h)

Connection values

6.9

Cooling (kW)

4.2

Electricity (kW)

Step

Configure your hatchery layout

With Smart incubation you can plan for growth from the very start. The following options demonstrate which hatchery layout you will need, to cater not only for your business needs today, but also to grow your business in the future.

1 SmartSet 38 Setter 1 SmartHatch Hatcher Production Set 19,200 eggs per week in 4 out of 5 weeks 1 hatch day per week in 4 out of 5 weeks Average of 16,000 chicks per hatch day 610 kWh electricity 465 kWh cooling power

Energy consumption

1 SmartSet 77 Setter 1 SmartHatch Hatcher Production

Set 38,400 eggs per week in 4 out of 5 weeks 2 hatch days per week in 4 out of 5 weeks Average of 16,000 chicks per hatch day 610 kWh electricity 465 kWh cooling power

Energy consumption

1 SmartSet 115 Setter 1 SmartHatch Hatcher Production

Set 38,400 eggs per week 2 hatch days per week Average of 16,000 chicks per hatch day 610 kWh electricity 465 kWh cooling power

Energy consumption

3 SmartSet 115 Setters 3 SmartHatch Hatchers Production

Set 115,200 eggs per week 2 hatch days per week (6 also possible) Average of 48,000 chicks per hatch day 1830 kWh electricity 1395 kWh cooling power

Energy consumption

Note: All energy values shown are based on estimations of energy consumption per incubation cycle. Cooling power can be supplied by: (ground) water, where 1 kW cooling power equals 144 l/h of water at 12C (with T = 6C), or by chiller, where 1 kW cooling power equals 0,3 kW electricity (with chiller ESEER of 3,5).

Step

Choose additional equipment

To complement SmartSet Setters and SmartHatch Hatchers, Pas Reform supplies a full range of additional equipment to support best practice and make operations smooth and efficient in your new hatchery. These may include: 1 Egg setting equipment 2 Egg transfer equipment 3 Chick handling and washing equipment 4 Climate control equipment Need more help? Pas Reforms experienced team can provide practical help and support when planning and installing your new hatchery.

Pas Reform Hatchery Technologies P.O. Box 2 7038 ZG Zeddam The Netherlands Telephone +31 314 659 111 Fax +31 314 652 575 info@pasreform.com www.pasreform.com

You might also like

- Poultry Business Plan For Layers and BroilersDocument8 pagesPoultry Business Plan For Layers and BroilersOgieva ElvisNo ratings yet

- Business Plan On Egg ProductionDocument7 pagesBusiness Plan On Egg ProductionFaith Uzochukwu75% (12)

- Business Plan For PoultaryDocument6 pagesBusiness Plan For PoultaryBudhathoki Yoshiko100% (1)

- Management Guide For Laying Hens in Deep Litter, Perchery and Free-Range SystemsDocument16 pagesManagement Guide For Laying Hens in Deep Litter, Perchery and Free-Range SystemsVali Marius0% (1)

- Fahad Ali 2019 Internship ReportDocument16 pagesFahad Ali 2019 Internship ReportFahad Ali100% (3)

- Guide For Keeping Egg Laying Birds (Layers) in Uganda: Before Your Layer Chicks Arrive at HomeDocument4 pagesGuide For Keeping Egg Laying Birds (Layers) in Uganda: Before Your Layer Chicks Arrive at HomeSabila Alex100% (1)

- Poultry Farming BusinessDocument7 pagesPoultry Farming BusinessNikhil ShitoleNo ratings yet

- 8.business Plan of Srinagar Agro FarmDocument9 pages8.business Plan of Srinagar Agro FarmSantosh BhandariNo ratings yet

- Heat Pump Calculation (Train)Document3 pagesHeat Pump Calculation (Train)gopaltryNo ratings yet

- Poultry Business1Document12 pagesPoultry Business1awais_uetpkNo ratings yet

- Harchery pdf-1708642450Document33 pagesHarchery pdf-1708642450Ogochukwu50% (2)

- TLE Animal Prod 7&8 Q1 Week 7Document8 pagesTLE Animal Prod 7&8 Q1 Week 7lady catherine enriquezNo ratings yet

- Business Plan HacheryDocument52 pagesBusiness Plan HacherypipestressNo ratings yet

- Design, Construction and Performance Evaluation of An Electric Powered Egg IncubatorDocument6 pagesDesign, Construction and Performance Evaluation of An Electric Powered Egg IncubatorInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Producing Broilers and Fryers - An Instructional Article on Raising ChickensFrom EverandProducing Broilers and Fryers - An Instructional Article on Raising ChickensNo ratings yet

- Harvard Tools For Small Animal SurgeryDocument7 pagesHarvard Tools For Small Animal SurgeryJoel GoodmanNo ratings yet

- Physics Form 5 Notes PDFDocument58 pagesPhysics Form 5 Notes PDFeltytan100% (5)

- PoultryproductionDocument46 pagesPoultryproductionPhen Montalbo100% (2)

- The Ancient Quail Farming Tricks: How To Raise Highly Productive Quail BirdsFrom EverandThe Ancient Quail Farming Tricks: How To Raise Highly Productive Quail BirdsNo ratings yet

- Future Scope of Commercial Hatcheries in The WorldDocument14 pagesFuture Scope of Commercial Hatcheries in The WorldShizraNo ratings yet

- Incubators GQF 1502 Cabinet Incubators For Poultry Hatching TraysDocument2 pagesIncubators GQF 1502 Cabinet Incubators For Poultry Hatching Traysngoclinhtu9816No ratings yet

- Egg Incubator ThesisDocument8 pagesEgg Incubator ThesisPaperHelpCanada100% (2)

- New Book On IncubatorDocument58 pagesNew Book On IncubatorRed PhoenixNo ratings yet

- Breeder MgtessDocument48 pagesBreeder MgtessIcaNo ratings yet

- Tetra SLDocument28 pagesTetra SLCarlos Estuardo Amaya DomínguezNo ratings yet

- Broiler Poultry Farming Business PlanDocument4 pagesBroiler Poultry Farming Business Planolatunji nana hauwaNo ratings yet

- Anumand Mano K 19-bpp-09Document48 pagesAnumand Mano K 19-bpp-09MhD ANsHaDNo ratings yet

- Project Study 1 3Document27 pagesProject Study 1 3Princess Mae DesaculaNo ratings yet

- Eggs Incubators: Ecochicks Poultry 120 Quail Eggs Capacity Jn2-60Document2 pagesEggs Incubators: Ecochicks Poultry 120 Quail Eggs Capacity Jn2-60iccanxNo ratings yet

- Poultry Farming Project ProposalDocument12 pagesPoultry Farming Project ProposalTuff Aberts100% (1)

- Alternatives To Laying Hens Breeding in Peasant Households: L.C. StafieDocument8 pagesAlternatives To Laying Hens Breeding in Peasant Households: L.C. StafieLeonard Constantin STAFIENo ratings yet

- Meal MasterDocument4 pagesMeal MasterUri DrachNo ratings yet

- Pollos - Planning The Small Poultry Processing OperationDocument9 pagesPollos - Planning The Small Poultry Processing Operationospino1No ratings yet

- Fresh / Chilled / Frozen Chicken Franchises Mr. Kunal PathreDocument17 pagesFresh / Chilled / Frozen Chicken Franchises Mr. Kunal PathreOnkarPathreNo ratings yet

- CXC Agricultural Science SbaDocument14 pagesCXC Agricultural Science Sba4am.vfxNo ratings yet

- Broiler & ManagmentDocument8 pagesBroiler & ManagmentrajeevknpNo ratings yet

- Small PoultryDocument16 pagesSmall PoultryArshad Rashid ShahNo ratings yet

- Catalog Incubator2013 IPEEDocument16 pagesCatalog Incubator2013 IPEEolunguNo ratings yet

- Exercise No. 2 Poultry Housing and Equipment ROLLONDocument12 pagesExercise No. 2 Poultry Housing and Equipment ROLLONJIM ALDRIX ROLLONNo ratings yet

- Poultry FamingDocument6 pagesPoultry FamingFiker Er MarkNo ratings yet

- Management Guide: For Laying Hens in Deep Litter, Perchery and Free-Range SystemsDocument34 pagesManagement Guide: For Laying Hens in Deep Litter, Perchery and Free-Range SystemsSri PurwantiNo ratings yet

- Lesson Title:: Perform Estimation and Basic CalculationDocument8 pagesLesson Title:: Perform Estimation and Basic Calculationlady catherine enriquezNo ratings yet

- Automation in Poutry ProductionDocument63 pagesAutomation in Poutry ProductionWan Nur Hidayah67% (3)

- Hy-Line Brown Conventional Systems EnglishDocument107 pagesHy-Line Brown Conventional Systems EnglishSalahNo ratings yet

- Poultry Housing: Table 1 Poultry Production CyclesDocument2 pagesPoultry Housing: Table 1 Poultry Production CyclesMuhammad JameelNo ratings yet

- Eggs Inners IMPDocument12 pagesEggs Inners IMPKalil RahimanNo ratings yet

- New ProjectDocument15 pagesNew ProjectdivineNo ratings yet

- The Department of Computer Science: Honours DegreeDocument33 pagesThe Department of Computer Science: Honours Degreeprofessor dubeNo ratings yet

- Market MPDFDocument7 pagesMarket MPDFMoiemen AhmedNo ratings yet

- Peking Duck Breeders Require Special ManagementDocument5 pagesPeking Duck Breeders Require Special ManagementLevi June Lloren-Nalzaro Viloria-SolitoNo ratings yet

- Broiler ProductionDocument14 pagesBroiler ProductionDañela BelmonteNo ratings yet

- A500 Rocket Composter - Tidy Planet 2013Document3 pagesA500 Rocket Composter - Tidy Planet 2013Corina PaulaNo ratings yet

- Unit 7 SwineDocument9 pagesUnit 7 SwineMaria Lourdes samontinaNo ratings yet

- Poultry Farming in IndiaDocument7 pagesPoultry Farming in IndiaBehera RakeshNo ratings yet

- Asgn - 2Document5 pagesAsgn - 2Navid Al GalibNo ratings yet

- IncubatorDocument19 pagesIncubatorjamesyupNo ratings yet

- Design and Implementation of Solar PV Poultry Incubator: Nithin T Abraham, Shaema Lizbeth Mathew, C.A Pradeep KumarDocument3 pagesDesign and Implementation of Solar PV Poultry Incubator: Nithin T Abraham, Shaema Lizbeth Mathew, C.A Pradeep KumarShilpa KßhNo ratings yet

- BV 300 Layer Management GuideDocument27 pagesBV 300 Layer Management GuideAyush SharmaNo ratings yet

- Egg Production Management SystemDocument10 pagesEgg Production Management SystemBaranishankarNo ratings yet

- Pub p627 PubDocument29 pagesPub p627 PubSantiago Fortunatoc Cercado RamosNo ratings yet

- LED Vs CFL Study Energy EfficiencyDocument6 pagesLED Vs CFL Study Energy EfficiencyUdhayakumar VenkataramanNo ratings yet

- TNEB Online PaymentDocument1 pageTNEB Online PaymentShanthosh GNo ratings yet

- Beach Enclave Swimming Pool - OutdoorDocument1 pageBeach Enclave Swimming Pool - Outdoormirali74No ratings yet

- National Energy Efficiency Action Plan (Neeap) Ghana Period (2015-2020)Document37 pagesNational Energy Efficiency Action Plan (Neeap) Ghana Period (2015-2020)Apolo FumbujaNo ratings yet

- Case StudyDocument20 pagesCase StudySubramanyam VemulaNo ratings yet

- Appendix Units of Measure: A.1 Abbreviations For SI UnitsDocument5 pagesAppendix Units of Measure: A.1 Abbreviations For SI UnitslformigoniNo ratings yet

- Bosch SpreadsDocument47 pagesBosch SpreadshtalibNo ratings yet

- PDFDocument34 pagesPDFelectrical zuhair0% (1)

- Tugas MetroDocument14 pagesTugas MetroAdeliya Afriyani KusumaningtyasNo ratings yet

- Unit ConversionsDocument10 pagesUnit ConversionsAnish MohanNo ratings yet

- Arduino Energy Meter PDFDocument16 pagesArduino Energy Meter PDFkesar2No ratings yet

- Girding The Grid: How Utilities Reduce Costs and Boost Efficiency With GasDocument9 pagesGirding The Grid: How Utilities Reduce Costs and Boost Efficiency With GasasuhuaneNo ratings yet

- 2011ARDocument72 pages2011ARMika AurelioNo ratings yet

- (Science in The Real World) Richard Hantula-How Do Solar Panels Work - Chelsea Clubhouse (2009) PDFDocument33 pages(Science in The Real World) Richard Hantula-How Do Solar Panels Work - Chelsea Clubhouse (2009) PDFKan ChoraNo ratings yet

- Energy Report Card - Barbados - Dec 2018 0Document9 pagesEnergy Report Card - Barbados - Dec 2018 0Rahul ChoudharyNo ratings yet

- Unit Rate (Per/ KWH Cost) in Rs Power Rating (Watts) No of AppliancesDocument4 pagesUnit Rate (Per/ KWH Cost) in Rs Power Rating (Watts) No of AppliancesVarun Singh ChandelNo ratings yet

- PDFDocument11 pagesPDFIvan JugovicNo ratings yet

- Energy Saving in Textile ProcessingDocument7 pagesEnergy Saving in Textile Processingsaidurtex0% (1)

- NSW Small Wind Turbine Consumer GuideDocument78 pagesNSW Small Wind Turbine Consumer Guideanand sahuNo ratings yet

- 002 LD SD 02Document11 pages002 LD SD 02marab12No ratings yet

- Bescom TariffDocument4 pagesBescom TariffkarthikvmandyaNo ratings yet

- ® Elevator: Kunshan KOYO Elevator LTDDocument18 pages® Elevator: Kunshan KOYO Elevator LTDApexBD01No ratings yet

- Manila Standard Today - April 9, 2012 IssueDocument16 pagesManila Standard Today - April 9, 2012 IssueManila Standard TodayNo ratings yet

- Microgeneration and REGOs FactsheetDocument2 pagesMicrogeneration and REGOs FactsheetTony CarrollNo ratings yet

- T DocumentDocument54 pagesT DocumentMohd RazaNo ratings yet

- A100 DIN BrochureDocument2 pagesA100 DIN BrochureMunteanu LucianNo ratings yet

- Electric EnergyDocument3 pagesElectric EnergyWillis Chekov0% (1)

- ACT - Home Energy Audit PDFDocument6 pagesACT - Home Energy Audit PDFPathmavel Manickasivam0% (1)