Professional Documents

Culture Documents

Analytical Methods MSE528: Chemical Analysis Structural Analysis Physical Properties

Analytical Methods MSE528: Chemical Analysis Structural Analysis Physical Properties

Uploaded by

CLPHtheoryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analytical Methods MSE528: Chemical Analysis Structural Analysis Physical Properties

Analytical Methods MSE528: Chemical Analysis Structural Analysis Physical Properties

Uploaded by

CLPHtheoryCopyright:

Available Formats

Analytical Methods

MSE528

Chemical analysis

Structural Analysis

Physical Properties

X-Ray method

Laue Techniques: rotating Xtal

Debye-Scherrer: Powder Method

Diffraction

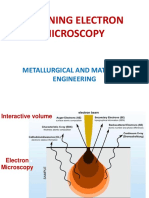

Electron Microscope

Transmission Electron Microscope (TEM)

Scanning Electron Microscope (SEM)

SPM & AFM

Microanalysis: EDAX, AES and XPS

X-Ray method

Laue Techniques: rotating Xtal

Debye-Scherrer: Powder Method

Diffraction

X-ray powder diffraction (XRD) is one of the

most powerful technique for qualitative and

quantitative analysis of crystalline

compounds. The technique provides

information that cannot be obtained any

other way. The information obtained includes

types and nature of crystalline phases

present, structural make-up of phases,

degree of crystallinity, amount of amorphous

content, microstrain & size and orientation of

crystallites.

X-ray diffraction has application in most fields dealing with solid

materials. XRD identifies crystalline compounds as opposed to X-ray

Fluorescence (XRF) or other spectro-chemical methods that identifies

just the elements. Areas of application are quite wide and include

metals, organic and inorganic compounds.

Some of the relevant areas are listed and discussed below:

Airborne dusts and particulate

Hazardous Inorganic chemicals

Asbestos

Metals

Biomaterials

Pharmaceuticals

Catalysts

Polymers

Ceramics and Composites

Rocks and minerals

Clays & Soils

Semiconductors

Corrosion Products

A schematic of typical optics is shown below.

Typically for a fine filament tube the filament length Lx is 12-16mm and its width Wx is 0.04mm.

nl = 2d sin q

In the scanning electron microscope (SEM) a very fine 'probe' of

electrons with energies up to 40 keV is focused at the surface of the

specimen in the microscope and scanned across it in a 'raster' or pattern

of parallel lines. A number of phenomena occur at the surface under

electron impact: most important for scanning microscopy are the

emission of secondary electrons with energies of a few tens eV and re-

emission or reflection of the high-energy backscattered electrons from

the primary beam. The intensity of emission of both secondary and

backscattered electrons is very sensitive to the angle at which the

electron beam strikes the surface, i.e. to topographical features on the

specimen. The emitted electron current is collected and amplified;

variations in the resulting signal strength as electron probe is scanned

across the specimen are used to vary the brightness of the trace of a

cathode ray tube being scanned in synchronism with the probe. There is

thus a direct positional correspondence between the electron beam

scanning across the specimen and the fluorescent image on the cathode

ray tube.

The magnification produced by scanning microscope is the ratio between

the dimensions of the final image display and the field scanned on the

specimen. Usually magnification range of SEM is between 10 to 200 000

X. and the resolution (resolving power) is between 4 to 10 nm (40 - 100

Angstroms) .

How the SEM Works

The SEM uses electrons instead

of light to form an image. A

beam of electrons is produced

at the top of the microscope by

heating of a metallic filament.

The electron beam follows a

vertical path through the column

of the microscope. It makes its

way through electromagnetic

lenses which focus and direct

the beam down towards the

sample. Once it hits the sample,

other electrons ( backscattered

or secondary ) are ejected from

the sample. Detectors collect the

secondary or backscattered

electrons, and convert them to a

signal that is sent to a viewing

screen similiar to the one in an

ordinary television, producing

an image.

JEOL JSM-7500

Mag: 25 to 1,000kX

kV: 0.1 to 30kV

SEI: 1.0nm (15kV)

SEI: 1.5nm (1kV)

SEI: 4.0nm (0.1kV)

BEI*: 1.5nm (5kV)

BEI*: 1.7nm (3kV)

GB mode / r-filter / in-

lens BSE Detector

Highlights of the 7500F

5 axis tilt eucentric stage with automation standard on

all axes including compeucentric rotation.

Smooth mechanical stage movement at high mags via

TEM trackball & touch pad

Great low kV SE, low kV BSE and STEM Imaging

Enhanced environmental resistance

GB Mode and in column SE energy filter

In lens BSE Detector for ultra high res. BSE imaging

LABE detector

r-Filter

26

Live Image Comparison

The main image window can also be a live split or live quad display of

different detector signals with independent control of each signal

27

Specimen

stub Specimen

Electron probe

Electron

Electron probe

Gentle Beam

Reduces the effect of charging

28

Gentle Beam

Increases resolution by maintaining higher kV in the

gun & column. (Reduces Aberrations)

Accelerates secondary electrons off the sample,

especially at very low accelerating voltages.

Reduces charging.

Reduces contamination.

Lowers the kV to the sample increasing pure surface

topographic detail due to reduced beam penetration.

29

Gentle Beam

1KV X100,000 1KV X100,000

SEM Mode Resist Lines & Spaces Gentle Beam Mode

30

0.1kV in GB mode

50,000X 200,000X

Mesoporous Silica

Ultra-High Resolution SEM JSM-7500F

31

STEM Data

C Nano Tubes

32

EDS Spot Analysis in STEM

Sample: Carbon nanotube with catalyst particles

Mag: x 220,000

Acc. Voltage: 30kV

Imaging mode: STEM

EDS spot analysis clearly distinguishes between

Fe-containing catalyst particles (Spot A) and

carbon nanotube matrix (Spot B)

33

Electron Spectroscopy for Chemical Analysis (ESCA) or

X-ray Photoelectron Spectroscopy (XPS)

In a failure analysis technique primarily used in the identification of compounds on

the surface of a sample. It utilizes X-Rays with low energy (typically 1-2 keV) to

knock off photoelectrons from atoms of the sample through the photoelectric

effect. The energy content of these ejected electrons are then analyzed by a

spectrometer to identify the elements where they came from.

The incident X-Rays used in knocking off the electrons must possess energy that is

both monochromatic and of accurately known magnitude. The X-ray source

material must also be a light element since X-ray line widths, which must be as

narrow as possible in ESCA, are proportional to the atomic number of the source

material. It is for these reasons that commercial XPS systems typically use the K-

alpha X-rays of aluminum (Al K-alpha E = 1.487 keV) and magnesium (Mg K-alpha

E = 1.254 keV).

Schematic representation of the energies produced

from electron beam interaction with solid matter.

Luminescence is the emission of light from a solid

which is 'excited' by some form of energy. The term

broadly includes the commonly-used categories of

fluorescence and phosphorescence.

Field Emission Scanning Electron Microscopy (FESEM) is a

high-resolution imaging technique providing topographical and

structural information in plan view or in cross-section. Often

used in conjunction with SEM, Energy Dispersive X-Ray

Spectroscopy (EDX) is used to qualitatively and quantitatively

analyze the elements present in a selected area of the SEM

image. Together FE-SEM and EDX capabilities allow the

irradiation by a focused electron beam, imaging secondary or

backscattered electrons and energy analysis of x-rays.

Typical SEM applications include plan view and cross-sectional

imaging for process development and failure analysis. EDX

applications include specific defect analysis or compositional

analysis (for boron and heavier elements).

2.1nm resolution at 1kV

1.5nm resolution at 15kV

Cold finger and specimen exchange chamber

as standard

Optional integrated EDX system with 30

degree take-off angle

Fully digital imaging, image processing and

archiving system

Dual SE detectors for versatile imaging

New ExB energy filter

Compositional analysis

Elemental

Chemical

Electron diffraction/crystalographic

identification

Phase identification

Silicon devices

Precise Location

Compound semiconductors

Magnetic disks

Film Thickness

Gate Ox thickness

III - IV Superlattice

Step coverage

Gate Ox thickness

Gate to Silicon Interface

Interfacial oxide

Chemical analysis (microanalysis) in the scanning

electron microscope (SEM) is performed by measuring

the energy or wavelength and intensity distribution of X-

ray signal generated by a focused electron beam on the

specimen. With the attachment of the energy dispersive

spectrometer (EDS) or wavelength dispersive

spectrometers (WDS), the precise elemental

composition of materials can be obtained with high

spatial resolution. When we work with bulk specimens in

the SEM very precise accurate chemical analyses

(relative error 1-2%) can be obtained from larger areas

of the solid (0.5-3 micrometer diameter) using a n EDS

or WDS. Bellow is a example of EDS spectrum collected

in the SEM with EDS. The spectrum shows presence of

Al, Si, Ca, Mn and Fe in the steel slag phase.

Scanning Acoustic Microscopy (SAM) is an excellent technique for studying

buried solid interfaces of dissimilar materials. SAM is an internal imaging

analysis technique produced via ultrasonic waves reflecting or transmitting

at sample interfaces. The images are constructed by detecting reflection

(echo) or transmission of ultrasound from a solid state device shortly after

pulse-excitation by a focusing transducer. Features such as bonded

interfaces, density gradients or defects (delaminated interfaces, voids and

cracks) can be imaged non-destructively.

FTIR application

What is FTIR?

Applications of FTIR (general)

Applications of FTIR for semiconductor

industry

Remarks

FTIR

Fourier Transform Infrared Spectroscopy

Used for identifying or characterizing

organic (and some inorganic) compounds

(solid, powders, residues, solvents, liquids,

gas)

IR radiation is absorbed/transmitted;

resulting spectrum characteristic of

molecular structure

FTIR

Fingerprint type method (no 2 are same)

Detection of individual chemical compounds

or characteristic absorptions of chemical

functional groups (organic and some

inorganic)

Detection limit: picogram range

(monomolecular layers detectable on metal

surfaces)

Qualitative, quantitative

Reference libraries, spectral interpretation

Sampling techniques: transmission,

external reflection, internal reflection (ATR),

diffuse reflection, emission, and

photoacoustic spectroscopy

Detectors: triglycine sulfate (TGS), mercury-

cadmium-telluride (MCT)

FTIR with microscope

General Applications

Identify unknown compounds

-e.g. plastics, drugs (i.e. cocaine),

contamination (i.e. flux residues,

silicone, esters, grease, etc.)

Obtain structural information (organic functional groups)

-e.g. alkanes, alkenes, alkynes, aromatics, alcohols,

ethers, amines, aldehydes and ketones,

carboxylic acids, amides, etc.

Common uses in semiconductor

industry

Determination of interstitial oxygen and substitutional carbon

in processing wafers

Epitaxial film thickness measurements

Monitoring phosphorus in phosphosilicate thin films and both

phosphorus and boron in borophosphosilicate thin films

Measurement of the hydrogen content in oxide and nitride thin

films

Identification of particles and residues (most common)

Incoming materials characterization

Trace gas analysis

Carrier concentration measurements

Characterization of Si surfaces after cleaning operations

Measurement of Interstitial Oxygen

and Substitutional Carbon in Si

Wafers

Si-C, Si-O-Si

Advantages of FTIR for measurement of Cs

and Oi

Non-destructive

Cheaper

Faster

Reproducible

Sensitive (to dopants)

Excellent spatial resolution (5-10 um)

Specific to the Oi and Cs in Si

Epitaxial Film Thickness Applications

To determine epitaxial (Epi) layer film thickness

(the most commonly used high-resistivity Epi

layers are transparent to IR radiation)

3 methods (constant-angle observations making

use of either direct or modified measurement of

interference phenomena):

1) Interferogram Subtraction

2) Constant Angle Reflection Interference Spectroscopy

3) Cepstrum

Interferogram Subtraction

Constant Angle Reflectance

Interference

Advantages of FTIR for Epi thickness

measurements

speed of measurement

Non-destructive

Reproducible

Lends itself to automation

Operator independent

Particle/residue identification in Failure Analysis

Remarks

Many applications

May use other instruments/tools/techniques to

obtain additional information or confirmation

Relatively cheap, quick, accurate, internally

calibrated (self-calibrated)

Even with software and automation, still

recommend a chemist familiar with spectral

interpretation

You might also like

- SEM and TEM NotesDocument7 pagesSEM and TEM NotesVarshini Rajkumar100% (5)

- Principios de La MEBDocument27 pagesPrincipios de La MEBFernando Iván MedinaNo ratings yet

- Scanning Electron Microscopy (SEM) : Do It With Electrons !Document85 pagesScanning Electron Microscopy (SEM) : Do It With Electrons !Liza Sri MarningsihNo ratings yet

- Bab 7 6 Characterization 03 SEM and TEMDocument63 pagesBab 7 6 Characterization 03 SEM and TEMPutrik AgustinaNo ratings yet

- Syllabus 300620200523100605Document33 pagesSyllabus 300620200523100605swayangdash2003No ratings yet

- Characterization TechniquesDocument6 pagesCharacterization TechniquesKarunambika ArumugamNo ratings yet

- Scanning Electron MicrosDocument11 pagesScanning Electron MicrosVijay PradhanNo ratings yet

- Scanning Electron MicroscopeDocument6 pagesScanning Electron MicroscopeRaza AliNo ratings yet

- Lecture 3 Conventional-MicroscopeDocument45 pagesLecture 3 Conventional-Microscopearul1987No ratings yet

- Chapter 3Document23 pagesChapter 3POURNIMA kengaleNo ratings yet

- Materials ChracterisationDocument62 pagesMaterials ChracterisationAbdul MajidNo ratings yet

- TEM KaranDocument24 pagesTEM KaranKaushal SojitraNo ratings yet

- What Is Scanning Electron Microscopy (SEM)Document5 pagesWhat Is Scanning Electron Microscopy (SEM)mayheartNo ratings yet

- Scanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysisDocument10 pagesScanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysisJOHNNYNo ratings yet

- 10 AndrewsDocument6 pages10 AndrewsJuan Carlos Gonzalez LNo ratings yet

- Characterization Techniques: 1.1 OverviewDocument9 pagesCharacterization Techniques: 1.1 OverviewAmr TarekNo ratings yet

- Lecture 3.3 - Introduction To The Synthesis of Nanomaterials - SEM and TEMDocument30 pagesLecture 3.3 - Introduction To The Synthesis of Nanomaterials - SEM and TEMGian BanaresNo ratings yet

- Transmission Electron MicrosDocument97 pagesTransmission Electron MicrosAnonymous 0tqzNTWyyNo ratings yet

- Sem, Tem, DLSDocument84 pagesSem, Tem, DLSMadhuri HarshaNo ratings yet

- Methods On Destructive TestingDocument6 pagesMethods On Destructive TestingNiño UretaNo ratings yet

- SEM IntroDocument5 pagesSEM IntroSayan KarNo ratings yet

- Do It With Electrons !Document36 pagesDo It With Electrons !Lili QuishpeNo ratings yet

- Sem Lecture 8Document56 pagesSem Lecture 8sanju jarwalNo ratings yet

- Zaluzec 1 InstrumentationDocument97 pagesZaluzec 1 InstrumentationSimona TocanieNo ratings yet

- Electron Microscopy TechniquesDocument24 pagesElectron Microscopy TechniquesTayyab AyubNo ratings yet

- New Microsoft Office Word DocumentDocument159 pagesNew Microsoft Office Word Documenttapa_415027No ratings yet

- Scanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysisDocument11 pagesScanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysiskrunalNo ratings yet

- Material S. Presentation 1Document77 pagesMaterial S. Presentation 1Dagmawi HailuNo ratings yet

- Lecture - 9 - MicrosDocument33 pagesLecture - 9 - MicrosRachit GoyalNo ratings yet

- AP ProjectDocument19 pagesAP ProjectSahil YadavNo ratings yet

- Scanning Electron MicroscopeDocument7 pagesScanning Electron MicroscopezzaanNo ratings yet

- X-Ray Photoelectron Spectroscopy (XPS) : Paper - 4103 ADocument78 pagesX-Ray Photoelectron Spectroscopy (XPS) : Paper - 4103 Ahj kangNo ratings yet

- Scanning Electron MicrosDocument11 pagesScanning Electron MicrosRizki Yuni PratiwiNo ratings yet

- Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM)Document38 pagesScanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM)huma tariq100% (1)

- Sem-Tem-XrdDocument32 pagesSem-Tem-Xrdaditya raajNo ratings yet

- (Scanning Electron Microscopy) : Assignment-IiDocument11 pages(Scanning Electron Microscopy) : Assignment-IiDilli KrishnaNo ratings yet

- Unit Iv Material Characterization Testing Electron Microscope Working PrincipleDocument19 pagesUnit Iv Material Characterization Testing Electron Microscope Working PrinciplevizhideepaNo ratings yet

- Scanning Electron MicroscopeDocument11 pagesScanning Electron MicroscopeHanyuri VoNo ratings yet

- Scanning Electron MicroscopDocument21 pagesScanning Electron Microscopabhishek ranaNo ratings yet

- A Secondary Electron Scanning Electron Micrograph of A Ductile Fracture Surface in MolybdenumDocument12 pagesA Secondary Electron Scanning Electron Micrograph of A Ductile Fracture Surface in MolybdenumZahir Rayhan JhonNo ratings yet

- Sem, Tem, DtaDocument20 pagesSem, Tem, DtaAmira Mohamed AbdullahNo ratings yet

- What Is Scanning Electron MicrosDocument6 pagesWhat Is Scanning Electron MicrosAli Abbas Warwar AltaiNo ratings yet

- Scanning Process and Image Formation: Atomic Physics (Or Atom Physics) Is The Field ofDocument18 pagesScanning Process and Image Formation: Atomic Physics (Or Atom Physics) Is The Field ofgrinneNo ratings yet

- Scanning Electron MicrosDocument55 pagesScanning Electron MicrosAnson Chan100% (1)

- Mid-Semester Project Presentation: Topic: Material Characterization Using Eletron MicrosDocument12 pagesMid-Semester Project Presentation: Topic: Material Characterization Using Eletron MicrosNeil SharmaNo ratings yet

- Characterisation of NP (VK)Document19 pagesCharacterisation of NP (VK)Vaishnavi MoreNo ratings yet

- Introduction To Electron Microscopy and MicroanalysisDocument56 pagesIntroduction To Electron Microscopy and MicroanalysisPerlita2013100% (1)

- Scanning Electron Microscopy: Metallurgical and Materials EngineeringDocument45 pagesScanning Electron Microscopy: Metallurgical and Materials EngineeringSai Vamshi NampallyNo ratings yet

- Transmission Electron Microscopy and Its ApplicationsDocument12 pagesTransmission Electron Microscopy and Its ApplicationsMoayad TeimatNo ratings yet

- Electron Microscopy 2 2008Document51 pagesElectron Microscopy 2 2008Emanuel JaveNo ratings yet

- Kelompok III Adry E.Silitonga Mahraini NST Khorunnisa Junisa P. Barus Mispa HutasoitDocument35 pagesKelompok III Adry E.Silitonga Mahraini NST Khorunnisa Junisa P. Barus Mispa HutasoitKhoirunnisaNo ratings yet

- AnshuDocument9 pagesAnshusoumya jemyNo ratings yet

- Electron Detector For SemDocument25 pagesElectron Detector For Semmm11_nedNo ratings yet

- The Resolution in The Electron MicrosDocument8 pagesThe Resolution in The Electron MicrosInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Eds On Sem PrimerDocument26 pagesEds On Sem PrimerBryan RamosNo ratings yet

- Electron Microscopy LectureDocument78 pagesElectron Microscopy LectureParag PatilNo ratings yet

- Scanning Electron Microscope (SEM)Document51 pagesScanning Electron Microscope (SEM)Maaz ZafarNo ratings yet

- Optical Sources, Detectors, and Systems: Fundamentals and ApplicationsFrom EverandOptical Sources, Detectors, and Systems: Fundamentals and ApplicationsNo ratings yet

- QQQ Method Development Triple and OptimizationDocument46 pagesQQQ Method Development Triple and OptimizationCLPHtheoryNo ratings yet

- Mass Spectrometry Basics PDFDocument498 pagesMass Spectrometry Basics PDFCLPHtheoryNo ratings yet

- Becoming A Contagious Christian OutlineDocument4 pagesBecoming A Contagious Christian OutlineCLPHtheory100% (2)

- MEL761: Statistics For Decision Making: AnovaDocument54 pagesMEL761: Statistics For Decision Making: AnovaCLPHtheoryNo ratings yet

- StanfordFlex Basic CRRT Theory Rev2-06Document64 pagesStanfordFlex Basic CRRT Theory Rev2-06giyagirls100% (1)

- A Question From Last Year Final Exam: PrecipitatesDocument42 pagesA Question From Last Year Final Exam: PrecipitatesCLPHtheoryNo ratings yet