Professional Documents

Culture Documents

Irs

Uploaded by

rashmigodha0 ratings0% found this document useful (0 votes)

109 views37 pagesIndoor Residual Spraying (IRS) involves spraying insecticides on the interior walls of homes to control malaria-carrying mosquitoes. The insecticides are meant to repel, irritate, or kill mosquitoes that enter homes. Common insecticides used for IRS include DDT and deltamethrin. IRS provides months-long protection and does not require as much user compliance as other methods, but it does require infrastructure and resources to conduct spraying campaigns. Mosquito resistance to insecticides is a concern with IRS. Personal protective equipment and careful equipment maintenance are important for safety during IRS spraying operations.

Original Description:

etg

Original Title

Irs.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIndoor Residual Spraying (IRS) involves spraying insecticides on the interior walls of homes to control malaria-carrying mosquitoes. The insecticides are meant to repel, irritate, or kill mosquitoes that enter homes. Common insecticides used for IRS include DDT and deltamethrin. IRS provides months-long protection and does not require as much user compliance as other methods, but it does require infrastructure and resources to conduct spraying campaigns. Mosquito resistance to insecticides is a concern with IRS. Personal protective equipment and careful equipment maintenance are important for safety during IRS spraying operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

109 views37 pagesIrs

Uploaded by

rashmigodhaIndoor Residual Spraying (IRS) involves spraying insecticides on the interior walls of homes to control malaria-carrying mosquitoes. The insecticides are meant to repel, irritate, or kill mosquitoes that enter homes. Common insecticides used for IRS include DDT and deltamethrin. IRS provides months-long protection and does not require as much user compliance as other methods, but it does require infrastructure and resources to conduct spraying campaigns. Mosquito resistance to insecticides is a concern with IRS. Personal protective equipment and careful equipment maintenance are important for safety during IRS spraying operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 37

Indoor Residual Spray (IRS)

Indoor residual spraying (IRS) for

malaria control

Historically, the primary approach to malaria control has been to:

keep mosquitoes out of houses.

Treat perimeter of house (spray walls) with insecticide that

exhibits repellent actions.

If mosquitoes enter, then drive them out before they bite,

Treat perimeter of house with an insecticide that irritates

mosquitoes

If mosquitoes are not repelled or irritated, then kill as many

as possible that enter the house.

Treat perimeter of house with an insecticide that kills mosquitoes.

Chemical options for IRS include all classes of insecticides.

Pros and cons of IRS

Pros:

Once walls are sprayed, few issues of

user compliance.

Protects all people in the house Provides

continuous protections for months.

Cons:

Requires public health infrastructure to

Conduct and maintain spraying.

Resistance in mosquitoes to insecticides.

Insecticides for Adult Mosquito Control

Insecticides for IRS

Insecticide-

formulation

Dosage/m

2

Efficacy

(Wks)

Rounds

DDT-50% WP 1 gm 10-12 2

Malathion-25% WP 2 gm 6-8 3

Deltamethrin-2.5% WP 20 mg 10-12 2

Cyfluthrin-10% WP 25 mg 10-12 2

Lambda Cyhalothrin-

10% WP

25 mg 10-12 2

Space Sprays

Two forms of space-sprays, namely thermal fogs

and cold fogs can be dispensed by vehicle-mounted

(ULV) or hand-operated machines (Weekly

application).

Commonly used insecticides for space spray:

Pyrethrum- extract(2%), Malathion, Fenitrothion,

Pirimiphos methyl, Permethrin, Deltamethrin,

Lambda-cyhalothin and Cyphenothrin.

These insecticides instantly kill the mosquitoes, but

lack any residual effects.

Triple resistant -to DDT, Dieldrin and Malathion Double resistance- to DDT and Dieldrin Resistant to DDT Reports not available Quadruple resistance -to DDT, Dieldrin, malathion and deltamethrin Triple resistant -to DDT, Dieldrin and Malathion Double resistance- to DDT and Dieldrin Resistant to DDT Reports not available Quadruple resistance -to DDT, Dieldrin, malathion and deltamethrin Triple resistant -to DDT, Dieldrin and Malathion Double resistance- to DDT and Dieldrin Resistant to DDT Reports not available Quadruple resistance -to DDT, Dieldrin, malathion and deltamethrin Triple resistant -to DDT, Dieldrin and Malathion Double resistance- to DDT and Dieldrin Resistant to DDT Reports not available Quadruple resistance -to DDT, Dieldrin, malathion and deltamethrin

Susceptibility Status of An. culicifacies

and An. stephensi to Insecticides

Vector Type of

resistance

No. of

States

No. of

UTs

Total No.

of

districts

An.

culicifacies

DDT

Double

Triple

Quadruple

18

16

8

2

2

2

1

-

286

233

182

2

An.

stephensi

DDT

Double

Triple

7

6

3

1

1

1

34

27

8

Other vector species are mostly susceptible to insecticides

Double DDT & BHC

Triple DDT, BHC & Malathion

Quadruple DDT, BHC, Malathion and Synthetic

pyrethroids

Enormous instances of refusals or

locked houses (end user disinterest)

Poor maintenance of time table for

spray operations

Logistical problems like lesser no. of

trained spray crew, quality of spray

pumps, poor maintenance of spray

records etc.

IRS being a repeat intervention; adds up

to an enormous cost if repeated twice in

a year

Mud houses a huge problem for IRS

teams

Insecticide Residual Spraying (IRS)

Equipments in Vector Control

The main function of spraying equipment (sprayer) is to

atomize the spray fluids (which may be suspension, emulsion

or solution) into small droplets and eject it with some force

for proper distribution.

Ground Equipments Used for Vector Control

Equipment for the production of sprays (100-300 m droplet)

Equipment for the production of mists (50-100 m droplet)

Equipment for the production of aerosols (25-50 m droplet)

Equipment for the production of thermal fog (5-15 m droplet)

Equipment for the application of solid materials

www.stewardshipcommunity.com

Nozzle selection and maintenance can have

a major impact on the quality of your

application and the efficacy of the products

applied.

Nozzle selection and spray pressure will

have an impact on potential environmental

and personal contamination through either

run off and/or drift.

Nozzle selection and spray quality [drop size]

16 of 52

Classification of Pesticide Application by Droplets

Size

Very coarse spray > 500 m

Coarse spray 300-500 m

Medium spray 200-300 m

Fine spray 100-200 m

Mists 50-100 m

Coarse aerosols 25-50 m

Aerosols (Fine) < 25 m

Fog 5-15 m

Sprayers

Cutaway Diagram of a Compression Sprayer

HYDRAULIC ENERGY SPRAYERS

Delivery of Spray Solution Through Stirrup Pump

Sprayer

Trigger Valve Assembly

www.stewardshipcommunity.com

Better drift-control

Better biological

activity for some

products

More droplets from the same volume of water are produced if drop

size is decreased.

Which drop size is best may be dependent on the product used, the drift risk or

be a compromise.

Nozzle selection and spray quality [drop size]

17 of 52

Cone Nozzle

Fan Nozzle

Floodjet Nozzle

Cleaning of Nozzle Tip

www.stewardshipcommunity.com

Nozzle selection and spray quality

DO NOT -

Clean a nozzle with an abrasive implement

Clean a nozzle by blowing through it with your mouth

Use damaged or worn nozzles

Use fine spray drop sizes on a windy day

DO -

Wear gloves when handling nozzles

Clean a nozzle with water and a light brush

Protect nozzles from blockages with use of recomended filters

Frequently clean nozzles

Calibrate nozzles and sprayer every season

Replace the nozzle if damaged

Follow any product label recommendations

Change nozzles as necessary depending on the crop, growth stage and

product mode of action

38 of 52

Calibration of Sprayer Nozzle

Equipment of Mists

Equipments for Thermal Fogs

Fogging Operation using Swingfog

Machine

Thermal Nozzle of Fogger

Equipment for Solid Materials

The life of equipments depends upon handling and maintenance

Careless handling and poor maintenance can ruin even the best

equipment.

Lubrication instructions to be followed.

General inspection for cracks, loose connections, leakage wornout

washers and Hoses should not be bent, rolled and store flat.

Calibration of sprayer and nozzles output.

No pesticide material to leave overnight in the machine.

Sprayers should be stored upside down to ensure proper drainage and

condensing.

The nozzles should be cleaned thoroughly with kerosene.

Spare parts (washers, nozzles etc.) to keep in stock.

Maintenance of Pesticide Application

Equipment

Personal Protective Equipment

(PPE)

1 of 28

www.stewardshipcommunity.com

The 5 Golden Rules

1. Before using any Insecticide

product, always read its label and make sure you understand all

safety needs

2. Handle insecticide products carefully at all times to avoid contact or

contamination

3. Maintain sprayers well, fixing, for example, any leaks before starting

an application.

4. Practice good personal hygiene

5. Use appropriate protective clothing as last line of defence and not to

become careless and increase exposure risks.

2 of 28

Avoiding exposure risks

Reduce potential contamination through the adoption of good working

practices:

Always fix leaking sprayers before use.

Use nozzles that produce largest drop size advised by label.

(Equipment that produce finer droplets are more likely to cause

contamination)

Higher water volume rates are inherently safer than those more

concentrated. Use within label stated ranges.

Use spraying equipment that meets the FAO recommended specifications.

Always direct the spraying nozzle downwind.

Avoid spraying in very windy conditions.

Avoid walking through vegetation that has just been sprayed.

Immediately wash any splashes of undiluted product from the skin and eyes.

3 of 28

www.stewardshipcommunity.com

PPE: Label Information

Every product label will identify the protective equipment

requirements for both measuring/mixing as well as for application.

This information is shown as pictograms to help total

understanding by all product users, and is grouped into the following

activities.

Mixing liquids

Mixing solids Application

6 of 28

www.stewardshipcommunity.com

PPE: Use of pictograms that help

ensure product safety

Use gloves Use face visor Wash hands Use apron

Use boots Use dust mask Use respirator Use coverall

Note: Gloves and boots are tucked into coveralls

7 of 28

Pictogram for an example of a WHO Class II product

(moderately hazardous)

Harmful

Keep Locked

away

Use long sleeved

shirt and long

trousers

wear gloves When

handling

concentrate

Use face

shield

Wear boots

When

spraying

Wear long

sleeved shirt and

long trousers

Wear boots

Wash after use

8 of 28

PPE Storage and maintenance

Always store protective equipment separately from insecticide

products.

Wash gloves, aprons, boots and face shields after use.

Wash spray clothing separately from domestic washing.

Change respirator filters following the manufacturers guidelines.

10 of 28

You might also like

- Project Report On Surgical Gloves Manufacturing UnitDocument8 pagesProject Report On Surgical Gloves Manufacturing UnitEIRI Board of Consultants and PublishersNo ratings yet

- Calculation ExampleDocument20 pagesCalculation Examplepavankumar0001No ratings yet

- Fatigue Analysis of Flexible Pipes Using Alternative Element Types and Bend Stiffener Data PDFDocument100 pagesFatigue Analysis of Flexible Pipes Using Alternative Element Types and Bend Stiffener Data PDFmechmonkey007No ratings yet

- Janitors Module 1Document49 pagesJanitors Module 1g5nbNo ratings yet

- 1 Introduction To Analog IC DesignDocument41 pages1 Introduction To Analog IC Designnavinkumarrr588No ratings yet

- Pipe Stress Amp SupportDocument24 pagesPipe Stress Amp SupportShilpa GanganNo ratings yet

- Housekeeping A1Document49 pagesHousekeeping A1maenard glenn albaNo ratings yet

- Green Building Strategies and Passive Design TechniquesDocument37 pagesGreen Building Strategies and Passive Design TechniquesrashmigodhaNo ratings yet

- Pesticides BookletDocument8 pagesPesticides Bookletchethan kumar v100% (1)

- ESDEP Lecture 10 on Composite ConstructionDocument46 pagesESDEP Lecture 10 on Composite ConstructioniSoK11No ratings yet

- Label SedgehammerDocument5 pagesLabel SedgehammerCory HansonNo ratings yet

- Working Safely With Conformal Coatings - A Guide To Safe Working PracticesDocument4 pagesWorking Safely With Conformal Coatings - A Guide To Safe Working PracticesLee HitchensNo ratings yet

- Pilot Polymer Injection Using CMG Reservoir Simulator in A Productive Layer at TJX FieldDocument44 pagesPilot Polymer Injection Using CMG Reservoir Simulator in A Productive Layer at TJX FieldMuhammad Agha Hutama SyukronNo ratings yet

- Insect and Nematode Control in Michigan Field Crops: MSU Bulletin E-1582 2004 Field SeasonDocument15 pagesInsect and Nematode Control in Michigan Field Crops: MSU Bulletin E-1582 2004 Field SeasonANDERSON11765No ratings yet

- TrimecDocument2 pagesTrimecJohnny HuynhNo ratings yet

- Personal Protective Equipment (PPE)Document55 pagesPersonal Protective Equipment (PPE)syed fahimNo ratings yet

- Green DisinfectantsDocument2 pagesGreen DisinfectantsJuan Francisco RodríguezNo ratings yet

- Infection Control - MicrobiologyDocument9 pagesInfection Control - MicrobiologySarah KahilNo ratings yet

- Ais 41Document7 pagesAis 41s sanjaiNo ratings yet

- Spray Painting FullDocument10 pagesSpray Painting Fullatul100% (1)

- Captan 50 Wettable Powder: Danger PeligroDocument6 pagesCaptan 50 Wettable Powder: Danger PeligroBilly SteelNo ratings yet

- COVID-19 Cleaning AlternativesDocument4 pagesCOVID-19 Cleaning AlternativesYas AlbNo ratings yet

- Permethrin SFR 36.8% Label 1Document96 pagesPermethrin SFR 36.8% Label 1meisssamNo ratings yet

- PPE Pesticide ControlDocument52 pagesPPE Pesticide Controlydmisra100% (1)

- 3m Screen - Printable Psa sp7202 Process Guide en 0122Document24 pages3m Screen - Printable Psa sp7202 Process Guide en 0122Hayden LeeNo ratings yet

- Sds Castrol Grease LM 2 BiDocument4 pagesSds Castrol Grease LM 2 BiengturcompNo ratings yet

- Safety Data Sheet: Product Name: RPOE Series ISO VG 32 To 220Document7 pagesSafety Data Sheet: Product Name: RPOE Series ISO VG 32 To 220Luis Villarreal PiscoyaNo ratings yet

- Dow Corning (R) 200 Fluid, 50 Cst.Document11 pagesDow Corning (R) 200 Fluid, 50 Cst.Sergio Gonzalez GuzmanNo ratings yet

- Safety Data Sheet Energol THB 46Document4 pagesSafety Data Sheet Energol THB 46zaidan hadiNo ratings yet

- Tordon 101: HerbicideDocument9 pagesTordon 101: HerbicideTushar ChoudharyNo ratings yet

- Trimec Classic Application Manual: Thank You For Choosing Prograss ChemicalDocument7 pagesTrimec Classic Application Manual: Thank You For Choosing Prograss Chemicalnathan1991wilesNo ratings yet

- Infection Control in Restorative DentistryDocument32 pagesInfection Control in Restorative Dentistryjamaica faith ramonNo ratings yet

- Pesticide Use and Your Personal Protective Equipment (PPE)Document6 pagesPesticide Use and Your Personal Protective Equipment (PPE)AgriSafeNo ratings yet

- Tcs p101Document3 pagesTcs p101Theodoor KoenenNo ratings yet

- 043142yamalube 4T 20W-50 PDFDocument4 pages043142yamalube 4T 20W-50 PDFJexelle Marteen Tumibay PestañoNo ratings yet

- Lesson 1:: Safety Measure in Farm OperationsDocument37 pagesLesson 1:: Safety Measure in Farm Operationsmarjorie gomezNo ratings yet

- LABEL Bifenthrin Termiticide Insecticide 1 LitreDocument14 pagesLABEL Bifenthrin Termiticide Insecticide 1 Litrelex_reynolds1No ratings yet

- Spray Painting, WHSPRO-018 CMDocument6 pagesSpray Painting, WHSPRO-018 CMsanthoshNo ratings yet

- 043060castrol Alphasyn EP 68Document4 pages043060castrol Alphasyn EP 68Henry SNo ratings yet

- Safety Equipment: Histology LaboratoryDocument8 pagesSafety Equipment: Histology LaboratoryArldrick John SalutNo ratings yet

- Caution: Keep Out of Reach of ChildrenDocument4 pagesCaution: Keep Out of Reach of ChildrenReja dwiNo ratings yet

- 19 25 53 23 02 2017 Provisia - NVA - 2017 04 522 0004Document12 pages19 25 53 23 02 2017 Provisia - NVA - 2017 04 522 0004jcffjmitfdvhyt643dNo ratings yet

- EverGreen Pro 60-6 Specimen LabelDocument6 pagesEverGreen Pro 60-6 Specimen LabelKaustav MukherjeeNo ratings yet

- UL Toshiba Guidelines, For Cleaning, Disinfection, and Sterilization of TransducersDocument8 pagesUL Toshiba Guidelines, For Cleaning, Disinfection, and Sterilization of TransducersfjvillamunozNo ratings yet

- CNNP Cleanroom ProtocolsDocument24 pagesCNNP Cleanroom ProtocolskushalNo ratings yet

- Lockup 0 0 7Document1 pageLockup 0 0 7Cory HansonNo ratings yet

- Dow 3504Document2 pagesDow 3504khantoNo ratings yet

- BASF Poast 17516 LabelDocument25 pagesBASF Poast 17516 Labelzvonko.jacimovskiNo ratings yet

- Castrol CRB TurbomaxDocument10 pagesCastrol CRB Turbomaxzeta10151015No ratings yet

- TriGene Data SheetsDocument4 pagesTriGene Data Sheetssidsmith1No ratings yet

- PSEP43Document6 pagesPSEP43adem endrisNo ratings yet

- MSDS Castrol Hyspin AWH-M 68Document5 pagesMSDS Castrol Hyspin AWH-M 68Teguh SNo ratings yet

- 3m-Cleaning Disinfecting RR Coronavirus v3Document4 pages3m-Cleaning Disinfecting RR Coronavirus v3Drg Arya WicaksonoNo ratings yet

- Group 2B Insecticide FipronilDocument15 pagesGroup 2B Insecticide FipronilEvelyn KlineNo ratings yet

- Infection ControlDocument30 pagesInfection Controlsondos aliNo ratings yet

- Safety Equipment and Emergency ProceduresDocument2 pagesSafety Equipment and Emergency ProceduresctcasipleNo ratings yet

- Amistar Top Approved LabelDocument20 pagesAmistar Top Approved Labelmak_1912No ratings yet

- Chess Insecticide LabelDocument4 pagesChess Insecticide LabelssangachonuerNo ratings yet

- Gramoxone 250 Herbicide MsdsDocument8 pagesGramoxone 250 Herbicide Msdsjessieca liusenNo ratings yet

- Cleaning and Disinfecting 3M Reusable Elastomeric Half and Full Facepiece Respirators Following Potential Exposure To CoronavirusesDocument7 pagesCleaning and Disinfecting 3M Reusable Elastomeric Half and Full Facepiece Respirators Following Potential Exposure To CoronavirusesYOFE SITEPUNo ratings yet

- Health and Safety Guidelines For PaintingDocument8 pagesHealth and Safety Guidelines For PaintingCantir DumitruNo ratings yet

- Slide-In Vacuum Tank Operator'S Manual: WarningDocument32 pagesSlide-In Vacuum Tank Operator'S Manual: WarningJhon Edison CastroNo ratings yet

- Pathfile: Directions For Use - Pathfile 0) Composition 1) Indications For UseDocument6 pagesPathfile: Directions For Use - Pathfile 0) Composition 1) Indications For UseDimitarNo ratings yet

- Bartan HV46Document4 pagesBartan HV46stijn VanhauwaertNo ratings yet

- PAR III TURF HERBICIDE Label PDFDocument8 pagesPAR III TURF HERBICIDE Label PDFLen BenschopNo ratings yet

- Flex - A - USA LabelDocument18 pagesFlex - A - USA Labelmarv4791No ratings yet

- Reports MemoDocument2 pagesReports MemorashmigodhaNo ratings yet

- Making The Journey More Attractive All Routes Lead To Amsterdam Different Approaches in Europe and AmericaDocument5 pagesMaking The Journey More Attractive All Routes Lead To Amsterdam Different Approaches in Europe and AmericaritikaritikaNo ratings yet

- MohitDocument7 pagesMohitrashmigodhaNo ratings yet

- Lab 8 Network AnalystDocument11 pagesLab 8 Network AnalystrashmigodhaNo ratings yet

- Archdesign PDFDocument219 pagesArchdesign PDFAdina CampianNo ratings yet

- Barry Construction of Buildings Volume 2Document202 pagesBarry Construction of Buildings Volume 2nourhan100% (9)

- INTERIOR DESIGN SyllabusDocument1 pageINTERIOR DESIGN SyllabusrashmigodhaNo ratings yet

- Urban PlannerDocument19 pagesUrban PlannerrashmigodhaNo ratings yet

- SeminarDocument105 pagesSeminarrashmigodhaNo ratings yet

- The Solar EnvelopeDocument8 pagesThe Solar EnveloperashmigodhaNo ratings yet

- Urban AtriumDocument10 pagesUrban AtriumrashmigodhaNo ratings yet

- Mole Conversion Worksheet 2015 ANSWER KEYDocument2 pagesMole Conversion Worksheet 2015 ANSWER KEYFebbie Ibatuan100% (1)

- Term Project: Power Requirement For Grinding of Coffee Beans and Screen AnalysisDocument2 pagesTerm Project: Power Requirement For Grinding of Coffee Beans and Screen AnalysisWellington FloresNo ratings yet

- Development of A Rapid and Eco-Friendly UHPLC Analytical Method For The Detection of Histamine in Fish ProductsDocument18 pagesDevelopment of A Rapid and Eco-Friendly UHPLC Analytical Method For The Detection of Histamine in Fish ProductsRiyadhi Pasca SyahputraNo ratings yet

- Final SotAR TU1207Document415 pagesFinal SotAR TU1207mikorizNo ratings yet

- Brochure - Titrator - T50Document2 pagesBrochure - Titrator - T50Agus TrionoNo ratings yet

- Momentum Linkage ProblemsDocument18 pagesMomentum Linkage ProblemsAna Lorraine DalilisNo ratings yet

- Acid Base Serial DilutionsDocument6 pagesAcid Base Serial DilutionsLindsey MaycockNo ratings yet

- Equilibrium of Particles - Part 2Document3 pagesEquilibrium of Particles - Part 2Ralph Denver RomanoNo ratings yet

- MSDS QS 705 - 020110Document2 pagesMSDS QS 705 - 020110Jet ToledoNo ratings yet

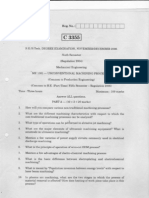

- Ucm Anna Univ Question PapersDocument24 pagesUcm Anna Univ Question PapersNarayanan SubramanianNo ratings yet

- Capacitors: An OverviewDocument60 pagesCapacitors: An OverviewKish ShenoyNo ratings yet

- Tig Welding W19 12 3 LSiDocument2 pagesTig Welding W19 12 3 LSiKoen BidlotNo ratings yet

- APT001-S-DS-PI-004 Insulation - Gasket - Data - Sheet - Rev0+Document10 pagesAPT001-S-DS-PI-004 Insulation - Gasket - Data - Sheet - Rev0+Roy RahadianNo ratings yet

- Eva TaneDocument1 pageEva TaneAsima AtharNo ratings yet

- Machine Design and Shop Practice Problems GuideDocument156 pagesMachine Design and Shop Practice Problems GuidesedexxNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument11 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyAna MariaNo ratings yet

- ASTM B 630 Standard Preparation For ChromiumDocument2 pagesASTM B 630 Standard Preparation For Chromiumneno2405No ratings yet

- Providing Custom Solutions for Latex Compounds and ProductsDocument14 pagesProviding Custom Solutions for Latex Compounds and ProductsVenkadesh SubramanianNo ratings yet

- MIL control valves for process industriesDocument8 pagesMIL control valves for process industriesGovarthanan GopalanNo ratings yet

- Prediction of Thrust Force and Torque in Drilling On Aluminium AlloyDocument7 pagesPrediction of Thrust Force and Torque in Drilling On Aluminium Alloyanilsamuel0077418No ratings yet

- GUIDELINES ON MEDICAL SURVEILLANCEDocument139 pagesGUIDELINES ON MEDICAL SURVEILLANCEdean0160260% (1)

- INTRODUCTION TO PATTERN CHEMISTRY Parts 1-3Document353 pagesINTRODUCTION TO PATTERN CHEMISTRY Parts 1-3Yuri TarnopolskyNo ratings yet

- Rociador EC 11Document8 pagesRociador EC 11Alejandro Chumpitaz MarchanNo ratings yet

- RedoxDocument14 pagesRedoxsaraNo ratings yet