Professional Documents

Culture Documents

Microbiological Test of Medical Devices

Uploaded by

bijendra_sinhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microbiological Test of Medical Devices

Uploaded by

bijendra_sinhaCopyright:

Available Formats

Microbiological tests related to industries of medical devices..........

1. BACTERIAL ENDOTOXIN TEST BY GEL CLOT METHOD:

1.

a. b. c. d. e. f. g. h.

PROCEDURE:

MATERIALS REQUIRED:

Limulus Amoebocyte Lystate (LAL) Reagent. Control Standard Endotoxin (CSE). Lal Reagent Water (LRW). Vortex shaker. Heating Block. Micropipette with sterile tip. Depyrogenated glass test tubes (15x100 & 10x75 mm). Aluminium foil and forceps. All materials coming in contact with the specimen or test reagents must be rendered endotoxin free by heating at 2500C for 60 minutes.

PREPARATION OF ENDOTOXIN:

a. b. c. d. e. Reconstitute CSE as per Certificate of Analysis (COA). Record the date of preparation on the vial. Vortex the vial for 15 minutes after rehydration. Vortex for at least 5 minutes immediate prior to each use or as specified in COA. Reconstituted CSE can be stored at 2-80C for up to 28 days in the refrigerator or as per manufacturers instructions. Dilute the endotoxin with LRW to a concentration of 0.5 EU/ml (4). Each dilution should be vortexed for 60 seconds prior to proceeding to the next dilution. Refer table I: - If concentration of CSE is 40 EU/ml as per COA supplied by manufacturer. Using the 0.05 EU/ml endotoxin dilution, prepare the dilution of 0.125EU/ml (), where is Lysates sensitivity.

TABLE I

Example: - If as per COA stock concentration of CSE is 40 EU/ml, then: S. Dilution ratio CSE LRW Dilution Concentration of Endotoxin No. 1. 1:80 0.1 ml 7.9 ml 4 0.5 EU/ml 2. 1:4 1.0 ml of 4 3.0 ml 0.125 EU/ml

Calculate the Maximum Valid Dilution (MVD) by the formula: MVD = Endotoxin limit as specified in Pharmacopoeia. / Lysate sensitivity as per COA. ANTICOAGULANT SOLUTION: Sample size: - Three blood bag per batch and make a pooled sample. MVD calculation: MVD = 5.56EU/ml / 0.125EU/ml = 1:44. Sample dilution is prepared at MVD / 2 = 0.1 ml sample + 2.1 ml LRW. MEDICAL DEVICES: I. Sample size: 10 pieces from each lot / batch.

PREPARATIO OF SAMPLE DILUTION:

II. Preparation of Extract: The process of preparing an extract {20ml water for injection (WFI) per device} for LAL test may vary for each device. This extract is kept for 1 hour at controlled temperature (20 250C). a. Syringes (10 pieces / batch) are flushed by 20 ml WFI (20ml WFI / device). b. 3 way stop cock (10 pieces / batch) can be disassembled and immersed in 200 ml WFI. c. Tubing products (10 pieces / batch) can be immersed in 200 ml WFI by cutting into pieces and d. I.V. Cannula (10 pieces / batch) pass 200 ml of WFI through 10 pieces of I.V. Cannula (20 ml WFI / device). Calculation of MVD: The endotoxin limit for the extract is calculated by the formula: KxN / V. Where K = Amount of endotoxin allowed per device. N = Number of medical device tested. V = Total volume of the rinse. Endotoxin limit = 20x10 / 200 = 1EU/ml. Now MVD for medical devices = Endotoxin limit / Lysates sensitivity. = 1 EU/ml / 0.125 EU/ml = 8. MVD = 1:8. Sample dilution is prepared at MVD / 2 = 0.4 ml of sample + 1.6 ml LRW.

PREPARTAION OF LAL:

Reconstitute LAL Reagent as per manufacturers instruction. LAL reagent sensitivity is 0.125 EU/ml. Transfer the prepared sample dilution, LRW and CSE in the assay tubes in duplicate and add 100l of reconstituted LAL reagent to each tubes (as per table - II): -

TABLE II

TUBE NO. 1, 2 3, 4 5, 6 7, 8 9, 10 11, 12 13, 14 Blank 2 /2 /4 NPC PPC LRW 100 l 50 l 50 l 75 l 50 l CSE 50 l(4) 100 l() 50 l() 25 l() 50 l(4) PRODUCT 50 l 50 l LYSATE 100 l 100 l 100 l 100 l 100 l 100 l 100 l

Incubate the assay tubes at 370C (10C) in heating block for 60 minutes. Each tube is inverted at 1800. Compare the sample vials to the control vials. A positive reaction is characterized by the formation of a firm gel that remains intact momentarily when the tube is inverted. This should be observed in the positive control vials (2, , /2, /4) and in the positive product control (PPC) vial. A negative test is characterized by the absence of solid clot after inversion. This should be observed in the negative control (blank) vial and in the negative product control (NPC) vial. The Lysate may show an increase in turbidity or viscosity; this is considered as negative result.

INTERPRETATION OF RESULT: -

Record positive and negative results for the test sample vials. Test results are valid only when the PPC is positive at 2 endotoxin concentration and NPC is negative. Repeat the test when a positive result is found for 1 tube of NPC and a negative result for the other one. The sample complies with the test when a negative result is found for both tubes of NPC in the repeat result. If the test is positive for sample under test at a dilution less than the MVD, the test may be repeated at a dilution not greater than MVD.

PRECAUTION DURING TEST: Careful techniques must be used to avoid microbial contamination. All glassware and materials must be endotoxin free. pH of sample should be 6.8 8.0. Samples to be tested must be stored in such a way that all bacteriological activity is stopped or the

endotoxin level may increase with time. Assay tubes should not be removed from incubation or disturbed prior to the time specified for reading the test. Switch on the heating block 1 hour before starting the test to get the constant temperature. Monitor the temperature after every 15 minutes during the incubation period.

2. ABNORMAL TOXICITY TEST: PROCEDURE: Test animal: - Select 5 healthy mice weighing between 17-23 grams.

PREPARATION OF EXTRACT: Make 50 ml saline solution (0.9% w/v) in Depyrogenated conical flask then take 5 pieces of the batch and pass 10 ml of saline from each piece with 10 mldepyrogenated glass syringe slowly. After pass the saline from piece put that piece in passed saline. The preparation of extract should be done under Laminar Air Flow. Then autoclave this extract at 1210C for 15 minutes.

METHOD: Inject intravenously each of five mice 1.0 ml of test solution using 26 gauge needle of half inch. The time of injection should normally be 15 30 seconds.

INTERPRETATION OF RESULT: Observe the mice at the time of injection after 24, 48 and 72 hours. All the mice survive; the sample passes the test for toxicity. If one or more animals die, repeat the test using at least another 10 mice, similar to those used in previous test but weighing 20 3 grams. If all mice survive for 72 hours, the sample passes the test for toxicity.

Product Bio-burden test

Sample selection: The sample for bio-burden testing are collected on random basis after they are packed and are ready for sterilization but not sterilized. Quantity: As given in table I: Table I Name of product Quantity required I.V. Cannula, Three way stop cock, Syringes 10 pieces Other disposables 05 pieces Frequency: At least one batch in every 15 days is tested for microbial bio-burden. Treatment solution: Buffered sodium chloride peptone solution pH 7.00.1 with 0.5% tween 80 made as given in table II, previously sterilized at 1210C for 15 minutes. Table II S. No. Description Quantity required 1. Di-hydrogen potassium phosphate 3.6g 2. Di-Sodium hydrogen phosphate 7.2g 3. Sodium Chloride 4.3g 4. Peptone 1.0g 5. D. M. / Distilled water 1000 ml. Preparation of Media: Prepare Soybean casein digest agar (SCDA) and Sabouraud Dextrose Agar (SDA) as per requirement and sterilize at 1210C for 15 minutes. Test procedure: Each sample is aseptically immersed separately in 100ml. of treatment solution. Shake the flask for some time. Transfer to membrane filter of size 0.45 and filter immediately. Now, transfer 5 membrane filters to the surface of SCDA and transfer the other 5 membrane filters to the surface of SDA. Incubation: The SCDA plates are incubated at 300C-350C for 3 days and SDA agar plates are incubated at 200C-250C for 5 days. Interpretation of results: On completion of incubation, the colonies of each plate are counted and average of all pates is calculated. Average bio-burden is calculated by following formula: Average Bio-burden = Total No. of cfu observed / No. of plates. Percentage recovery is calculated by using following factor: Percentage recovery = Average bio-burden X 100 / 83.39 The result should complying limits shown in table III. Table - III Name product of Medium Normal count (cfu/ml) I.V. Cannula, SCDA 30 Three way stop SDA 20 cock, Syringe Alert level (cfu/ml) 35 25 Action level (cfu/ml) 40 30

Other disposables

SCDA SDA

100 50

125 75

150 100

Steps taken on alert and action level: During alert level the corrective action like increasing the frequency of spray, mopping and fumigation of clean room is undertaken under the guidance of Q. C. Department. If total counts are crossing action level, microbiologist should advice the concerned department in writing about the preventive steps.

You might also like

- College Level Math Practice TestDocument17 pagesCollege Level Math Practice TestHarsha Kasaragod100% (1)

- Thumb Rules For Civil Engineers PDFDocument4 pagesThumb Rules For Civil Engineers PDFA KNo ratings yet

- Autoclave Biological Indicator 8-31-11Document10 pagesAutoclave Biological Indicator 8-31-11Hamed SahebiNo ratings yet

- Iso 11737 2 2019Document11 pagesIso 11737 2 2019Mubin MuhammadNo ratings yet

- SOP For Analysis of WaterDocument9 pagesSOP For Analysis of WaterGencay ErginNo ratings yet

- 671 - BP Well Control Tool Kit 2002Document20 pages671 - BP Well Control Tool Kit 2002Uok Ritchie100% (1)

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Microbiological Pharmaceutical Quality Control LabsDocument7 pagesMicrobiological Pharmaceutical Quality Control LabsDede Kizzy Black100% (1)

- SterilizationDocument35 pagesSterilizationGeeta BhagchandaniNo ratings yet

- SOP For Bacterial Endotoxin (LAL) TestDocument3 pagesSOP For Bacterial Endotoxin (LAL) TestKranti yadavNo ratings yet

- Bedia CLS 40 45 GBDocument36 pagesBedia CLS 40 45 GBkadir kayaNo ratings yet

- The Network+ Cram Sheet: Networking ConceptsDocument4 pagesThe Network+ Cram Sheet: Networking ConceptsISTAKHAR UDDIN AHAMED100% (1)

- 3 2 - MicrobiologicalQualityControl 1Document37 pages3 2 - MicrobiologicalQualityControl 1Tong ChanNo ratings yet

- Gamma Radiation SterilizationDocument2 pagesGamma Radiation Sterilizationananth67% (3)

- EO Annual Requalification ReviewDocument30 pagesEO Annual Requalification ReviewVenkatesh VenkateshNo ratings yet

- Validation of Sterilization ProcessesDocument3 pagesValidation of Sterilization ProcessesNovitra DewiNo ratings yet

- Use of Chemical & Biological Indicators - 2014 2Document56 pagesUse of Chemical & Biological Indicators - 2014 2jerimiah_manzonNo ratings yet

- Microbial Limit Test Validation ProtocolDocument12 pagesMicrobial Limit Test Validation ProtocolMubarak Patel100% (1)

- 10053865Q00 - PB560 Ventilator & Power Pack Essential Requirements Matrix PDFDocument56 pages10053865Q00 - PB560 Ventilator & Power Pack Essential Requirements Matrix PDFNguyễn Lucy0% (1)

- Bacterial Endotoxin Test 14 03 17 PDFDocument61 pagesBacterial Endotoxin Test 14 03 17 PDFsumarni rikamNo ratings yet

- Appendix XVI B. Microbiological Examination of Non-Sterile Products - British PharmacopoeiaDocument30 pagesAppendix XVI B. Microbiological Examination of Non-Sterile Products - British PharmacopoeiaGeotamNo ratings yet

- Revital Heathcare (Epz) Limited Quality Control Department Sterility Test Raw Data SheetDocument2 pagesRevital Heathcare (Epz) Limited Quality Control Department Sterility Test Raw Data SheetMusyoka UrbanusNo ratings yet

- Autoclave SOPDocument7 pagesAutoclave SOPdeepanmb007No ratings yet

- Wipak Steriking Sterilization Pouches and RollsDocument4 pagesWipak Steriking Sterilization Pouches and RollsAnonymous tbJ24554No ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Sterilization Validation QsiteDocument52 pagesSterilization Validation Qsiteskype2121No ratings yet

- How To Validate An AutoclaveDocument3 pagesHow To Validate An AutoclaveqhpuongNo ratings yet

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210No ratings yet

- 03 VDmax Method1 FAQDocument4 pages03 VDmax Method1 FAQFrengki Hadi Eko SantosoNo ratings yet

- Bioburden:The Burden On Our Biological OperationsDocument48 pagesBioburden:The Burden On Our Biological OperationsSurendar Kesavan100% (1)

- Tle Questions Answer KeyDocument14 pagesTle Questions Answer KeyDerlyn FernandezNo ratings yet

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- Cleanroom Validation Results Sampling and Common DispensingDocument18 pagesCleanroom Validation Results Sampling and Common DispensingJanple Alzar100% (2)

- Autoclaves - Proper Operation and ValidationDocument7 pagesAutoclaves - Proper Operation and Validationgrace holmNo ratings yet

- ETO Sterilization ValidationDocument44 pagesETO Sterilization ValidationCRYSTAL2100100% (1)

- In Use StabilityDocument6 pagesIn Use Stabilitytantri ayu lestariNo ratings yet

- IEEE and IEC StandardsDocument11 pagesIEEE and IEC StandardschupzptNo ratings yet

- Media Fill Indicador de ColorDocument6 pagesMedia Fill Indicador de Colorsteven correaNo ratings yet

- AG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseDocument5 pagesAG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseKarina GorisNo ratings yet

- Sop For Bio-BurdenDocument5 pagesSop For Bio-BurdenMusyoka UrbanusNo ratings yet

- Instruction - SterilizationDocument36 pagesInstruction - SterilizationGiang100% (1)

- Biocompatibility ISO 10993 - Material Certificates Are Not Enough!Document7 pagesBiocompatibility ISO 10993 - Material Certificates Are Not Enough!Vidyashree PujariNo ratings yet

- Nystatin Oral Suspension AMVDocument33 pagesNystatin Oral Suspension AMVOm PandeyNo ratings yet

- MicroDocument3 pagesMicroPrince MoniNo ratings yet

- Ethylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)Document30 pagesEthylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)SACHIN KUMARNo ratings yet

- Endotoxin Test Protocol PTSDocument5 pagesEndotoxin Test Protocol PTSSebastián SalazarNo ratings yet

- General Test ProcedureDocument5 pagesGeneral Test ProcedureRahul PatilNo ratings yet

- Sterilization Validation Report SampleDocument2 pagesSterilization Validation Report SampleHamidAliShahNo ratings yet

- Dry Heat Sterilization 2Document7 pagesDry Heat Sterilization 2RogerioNo ratings yet

- General Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseDocument5 pagesGeneral Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseSuman Katteboina0% (1)

- Eto Sterilization Process PDFDocument2 pagesEto Sterilization Process PDFCraigNo ratings yet

- BME-01 Equipment Iddentification TagDocument4 pagesBME-01 Equipment Iddentification TagPAPPU RANJITH KUMARNo ratings yet

- Technical Tip: Product Adoption For Ethylene Oxide SterilizationDocument2 pagesTechnical Tip: Product Adoption For Ethylene Oxide SterilizationSyed Hassan Waqar Gilani100% (1)

- List of Labs For PPE For Medical UseDocument5 pagesList of Labs For PPE For Medical UseAditya MeshramNo ratings yet

- MICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesDocument2 pagesMICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesAjesh Tk100% (1)

- Validation of Microbial Recovery From Pharmacopeial Articles EpaDocument10 pagesValidation of Microbial Recovery From Pharmacopeial Articles EpaMarco HernandezNo ratings yet

- Supplement 7 TS Qualification Storage Areas ECSPP ECBSDocument32 pagesSupplement 7 TS Qualification Storage Areas ECSPP ECBSMilagros BorhorquezNo ratings yet

- Microbial Limit TestDocument29 pagesMicrobial Limit TestJai MurugeshNo ratings yet

- A) Purpose of The Examination:: Sop No. Imm /Qm/10 Issue No.: 04 ISSUE DATE: 15april 2015 REV. NO.: 00 Rev. Date: 00Document7 pagesA) Purpose of The Examination:: Sop No. Imm /Qm/10 Issue No.: 04 ISSUE DATE: 15april 2015 REV. NO.: 00 Rev. Date: 00prityNo ratings yet

- SOP: Retro-Orbital Blood Collection in The RatDocument5 pagesSOP: Retro-Orbital Blood Collection in The RatSipend AnatomiNo ratings yet

- Attachment 4 - Technical Bulletin - Selection of EpcdDocument2 pagesAttachment 4 - Technical Bulletin - Selection of Epcdyagnaashi90920% (1)

- Sop - RLAFDocument5 pagesSop - RLAFNishit SuvaNo ratings yet

- Is 14543. 2004 Packaged Drinking Water SpecificationsDocument35 pagesIs 14543. 2004 Packaged Drinking Water SpecificationsRahmathNo ratings yet

- Agappe Chitra Magna IFU 14 May PDFDocument2 pagesAgappe Chitra Magna IFU 14 May PDFDharmesh PatelNo ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Longman English Grammar PracticeDocument83 pagesLongman English Grammar Practicebijendra_sinhaNo ratings yet

- Relation Between Ratti and CaratDocument2 pagesRelation Between Ratti and Caratbijendra_sinhaNo ratings yet

- Petals - Edition 38Document35 pagesPetals - Edition 38bijendra_sinhaNo ratings yet

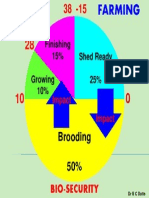

- Broiler - When & Where To ConcentrateDocument1 pageBroiler - When & Where To Concentratebijendra_sinhaNo ratings yet

- Supervisor ManualDocument38 pagesSupervisor Manualbijendra_sinhaNo ratings yet

- Roasting Matte To Nickel Oxide and MetalDocument7 pagesRoasting Matte To Nickel Oxide and MetalDavid SanchezNo ratings yet

- Soil Bearing Capacity CalculationDocument29 pagesSoil Bearing Capacity CalculationJohn Jerome TerciñoNo ratings yet

- Mv324 Data SheetDocument17 pagesMv324 Data SheetGianmarco CastilloNo ratings yet

- Database Management Systems: Lecture - 5Document37 pagesDatabase Management Systems: Lecture - 5harisNo ratings yet

- DRK109A&B Touch-Screen Bursting Strength TesterDocument2 pagesDRK109A&B Touch-Screen Bursting Strength Testermohamadreza1368No ratings yet

- Schiotz TonometerDocument9 pagesSchiotz TonometerDR_LUBYNo ratings yet

- 125 Tractor: (Specifications and Design Subject To Change Without Notice)Document5 pages125 Tractor: (Specifications and Design Subject To Change Without Notice)Gary LarsonNo ratings yet

- Correlated Optical Convolutional Neural Network With "Quantum Speedup"Document27 pagesCorrelated Optical Convolutional Neural Network With "Quantum Speedup"jaccneeNo ratings yet

- Wrong Number Series 23 June by Aashish AroraDocument53 pagesWrong Number Series 23 June by Aashish AroraSaurabh KatiyarNo ratings yet

- LRL 1220 DDocument6 pagesLRL 1220 DDEShifNo ratings yet

- Chapter 9 and 10Document18 pagesChapter 9 and 10billNo ratings yet

- Teacher PPT - Scientific RevolutionDocument13 pagesTeacher PPT - Scientific Revolutionapi-441776741No ratings yet

- Metric Ton Is 1000 KGDocument5 pagesMetric Ton Is 1000 KGmcpayodNo ratings yet

- Asco Series 042 Gas Shutoff CatalogDocument4 pagesAsco Series 042 Gas Shutoff CatalogRoqueNetNo ratings yet

- Handheld Vital Signs Monitor: XH-30 SeriesDocument4 pagesHandheld Vital Signs Monitor: XH-30 SeriesTopan AssyNo ratings yet

- Bsi 2 A. 175, Alumminium Aloy Bolts Nov 1962 PDFDocument15 pagesBsi 2 A. 175, Alumminium Aloy Bolts Nov 1962 PDFengr_usman04No ratings yet

- Ratio Worksheet AKDocument12 pagesRatio Worksheet AKChika AuliaNo ratings yet

- SO100K Installation InstructionDocument32 pagesSO100K Installation InstructionAlwin Anno SastraNo ratings yet

- Optimizing Valve Actuator Parameters To Enhance Control Valve PerformanceDocument7 pagesOptimizing Valve Actuator Parameters To Enhance Control Valve PerformanceRomanStrikerNo ratings yet

- OS Prelude-1Document16 pagesOS Prelude-1YayatiNo ratings yet

- Bsm2300a SeriesDocument324 pagesBsm2300a SeriesIBRAHIMNo ratings yet

- Rodriguez-Castro Et Al 2022 Human Highly Modified Landscapes Restrict Gene FlowDocument20 pagesRodriguez-Castro Et Al 2022 Human Highly Modified Landscapes Restrict Gene FlowShara MotaNo ratings yet