Professional Documents

Culture Documents

1st Review

1st Review

Uploaded by

DeepakJain100 ratings0% found this document useful (0 votes)

24 views9 pagesatm machine

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentatm machine

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views9 pages1st Review

1st Review

Uploaded by

DeepakJain10atm machine

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 9

Hardware Project - Second Review

MULTIPURPOSE MACHINE USING SCOTCH-

YOKE MECHANISM

School of Mechanical and Building Sciences,

VIT University, Vellore - 632014

Prof. Satheesh Kumar S.

Project Guide

Prof. Bikash Routh

Project Reviewer

Avi Jain(11BME0378), Viraj Bhambri(11BME0388),

Arun Krishnan Unni(11BME0274)

OBJECTIVE

To use the concept of Scotch-Yoke Mechanism to design a machine capable

of performing more than one task.

To be able to run two or more operations on a single machine using one

power source.

To effectively reduce the time required for operations like blank cutting.

To accommodate the operation of 2 hacksaw blades and a stamping

machine through less consumption of power and time.

Thus, contribute in increasing productivity of the plant in which the machine

operates.

To reduce requirement of personnel.

Hardware Project - Second Review , School of Mechanical and Building Sciences 2

INTRODUCTION

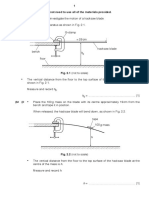

Scotch Yoke:-

It is the second inversion of a double slider crank chain mechanism in which

one of the sliders is fixed.

It converts the linear motion of a slider into rotational motion or vice versa.

The piston or other reciprocating part is directly coupled to a sliding yoke with

a slot that engages a pin on the rotating part.

In our project, we are using the scotch-yoke to convert the rotatary motion

into reciprocating motion.

Hardware Project - Second Review , School of Mechanical and Building Sciences 3

Power Hacksaw:-

Power hacksaws are used to cut large sizes (sections) of metals such as

steel.

It functions by drawing a blade containing cutting teeth through the work

piece. The sawing machine is faster and easier than hand sawing.

Generally, a slider crank mechanism is used in power hacksaws.

Different types of blades are available for different materials (included in

report). For steel, the recommended TPI = 6.

Recommended cutting speed for steel = 30 m/min

Hardware Project - Second Review , School of Mechanical and Building Sciences 4

Power hacksaw blades differ from hand hacksaw blades in that they are

generally heavier, made in longer sizes, and have fewer teeth per inch.

Materials commonly used in manufacturing power hacksaw blades are high-

speed tungsten steel and high-speedmolybdenum steel.

There are three set patterns: raker, wave, and straight.

Hardware Project - Second Review , School of Mechanical and Building Sciences 5

Stamping:-

Stamping is a small but important stage of manufacturing.

Involves a simple reciprocating mechanism to imprint the date, company

label etc. on the final manufactured product.

If this process is integrated with another process can help in benefitting the

productivity of the plant.

Hardware Project - Second Review , School of Mechanical and Building Sciences 6

DESIGN CALCULATIONS

From the standard data available, the following were assumed for a steel

shaft of more than 2 thickness:

1) Teeth per inch = 4-6

2) Strokes per min = 60-120

3) Feed = 0.003-0.009 inch/stroke

After calculations for a .25 hp motor with a 35mm pulley, the following

parameters for a 2 stage reduction were finalized:

1) 1

st

reduction: Pulley dia = 210mm, rpm = 240

2) 2

nd

reduction: Drive pulley dia = 50mm, rpm=240 ; driven pulley dia =

200mm for 60rpm (rpm is fixed for steel)

Hardware Project - Second Review , School of Mechanical and Building Sciences 7

Hardware Project - Second Review , School of Mechanical and Building Sciences 8

SCOTCH

YOKE

MACHINE

BLANK

CUTTING

1

STAMPING

BLANK

CUTTING

2

THANK YOU

Hardware Project - Second Review , School of Mechanical and Building Sciences 9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design and Fabrication of Advanced Pneumatic Hacksaw Cutting MachineDocument4 pagesDesign and Fabrication of Advanced Pneumatic Hacksaw Cutting MachineBONFRING100% (1)

- Module 1 - Maintaining and Repairing Audio Products and SystemDocument52 pagesModule 1 - Maintaining and Repairing Audio Products and SystemAko Lang Poh70% (20)

- Bachelor of Engineering in Mechanical Engineering: Dr. Babasaheb Ambedkar Marathwada University, AurangabadDocument26 pagesBachelor of Engineering in Mechanical Engineering: Dr. Babasaheb Ambedkar Marathwada University, Aurangabadvikas shelkeNo ratings yet

- Plumbing Book Artisan Level 1Document47 pagesPlumbing Book Artisan Level 1Patrick Macharia100% (4)

- EclipseDocument2 pagesEclipseapi-262447022No ratings yet

- TMC 4102 Class NotesDocument42 pagesTMC 4102 Class NotesJpricarioNo ratings yet

- High Speed 4 Way Hacksaw MachineDocument21 pagesHigh Speed 4 Way Hacksaw MachineSAURABH CHOUDHARYNo ratings yet

- Report Lab 1Document4 pagesReport Lab 1Sulaiman RoslanNo ratings yet

- Lab 4 Oscillation of Hacksaw BladeDocument4 pagesLab 4 Oscillation of Hacksaw BladeWILLY TanNo ratings yet

- Skema Jawapan Fizik Kertas 3 Tingkatan 4 Peperiksaan Sumatif 1 2018Document4 pagesSkema Jawapan Fizik Kertas 3 Tingkatan 4 Peperiksaan Sumatif 1 2018Azrul AkmarNo ratings yet

- Understanding Technical English 1Document67 pagesUnderstanding Technical English 1egglestona100% (6)

- Unit 7 Metal Sawing: StructureDocument9 pagesUnit 7 Metal Sawing: StructureRavi KumarNo ratings yet

- Pipefitting: Basic EngineeringDocument40 pagesPipefitting: Basic Engineeringmohamed Abo-EwishaNo ratings yet

- Conduit Bender GuideDocument12 pagesConduit Bender Guideyomero1969100% (4)

- Workshop Manual For Fitting, Welding and Machine ShopDocument51 pagesWorkshop Manual For Fitting, Welding and Machine ShopHittendra Singh100% (3)

- Signed-Off - TLE - IA - SMAW - Mod1 - Materials-and-Tools G7Document30 pagesSigned-Off - TLE - IA - SMAW - Mod1 - Materials-and-Tools G7Ria Lalene S. TabamoNo ratings yet

- Ibong Tiririt (MDSP 5)Document14 pagesIbong Tiririt (MDSP 5)Stephanie ParkNo ratings yet

- Homemade Ripstik WaveboardDocument10 pagesHomemade Ripstik WaveboardmfdbNo ratings yet

- Machine Design Final Coaching Shuffled PDFDocument385 pagesMachine Design Final Coaching Shuffled PDFJaypes ManzanoNo ratings yet

- Pedal Power HacksawDocument41 pagesPedal Power Hacksawsunny86% (7)

- Mod 7.1 & 7.2Document5 pagesMod 7.1 & 7.2SeanRiniFernandoNo ratings yet

- Hack SawsDocument7 pagesHack SawsKaraboNo ratings yet

- Solar Wood CutterDocument13 pagesSolar Wood Cuttern_amarsinh9938No ratings yet

- Pilana Metal Cutting Tools enDocument32 pagesPilana Metal Cutting Tools enBryan ThorntonNo ratings yet

- Band Saw Blade Reference Guide: Bulletin 1037Document8 pagesBand Saw Blade Reference Guide: Bulletin 1037Palaniappan SolaiyanNo ratings yet

- Chapter 1: INRODUCTION: Project Report: Diploma: Sem 2: 2012-13Document28 pagesChapter 1: INRODUCTION: Project Report: Diploma: Sem 2: 2012-13muralibeee2874No ratings yet

- Lesson Plan Practice TeachingDocument8 pagesLesson Plan Practice Teachingjosephstayhappy.29No ratings yet

- Metalworking ToolsDocument6 pagesMetalworking ToolsHoai nam100% (1)

- Hand Tools IdentificationDocument54 pagesHand Tools IdentificationRandy StribleyNo ratings yet