Professional Documents

Culture Documents

PF Proposed Hand-Over Meeting

Uploaded by

jayeshjpillaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PF Proposed Hand-Over Meeting

Uploaded by

jayeshjpillaiCopyright:

Available Formats

PROPOSED VISUAL DISPLAY BOARD AND SHIFT HAND-OVER MEETING

01 March 2008

Proposed PF Visual Display Board & Shift Hand-over Meeting

Significance:

Communication gaps can result to production downtime/delays. Communication gaps can lead to serious mistakes. Communication is becoming more critical as we move into multi-product manufacturing.

Proposed PF Visual Display Board & Shift Hand-over Meeting

AS IS:

Two shift hand-over. One between out-going and in-coming shift leads. Another one between outgoing and in-coming supervisor or Lead Tech. Very little participation from the technicians. No participation from Maintenance Technician. Team members knows very little of what is happening in other modules. Weak team engagement. Very distracting. Too many interference.

(radio & phone calls, late comers).

Proposed Visual Display Board & Shift Hand-over Meeting

TO BE:

To have a single shift hand-over meeting. To centralize the display board to provide a one stop overview of the plant daily shift performance. To use the display board as a tool for shift handover meeting. To create ownership/accountability of metrics. To improve the hand-over of information (ie. work instructions, learning's, other communication.) To improve team engagement.

TO BE:

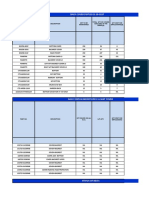

PF-1 VISUAL DISPLAY BOARD

Guidelines Safety Quality Supply / Productivity Report Team Engagement

Meeting Agenda Shift Lead

Safety Daily report Shift Lead

Quality Event / Atypical daily report Shift Lead

Dispensing Shift Output Technician

TCM-710 Compression Shift Output Technician

Kaizen Submission All

Work Instructions / Communication Shift Lead

Safety talk

Shift Lead

Meeting Dos & Don'ts Shift Lead

Safety Incident report Shift Lead

cGMP / GDP daily report Shift Lead

Charging Shift Output Technician

TCM-720 Compression Shift Output Technician

Work Assignment Shift Lead

Work cGMP / GDP Instructions / talk Communication Shift Lead

Shift Lead

Other Metrics

Shift Lead

RFT report

Shift Lead

HSM Shift Output

Technician

TCM-730 Compression Shift Output Technician

Shift Attendance

Shift Lead

Work Instructions / Communication Shift Lead

5 S talk Shift Lead

3 ROWS DESIGN. USING A4 SIZE PAPER

TO BE: SHIFT HAND-OVER MEETING AGENDA:

Safety Shift Lead Safety daily report (traffic light) Incident/Accident report (brief) Quality Shift Lead Event / Atypical Report. 5 Why? Productivity Technician Production output (qty, yield). Downtime hours. Why? Work order status. On schedule or behind schedule, how many days? Team Engagement Shift Lead Kaizen submission by technician Work instruction / communication Safety talk cGMP / GDP talk 5 S talk

TO BE: SHIFT HAND-OVER MEETING AGENDA:

Required to attend from out-going shift Shift Lead Shift Supervisor 1 Technician from each module Maintenance Technician Required to attend from in-coming shift All. Including Maintenance Technician. Except technicians assigned to take-over the module Hand-over procedure - 1 to 1 (To take place at the module) Step 1 - The in-coming shift lead shall assign a technician to take-over the modules that cannot stop operation. A 1 to 1 hand-over shall take place at the module. Step 2 - Module out-put, issues encountered shall be discussed in brief. MPD and clean & usage log shall be checked by the in-coming technician for completeness. This action would help drive the reduction of GDP errors.

TO BE: SHIFT HAND-OVER MEETING AGENDA:

Hand-over procedure Group (To take place at the Visual Board) Step 1 The out-going Shift Lead shall report the safety performance. To discuss in brief any incident report. Step 2 The out-going shift Lead shall report the quality performance. To discuss in brief any event or atypical. Step 3 The out-going shift technician (designated for each module) shall report the production performance. To explain brief why target is not met & any issue. Step 4 The out-going shift lead shall report any new instructions/communications. Step 5 The out-going shift can leave. Step 6 The in-coming shift lead shall continue with the meeting to discuss the days work assignment, safety talk, cGMP talk and 5 S talk & any CI suggestions. Step 7 - End the meeting.

TO BE: SHIFT HAND-OVER GROUD RULES:

Meeting Ground Rules

1. Be on-time.

Responsibility

All Out-going shift All All All All

2. Update the visual display board before meeting starts. 3. Provide full attention. One meeting policy.

4. Switch-off walkie talkie.

5. Speak clearly.

6. Lengthy discussion shall be placed on a parking lot.

Meeting Timing: Morning - 7:30am to 7:45am Night - 7:30pm to 7:45pm

Meeting Venue: Visual Display Board

SAFETY REPORTING

Safety Traffic Light Daily Reporting

Date

01 March

02 March

Team

A B C D

Status

Remarks

IBC lid drop-out. Walkie stacker hit the wall.

RED YELLOW GREEN

ACCIDENT / LOST TIME INCIDENT or NEAR MISS NO ISSUE

QUALITY REPORTING

Quality Daily Reporting

Event / Atypical Daily Reporting

Date

01 March 08 02 March 08

Team

A B C D

# of Event/Atypical Raised

2 1 0 1

To report in brief any event or atypical

GMP / GDP Traffic Light Daily Reporting

Date

01 March

02 March

Reported by

Tan Peter John Robert

Status

Remarks

IBC # 007 - Missing entry on the clean & usage log . MPD - Section C, over-writing.

To be checked & reported by out-going shift. 1. 2. MPD check for previous shift. Clean & usage log check for previous shift

RED YELLOW GREEN

cGMP / GDP NON-CONFORMANCE NEEDS IMPROVEMENT NO ISSUE

PRODUCTIVITY REPORTING

Productivity Reporting

USE EXISTING FORMS

To add a shift target for compression. Example: TCM 710 = 10 drums per shift TCM 720 = 15drums per shift. Or Strength, 10/10 = 10 drums per shift Strength, 10/20 = 15 drums per shift

TEAM ENGAGEMENT REPORTING

Team Engagement Reporting

Kaizen submission tracking TEAM D

Jan Feb March April May

Submitted

NO NAME

Implemented

Submitted

Implemented

Submitted

Implemented

Submitted

Implemented

Submitted

Implemented

1 2 3 4 5 6 7 8 9 10 11 12

Azman Husin Niranjan Kumar Chen Yu Min, Richard Hou Fang Tao, Hoft Ooi Kim Seong Lim Hwee Kiang Yusainie Bin Rahmat Lee Teck Hock Angelo Udayan Heng Wei Jie Rajesh Umakanthan

IIII

II

Total number of suggestions is to be use as a performance appraisal target.

Team Engagement Reporting

Period: 11 April - 27April Dispensing & Charging High Shear Module Compression Others

Chen Y M (Lead) Lim W K Rajesh

LEE (Lead) Udayan Heng W J Azman (Mentor)

Kumar (Lead) Ooi Hoft Yus

Azman

(Compression leaning/Other assignment to swap with Kumar or Ooi)

Period: 30 April - 15 May Dispensing & Charging High Shear Module Compression Others

LEE (Lead) Udayan Heng W J

Chen Y M (Lead) Lim W K Rajesh Pairin (Mentor)

Kumar (Lead) Ooi Hoft Yus

Azman

(Compression leaning/Other assignment to swap with Kumar or Ooi)

Team Engagement Reporting

Safety, GMP & 5 S Talk

A THEME based communication. Example: Safety Basic PPE GMP Rule # 1. 5 S Sort

The THEME shall remain the same for 1 week and change every week. This would help drive awareness and behavior change

VIDEO

TO BE:

PF-1 VISUAL DISPLAY BOARD

Guidelines Safety Quality Supply / Productivity Report Team Engagement

Meeting Agenda

Shift Lead

Safety Daily report

Shift Lead

Quality Event / Atypical daily report

Shift Lead

Dispensing Shift Output

Technician

TCM-710 Compression Shift Output

Technician

Kaizen Submission

All

Safety talk

Shift Lead

Meeting Dos & Don'ts

Shift Lead

Safety Incident report

Shift Lead

cGMP / GDP daily report

Shift Lead

Charging Shift Output

Technician

TCM-720 Compression Shift Output

Technician

Work Instructions / Communication

cGMP / GDP talk

Shift Lead

Other Metrics

Shift Lead

RFT report

Shift Lead

HSM Shift Output

Technician

TCM-730 Compression Shift Output

Technician

Shift Attendance

5 S talk

Shift Lead

3 ROWS DESIGN. USING A4 SIZE PAPER

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Railway TimeDocument1 pageRailway TimejayeshjpillaiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 5 Whys Training Oct 12 2011Document23 pages5 Whys Training Oct 12 2011jayeshjpillaiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Measuring Your Process Capability: PreambleDocument13 pagesMeasuring Your Process Capability: PreamblejayeshjpillaiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Kerala Govt FundingDocument56 pagesKerala Govt FundingjayeshjpillaiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- VAT TaxDocument8 pagesVAT Taxsankar_rao333No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Pachakkari KrishiDocument58 pagesPachakkari Krishijayeshjpillai100% (2)

- KVATDocument147 pagesKVATjayeshjpillaiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Standardized Work and Problem SolvingDocument34 pagesStandardized Work and Problem Solvingjayeshjpillai100% (3)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PoP Adhoc OrganicDocument209 pagesPoP Adhoc OrganicummuzzzNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Introduction To Materials and Processes PDFDocument0 pagesIntroduction To Materials and Processes PDFjayeshjpillaiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- MSC Application Booklet For NUSDocument52 pagesMSC Application Booklet For NUSjayeshjpillaiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Malayalam Translation of World Famous Totto ChanDocument108 pagesMalayalam Translation of World Famous Totto Chanjayeshjpillai50% (6)

- How To Measure Flatness With Optical FlatsDocument3 pagesHow To Measure Flatness With Optical FlatsmanchiprasadNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Low Cost Green Houses For Vegetable ProductionDocument19 pagesLow Cost Green Houses For Vegetable Productionqfarms100% (2)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Adujeevitham by BenyaminDocument103 pagesAdujeevitham by BenyaminjayeshjpillaiNo ratings yet

- Beginners Guide To CorrosionDocument10 pagesBeginners Guide To Corrosionshamu081No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Requirements For Urban Buses in New ZealandDocument48 pagesRequirements For Urban Buses in New ZealandasdfNo ratings yet

- Cover Status Report - Latest 03-10-2017Document15 pagesCover Status Report - Latest 03-10-2017Anonymous PP9ecXDBNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Chapter 5 BridgesDocument78 pagesChapter 5 BridgesWendimu TolessaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tentative CatalogueVIJ20191226206Document42 pagesTentative CatalogueVIJ20191226206VamshiNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Chapter 9 HighwayDocument25 pagesChapter 9 HighwayBeau NorNo ratings yet

- AGPT05 19 Guide To Pavement Technology Part 5 Pavement EvaluationDocument274 pagesAGPT05 19 Guide To Pavement Technology Part 5 Pavement Evaluationwilly praviantoNo ratings yet

- Rfi Report - For IcDocument5 pagesRfi Report - For IcGera Amith KumarNo ratings yet

- RRL Transpo Catarungan-SerraDocument4 pagesRRL Transpo Catarungan-Serrakyle catarunganNo ratings yet

- Around Madeira by Bus GuideDocument44 pagesAround Madeira by Bus GuideSosonanaNo ratings yet

- Travel Demand ManagementDocument27 pagesTravel Demand ManagementPranav MishraNo ratings yet

- Last Clear Chance - Raynera Vs HicetaDocument4 pagesLast Clear Chance - Raynera Vs HicetaanamergalNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- 18 Primax Deflectometro Lineal de Impacto PDFDocument12 pages18 Primax Deflectometro Lineal de Impacto PDFLan LavistoNo ratings yet

- HW1 F15Document1 pageHW1 F15Prasanth Kumar Yadav0% (2)

- Gross, S., Klemmer, L. (Eds.) - Introduction To Tourism Transport-CABI (2014)Document250 pagesGross, S., Klemmer, L. (Eds.) - Introduction To Tourism Transport-CABI (2014)Camila Teixeira50% (2)

- Chandni Chowk Redevelopment Plan: Red Fort To Fatehpuri Masjid Road StretchDocument21 pagesChandni Chowk Redevelopment Plan: Red Fort To Fatehpuri Masjid Road StretchSania MehraNo ratings yet

- Asphalt - Hot Mix Design - MarshallDocument61 pagesAsphalt - Hot Mix Design - MarshallMizanul Hoque100% (1)

- The Implementation of API RP 1102 Code To Evaluate Gas Pipeline Road CrossingDocument10 pagesThe Implementation of API RP 1102 Code To Evaluate Gas Pipeline Road CrossingRagil Siswo UtomoNo ratings yet

- Task Risk Assessment For Sign Boards InstallationDocument19 pagesTask Risk Assessment For Sign Boards InstallationVenkadesh Periathambi100% (5)

- By: Engr. Renz Wilson Libatique Etrata, May 2017: Contractual, Management, and Quality Aspects of ConstructionDocument7 pagesBy: Engr. Renz Wilson Libatique Etrata, May 2017: Contractual, Management, and Quality Aspects of ConstructionKier Lorenz FernandezNo ratings yet

- Example Proposal TemplateDocument12 pagesExample Proposal TemplateNur HazimahNo ratings yet

- Road Design: 3.1 Horizontal and Vertical AlignmentDocument53 pagesRoad Design: 3.1 Horizontal and Vertical Alignmentfatinaainaa100% (1)

- BCA Investigation: Shop/Office - Clarendon ST, South MelbourneDocument23 pagesBCA Investigation: Shop/Office - Clarendon ST, South MelbourneDean DL Leeson100% (1)

- Boq No. Particulars Unit BOQ QTY Basic Rate Basic AmountDocument18 pagesBoq No. Particulars Unit BOQ QTY Basic Rate Basic AmountmanojNo ratings yet

- Honda Siel Project ReportDocument97 pagesHonda Siel Project ReportPavan KhandelwalNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tsclist PDFDocument112 pagesTsclist PDFRatanSinghSinghNo ratings yet

- Final ReportDocument26 pagesFinal Reportdishant1992No ratings yet

- Austroads Research ReportDocument49 pagesAustroads Research ReportyasNo ratings yet

- Construction Protection Plan: For Historic PropertiesDocument62 pagesConstruction Protection Plan: For Historic PropertiesMohd AfifNo ratings yet

- NavathirupathiDocument5 pagesNavathirupathiE.C.MADHUDUDHANA REDDYNo ratings yet