92% found this document useful (13 votes)

4K views47 pages03 Ball Mill EDM

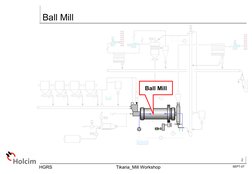

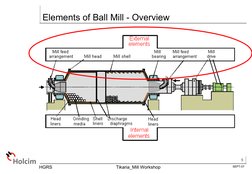

The document discusses various aspects of ball mill systems including:

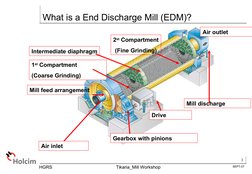

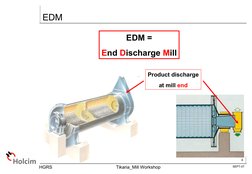

1) An end discharge mill (EDM) which discharges product at the mill end.

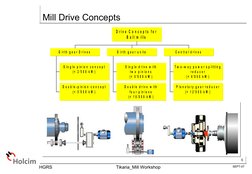

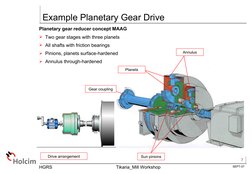

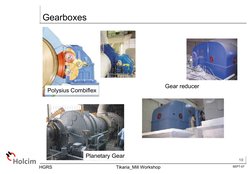

2) Different drive concepts for ball mills including girth gear drives and planetary gear drives.

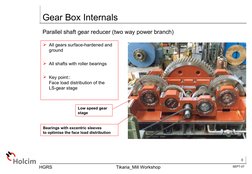

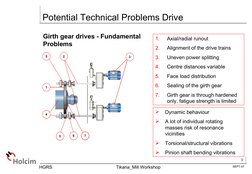

3) Potential technical problems with drives including misalignment and uneven power splitting.

4) Internal elements of ball mills including liners, grinding media, and diaphragms.

Uploaded by

Vishnu Vardhan . CCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

92% found this document useful (13 votes)

4K views47 pages03 Ball Mill EDM

The document discusses various aspects of ball mill systems including:

1) An end discharge mill (EDM) which discharges product at the mill end.

2) Different drive concepts for ball mills including girth gear drives and planetary gear drives.

3) Potential technical problems with drives including misalignment and uneven power splitting.

4) Internal elements of ball mills including liners, grinding media, and diaphragms.

Uploaded by

Vishnu Vardhan . CCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Introduction to Ball Mill Systems

- End Discharge Mill (EDM) Details

- Ball Mill Drive Systems

- Ball Mill Components

- Grinding Parameters and Optimization

- Mill Ventilation and Cooling