Professional Documents

Culture Documents

Volume 2 Raw Material Preparation Workshop-2010.2.12

Volume 2 Raw Material Preparation Workshop-2010.2.12

Uploaded by

Yasin YimamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volume 2 Raw Material Preparation Workshop-2010.2.12

Volume 2 Raw Material Preparation Workshop-2010.2.12

Uploaded by

Yasin YimamCopyright:

Available Formats

3000t/d 3000t/d Cement Projectof National Cement Share Company,Ethiopia

Design NoCGJC0806

Training material

Volume 2 Raw Material Preparation Workshop

NHI SHENYANG HEAVY MACHINERY GROUP CO.,LTD SICHUAN CALCINER TECHNOLOGY CO.,LTD Sep.2010

Hai

Zhou

Prepared Xu

Tao Yong

Translated Pi :

Xian

Review Zhao :

CheckedXu Cheng gang : Jie

Approved Chang

NHI SHENYANG HEAVY MACHINERY GROUP CO.,LTD SICHUAN CALCINER TECHNOLOGY CO.,LTD Sep.2010

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Catalog

FOREWORD......................................................................... 2 CHAPTER 1

PROCESS FLOW AND PROCESS EQUIPMENT ..................... 4

BRIEF INTRODUCTION OF PROCESS FLOW ......................................

CHAPTER 2

1.

2. WORKING PRINCIPLE OF MAIN EQUIPMENTS ................... 17 CHAPTER 3 OPERATION CONTROL ............................................................ 21 1. CONTROL PARAMETER ............................................................... 21 2. AUTOMATIC CONTROL CIRCUIT ................................................ 24

CHAPTER 4 PREPARATION BEFORE STARTUP......................................... 26 1. INSPECTION AND PREPARATION .................................... 26 2. INSPECTION AND PREPARATION OF ELECTRICAL EQUIPMENT33

CHAPTER 5 STARTUP AND STOP ............................................................... 35 1.

STARTUP ..................................................................................

35

2. INSPECTION AND REGULATION TO RUNNING SYSTEM48 3. NORMAL STOP SEQUENCE OF THE SYSTEM .................... 52 4. HANDLING AND ORDINARY TROUBLE-SHOOTING

TO EMERGENT SHUTDOWN ...................................................................................

64

CAUTIONS IN TEST RUN ....................................................... 69

CHAPTER 6

1. GENERAL ............................................................................................... 69 2. PREPARATIONS FOR TRIAL PRODUCTION ....................................... 71 3. GISTS AND PRECAUTIONS FOR TEST RUN ......................................... 72 4. PRECAUTIONS ....................................................................... 74

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Chapter1 Foreword

211 221 231 L11 241 311 321 331 Raw material preparation workshop includes 211 limestone, clay crushing and conveying, 221 limestone,clay preblending and conveying, 231 gypsum crushing and conveying, pumice conveying, L11 raw coal crushing and conveying, 241 united preblending and conveying, 311 raw material proportioning silo bottom, 321 raw meal grinding and conveying, 331 raw meal hogogenization silo top. In order to specify our design purpose and operation, we write this operating specification based on abroad and domestic design documentations as well our experience on cement plant. This specification narrates the operation and precautions of raw material preparation system. At phase of test run, pay attention to the special requirements on performance of electromechanical equipments, in addition, properly regulate and decided parameters and operation methods based on actual situation of cement plant. The system is controlled in CCR.In order to guarantee production and improve operation factors, the operator must seriously read this specification, and comprehend the construction, working principle and performance of all equipments,skillfully master the operation, maintenance and repair on single

NHI / SICHUAN CALCINER COMPAY 2

3000t/d Cement Projectof National Cement Share Company,Ethiopia

machine, so as to solve emergent problems in production. 1 2 3 4 Test run must comply with:1.proper cooperating, hold the ground,obey to command. 2. guarantee personnel safety 3.guarantee the safety of equipments, especially the host machine 4.be sure of free flow of material (or gas).

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Chapter2 Processflowandequipment

1. briefintroductionofprocessflow 6 1 2 3 4 5 6 The process is divided into following 6 items:limestone, clay crushing and conveyingLimestone, claying preblending and conveyingGypsum crushing and conveying, pumice conveying Raw coal crushing and conveying United preblending and conveying Raw meal preparation 1.1 System of limestoneclay crushing and conveying 1.1.1 Process flow of limestone, clay crushing and conveying 100010001000mm 150t 211.AF01 211.HC0275mm 90%211.BC03211.BC04221.BC01 221.ST02221.ST02 Limestone size should be100010001000mm,and unload from dump truck to 150t limestone silo. Use speed-adjustable heavy duty apron feeder (211.AF01) to feed limestone into hammer crusher (211.HC02). Crushed limestone is then through belt conveyor (211.BC03211.BC04) sent to belt conveyor

(221.BC01), finally be discharged to limestone stockpile by side cantilever stacker 221.ST02, which transfers materials by traverse on rail. (211.BF08)211.AF01 211.BC03211.BC04 (211.FN09) 211.BC04

NHI / SICHUAN CALCINER COMPAY 4

3000t/d Cement Projectof National Cement Share Company,Ethiopia

211.BF12 211.BC04 211.BC04 There is a set of plenum pulse bag filter (211.BF08) in the LS crushing workshop. It extracts dusty gas from the apron feeder (211.AF010)and belt conveyor (211.BC03211.BC04) at the discharging place. The dusty gas then gets purified by the filter and discharged to the atmosphere by the fan(211.FN09). High pressure pulse air would blow the dust from the filter, then the dust would fall into the dust collection bucket and be unloaded to the belt conveyor (211.BC04) by the dust discharger. There is a set of pulse bag filter (211.BF12). It extracts dusty gas from the belt conveyor (211.BC04). Purified gas would be discharged into the atmosphere. High pressure pulse air would blow the dust from the filter, then the dust would fall into the dust collection bucket and be unloaded to the belt conveyor (211.BC04). 1.1.2 Process flow of clay conveying 50t 211.AF05211.BC06 211.BC07211.BC04221.BC01 221.ST02221.ST02 Clay is transported into plant and directly unloaded to 50t clay bin.Medium apron feeder211.AF05feed clay to belt conveyer211.BC06,and then through belt conveyer211.BC07211.BC04comes to belt conveyer221.BC01, and then be discharged to clay stockpile by side cantilever stacker221.ST02, which transfers materials by traverse on rail. 211.BF10211.BF11 211.BF12 211.BC06211.BC07211.BC04 211.BC06211.BC04 Three single pulse bag filters211.BF10211.BF11211.BF12are set at

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

transfer point in the process of conveying clay, which extracts dusty gas at the discharging point of belt conveyer211.BC06211.BC07 211.BC04and then the gas be purged and emitted into atmosphere. High pressure pulse air blows the dust into the collecting bucket and the dust be unloaded to the belt conveyor (211.BC06211.BC04) by the dust discharging machine. 1.2 System of limestoneclay preblending and conveying 1.2.1 Process flow of limestone preblending and conveying 221.RE03 221.BC04 221.BC07221.BC08 311.BC01 311.VV02 1, 311.BC03 Limestone stacked in preblending stockpile is reclaimed by bridge scraper reclaimer221.RE03and then fed to belt conveyer221.BC04, then pass belt conveyers221.BC07221.BC08 311.BC01in turn, enter electrohydraulic side tee distributing valve 311.VV02(check the position of tee valve before startup), finally enter limestone proportioning silo through rotation of reversible belt conveyer 311.BC03 221.BF09 311.BF18 221.BC07221.BC08 221.BC08311.BC01 311.BF13 311.BC01 There are two single pulse bag filters221.BF09311.BF18at transfer point in the process of conveying limestone.They extract dusty gas at discharging point of belt conveyer221.BC07221.BC08, the dusty gas is discharged to to atmosphere after purge. High pressure air blows the dust on collecting bag down to dust bucket and then the bucket discharger unloads it to belt conveyer221.BC08

NHI / SICHUAN CALCINER COMPAY 6

3000t/d Cement Projectof National Cement Share Company,Ethiopia

311.BC01.A single pulse bag filter 311.BF13is set at the top of limestone proportioning silo used to extract dusty gas.After filtration, the dust is discharged to atmosphere, and then the high pressure air blows the dust on bag, which falls into bucket to be discharged to belt conveyer311.BC01. 1.2.2 Process flow of clay preblending and conveying 221.RE05 221.BC06 221.BC07221.BC08 311.BC01 311.VV02 2 Clay stacked in preblending stockpile is reclaimed by side scraper reclaimer 221.RE05and then fed to belt conveyer221.BC06, then pass belt conveyers 221.BC07221.BC08 311.BC01in turn, enter clay proportioning silo through electrohydraulic side tee distributing valve 311.VV02(make sure the tee valve place at position 2 before startup). 221.BF09 311.BF18 221.BC06221.BC07221.BC08 221.BC08311.BC01 (311.BF14) (311.FN15) There are two single pulse bag filters221.BF09311.BF18at transfer point in the process of conveying clay.They extract dusty gas at discharging point of belt conveyer221.BC06221.BC07221.BC08, the dusty gas is discharged to atmosphere after purge. High pressure air blows the dust on collecting bag down to dust bucket and then the bucket discharger unloads it to belt conveyer221.BC08 311.BC01 .A single pulse bag filter 311.BF14 is set at the top of clay proportioning silo used to extract dusty gas.After filtration, the dust is discharged to atmosphere by fan(311.FN15), and then the high pressure air blows the dust on bag, which falls into bucket to be discharged to clay silo.

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

1.2.3 Process flow of high quality LS preblending and conveying 221.RE05 221.BC06 221.BC07 221.BC08 311.BC01311.VV02 1,311.BC03 High quality LS stacked in preblending stockpile is reclaimed by side scraper reclaimer221.RE05and then fed to belt conveyer221.BC06, then pass belt conveyers221.BC07221.BC08 311.BC01in turn, enter electrohydraulic side tee distributing valve 311.VV02(make sure the tee valve place at position 1 before startup), finally enter high quality LS proportioning silo through reversal rotation of reversible belt conveyer311.BC03 221.BF09 311.BF18 221.BC06221.BC07221.BC08 221.BC08311.BC01 (311.BF14) (311.FN15) There are two single pulse bag filters221.BF09311.BF18at transfer point in the process of conveying high quality LS.They extract dusty gas at discharging point of belt conveyer221.BC06221.BC07221.BC08, the dusty gas is discharged to atmosphere after purge. High pressure air blows the dust on collecting bag down to dust bucket and then the bucket discharger unloads it to belt conveyer221.BC08311.BC01.A single pulse bag filter 311.BF14is set at the top of high quality LS proportioning silo used to extract dusty gas.After filtration, the dust is discharged to atmosphere by fan(311.FN15), and then the high pressure air blows the dust on bag, which falls into bucket to be discharged to clay silo. 1.3 System of gypsum crushing and conveying, pumice conveying 1.3.1

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Process flow of gypsum crushing and conveying 231.TR14 60t 231.AF01231.HC02 Gypsum is transported into plant and directly unloaded to 60t gypsum bin by dumper231.TR14.Medium apron feeder231.AF01feeds gypsum to hammer crusher231.HC02. 25mm 90%231.BC03 231.BC04 231.BC05 241.BC02 241.BC02a241.BC02a The crushed gypsum90% of size25mmvia belt conveyer231.BC03 231.BC04 231.BC05 drops on belt conveyer 241.BC02 and then be discharged , to united preblending stockpile by discharging car241.BC02a, which transfers materials by traverse on rail. (231.BF06)231.AF01 231.BC03 (231.FN07) 231.BC03 231.BF08231.BF09231.BF10 231.BC03231.BC04 231.BC05 231.BC04 231.BC05241.BC02 There is a set of pulse bag filter (231.BF06) in gypsum crushing workshop. It extracts dusty gas from the apron feeder (211.AF010)and belt conveyor (211.BC03). The dusty gas then gets purified by the filter and discharged to the atmosphere by the fan(231.FN07). High pressure pulse air would blow the dust from the filter, then the dust would fall into the dust collecting bucket and be unloaded to the belt conveyor (231.BC03) by the dust discharger. There are three sets of pulse bag filter (231.BF08231.BF09231.BF10)at transfer station of gypsum. They extract dusty gas from the belt conveyor (231.BC03231.BC04 231.BC05). The purified gas would be discharged into the atmosphere. High

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

pressure pulse air would blow the dust from the filtering bag, then the dust would fall into the dust collectiing bucket and be unloaded to the belt conveyor (231.BC04231.BC05241.BC02). 1.3.2 Process flow of pumice conveying K11.TR05 60t K11.AF01K11.BC02 231.BC04231.BC05241.BC02 241.BC02a 241.BC02a Pumice is transported into plant and directly unloaded to 60t clay bin by dumper K11.TR05 .Medium apron feeder K11.AF01 feed pumice to belt conveyer K11.BC02 ,and then through belt conveyer 231.BC04 231.BC05 comes to belt conveyer241.BC02, and then be discharged to united preblending stockpile by discharging car241.BC02a, which transfers materials by traverse on rail. K11.BF03K11.BF04 231.BF09231.BF10 K11.BC02231.BC04231.BC05 K11.BC02 231.BC04 231.BC05241.BC02 There are 4 sets of pulse bag filter (K11.BF03 K11.BF04 231.BF09 231.BF10) at the transfer point in the process of conveying pumice. They extract dusty gas from belt conveyor (K11.BC02231.BC04231.BC05). The dusty gas then gets purified by the filters and discharged to the atmosphere. High pressure air would blow the dust from the filter, then the dust would fall into the dust collecting bucket and be unloaded to the belt conveyor (K11.BC02 231.BC04 231.BC05 241.BC02) by the dust discharger. 1.4 Process flow of raw coal crushing and conveying L11.TR19 60t L11.AF01L11.HC02

NHI / SICHUAN CALCINER COMPAY

10

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Raw coal is transported into plant and directly unloaded to 60t clay bin by dumper L11.TR19 .Medium apron feeder L11.AF01 feed raw coal to ring hammer crusherL11.BC02. 25mm 90%L11.BC03 L11.BC04 L11.BC05 241.BC01 241.BC01a241.BC01a Crushed raw coal above 90% size25mmis transported through belt

conveyer L11.BC03 L11.BC04 L11.BC05 and comes to belt conveyer 241.BC01 , and then be discharged to united preblending stockpile by discharging car241.BC01a, which transfers materials by traverse on rail. (L11.BF06) L11.AF01L11.BC03 (L11.FN07) L11.BC03 L11.BF08L11.BF10L11.BF12 L11.BC04 L11.BC05 241.BC01(L11.FN09 L11.FN11L11.FN13) L11.BC04L11.BC05 There is a set of antiexplosion pulse bag filter (L11.BF06) in raw coal crushing workshop. It extracts dusty gas from the apron feeder (L11.AF01)and belt conveyor (L11.BC03). The dusty gas then gets purified by the filter and discharged to the atmosphere by the fan(L11.FN07). High pressure pulse air would blow the dust from the filter, then the dust would fall into the dust collecting bucket and be unloaded to the belt conveyor (L11.BC03) by the dust discharger. There are three sets of antiexplosion pulse bag filter (L11.BF08L11.BF10L11.BF12)at transfer station. They extract dusty gas at the discharging point of the belt conveyor (L11.BC04L11.BC05241.BC01). The purified gas would be discharged into the atmosphere by fan (L11.FN09 L11.FN11 L11.FN13). High pressure pulse air would blow the dust from the filtering bag, then the dust would fall into the dust collectiing bucket and be unloaded to the belt conveyor (L11.BC04L11.BC05).

NHI / SICHUAN CALCINER COMPAY 11

3000t/d Cement Projectof National Cement Share Company,Ethiopia

1.5 System of united preblending and conveying 1.5.1 Process flow of gypsum reclaiming and conveying 241.RE04 241.BC11 241.BC12241.BC13241.VV14 1511.BC01 511.BC01511.BC03 gypsum stacked in preblending stockpile is reclaimed by side scraper reclaimer241.RE04and then fed to belt conveyer241.BC11, then pass belt conveyers241.BC12241.BC13in turn, enter electrohydraulic tee distributing valve 241.VV14(make sure the tee valve place at position 1 before startup), finally enter gypsum silo through reversal rotation of reversible belt conveyer 511.BC01 241.BF19241.BC20 241.BC12241.BC13 241.BC12 241.BC13 (511.BF66), 511.VM81 511.VM82 511.VM85 (511.FN68) 2# There are two single pulse bag filters241.BF19241.BC20at transfer point in the process of conveying gypsum.They extract dusty gas at discharging point of belt conveyer241.BC12241.BC13, the dusty gas is discharged to atmosphere after purge. High pressure air blows the dust on collecting bag down to dust bucket and then the bucket discharger unloads it to belt conveyer 241.BC12 241.BC13.A pulse bag filter 511.BF66is set at cement mill head bin,when convey gypsum,open electrical valves 511.VM81 511.VM82

511.VM85 ,meanwhile, close other electrical valves.After filtration, the dust extracted at gypsum transfer point and gypsum silo is discharged to atmosphere by

NHI / SICHUAN CALCINER COMPAY 12

3000t/d Cement Projectof National Cement Share Company,Ethiopia

fan(511.FN68), and then the high pressure air blows the dust into dust collecting bucket to be discharged into pumice silo 2#. 1.5.2 Process flow of pumice reclaiming and conveying 241.RE04241.BC11 241.BC12241.BC13241.VV14 1 511.BC01 511.BC01 511.BC05 511.BC05 1# 2#241.VV14 2 511.BC04 511.BC04 2# The pumice stocked in united preblending stockpile is reclaimed by pumice reclaimer and sent to belt conveyer 241.RE04 as well as belt conveyer 241.BC12 241.BC13 later pumice enters electrical tee valve , 241.VV14 tee valve at position1 and then drops on belt conveyer511.BC01to be brought to belt conveyer 511.BC05 through positive rotation of belt conveyer 511.BC01 , and then pumice is conveyed to pumice silo 1# through reversible belt conveyer 511.BC05. Pumice would enter belt conveyer 511.BC04 via electrical tee valve241.VV14(the valve places at position 2)and reversible belt conveyer 511.BC04to enter silo 2#. 241.BF19241.BC20 241.BC12241.BC13 241.BC12 241.BC13 (511.BF66), 1# 511.VM81 511.VM84 511.VM87 2#511.VM83511.VM86 (511.FN68) 2# There are two single pulse bag filters241.BF19241.BC20at transfer point in the process of conveying pumice.They extract dusty gas at discharging point of belt conveyer241.BC12241.BC13, the dusty gas is discharged to atmosphere

NHI / SICHUAN CALCINER COMPAY 13

3000t/d Cement Projectof National Cement Share Company,Ethiopia

after purge. High pressure air blows the dust sticking on collecting bag down to dust bucket and then the bucket discharger unloads it to belt conveyer241.BC12 241.BC13.A pulse bag filter 511.BF66is set at cement mill head bin.When pumice enters silo 1#,open electrical valves 511.VM81 511.VM84 511.VM87,meanwhile, close other electrical valves. When pumice enters silo 2#, open electrical valve511.VM83511.VM86 and close other electrical valves. After filtration, the dust extracted at gypsum transfer point and pumice silo is discharged to atmosphere by fan(511.FN68), and then the high pressure air blows the dust sticking to filtering bag into dust collecting bucket to be discharged into pumice silo 2#. 1.5.3 Process flow of raw coal reclaiming and conveying 1.5.3.1 reclaiming 241.RE03241.BC05 241.BC06241.BC07241.VV08 1241.BC09241.VV10 241.BC07241.MD22 241.MT23 241.MT23241.VV08 2 The raw coal stocked in united preblending stockpile is reclaimed by reclaimer 241.RE03and sent to belt conveyer241.BC05as well as belt conveyer , 241.VV08 tee 241.BC06 241.BC07 later pumice enters electrical tee valve valve at position1 and then drops on belt conveyer241.BC09to be brought to electrical tee valve241.VV10 and finally enters two raw coal bins. There is a metal detector(241.MT23) and iron remover 241.MD22 on belt conveyer 241.BC07 .When metal detector 241.MT23 finds out metal, electrical tee valve 241.VV08shall be pushed to position 2 to discharge waste materials. 1.5.3.2 forklift unloading 241.NG21 241.BC05 241.BC06241.BC07241.VV08 1 241.BC09

NHI / SICHUAN CALCINER COMPAY 14

3000t/d Cement Projectof National Cement Share Company,Ethiopia

241.VV10 241.BC07 241.MD22 241.MT23 241.MT23 241.VV082 Forklift discharges the raw coal into raw coal bin. Open rod gate241.NG21, raw coal enters belt conveyer241.BC05and then belt conveyer241.BC06 241.BC07 subsequently enters electrical tee valve 241.VV08 , (the valve places at position 1), and again via belt conveyer241.BC09enters electrical tee valve 241.VV10 , finally enters the two raw coal bins. There is a metal detector(241.MT23) and iron remover 241.MD22 on belt conveyer

241.BC07 .When metal detector 241.MT23 finds out metal, electrical tee valve 241.VV08shall be pushed to position 2 to discharge waste materials. 241.BF15241.BF17 241.BC06241.BC07241.BC09 (241.FN16241.FN18) 241.BC07 241.BC09 There are two antiexplosion pulse bag filters 241.BF15 241.BF17 transfer at point in the process of conveying raw coal.They extract dusty gas at discharging point of belt conveyer241.BC06241.BC07241.BC09, the dusty gas is discharged to atmosphere after purge of fan (241.FN16241.FN18). High pressure air blows the dust sticking on collecting bag down to dust bucket and then the bucket discharger unloads it to belt conveyer241.BC07241.BC09. 1.6 Process flow of raw meal preparation 311.NG04311.NG06 311.SQ05311.WF07311.WF08 311.WF09311.BC10321.VV01 Limestone, clay and high quality limestone stocked in proportioning silo are respectively discharged by rod gate311.NG04311.NG06and rotary discharger

NHI / SICHUAN CALCINER COMPAY

15

3000t/d Cement Projectof National Cement Share Company,Ethiopia

311.SQ05 the proportion set by quality control system or man, which then sent in to belt conveyer 311.BC10 after weighing of belt scale 311.WF07 311.WF08 311.WF09and finally via electrical tee valve321.VV01 enters mill. 311.BF16 (311.FN17) 311.BC10 321.BF08321.BE07 (321.FN09) 311.BC10 A set of pulse dust collector311.BF16at the bottom of proportioning silo extracts dusty gas under belt scales. The dusty gas is discharged to atmosphere by fan(311.FN17).High pressure air blows the dust sticking to filtering bag down to dust bucket and be discharged to belt conveyer311.BC10. There is a pulse dust collector321.BF08at transfer point,which extracts dusty gas at discharging point of belt conveyer 321.BE07 the dusty gas is discharged to atmosphere after purge. , High pressure air blows the dust sticking on collecting bag down to dust bucket and then the bucket discharger unloads it to belt conveyer311.BC10. The system uses vertical mill,which unites effective grinding and drying togeter. 321.PG02 321.RM03321.FN19 250 321.FV05321.BC06 321.BE07 321.BE07311.BC10 311.BC10321.RM03a 321.CS10 321.CS10a1 321.CS10a2 321.AS13 321.AS13331.BE01 331.BE01

NHI / SICHUAN CALCINER COMPAY

16

3000t/d Cement Projectof National Cement Share Company,Ethiopia

331.AS02331.DG04 321.CS10321.FN11 321.BF32 The proportioned mixture via tee airlocking valve 321.PG02 falls into vertical mill321.RM03from feeding opening, meanwhile, the 250 waste gas from high temperature fan enters mill from air inlet.The hard-grinding materials and unexpected metal pieces through blowhole would sink, and then come to scraper, deslagging hole,gravity flap valve 321.FV05 in turn, enter belt conveyer 321.BC06 and then elevator 321.BE07 and belt conveyer 311.BC10 finally , it is conveyed to mill. The fine powder, after grinding, enters cyclone separator 321.RM03a along with air flow, which is classifed by seperator 321.CS10 under high speed air flow.The classified materials via rotary

discharger321.CS10a1,321.CS10a2 drop into chute 321.AS13 and be sent to elevator 331.BE01 ,and then be unloaded to chute 331.AS02 enter raw meal and distributor331.DG04,finally be fed into raw meal homogenization silo.The separated dusty gas is blown to kiln inlet EP321.BF32by circulating fan 321.FN11. 2. Workingprincipleofmainequipments 2.1 Working principle of raw mill(vertical mill) 321.PG02 80% 321.CS10 Vertical mill makes use of material bed to grind materials.The working principle

NHI / SICHUAN CALCINER COMPAY

17

3000t/d Cement Projectof National Cement Share Company,Ethiopia

of the machine:materials go through tee airlocking valve 321.PG02, feeddown chute and enter mill to be accumulated at the center of table, under centrifugal force, materials moves towards table edge and be grinded by roll(grinding roll operates through pressure boost of hydraulic system).Grinding table is 80% faster than the ball mill with same diameter. Materials not only be grinded under roll, also be pushed outward through retention ring and drop into air ring.With high speed air flow, materials are brought to upper separator to be classified. Coarse powder is regrinded at table. The eligible product is brought out with air flow and then enters cyclone separator321.CS10.Due to high speed of air flow, heat transfers fastly. Small granule is dried instantly and large granule is mostly dried, which would be further dried in the process of regrinding.The hard grinding material and unexpected metal piece would go through blowhole, drop and be discharged out through scraper and deslagging hole. 2.2 Working principle of cyclone separator 12~25m/s Cyclone separator consist of air inlet pipe, cylinder shell,cone and vent pipe.When dusty gas enters separator at a tangent with speed 12~25m/s from air inlet pipe, air flow changes beeline movement into circular movement, at this time, the air eddies from top-down along the wall, general called external eddy.When the eddy comes to cone, by shrink of cone, it would shift to center radially. According to invariant of rotary torque, centrifugal force would continously rise as keep invariant

NHI / SICHUAN CALCINER COMPAY 18

3000t/d Cement Projectof National Cement Share Company,Ethiopia

tangent speed, rotary diameter lessens and angle speed keeps rise.When air flow reaches the lower part of cone, it would reverse upward at center of vent pipe in same spiral direction and keep spiral moving, which is called internal eddy. When air flow rotates,the dust would be thrown to wall under centrifugal force.Due to collision with wall, dust loses inertia force and fall into dust bucket.The other small part of air from vent pipe would flow towards the top of cyclone,and then shift downward along outside of the vent pipe, when it comes to lower part of vent pipe, it would reverse upward and be discharged from vent pipe with ascending air flow.The dust in this part of air along with dust in ascending air flow are ejected. 2.3 Brief introduction of single stage hammer crusher This is a special single stage crusher used in cement industry, which is for the crushing of brittle mineral of medium intensity, like limestone, marl, shale, gypsum and coal. It is characterized of accepting big feeding, crushing raw mineral into required feeding sizes once. And a consequent discharging grate is employed and is much more suitable to deal with moisture and soil in the mineral. This machine is protected by a special device, which can have indestructible foreign metal matters rebounded onto the feeder, and the operator can halt to deal with it according to some strange metallic sound. The working principle of this machine is that minerals are fed into the crusher through its feed inlet by feeder, and crushed or tossed by the hammers on the rapidly turning rotor. Tossed minerals that hit on the impact plate shall be further

NHI / SICHUAN CALCINER COMPAY

19

3000t/d Cement Projectof National Cement Share Company,Ethiopia

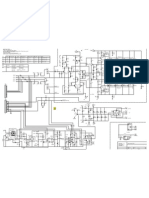

crushed by it, at the same time minerals at the upper space within crush by collision among themselves. Crushing process mentioned above continue between the rotor and the crushing board. After crushed at the upper space within, material are to be carried to the lower space by the rotor, and crushed again at the working zone, formed by rotor and grate plate, until it can be discharged out of the grate gaps. 3. process flow sheet and equipments Process folw sheet and equipments,Please See volume 1.

NHI / SICHUAN CALCINER COMPAY

20

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Chapter3OperationControl

This chapter includes the control parameters list and automatic control circuit. The main purpose is to help the operator be familiar with main measuring points and control parameters of the equipment of this workshop in order to ensure the normal operation of the equipment. 1. Controlparameter

S/N 1 Equipment No. 211.AF01 Measuring points Current of heavy apron feeder motor Rotation speed of heavy apron feeder motor Temperature of the main bearing of the hammer crusher Current of the main motor of hammer crusher Temperature of the motor winding of hammer crusher Temperature of the motor bearing of hammer crusher The opening degree of the fan inlet valve Current of medium apron feeder motor Rotation speed of medium apron feeder motor Rotation speed of medium apron feeder motor Temperature of the main bearing of the ring hammer crusher Temperature of the main motor of the ring hammer crusher Temperature of the motor bearing of the ring hammer crusher Current of medium apron feeder motor Parameter Observation Adjustment Observation Observation Observation Observation Adjustment Observation Adjustment Adjustment Observation Observation Observation Observation

211.HC02

211.HC02.M01

211.FN09a

211.AF05

6 7

L11.AF01.M01 L11.HC02

L11.HC02.M01

9 10

L11.HC02.M01 231.AF01.M01

NHI / SICHUAN CALCINER COMPAY

21

3000t/d Cement Projectof National Cement Share Company,Ethiopia

S/N

Equipment No.

11 12 13

231.HC02 231.HC02.M01 231.HC02.M01

Measuring points Rotation speed of medium apron feeder motor Temperature of the main bearing of the impact crusher Current of the main motor of the impact crusher Current of medium apron feeder motor Rotation speed of medium apron feeder motor The opening degree of the fan inlet valve Discharger of belt conveyor Discharger of belt conveyor Gypsum proportioning silo level 1# Pumice 1# proportioning silo level 2# Pumice 2# proportioning silo level Clinker proportioning silo level Coal silo level High quality limestone proportioning silo level Clay proportioning silo level Limestone proportioning silo level Position of the valve plate of Tee distribution valve Position of the valve plate of Tee distribution valve Position of the valve plate of Tee distribution valve Position of the valve plate of Tee distribution valve Metal detector () Feed amount of belt weigher (limestone)

Parameter Adjustment Observation Observation Observation Observation Adjustment Adjustment / ON/OFF / ON/OFF 08m 08m 08m 09m 06m 014m 014m 014m Control Control Control Control Observation 2250t/h

14

K11.AF01.M01

15 16 17 18 19 20 21 22 23 24 25 26

231.FN07a 241.BC01a 241.BC02a

241.VV08

27

241.VV10

28

241.VV14

29 30 31

311.VV02 241.MT23 311.WF07

NHI / SICHUAN CALCINER COMPAY

22

3000t/d Cement Projectof National Cement Share Company,Ethiopia

S/N 32 33 34 35

Equipment No. 311.WF08 311.WF09 311.MT12 321.VV01

36

321.RM03

37

321.RM03.M01

38

321.RM03.GB01

39

321.LQ04

40

321.RM03b

41

321.RM03a

42 43

321.CS10 321.VM22

44

321.VM24

Measuring points Feed amount of belt weigher (clay) Feed amount of belt weigher (high quality clay) Metal detector Position of valve plate of pneumatic tee distribution valve Outlet pressure difference of raw mill Outlet temperature of raw mill Inlet temperature of raw mill Raw mill vibration Inlet negative pressure of raw mill Thrust bearing temperature of raw mill Bearing temperature of the main motor of raw mill Winding temperature of the main motor of raw mill Current of the main motor of raw mill Bearing temperature of the main gear box of raw mill Outlet pressure of the lubrication station of main gear box of the raw mill Lubricant temperature Sealing air pressure of the raw mill press roller Rotation speed of raw mill separator Separator current Outlet pressure difference of cyclone separator Opening degree of hot air valve (to electric dust filter) Opening degree of the inlet cold air valve of raw mill

Parameter 660 t/h 660 t/h Observation Control 6500Pa Observation Observation Observation 200Pa Observation Observation Observation Observation Observation Observation Observation 8000Pa Control Observation 6001200Pa Control Control

NHI / SICHUAN CALCINER COMPAY

23

3000t/d Cement Projectof National Cement Share Company,Ethiopia

S/N 15

Equipment No. 321.VM23

46

321.FN11

47

321.FN11.M01

48 49 50 51 52

321.FN11a 331.BE01 321.BE07 331.BL05

Measuring points Opening degree of the outlet hot air valve of raw mill Circulating fan of raw mill Outlet negative pressure Inlet negative pressure Fan bearing temperature Fan vibration Temperature of the bearing of the main motor of raw mill Temperature of the winding of the main motor of raw mill Current of the main motor of circulating fan of raw mill Opening degree of the inlet valve of circulating fan of raw mill Current of elevator motor Current of elevator motor Outlet pressure of Roots fan Raw meal homogenizing silo level

Parameter Control

911kPa 01000Pa Observation Observation Observation Observation Observation Control Observation Observation 19.6kPa 039m

2. Automaticcontrolcircuit In order to improve the operation efficiency for production and reduce labor intensity, this system uses a combine method of computer control and automatic parameter adjustment circuit. The important parameters of the system are

controlled automatically as much as possible, reducing the possibility of maloperation by human so as not to affect production. 1 Weigh feeder automatic control system 311WF07311WF08

NHI / SICHUAN CALCINER COMPAY

24

3000t/d Cement Projectof National Cement Share Company,Ethiopia

311WF09/ The speed of the belt of the weigh feeder (311WF07311WF08311WF09) is adjusted according to the setup value of feeding amount of the weigh feeder, making the real feed amount equal to the setup value. The setup vale is manual/automatic. (2) 241.MT23241.VV08 2,; When the metal detector (241.MT23) has detected metal, the valve plate of the Tee distribution valve (241.VV08) is automatically turned to position 2, then the Tee distribution valve begins to discharge the foreign materials. (3) 311.MT12321.VV01 2,; When the metal detector (311.MT12) has detected metal, the valve plate of the Tee distribution valve (321.VV01) is automatically turned to position 2, then the Tee distribution valve begins to discharge the foreign materials. (4) ; The mill feed amount is controlled according to the pressure difference between inlet and outlet. (5) The opening degree of the front valve of the fan of mill is adjusted according to the inlet negative pressure. (6) 321.VM22 321.VM24 The opening degree of 321.VM22 circulating air valve and 321.VM24 cold air valve is adjusted according to the outlet temperature of the mill. (7) 321.FN33 321.FN19 The rotation speed of 321.FN33 fan controls the outlet negative pressure of 321.FN19 ID fan. (8) . The mill outlet temperature alarm initiates water spraying in the mill.

NHI / SICHUAN CALCINER COMPAY

25

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Chapter4Preparationbeforestartup

All equipments of the system must be carefully inspected and regulated before startup.This is a rule must be seriously carried out in prduction. 1. InspectionandPreparation 1.1 Inspection and regulation on lubricating unit and quantity Lubrication plays a key role in securing a long term steady running. The quantity of lubrication oil must be properly since it directly effects on the running of the equipment: If it is too much, the equipment will go overheat; on the contrary, the equipment will be damaged. Introduction of each single machine provided by the manufacturer should be closely followed in periodic check and lubrication oil renewing. The oil type and trade mark should be right, and the quality should meet the requirements, no water and no foreign matters. 1.1.1 The oil quantity in the lubrication device of apron feeder shall be determined after the commissioning, it will be ok when the equipment can well running and oil can just overflow from each lubricated spot. 1.1.2 Feed lubrication oil into the gear box of apron feeder according to the oil scale. The lubrication oil should be filtered and cleaned. 1.1.3 Appropriate sum of lubrication oil and grease are poured into the main bearing

NHI / SICHUAN CALCINER COMPAY 26

3000t/d Cement Projectof National Cement Share Company,Ethiopia

and drive unit of crusher, keep free flow. 1.1.4 Appropriate sum of lubrication oil and grease are poured into the drive unit of stacker and side scraper reclaimer, keep free flow. 1.1.5 Appropriate sum of lubrication oil and grease are poured into the main bearing and drive unit of elevator, keep free flow. 1.1.6 The lubrication system of main gear box of raw mill should be proper,oil level is between the upper and lower oil scale.Each joint of pipeline should be no oil leakage,instruments works well,pipeline and valve are smooth,oil temperature should be appropriate. 1.1.7 Keep proper oil quantity of hydraulic pressure,ensure the free-flowing of oil and no leakage,and the valve start-stop is flexible, as well as instruments are soundness. 1.1.8 Keep proper oil quantity of grinding rollers circulatory oil system,and there should be free-flowing of oil and no leakage, the valve start-stop is flexible, as well as instruments are soundness. 1.1.9 Oil quantity of grease-box on mill-choosing machine is proper. 1.1.10 Grease the drive units (gear box,motor,shaftjoint) of the rest equipments. 1.1.11 Grease bearings and movable parts of all equipments. 1.1.12 Grease actuator of electrical valves. 1.2

NHI / SICHUAN CALCINER COMPAY

27

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Inspection and sealing of manholes and inspection doors inside the equipment Before startup, inside of the equipment should be checked thoroughly. Clear away all the odds left behind during the installation or maintenance, in case incur block or damages to equipment; and close all the manholes, cleaning holes and inspection gates to prevent leakage of air, material and oil etc. during the production. 1.2.1 Check out the material bin, clear away the metal parts and other odds and ends in it. 1.2.2 Timely clear away metal foreign matters within the crusher (including the grate plate) 1.2.3 All the openings on the crusher body must be closed tightly. 1.2.4 Odds and ends should be cleared away immediately from the filter and belt conveyor. 1.2.5 The observation hole of elevator shall be closed. 1.3 gates In order to keep the free-flowing of material,the rod valve at the bottom of raw material proportioning silo should be opened to appropriate degree. 1.4 Inspection on equipment fastening Before startup, the fastening state at each equipment must be checked, all of the connecting bolts, anchor bolts etc. must be screwed up tightly. 1.4.1

NHI / SICHUAN CALCINER COMPAY

28

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Screw up all the anchor bolts of apron feeder, connections of mechanic parts.

ensuring securing all the

1.4.2 Lock up tightly bolts and anchor bolts at each part of crusher, and screw up the rotor lathedog tightly. 1.4.3 All parts of belt conveyor need fastening connecting, anchor bolts screwed up. 1.4.4 All parts of elevator must be linked firmly, foundation bolts are screwed down, backstop and takeup are intact. 1.4.5 Make sure loose-vulnerable parts are tightened up. 1.4.6 First of all, check the manual flexibility of all of the electric valves on site, and the firmness of the valve shaft and linkage, after that, take a remote control on it, make sure the open-close direction onsite is in accordance with that of control room, and the accuracy of opening and indication. If there is a upper limit or lower limit on the switch, the check of limit signal return with control room is needed. 1.4.7 Inspect the equipments fastening, for example, the liner bolts, the inside bolts and foundation bolts of mill, the fixed bolts of elevator chain bucket. The easy to loose parts at equipment drive units should be checked strictly. 1.5 Inspection on cooling water system The protection of cooling water system is very important.make sure whether or not the conduit valve is opened before startup.There is no leakage of pipeline joint.Pay special attention to the oil cooler of lubrication system,it is forbidden that

NHI / SICHUAN CALCINER COMPAY

29

3000t/d Cement Projectof National Cement Share Company,Ethiopia

water flows into oil. A proper control on the quantity of cooling water is needed. If it is too little, the equipment will go overheat; on the contrary, it will cause unnecessary waste. 1.6 Inspection on instruments There are so many instruments like fuel gauge, offset switch, temperature and pressure gauge, level indicator on site.Workers rely on them to see the running status of equipments.Before startup, make a thorough inspection, guarantee the power supply and display. Check the contact to control room. 1.7 Adjustment and Preparation Before the system startup, all the preparations should be ready, so as to assure a sound startup of the whole system. 1.7.1 Adjustment & preparation of apron feeder 1.7.1.1 Before the commissioning, the rotation direction of gear box must be checked, counter rotation is not allowed. 1.7.1.2 Conduct lubrication device commissioning and make it run properly, at each lubrication area oil overflowing. Content in the grease container should be kept at its usual level. Fill the gear box with lubrication oil that is filtered and clean to the oil

NHI / SICHUAN CALCINER COMPAY 30

3000t/d Cement Projectof National Cement Share Company,Ethiopia

scale, then grease up each lubrication area. 1.7.1.3 Regulate the tension unit so as to make the link joints more tensive and of smaller deflection, thereby ensure a sound mesh of the principal and subordinate chain pulleys and possibly make an approximate pull at both of the screw mandrels. 1.7.1.4 Make sure the link joint bolt screw up; looseness is forbidden. 1.7.1.5 After each part is approved fine, start it unloaded at a slow speed in a slow way. Gradually speed up this normal running equipment to its normal speed then keep it running for hours (no less than 30min, and the actual situation determines the time) 1.7.1.6 20% Loaded running comes after the examination on the unloaded commissioning. And before the loaded running, it shall use about 20% crushed stone or fine stuff in the limestone receiver hopper to serve as buffering layer. 1.7.2 Regulation & preparation of crusher 1.7.2.1 Make sure motors turn in right direction. 1.7.2.2 Properly pour the lubrication oil and grease into the main bearings, driving parts etc. Hydraulic system works normally. 1.7.2.3 Make sure there are no foreign metal matters within the crusher, check the rotor turning, eliminate all unwanted metallic chink. 1.7.2.4 Make sure bolts of each part and anchor bolts are locked up tightly, and all the

NHI / SICHUAN CALCINER COMPAY

31

3000t/d Cement Projectof National Cement Share Company,Ethiopia

openings in the machine closed firmly. 1.7.3 Regulation and preparation of pulse bag filter 1.7.3.1 Check the rotating direction of main exhaust fan, whether or not thers is abnormal sound and noise. 1.7.3.2 Check whether or not there are foreign matters within, the filtering bags in the right place. 1.7.3.3 Check each lubrication area, filling with enough lubrication oil. 1.7.3.4 Make sure bolts of each part and anchor bolts are locked up tightly, and all the openings in the machine closed firmly. 1.7.4 Regulation and preparation of belt conveyer 1.7.4.1 Add enough lubrication oil into the gear boxes, motors and each lubrication area, shaft joint oiled as required. 1.7.4.2 Make sure electric signal and control unit are wired up correctly. 1.7.4.3 Start up motor, and comfirm the pulley roller turns in a right direction. 1.7.4.4 Pull rope switch, offset switch etc. are in good working condition; training idler works well, cleaning unit is in good state 1.7.4.5 Roller and carrier roller run freely, conveyer belt tie-in is flat and straight. 1.7.5 Regulation and preparation of elevator

NHI / SICHUAN CALCINER COMPAY 32

3000t/d Cement Projectof National Cement Share Company,Ethiopia

1.7.5.1 Add enough lubrication oil into the gear boxes, motors and each lubrication area, shaft joint oiled as required. 1.7.5.2 Make sure electric signal and control unit are wired up correctly. 1.7.5.3 Clutch and auxiliary drive run stably. 1.7.5.4 Reducer and hydraulic coupler of motor run stably. 1.7.5.5 Traction element runs normally, no slipping or deviateion.Material bucket doesnt collide with other elements. 1.7.6 Regulation and preparation of all equipments Carefully inspect electrical butterfly valve at inlet of fan, ensure sound operation. 2. Inspectionandpreparationofelectricalequipment 2.1 Check whether or not the power supply is closed. 2.2 Switch gear of electricity is pushed to its working position, air switch on it should be closed. Take strict precautions againt miss on power transmission when operators maitain equipment. 2.3 Make sure the transmission conditions of HV equipment, then start the transmission job. 2.4 Make sure work bench and buttons, option switches, indicator lights, alarms of

NHI / SICHUAN CALCINER COMPAY 33

3000t/d Cement Projectof National Cement Share Company,Ethiopia

dynamic control cabinet in good state. 2.5 Check the preparation for the equipment, if it is not ready, contact the electric department and site personnel. 2.6 PC Local power supply to PC. 2.7 Optional switch of site equipments shall be pushed to central control. 2.8 Check power supply to HV equipments and then start it. System would be ready to start up only when above works are done. Start up system in sequence.

NHI / SICHUAN CALCINER COMPAY

34

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Chapter5StartupandStop

This chapter narrates the operational gist.Pay attention to some special regulations on electromechanical equipments. 1. startup 1.1 Startup sequence for limestone, clay crushing and conveying 1.1.1 Startup sequence for limestone crushing and conveying

No. 1 Operating Sequence Make sure the limestone stack pile in preblending area is ready for receiving. 1Make sure limestone receiver hopper filled with material. 2Buffer layer is ready. control room sends out advance warning signal of startup 1 startup dust collecting group 2 211.BF12 start up dust collector 3 211.FN09 211.BF08 start up fan 211.FN09 and then , dust collector211.BF08. Start up the group that conveying limestone to preblending stockpile 1221.ST02start up stacker 2221.BC01start up belt conveyer. 3211.BC04start up belt conveyer. 4211.BC03start up belt conveyer. start up group of limestone crushing 1211.HC02 Start up hammer crusher. 2211.AF01 Start up heavy duty apron feeder Inspection and Regulation Check the reserves

2 3

inspect on site

inspect on site

Inspect the motor current of stacker as well as its running status. Inspect the motor current of belt conveyer as well as its running status.

1 Inspect the drive unit. 2 Pay attention to startup current. 3 Pay attention to temperature.

35

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence

Inspection and Regulation 4 5 Run without load for 5m after normal rev is reached. 5 Slightly regulate the speed of apron feeder according to current of crusher so as to stablized the feeding.

1.1.2 Startup sequence for clay conveying

No. 1 Operating Sequence Make sure the clay stack pile in preblending area is ready for receiving. 1Make sure clay receiver hopper filled with material. 2Buffer layer is ready. control room sends out advance warning signal of startup 1 start up dust collecting group. 2 211.BF12 start up dust collector. 3 211.BF11 start up dust collector. 4 211.BF10 start up dust collector. Start up the group that conveying clay to preblending stockpile 1221.ST02start up stacker. 2221.BC01start up belt conveyer. 3211.BC04start up belt conveyer. 4211.BC07start up belt conveyer. 5211.BC06start up belt conveyer. 6 211.AF05 start up medium-size apron feeder. Inspection and Regulation Check the reserves

2 3

inspect on site

inspect on site

1 Inspect the motor current of stacker as well as its running status. 2 Inspect the motor current of belt conveyer as well as its running status. 3 Notice the startup current of apron feeder.

1.2 Startup sequence of limestone, clay preblending and conveying system 1.2.1 limestone preblending and conveying

NHI / SICHUAN CALCINER COMPAY

36

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No. 1 2 3

Operating Sequence Make sure the limestone silo is ready for receiving. control room sends out advance warning signal of startup 311.VV021Push electric tee valve311.VV02 to position 1 start up dust collecting group for limestone entering silo 1 311.BF13 start up dust collector. 2 311.BF18 start up dust collector. 3221.FN10start up fan. 4 221.BF09 start up dust collector. start up limestone reclaiming and conveying group 1 311.BC03 start up belt conveyer in positive rotation. 2311.BC01start up belt conveyer. 3221.BC08start up belt conveyer. 4221.BC07start up belt conveyer. 5221.BC04start up belt conveyer. 6221.RE03start up bridge scraper reclaimer.

Inspection and Regulation Inspect on site, low level of material.

Inspect on site and confirm

inspect on site

1 Inspect the motor current and running status of bridge scraper reclaimer. 2 Inspect motor current and running status of belt conveyer. 3 311.BC03 Inspect belt conveyer, confirm it runs forward.

1.2.2 Startup sequence of clay preblending and conveying

No. 1 2 3 Operating Sequence Make sure the clay silo is ready for receiving. control room sends out advance warning signal of startup 311.VV022Push electric tee valve311.VV02 to position 2 startup dust collecting group for clay entering silo 1311.FN15starup fan 2 311.BF14 start up dust collector 3 311.BF18 start up dust collector 4221.FN10start up fan 5 221.BF09 start up dust Inspection and Regulation Inspect on site, low level of material.

Inspect on site and confirm.

inspect on site

NHI / SICHUAN CALCINER COMPAY

37

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence collector start up clay reclaiming and conveying group 1311.BC01 Start up belt conveyer. 2221.BC08 Start up belt conveyer. 3221.BC07 Start up belt conveyer. 4221.BC06 Start up belt conveyer. 5221.RE05 Start up side scraper reclaimer.

Inspection and Regulation 1 Inspect the motor current and running status of bridge scraper reclaimer. 2 Inspect motor current and running status of belt conveyer.

1.2.3 Startup sequence of high quality limestone preblending and conveying

No. 1 2 3 Operating Sequence Make sure the high quality LS silo is ready for receiving. control room sends out advance warning signal of startup 311.VV021Push electric tee valve311.VV02 to position 1 Start up dust collecting group for high quality LS entering silo 1311.FN15start up fan 2 311.BF14 start up dust collector. 3 311.BF18 start up dust collector. 4221.FN10start up fan. 5 221.BF09 start up dust collector. start up high quality LS reclaiming and conveying group 1 311.BC03 start up belt conveyer,run backward. 2311.BC01start up belt conveyer. 3221.BC08start up belt conveyer. 4221.BC07start up belt conveyer. 5221.BC06start up belt conveyer. 6221.RE05start up side scraper reclaimer. Inspection and Regulation Inspect on site, low level of material.

inspect on site and confirm the position

Inspect on site

1 Inspect the motor current and running status of bridge scraper reclaimer. 2 Inspect motor current and running status of belt conveyer. 3 311.BC03 Inspect belt conveyer, confirm it runs backward.

1.3

NHI / SICHUAN CALCINER COMPAY

38

3000t/d Cement Projectof National Cement Share Company,Ethiopia

Startup sequence of gypsum crushing&conveying, pumice conveying 1.3.1 Startup sequence of gypsum crushing and conveying

No. 1 Operating Sequence Make sure the gypsum stackpile at united preblending area is ready for receiving. 1 Make sure gypsum receiver hopper filled with material. 2 Buffer layer is ready. control room sends out advance warning signal of startup start up dust collecting group 1 231.BF10 start up dust collector 2 231.BF09 start up dust collector 3 231.BF08 start up dust collector 4 231.FN07 231.BF06 start up fan 231.FN07 and then dust collector231.BF06. start up group that conveying gypsum to preblending stockpile. 1 241.BC02a start up discharging car 2241.BC02start up belt conveyer. 3231.BC05start up belt conveyer. 4231.BC04start up belt conveyer. 5231.BC03start up belt conveyer. start up gypsum crushing group 1231.HC02 Start up hammer crusher. 2231.AF01 Start up medium-size apron feeder. Inspection and Regulation Check the reserves

2 3

Inspect on site

Inspect on site

1 .Inspect the motor current and running status of discharging car 2 Inspect motor current and running status of belt conveyer.

1 Inspect the drive device. 2Notice the startup current 3Notice the temperature at each point. 4 5 Run without load for 5m after it runs at normal rev. 5 Slightly regulate the speed of apron feeder according to current of crusher so as to stablized the feeding

NHI / SICHUAN CALCINER COMPAY

39

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence

Inspection and Regulation

1.3.2 Startup sequence of pumice conveying system

No. 1 Operating Sequence Make sure the pumice stackpile at united preblending area is ready for receiving 1 Make sure pumice receiver hopper filled with material. 2 Buffer layer is ready. control room sends out advance warning signal of startup start up dust collecting group 1 231.BF10 start up dust collector. 2 231.BF09 start up dust collector. 3 K11.BF04 start up dust collector. 4 K11.BF03 start up dust collector. start up the group that convey pumice into preblending stockpile. 1 241.BC02a start up discharging car. 2241.BC02start up belt conveyer. 3231.BC05start up belt conveyer. 4231.BC04start up belt conveyer. 5K11.BC02start up belt conveyer. 6 K11.AF01 start up medium-size apron feeder. Inspection and Regulation Check the reserves.

2 3

Inspect on site

Inspect on site

1 .Inspect the motor current and running status of discharging car 2 .Inspect the motor current and running status of belt conveyer.

1.4 Startup sequence of raw coal crushing and conveying

No. 1 Operating Sequence Inspection and Regulation Make sure the raw coal stackpile at united Check the reserves preblending area is ready for receiving 1Make sure raw Inspect on site coal receiver hopper filled with material. 2 Buffer layer is ready. control room sends out advance warning signal of startup

40

2 3

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence start up dust collecting group 1 L11.FN13 L11.BF12start up fanL11.FN13,and then dust collectorL11.BF12. 2 L11.FN11 L11.BF10 start up fanL11.FN11,and then dust collectorL11.BF10. 3 L11.FN09 L11.BF08 start up fanL11.FN09,and then dust collector L11.BF08. 4 L11.FN07 L11.BF06 start up fanL11.FN07,and then dust collector L11.BF06. Start up the group that convey raw coal to preblending stockpile. 1 241.BC01a start up discharging car. 2241.BC01start up belt conveyer. 3L11.BC05start up belt conveyer. 4L11.BC04start up belt conveyer. 5L11.BC03start up belt conveyer. start up raw coal crushing group. 1L11.HC02 Start up ring hammer crusher. 2L11.AF01 start up medium-size apron feeder.

Inspection and Regulation

Inspect on site

1 .Inspect the motor current and running status of discharging car 2 .Inspect the motor current and running status of belt conveyer.

1 Inspect the drive device. 2Notice the startup current 3Notice the temperature at each point. 4 5 Run without load for 5m after it runs at normal rev. 5 Slightly regulate the speed of apron feeder according to current of crusher so as to stablized the feeding

1.5 Startup sequence of united preblending and conveying 1.5.1 Startup sequence of gypsum reclaiming and conveying

NHI / SICHUAN CALCINER COMPAY

41

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No. 1 2

Operating Sequence Make sure gypsum silo is ready for receiving. control room sends out advance warning signal of startup 241.VV141 511VM82 511VM85 511VM81 Push electrical tee valve 241.VV14 to position 1 open electrical butterfly valve 511VM82 511VM85511VM81. start up dust collecting group for gypsum entering silo. 1 511.FN68 511.BF66 start up fan 511.FN68 and then dust collector , 511.BF66. 2 241.BF20 start up dust collector. 3 241.BF19 start up dust collector. start up gypsum reclaiming and conveying group 1511.BC03 start up reversible belt conveyer. 2511.BC01 start up reversible belt conveyer, backward. 3241.BC13start up belt conveyer. 4241.BC12start up belt conveyer. 5241.BC11start up belt conveyer. 6241.RE04 Start up side scraper reclaimer.

Inspection and Regulation Inspect on site, low level of material.

inspect on site and confirm the position

Inspect on site

1 Inspect the motor current and running status of bridge scraper reclaimer. 2 Inspect motor current and running status of belt conveyer. 3 511.BC01 Confirm belt conveyer 511.BC01 backward. ,

1.5.2 Start up sequence of pumice reclaiming and conveying 1.5.2.1 1# Entering pumice silo 1#

No. 1 2 Operating Sequence 1#.Make sure pumice silo 1# is ready for receiving. control room sends out advance warning signal of startup 241.VV141 511VM81 511VM84 511VM87 Push electrical tee valve 241.VV14 to position 1 open electrical butterfly valve511VM81,511VM84,511VM87. Inspection and Regulation Inspect on site, low level of material.

inspect on site and confirm the position

NHI / SICHUAN CALCINER COMPAY

42

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence 1# start up dust collecting group for pumice entering silo 1 511.FN68 511.BF66 start up fan511.FN68, and then dust collector 511.BF66. 2 241.BF20 start up dust collector. 3 241.BF19 start up dust collector. start up pumice reclaiming and conveying group. 1511.BC05 Start up reversible belt conveyer. 2511.BC01 Start up reversible belt conveyer. 3241.BC13start up belt conveyer. 4241.BC12start up belt conveyer. 5241.BC11start up belt conveyer. 6241.RE04 Start up side scraper reclaimer.

Inspection and Regulation

Inspect on site

1 Inspect the motor current and running status of bridge scraper reclaimer. 2 Inspect motor current and running status of belt conveyer. 3 511.BC01 Confirm belt conveyer 511.BC01, forward.

1.5.2.2 2# Entering pumice silo 1#

No. 1 2 Operating Sequence 2# Make sure pumice silo 2# is ready for receiving. control room sends out advance warning signal of startup 241.VV142 511VM83511VM86Push electrical tee valve241.VV14 to position 2 open electrical butterfly valve511VM83,511VM86. 2# start up dust collecting group for pumice entering silo 2#. 1 511.FN68 511.BF66 start up fan 511.FN68 ,and then dust collector511.BF66. 2 241.BF20 start up dust collector. 3 241.BF19 start up dust collector. start up pumice reclaiming and conveying group. 1511.BC04 Start up reversible belt conveyer. Inspection and Regulation Inspect on site, low level of material.

inspect on site and confirm the position

Inspect on site

1 Inspect the motor current and running status of bridge scraper reclaimer.

NHI / SICHUAN CALCINER COMPAY

43

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence 2241.BC13start up belt conveyer. 3241.BC12start up belt conveyer. 4241.BC11start up belt conveyer. 5241.RE04 Start up side scraper reclaimer.

Inspection and Regulation 2 Inspect motor current and running status of belt conveyer.

1.5.3 Startup sequence fo raw coal reclaiming and conveying 1.5.3.1 Reclaiming

No. 1 2 Operating Sequence Make sure raw coal bin is ready for receiving. control room sends out advance warning signal of startup 241.VV081Push electrical tee valve241.VV08 to position 1. Inspection and Regulation Inspect on site, low level of material.

inspect on site and confirm the position 241.VV08 2 If metal detector finds out metals, tee valve 241.VV08 shall be pushed to position 2 and discharge the waste slag.

start up dust collecting group for raw coal entering silo. 1 241.FN18 241.BF17 Start up fan 241.FN18 and then dust collector 241.BF17. (2) 241.FN16 241.BF15 Start up fan 241.FN16 and then dust collector 241.BF15. start up raw coal reclaiming and conveying group. 1 241.MT23 start up metal detector241.MT23. 2241.MD22 Start up iron remover241.MD22. 3241.BC09start up belt conveyer. 4241.BC07start up belt conveyer. 5241.BC06start up belt

Inspect on site

1 Inspect the motor current and running status of bridge scraper reclaimer. 2 Inspect motor current and running status of belt conveyer. 3 Inspect the running status of iron remover. 4

NHI / SICHUAN CALCINER COMPAY

44

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence conveyer. 6241.BC05start up belt conveyer. 7241.RE03 Start up side scraper reclaimer.

Inspection and Regulation Confirm the sensitivity of metal detector.

1.5.3.2 Forklift unloading

No. 1 2 Operating Sequence . Make sure raw coal bin is ready for receiving. control room sends out advance warning signal of startup 241.VV081Push electrical tee valve241.VV08 to position 1. Inspection and Regulation Inspect on

site, low level of material.

inspect on site and confirm the position 241.VV08 2 If metal detector finds out metals, tee valve 241.VV08 shall be pushed to position 2 and discharge the waste slag.

start up dust collecting group for raw coal entering silo. 1 241.FN18 241.BF17 start up fan 241.FN18 and then dust collector241.BF17. 2 241.FN16 241.BF15start up fan241.FN16, and then dust collector241.BF15. 1241.MT23 Start up metal detector. 2241.MD22 Start up iron remover. 3241.BC09 start up belt conveyer. 4241.BC07 start up belt conveyer. 5241.BC06 start up belt conveyer. 6241.BC05 start up belt conveyer. 7241.NG21 Han open rod gate241.NG21.

Inspect on site

1 Inspect the running status of iron remover. 2 Inspect motor current and running status of belt conveyer. 3 Confirm the sensitivity of metal detector.

1.5.6 Startup sequence of raw meal preparation

NHI / SICHUAN CALCINER COMPAY

45

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence 1 Check the material level of raw meal homogenization silo. 2 Confirm the preparation work is done before raw mill run. 1 Make sure it is not low material level for raw material proportioning silo. 2Make sure the raw material conveying system run normally. check the position of valves.

Inspection and Regulation Inform relating department to cooperate with each other.

Check the material level of each silo.

1 valves fully open 2 Regulate opening of valve at inlet of circulating fan 1 Make sure the selected oil pump pipe valves are open. 2 Check the oil temperature of oil tank

start up raw meal conveying system. 1 Start up dust collecting group for conveying raw meal to silo 1331.FN35 start up fan. 2331.BF34 start up dust collector. 3321.BF48 start up dust collector. 4321.BF47 start up dust collector. 2 start up the group that raw meal is fed to silo 1331.BL05start up roots fan. 2331.FN03 Start up chute fan. 3331.BE01 Start up elevator. 4321.FN18 Start up chute fan. 5 321.FN17 Start up chute fan. 6321.FN16 Start up chute fan. 7321.FN15 Start up chute fan. 8321.FN14 Start up chute fan. 9 321.CS10a1 321.CS10a2 Start up airlocking valve. start up circulating system. 1

1 321.VM22 321.VM23321.VM24

NHI / SICHUAN CALCINER COMPAY

46

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence Start up hor air group for raw meal grinding 1321.FN11 Start up circulating fan. 2 Start up control valve of hot air. 2 Start up material circulating group. 1321.FN09start up fan. 2321.BF08start up dust collector. 3 321.BE07 start up elevator. 4321.BC06 Start up belt conveyer.

Warm up machine,gradually increase hot blast volume(fed into mill) while slowly rise the temperature of gas being discharged out of mill.

start up raw meal grinding group 1 Start up heater at lubrication station of main reducer. 2 Start up clutch and let it mesh. 3321.RM03b Roll bearing seal fan. 4321.RM03a Start up raw mill separator. 5 Start up Lv oil pump of main reducer. 6

Inspection and Regulation 321.VM23 321.VM22 321.VM24 Hot blast control valves includes 321.VM22 321.VM23 321.VM24.When hot blast group starts, valve 321.VM23 gradually widen and valve 321.VM22 narrow till production become stable.Cold blast valve 321.VM24 is individually controlled according to the temperature of gas entering mill. 1 Notice the temperature of hot blast at mill inlet. 2 100 Temperature of gas out of mill shall be not more than 100 3 200300Pa Regulate inlet valev of fan, control negative pressure of mill between 200 300Pa. 4 200 300Pa Cooperate with the control to kiln system and waste gas treatment, keep negative pressure of outlet at kiln inlet high temperature fan between 200 300Pa. 5 250When warming up machine, hot blast of mill would not exceed 250 on the premise of keep temperature of gas out of mill. Inspect the mesh of clutch. The ineternal start & stop sequence of the raw meal is only for reference, it is necessary to operate strictly according to the operation manual of the raw meal. Inspect the running status of heater. Inspect the running status of seal fan. Inspect the running status of motor of

47

NHI / SICHUAN CALCINER COMPAY

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence Start up Hv oil pump of main reducer. 7 Start up main drive motor of raw mill. 8 Stop Hv oil pump of main reducer.

Inspection and Regulation Lv oil pump. Notice current,vibration,thin oil station, cooling system of main motor. See operating specification for startup/stop of raw mill.

Start up the system that convey proportioned material at bottom of raw material silo to mill start up dedusting group for conveying proportioned material at bottom of raw material silo to mill 1311.FN17start up fan. 2311.BF16start up dust collector. (2) Start up thr group that convey proportioned material at bottom of raw material silo to mill 1 321.PG02 start up tee airlocking gate. 2( 1) Confirm tee distributing valve(position 1) 3311.MT12 Start up metal detector. 4311.MS11 Start up permanent magnet remover 5311.BC10 Start up belt conveyer. 6311.WF07311.WF08 311.WF09 Start up belt scale. 7311.SQ05 Start up rotary discharger. 8311.NG04311.NG06 start up rod gate. After system become stable, start up auto-regulation loop.

1 Inspect on site 2: Set raw material proportion as per requirements from lab. limestone clay7624 3 321.VV01 2 If metal detector finds out metals, tee valve 321.VV01 shall be pushed to position 2 and discharge the waste slag.

observe the running status of loop.

2. Inspectionandregulationtorunningsystem Crushing system shall be inspected carefully in production, the major items shall be inspected as: table of inspected items

NHI / SICHUAN CALCINER COMPAY

48

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Description 1/3 Minerals in the limestone receiving bin are less than 1/3 of its effective capacity.

Inspection and diagnosis Minerlas havent been carried to the bin for a long time. 1 Storage in the material bin is too little 2 Material bin outlet is blocked up 3 Power of crusher becomes diminished

1 Feeding from the apron feeder is too little.

2 The feeding is too much, material is of moist and big size.

Crusher power becomes high

(3) Temperature of bearing of apron feeder

check the temperature of bearing is high or not.

1 temperature of main bearing of crusher

80 Highest temperature of main bearing is not more than 80 Current should not exceed the rated value for a long time

2Current of main motor

3 Abnormal sound in the running crusher

1 Collision of hammer head and bar grate 2 Anchorage bolts, liner plate bolts and fasteners go loose. 3 Iron piece in machine

operation and regulation 1Shut down apron feeder 2 Check minerals transported into plant. 1 Enhance transporation capactiy. 2 Clear away the block in the material outlet till the feeding becomes normal. Regulate the feeding speed, decrease the feeding properly Find out the cause if the temperature exceeds the expectation, and deal with it Find out the cause if the temperature exceeds the expectation, and deal with it Find out the cause if the current exceeds the rated value, and deal with it. 1 Check out the space between hammer head & bar plate , dispose it at once. 2 Immediately tighten up the loose bolts 3 remove iron piece

NHI / SICHUAN CALCINER COMPAY

49

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Description 4 Oil and ash leakages appear at each part

Inspection and diagnosis Oil seal is damaged, seal at connected part goes loose.

5 Sudden halt of crusher

off-tracking of belt conveyor

Bucket of elevator falls

Elevator shaft or chain breaks

reclaiming fluctuate highly.

operation and regulation Change the oil seal, adjust the seal at connected parts Before the cause is Equipment breaks down or found out, machine should not be forced into motor trips action again Restart should be conducted after material in machine is cleared away. Visitatorial Regulate the drive and inspection return drum pulleys or carrier roller in time (conducted after halted) 1 Stop mill and raw material proportioning conveying system at once 2 Open the inspection The current hole at head and periodically change or obeserve the track. current sharply rises. 3 Open lower inspection hole and observe running status of bucket. 4 Above actions shall be slow. 1 0 Shut Elevator current nearing down the whole system to overhaul 0. 2 Blocking-up at mill discharging opening. 3 Separator current drops. 1 1 Improper angle of reclaimer regulate the angle rake 2

NHI / SICHUAN CALCINER COMPAY

50

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Description

abnormal sound of scraper chain

Inspection and diagnosis 2 many massive material 3 Tightwire rupture or abrased 1 abnormal oil pouring on scraper chain 2 Bad mesh between scraper chain and pulley(head and tail)

operation and regulation inspect relevant crushing system 3 Inspect and repair

1 Inspect the oil level of oil tank and oiling device 2 Regulate the takeup

dust collecting system

overfeeding to mill

10

feeding quantity is insufficient 11

Working state of exhaust air duct reflects the working Visitatorial inspection, and state of dust collector. If eyeballing measurement there is heavy dust at the exhaust air duct, it indicates the machine works abnormally, if soot discharging is in a good state, it shows the effective work of dust collector 1 1 The inlet and outlet subpressure of mill is reduce the overpressure feeding quantity,and 2 small feeding should be Mill is overcurrent running for a period of 3 time Main reducer is overheat 2 Stabilize each parameter values about feeding quantity after normal running 1 the inlet and outlet subpressure of mill are Slowly increase the overpressure feeding quantity till the 2Mill is parameter value is overcurrent. normal.

NHI / SICHUAN CALCINER COMPAY

51

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Description Temperature of gas out of mill is overhigh.

12

13

Temperature of gas out of mill is too low.

Air volume out of mill is too high 14

Air volume out of mill is too low 15

16

Th pressure of mill hydraulic pressure system is insufficient fineness of raw meal

operation and regulation 1 Increase feeding if feeding is little. 2 321.VM24 Broaden opening of cold blast valve 321.VM24 ,if gas temperature is high. 1 Temperature of gas out of mill is too low. 2 321.VM24 321.CS10 321.FN11 The inlet Narrow and outlet sub-pressure of the inlet valve opening double cyclone filter of system fan 321.CS10 are too high 321.FN11 321.CS10 321.FN11 The inlet and outlet sub-pressure of Broaden the inlet valve double cyclone filter are too opening of system fan low. 321.FN11 Pressure gauge shows the pressure Check whether there is is insufficient oil leakage or not laboratory analyze the fineness 1 321.FN11a Regulate opening of valve321.FN11a 2 control speed of separator. Properly cut down the feeding quantity

Inspection and diagnosis Temperature of gas out of mill is overhigh.

17

18

raw meal moisture is higher

laboratory analyze moisture

3. Normalstopsequenceofthesystem 3.1 Stop sequence of limestone, clay crushing and conveying system 3.1.1 Stop sequence of limestone crushing and conveying

No. Operating Sequence Inspection and Regulation

NHI / SICHUAN CALCINER COMPAY

52

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No. 1

Operating Sequence Affirm the range of stop

Inspection and Regulation Check running status of equipment. Empty materials inside.

stop LS crushing group 1211.AF01 stop heavy apron feeder. 2211.HC02 stop hammer crusher. Stop the group for conveying LS to preblending stockpile. 1211.BC03 Stop belt conveyer211.BC03. 2211.BC04 Stop belt conveyer211.BC04 3221.BC01 Stop belt conveyer211.BC04 221.ST02 Stop stacker221.ST02. stop dust collecting group 1211.BF08 Stop dust collector211.BF08. 2211.FN09 Stop fan211.FN09. 3211.BF12 Stop dust collector211.BF12. Overhaul and repair after the system completely stops.

material on belt.

empty the

stop timely to avoid accumulation on belt.

make sure power off.

3.1.2 Stop sequence of clay conveying system

No. 1 Operating Sequence Affirm the range of stop Stop the group for conveying clay to preblending stockpile. 1211.AF05 Stop medium size apron feeder. 2211.BC06 Stop belt conveyer211.BC06. 3211.BC07 Stop belt conveyer211.BC07. 4211.BC04 Stop belt conveyer211.BC04. 5221.BC01 Stop belt conveyer221.BC01. 221.ST02 Inspection and Regulation empty the material on belt.

NHI / SICHUAN CALCINER COMPAY

53

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No.

Operating Sequence Stop stacker221.ST02 stop dust collecting group. 1211.BF10 Stop dust collector211.BF10. 2211.BF11 Stop dust collector211.BF11. 3211.BF12 Stop dust collector211.BF12. Overhaul and repair after the system completely stops.

Inspection and Regulation

stop timely to avoid accumulation on belt.

make sure power off.

3.2 Stop sequence of limestone, clay preblending and conveying system 3.2.1 Stop sequence of limestone preblending and conveying system

No. 1 221.RE03 Stop bridge scraper reclaimer221.RE03. 221.BC04 Stop belt conveyer221.BC04 221.BC07 Stop belt conveyer221.BC07 221.BC08 Stop belt conveyer221.BC08 311.BC01 Stop belt conveyer311.BC01 311.BC03 Stop belt conveyer311.BC03 stop dust collecting group for LS entering silo 1221.BF09 Stop dust collector221.BF09. 2221.FN10 Stop fan 221.FN10. 3311.BF18 Stop dust collector311.BF18. 311.BF13 Stop dust collector311.BF13. Overhaul and repair after the system completely stops. Operating Sequence Affirm the range of stop Inspection and Regulation check running status of equipments 1 see operating specification for startup/stop of reclaimer. 2 empty the material on belt.

stop timely to avoid accumulation on belt.

make sure power off.

3.2.2 Stop sequence of clay preblending and conveying

NHI / SICHUAN CALCINER COMPAY 54

3000t/d Cement Projectof National Cement Share Company,Ethiopia

No. 1

Operating Sequence Affirm the range of stop

stop clay reclaiming and conveying group 1221.RE05 Stop side scraper reclaimer221.RE05. 2221.BC06 Stop belt conveyer221.BC06. 3221.BC07 Stop belt conveyer221.BC07. 4221.BC08 Stop belt conveyer221.BC08. 5311.BC01 Stop belt conveyer311.BC01. stop dust collecting group for clay entering silo 1221.BF09 Stop dust collector221.BF09. 2221.FN10 Stop fan221.FN10. 3311.BF18 Stop dust collector311.BF18. 4311.BF14 Stop dust collector311.BF14. 311.FN15 Stop fan 311.FN15. Overhaul and repair after the system completely stops.

Inspection and Regulation check running status of equipments 1 see operating specification for startup/stop of reclaimer. 2 empty the material on belt.

stop timely to avoid accumulation on belt.

make sure power off.

3.2.3 Stop sequence of high quality LS preblending and conveying system