FITTING PRESENTATION

Prepared by: INSTRUMENT CENTRAL 21 June 2011

�END USER

Drilling : Hydraulic control line

- Sub surface safety valve

PGF

: Power Generation

- Hydraulic System - Pneumatic System

Prod

: Process & remote platform

- Hydraulic System - ESD & Control System

- Chemical Injection System

�BUSINESS UNIT

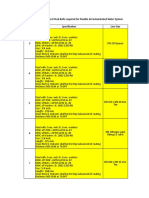

OIL & GAS PROCESS PLATFORM 1. ESD Panel ( range 0-150 PSIG) 2. Process Control ( range 0 150 PSIG ) 3. Chemical Injection Line ( range 0 1500 PSIG ) 4. Fire Pump ( range 0 200 PSIG ) 5. Hydraulic System ( range 0 - 6000 PSIG) REMOTE PLATFORM 1. ESD Panel ( AUTOCON Panel ) ( range 0-150 PSIG) a. ESD & Alarm System ( range 0 150 PSIG) b. Hydraulic system ( range 2000 3000 PSIG) c. Process Control System ( range 0 - 150 PSIG) 2. Chemical Injection System ( range 0 1500 PSIG) 3. Fire Protection System ( range 0 - 200 PSIG)

�316 Stainless Steel Tube Fittings

Female Nut Swagelok

Back Ferrule Swagelok

Front Ferrule Swagelok Front Ferrule Swagelok

Female Nut Gyrolok

Back Ferrule

Gyrolok

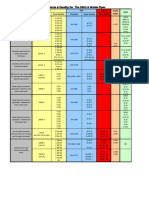

�Gyrolok Vs Swagelok

Back ferrule Gyrolok T Back ferrule Swagelok T

Front ferrule Gyrolok T

Front ferrule Swagelok T

Back ferrule Gyrolok T Front ferrule Gyrolok 1/4 T Front ferrule Gyrolok T

Back ferrule Swagelok T

Front ferrule Gyrolok 3/8 T Back ferrule Gyrolok 3/8T

Front ferrule Gyrolok T

Back ferrule Swagelok 3/8T

�Surface Hardening Methods Used in Tube Fitting (Swagelok)

316 SS Advanced Swagelok Tube Fitting Prior to Make-up

The elements of the fitting are depicted in cross-section prior to make up: the fitting nut (top), the advanced geometryback ferrule (left), the front ferrule (center), and the fitting body (right). The tube wall section is shown below the ferrules and body.

316 SS Advanced Swagelok Tube Fitting After to Make-up

During make-up, the front ferrule (center) is driven into the body of the fitting (right) and the tube (bottom) to create primary seals (tube and body), while the back ferrule (left) hinges inward to create a strong grip on the tube. The rear ferrule geometry allows for an improved engineering hinging action that translates axial (forward) motion into radial swaging action on the tube, yet operates with a low input force (torque) requirement. The improved radial colleting action of the back ferrule (the area to the left of the swage point) isolates and protects the swaged area of the tube, preventing the exposed vibration stress riser that is typical of bite-type fittings.

�Ordering Information

�Ordering Information (CONT)

Material Designator A = Aluminum B = Brass C20 = Alloy 20 HC = Alloy C-276 INC = Alloy 600 M = Alloy 400/R-405 NY = Nylon S = Steel SS = Stainless Steel T = PTFE TI = Titanium

Tube Size Designator 1 = 1/16 in.

2 = 1/8 in.

3 = 3/16 in. 4 = 1/4 in. 5 = 5/16 in. 6 = 3/8 in. 8 = 1/2 in.

10 = 5/8 in.

12 = 3/4 in. 16 = 1 in. 20 = 1 1/4 in. 24 = 1 1/2 in. 32 = 2 in.

Fitting Series Designator

0 = Fractional 1/16 to 3/8 in. and 1 1/4 to 2 in. 1 = Fractional 1/2 to 1 1/8 in. M = Millimeter tube size F = Female Swagelok tube fitting

Component Designator

0 = Fitting

1 = Body 2 1 = Nut 3 1 = Front ferrule 4 1 = Back ferrule

�Ordering Information (CONT)

Type of Fitting Designator 1 = Male connector 2 = Male elbow 3 = Tee, union 3TTF = Tee, female union 3TFT = Tee, female run 3TTM = Tee, male branch 3TMT = Tee, male run 4 = Cross, union 5 = 45 male elbow 6 = Union 6 = Reducing union 7 = Female connector 8 = Female elbow 9 = Elbow, union 9 = Elbow, reducing union 11 = Bulkhead male connector 61 = Bulkhead union 71 = Bulkhead female connector A = Adapter PC = Port connector PC = Reducing port connector R1 = Bulkhead reducer C = Cap P = Plug R = Reducer

End Connection Designator

AN = 37 male AN flare ANF = 37 female AN flare BT = Bored-through fitting GC = Gas chromatograph fitting F = Female thread K = Knurled nut KN = Knurled nut, nylon ferrules LV = Low-volume chromatograph fitting M = Metric tube ending OR = O-seal connection RP = ISO parallel pipe thread RG = ISO parallel pipe thread (gauge) RT = ISO tapered pipe thread ST = Straight thread with O-ring (for SAE/MS) W = Male pipe weld/tube socket weld ZV = Zero-volume chromatograph fitting Numeral = Size of second end

�Surface Hardening Methods Used in Tube Fitting ( Gyrolok)

CONTROLLED FERRULE DRIVE

Provides maximum user safety under high pressure/ vibration conditions. Prevents overstressing, which causes tubing failure and possible injury. System efficiency is improved by maximizing flow. Provides unmatched remake life. Maximizes value and economy.

GYROLOK SAFETY CHANGER NUT AND FERRULE SETS.

Safest, simplest device for component replacement

SILVERPLATED NUT THREADS

Extended product life at extreme temperatures (-325 F to +800 F)

PFA FERRULE COATING

Increased resistance to media and atmospheric corrosion

�Unit of measure/end connector codes Gyrolok

Examples: 4CM4 316 = 1/4 tube x 1/4 NPT male connector, 316 stainless steel 6RU3 BR ME = 6mm tube x 3/16 tube reducing union, brass

8LM4 316 EC = 1/2 tube x 1/4 male RT, male elbow, 316 stainless steel

�Unit of measure/end connector codes (cont)

1. The first number (4) identifies the tube O.D. size. For example, 4 = 4/16 for fractional fittings. 4 = 4mm for metric fittings. If there is no 5th group, sizes are fractional. 2. The letter group, (CM) identifies the type of fitting (Male Connector). See fitting locator, pages 2 and 3. 3. The third group, a number (4), is only necessary if the second tube connection size is different from the first tube O.D. size. For pipe sizes, a number is always required. 4. Material is identified in the fourth group. 5. With the exception of branch tees, the fifth group, if present, contains two letter codes. The first letter designates the unit of measure for the first number in the part numberie, E for fractional, M for metric. The second letter indicates the unit of measure (E or M), or thread type, for the second number in the part number. If there is no 5th group, all sizes are fractional.

�Unit of measure/end connector codes (cont)

6. Tee part numbering: TEES are described by first the run (1 and 2) and next the branch (3), for example: - TTM describes a tee that has tube connections at 1 and 2 and a male pipe thread at position 3. - TFT describes a tee that has tube connections at 1 and 3 and a female pipe thread at position 2. 7. Fittings cleaned for oxygen service: To order, add HPS 18 to the end of basic fitting part number. Example: 4CM4 316 HPS 18

8. Fittings cleaned for nuclear service: To order, add HPS 90 to the end of basic fitting

part number. Example: 4CM4 316 HPS 90 9. O-ring designator Viton R (45) is standard for SAE fittings. In the event no material is specified, Viton will be supplied. Buna (21) is standard for other fittings with Orings. Alternative O-ring materials are available, including silicone (01), and Buna-N (23). Example 6CMS631623

�Ferrule ( )

Swagelok

Gyrolok

�END OF PRESENTATION

THANKS