Professional Documents

Culture Documents

Horomill

Horomill

Uploaded by

sameh ibrahemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Horomill

Horomill

Uploaded by

sameh ibrahemCopyright:

Available Formats

The Horomill

HBM Process Conference, 10/97

By Sebastian Maibaum

Blue Circle Technical Centre

The Horomill

• Time frame of “new” developments in

cement grinding

• Introduction of the horizontal roller mill

concept

• Comparison with other developments

• Operating data

Blue Circle Technical Centre

Horomill - time frame

• FCB and Buzzi introduce Horomill on the

VDZ-conference 1993

• Horomill start up of 25 tph unit at Trino -

Italy in 1993

• High attention by the industry, e.g. Lafarge

buys Horomill for various plants

• Spring 1996 FLS introduces the Cemax

concept on the IEEE Conference in LA

Blue Circle Technical Centre

Horomill - time frame

• Start up of different units in summer 1996

• No immediate press releases

• Rumours of mechanical problems

• Horomill = HorroRmill ???

• FCB describes mechanical improvements

• Scale up problems seem under control now

and operating data is available from FCB

Blue Circle Technical Centre

Different developments

• Roller press gives good energy savings but

suffers of low mechanical reliability

• Few application without a ball mill

• VSM are successfully applied for raw meal

preparation, but few application in cement

• Higher acceptance of VSM for clinker

grinding in the Pacific region

• Ring-mill by Polysius

Blue Circle Technical Centre

Horizontal roller mill objectives

• Reduce energy consumption by application

of material bed communition

• Independent grinding unit due to “proven”

closed circuit design

• Improve mechanical reliability

• Low energy cost for auxiliary equipment

since only low mill ventilation required

Blue Circle Technical Centre

The Horomill

• Please refer to slides

Blue Circle Technical Centre

Horomill - design features

• Pressure is medium pressure

• Material bed communition shows good

energy utilisation

♦ advantage: low ventilation necessary

♦ disadvantage: gypsum dehydration needs HGG?

• Possible to influence material retention time

♦ scraper system

♦ amount of mill feed

Blue Circle Technical Centre

Horomill - design feature

• Ring and roller arrangement provides the

highest possible nib angle

• Gap between roller and shell 45 to 50 mm at

Horomill 3400

• Material discharge as known from ball mills

• No internals which tend to clock

♦ Drying can be done in separator circuit

♦ Gypsum dehydration by hot gases in sep-circuit

Blue Circle Technical Centre

Horizontal Roller Mill Technology

Horomill Cemax

Feeding One side Both sides

Discharge Opposite side Both sides

Discharge type Gravity Air sweeping

Mill speed Hypercritical Sub-critical

Mat. transport Scraper system Scoops

Closed circuiting Bucket elevator Air sweeping

Drying Separation air Air sweeping

Dr

Blue Circle Technical Centre

Influence of mill speed

• HOROMILL • CEMAX

♦ Mill is operating of ♦ Mill is operating at sub-

120 % of critical speed critical speed

♦ Constant material bed ♦ Scooping devices for

thickness conveying + distribution

♦ No sliding of material necessary

♦ Low aeration within ♦ Difficult to control

the material bed internal material transport

♦ Retention time can be ♦ Low recirculation load

influenced by scraper

Blue Circle Technical Centre

Horomill - operating data

• Horomill 2400 @ Trino/Italy

♦ Shell diameter: 2400 mm

♦ 25 tph CP 42.5 with characteristics such as

SD80

• Horomill 3400 Cimentas Izmir/Turkey

♦ PBC with 30% pozz. 3880 Blaine 17.3 kWh/t

closed circuit and 24.2 kWh/t total circuit

♦ Characteristics like closed circuit product

Blue Circle Technical Centre

Horomill - operating data

• Material characteristics identical such as

closed circuit with high efficiency separator

♦ strength development

♦ water demand

♦ setting time

• Cement with 70 % slag produced and 12 %

moisture of the slag

Blue Circle Technical Centre

Power consumption OPC

Specific power mill only grinding OPC • Aux. Equipment

100 OPC @ 3200 Bl

80

♦ Cemax

kWh/t - mill only

60

» ~ 8.5 kWh/t

40

♦ Horomill

20

» ~ 5.4 kWh/t

0

2000 2500 3000 3500 4000 4500 5000 5500 6000 ♦ CC Ball mill

SSA - Blaine » ~ 5 kWh/t

Ball Mill kWh/t Cemax kWh/t Horomill

Blue Circle Technical Centre

Horomill - conclusion

• Experience of several years and half a dozen

installations

• Lower vent air system of the two systems

• Scale up problems are under control

• Development of material characteristic

• Benefit for Blue Circle of new developments

• Suitable for cubic meter per ton comparison

Blue Circle Technical Centre

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BurnersDocument19 pagesBurnerssameh ibrahemNo ratings yet

- Grinding Aids ApplicationsDocument11 pagesGrinding Aids Applicationssameh ibrahemNo ratings yet

- Data Sheet 871AU010Document2 pagesData Sheet 871AU010sameh ibrahemNo ratings yet

- Brick Retaining SystemDocument13 pagesBrick Retaining Systemsameh ibrahemNo ratings yet

- Flames BowDocument32 pagesFlames Bowsameh ibrahemNo ratings yet

- AnemometerDocument3 pagesAnemometersameh ibrahemNo ratings yet

- Trouble Shooting Calciners and KilnsDocument8 pagesTrouble Shooting Calciners and Kilnssameh ibrahemNo ratings yet

- RHI Bulletin 2014-02-DataDocument52 pagesRHI Bulletin 2014-02-Datasameh ibrahemNo ratings yet

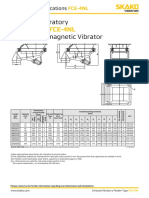

- Feeder Type FCE-4NL GBDocument2 pagesFeeder Type FCE-4NL GBsameh ibrahemNo ratings yet