Professional Documents

Culture Documents

Scaling of Mosfet

Uploaded by

hafizan840 ratings0% found this document useful (0 votes)

27 views12 pages1 introduction of mosfet

2 IC technology evolution

3 Type and parameter of scaling

Original Title

Scaling of Mosfet

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1 introduction of mosfet

2 IC technology evolution

3 Type and parameter of scaling

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views12 pagesScaling of Mosfet

Uploaded by

hafizan841 introduction of mosfet

2 IC technology evolution

3 Type and parameter of scaling

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 12

Scaling of MOSFET

After completing the unit, students should be

able to:

Explain the evolution of integrated circuit

Describe scaling of MOSFETS

Describe briefly some of the methods to

implement scaling.

Invented by Robert Noyce in 1960

Developed the chip using a 10 mm silicon

wafer

The demand in IC industry :

Increase its speed

Reduced power dissipation per function

Increased number of transistors and function

Reduced the cost of a chip pushes the scaling

down of a transistor feature size.

Minimum feature size is the smallest size that

can be achieved for a transistor by reducing its

gate length or interconnect linewidth.

In 1965, Gordon Moore, pointed out that the

number of transistors on a chip doubled every 18

to 24 months.

He made a prediction that integrated circuit

technology will doubled its effectiveness every

18 months.

The demand of having smaller and smaller

feature size is very obvious when the IC

technology moves from SSI to GSI.

Year 1947 1950 1961 1966 1971 1980 1990 2000

Techno-

logy

Inventi-on

of transis-

tor

Discrete

compon-

ent

Small Scale

Integra-tion

(SSI)

Medium

Scale

Integra-tion

Large Scale

Integra-tion

(LSI)

Very Large

Scale

Integra-tion

(VLSI)

Ultra Large

Scale

Integrat-ion

(ULSI)

Giga /Giant

Scale

Integrat-ion

(GSI)

Number of

transis-tor

per chip

1 1 Less than

30

30 - 100 100,000 1 million 40 million More than

40 million

Typical

products

- Diode,

Transis-tor

Logic

gates, Flip-

flop

Counter,

Multiplex-er,

Adder

Micropro-

cessor 8 bit,

ROM, RAM

Micropro-

cessor 16

bit, and 32

bit, DRAM

Pentium 2

with 300

MHz

Micropro-

cessor with

speed 10

GHz

Minimum feature size of transistor is the smallest size of IC

chip that is its gate length or interconnect line width of an IC.

Minimum feature size is measured in micrometers or microns

for example 0.18 mm in year 2000

In year 2008 the measurement is in nanometer that is the

introduction of 45 nm technology due to considerable

shrinking and increased in number of transistors.

More innovations on IC technology with reduced dimension,

improved leakage current to reduce power dissipation and

more transistors can be integrated on a chip with less cost are

in the roadmap with 32 nm, 22 nm, 16 nm and 11 nm

dimensions.

More advanced manufacturing or fabrication process is

needed when the dimension of transistor had reached the

atomic size.

The scaling parameter, is the factor by which

transistor dimensions are reduced, that is < 1.

The gate length, L

G

is L

G

and the gate width, Z

is Z for the scaling down the dimensions of a

transistor.

Shorter gate length and smaller gate thickness

give higher transconductance, g

m

.

Smaller gate width reduces input capacitance.

Line width (gate length) shrunk on a two to

three year cycle; in 2002 the line width was 0.13

mm to 0.18 mm and the die size was 2 cm

2

.

Constant voltage scaling & constant field scaling

Constant voltage scaling

lateral dimensions are scaled without reducing the power

supply voltage.

The disadvantage - the electric field increases as the minimum

feature length is reduced. This results to mobility degradation,

velocity saturation, lower breakdown voltages and increased

leakage currents.

Constant field scaling,

The lateral dimensions, length and width of the channel (L

G

, Z),

the perpendicular dimension, oxide thickness (d

ox

) and the

operating voltages (V

DS

, V

GS

, V

th

) of the MOSFETs are scaled and

thus are reduced by a factor .

constant field scaling results in reduction of power delay

product but it requires a reduction in the power supply voltage.

Therefore voltage scaling method is the preferred approach.

Majority of these parameters reduced by a

factor or .

Substrate doping increased by a factor to

reduce depletion widths to prevent punch-

through breakdown.

1

2

1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Test 1 Skee1013 20172018 - 1Document5 pagesTest 1 Skee1013 20172018 - 1Andy QklNo ratings yet

- EEE3091F Test 1 Questions - 2022Document3 pagesEEE3091F Test 1 Questions - 2022Student 80No ratings yet

- CGL - Instruction & Maintenance Manual Current Transformer Live TankDocument21 pagesCGL - Instruction & Maintenance Manual Current Transformer Live TankHari Krishna.MNo ratings yet

- Catalogue - 40.5kV T Type OVCB PDFDocument20 pagesCatalogue - 40.5kV T Type OVCB PDFGanesh Duraisamy0% (1)

- Ventiladores Del Sistema AdiabaticoDocument13 pagesVentiladores Del Sistema AdiabaticoVicente SantillanNo ratings yet

- Especificación Fluke 1550bDocument3 pagesEspecificación Fluke 1550bAngel Morell OrtizNo ratings yet

- LM555 and LM556 Timer CircuitsDocument69 pagesLM555 and LM556 Timer CircuitskatambarogersNo ratings yet

- Sizing of Earth CablesDocument1 pageSizing of Earth CablesLilet P. DalisayNo ratings yet

- Street Lighting Design - Layout & Calculations - Electrical4UDocument33 pagesStreet Lighting Design - Layout & Calculations - Electrical4Ulegasu zemene100% (1)

- Comparison: Design PointDocument25 pagesComparison: Design PointDan PopescuNo ratings yet

- UPS APC SRT 5-10kva - Hoja de DatosDocument6 pagesUPS APC SRT 5-10kva - Hoja de DatosGermanYPNo ratings yet

- Georadar ManualDocument39 pagesGeoradar ManualArmando BiringkanaeNo ratings yet

- Surge Protec IIDocument14 pagesSurge Protec IIRaj ChavanNo ratings yet

- XT532 DatasheetDocument1 pageXT532 DatasheetRehan ShaikhNo ratings yet

- Generation of Audible Sound With Ultrasonic Signals: A Technical Seminar Report OnDocument21 pagesGeneration of Audible Sound With Ultrasonic Signals: A Technical Seminar Report OnBhavana Reddy MettuNo ratings yet

- Delight EnterprisesDocument25 pagesDelight Enterprisesmotol9iNo ratings yet

- RB 1070 OmDocument35 pagesRB 1070 OmCapitanSalamiNo ratings yet

- Safety ClearanceDocument19 pagesSafety ClearanceAnand AgrawalNo ratings yet

- FRECON Company Profile 2021 en V1.0Document25 pagesFRECON Company Profile 2021 en V1.0wow greatNo ratings yet

- SPD Schneider PDFDocument44 pagesSPD Schneider PDFabhi_26tNo ratings yet

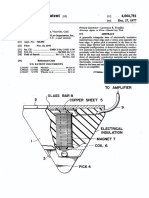

- U.S. Patent 4,064,781, Guitar Pick, Issued 1977.Document3 pagesU.S. Patent 4,064,781, Guitar Pick, Issued 1977.Anonymous a7S1qyXNo ratings yet

- Idealarc dc655 PDFDocument109 pagesIdealarc dc655 PDFLuis MartínezNo ratings yet

- ManualDocument82 pagesManualRicardo RojasNo ratings yet

- Black & Decker 120 W Inverter - PL120PDocument12 pagesBlack & Decker 120 W Inverter - PL120PkreutzNo ratings yet

- OUTdoorCTVT CatalogueDocument28 pagesOUTdoorCTVT CataloguemesinNo ratings yet

- Study of Electrical Tools & Symbols of Electrical Components Electrical ShockDocument55 pagesStudy of Electrical Tools & Symbols of Electrical Components Electrical ShockkrishnandrkNo ratings yet

- Touch Voltages Above Ground Gri D: Multiground+Document104 pagesTouch Voltages Above Ground Gri D: Multiground+Mori PourNo ratings yet

- Sony Hcd-lx10000 SMDocument86 pagesSony Hcd-lx10000 SMthecat2No ratings yet

- Tcchap 1Document13 pagesTcchap 1Muhammad Ramiz ZakirNo ratings yet

- Tutotial - V (Transmission Line Parameters) PDFDocument4 pagesTutotial - V (Transmission Line Parameters) PDFIshan PatilNo ratings yet