Professional Documents

Culture Documents

Module 1 Intro SCM

Uploaded by

luz_ma_60 ratings0% found this document useful (0 votes)

67 views20 pagesMany large firms are moving away from in-house Vertically Integrated structures to Supply Chain Management. Supply chains now deal with reverse logistics to handle returned products, warranty repairs, and recycling.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMany large firms are moving away from in-house Vertically Integrated structures to Supply Chain Management. Supply chains now deal with reverse logistics to handle returned products, warranty repairs, and recycling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

67 views20 pagesModule 1 Intro SCM

Uploaded by

luz_ma_6Many large firms are moving away from in-house Vertically Integrated structures to Supply Chain Management. Supply chains now deal with reverse logistics to handle returned products, warranty repairs, and recycling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 20

What is a Cadena de

suministro

A supply chain consists of the flow of products

and services from:

Raw materials manufacturers

Component and intermediate manufacturers

Final product manufacturers

Wholesalers and distributors and

Retailers

Connected by transportation and storage

activities, and

Integrated through information, planning,

and integration activities

Many large firms are moving away from

in-house Vertically Integrated structures

to Supply Chain Management

1

What is a Supply Chain?

(Cont.)

What is Supply Chain

Management?

The

design and management of seamless, value-

added processes across organizational boundaries

to meet the real needs of the end customer

Institute for Supply Management

Managing supply and demand, sourcing raw

materials and parts, manufacturing and assembly,

warehousing and inventory tracking, order entry

and order management, distribution across all

channels, and delivery to the customer

The Supply Chain Council

The planning and management of all activities

involved in sourcing and procurement, conversion,

and all logistics management activities also

includes coordination with channel partners,

which can be suppliers, intermediaries, third party

service providers, and customers.

Council of Supply Chain Management

Professionals

3

What is Supply Chain

Management? (Cont.)

Old paradigm - Firm gained synergy as a vertically

integrated firm encompassing the ownership and

coordination of several supply chain activities.

Organizational cultures emphasized short-term,

company focused performance.

New paradigm - Firm in a supply chain focuses

activities in its area of specialization and enters into

voluntary and trust-based relationships with supplier

and customer firms.

All participants in the supply chain benefit.

Boundaries are dynamic and extend from the firms

suppliers suppliers to its customers customers (i.e.,

second tier suppliers and customers).

Supply chains now deal with reverse logistics to

handle returned products, warranty repairs, and

recycling.

4

Importance of Supply Chain

Management

Firms have discovered value-enhancing and

long term benefits

Who benefits most? Firms with:

Large inventories

Large number of suppliers

Complex products

Customers with large purchasing budgets

Importance of Supply Chain

Management (Cont.)

Firms using Supply Chain Management:

1. Start with key suppliers

2. Move on to other suppliers,

customers, and shippers

3. Integrate second tier

suppliers and customers

(second tier refers to the

customers customers and

the suppliers suppliers)

Importance of Supply Chain

Management (Cont.)

Cost savings and better coordination of

resources are reasons to employ Supply

Chain Management

Reduced Bullwhip Effect- the magnified reduction of

safety stock costs based on coordinated planning and

sharing of information

Collaborative planning, forecasting, and replenishment

activities reduce the Bullwhip Effect and lead to better

customer service, lower inventory costs, improved

quality, reduced cycle time, better production

methods, and other benefits.

Origins of Supply Chain Management

1950s & 1960s

U.S. manufacturers focused on mass

production techniques as their principal

cost reduction and productivity

improvement strategies

1960s-1970s

Introduction of new computer technology

lead to development of Materials

Requirements Planning (MRP) and

Manufacturing Resource Planning (MRPII)

to coordinate inventory management

and improve internal communication

Origins of Supply Chain

Management (Cont.)

1980s & 1990s

Intense global competition led U.S.

manufacturers to adopt

Supply Chain Management along

with

Just-In-Time (JIT),

Total Quality Management (TQM),

and

Business Process Reengineering

(BPR) practices

Origins of Supply Chain Management

Cont.

2000s and Beyond

Industrial buyers will rely more on

third-party service providers

(3PLs) to improve purchasing and

supply management

Wholesalers/retailers will focus on

transportation and logistics more &

refer to these as quick response,

service response logistics, and

integrated logistics

10

Origins of Supply Chain Management

Cont.

11

The Foundations of Supply

Chain Management

Supplier management, supplier

Supply

evaluation, supplier certification,

Management

strategic partnerships

Operations

Demand management, MRP, ERP,

inventory visibility, JIT (AKA lean

production & Toyota Production

System), TQM (AKA Six Sigma)

Distribution

Transportation management, customer

relationship management, distribution

network, perfect order fulfillment, global

supply chains, service response

logistics

Integration

Process integration, performance

measurement

12

The Foundations of Supply

Chain Management (Cont.)

Purchasing Trends:

Long term relationships

Supplier management- improve performance

through

Supplier evaluation (determining supplier capabilities)

Supplier certification (third party or internal certification

to assure product quality and service requirements)

Strategic partnerships- successful and trusting

relationships with top-performing suppliers

13

Important Elements of Supply

Chain Management (Cont.)

Operations Trends:

Demand management- match

demand to available capacity

Linking buyers & suppliers via

MRP and ERP systems

Use JIT to improve the pull of

materials to reduce inventory

levels

Employ TQM to improve quality

compliance among suppliers

14

Important Elements of Supply

Chain Management (Cont.)

Distribution Trends:

Transportation management- tradeoff

decisions between cost & timing of

delivery/customer service via trucks, rail, water &

air

Customer relationship managementstrategies to ensure deliveries, resolve

complaints, improve communications, &

determine service requirements

Network design- creating distribution

networks based on tradeoff decisions between

cost & sophistication of distribution system

15

Important Elements of Supply Chain

Management (Cont.)

Integration Trends:

Supply Chain Process Integration- when supply chain

participants work for common goals. Requires intrafirm

functional integration. Based on efforts to change attitudes &

adversarial relationships

Supply Chain Performance Measurement- Crucial for

firms to know if procedures are working

16

Current Trends in Supply Chain

Management

Expanding the Supply Chain

U.S. firms are expanding partnerships

and building facilities in foreign markets

The expansion involves:

breadth- foreign manufacturing, office &

retail sites, foreign suppliers & customers

depth- second and third tier suppliers &

customers

17

Current Trends in Supply Chain

Management (Cont.)

Increasing Supply Chain Responsiveness

Firms will increasingly need to be more flexible

and responsive to customer needs

Supply chains will need to benchmark industry

performance and meet and improve on a

continuous basis

Responsiveness improvement will come from more

effective and faster product & service delivery

systems

18

Current Trends in Supply Chain

Management (Cont.)

The Greening of Supply Chains

- Producing, packaging, moving, storing, delivering and

other supply chain activities can be harmful to the

environment

Supply chains will work harder to reduce

environmental degradation

Large majority (75%) of U.S. consumers influenced by

a firms environmental friendliness reputation

Recycling and conservation are a growing alternative

in response to high cost of natural resources

19

Current Trends in Supply Chain

Management- Cont.

Reducing Supply Chain Costs

Cost reduction achieved through:

Reduced purchasing costs

Reducing waste

Reducing excess inventory, and

Reducing non-value added activities

Continuous Improvement through

Benchmarking- improve over competitors performance

Trial & error

Increased knowledge of supply chain processes

2009 South-Western, a division of

Cengage Learning

20

You might also like

- Trabajo en Clase Comparatives Superlatives Worksheet With Answers-Convertido-3Document1 pageTrabajo en Clase Comparatives Superlatives Worksheet With Answers-Convertido-3JOSE LUIS VILLAMIZAR SERRANONo ratings yet

- Chain of Production For A Pair of JeansDocument1 pageChain of Production For A Pair of JeansvimalparkNo ratings yet

- Difference Between Productivity and EfficiencyDocument4 pagesDifference Between Productivity and EfficiencyGee LeeNo ratings yet

- Susan Had A Party Last Week 10° 3PDocument2 pagesSusan Had A Party Last Week 10° 3PCarlos Enrique RochelsNo ratings yet

- Abhi - Introduction Scope and Historical Background of SCMDocument22 pagesAbhi - Introduction Scope and Historical Background of SCMKristin Pena100% (1)

- Scm1 IntroDocument88 pagesScm1 IntroPratishtha Bhalla100% (1)

- Supply Chain Management Session 01Document17 pagesSupply Chain Management Session 01Saima Nazir KhanNo ratings yet

- Book: Fundamentals of Supply Chain Management by John T. MentzerDocument36 pagesBook: Fundamentals of Supply Chain Management by John T. MentzerKrishna PatelNo ratings yet

- Introduction To Supply Chain ManagementDocument16 pagesIntroduction To Supply Chain ManagementhamzabilalNo ratings yet

- SCM Unit 1Document17 pagesSCM Unit 1syedluqman1100% (1)

- Introduction To Supply Chain ManagementDocument23 pagesIntroduction To Supply Chain ManagementxandercageNo ratings yet

- Chapter 1-Introduction To SCM PDFDocument27 pagesChapter 1-Introduction To SCM PDFThandolwethu MbathaNo ratings yet

- SCM Chapter 1Document24 pagesSCM Chapter 1Msy MesayNo ratings yet

- CH 1 SCMDocument8 pagesCH 1 SCMalinashahbaz2530No ratings yet

- Supply Chain PresentationDocument43 pagesSupply Chain Presentationanithavarghese73058100% (1)

- Lecture 02Document12 pagesLecture 02Syed Abdul Mussaver ShahNo ratings yet

- International Logistics: Lecture 5: Supply Chain Management and ProcurementDocument52 pagesInternational Logistics: Lecture 5: Supply Chain Management and ProcurementHồng Anh LêNo ratings yet

- Introduction To Supply Chain ManagementDocument48 pagesIntroduction To Supply Chain ManagementQuality OfficeNo ratings yet

- Chapter 1 For 2nd Yr Evolution of Supply ChainDocument25 pagesChapter 1 For 2nd Yr Evolution of Supply Chaintsion alemayehuNo ratings yet

- Unit II SCM MBADocument52 pagesUnit II SCM MBARaghav SharmaNo ratings yet

- Introduction To SCMDocument38 pagesIntroduction To SCMArif Shan50% (2)

- What Is Supply Chain and What Is Its Importance?Document6 pagesWhat Is Supply Chain and What Is Its Importance?muhammad qasimNo ratings yet

- CH 01Document23 pagesCH 01Karan MadaanNo ratings yet

- Supply Chain Management Report 1Document29 pagesSupply Chain Management Report 1Beberlie LapingNo ratings yet

- SCM MFM Session 1Document25 pagesSCM MFM Session 1Avilash PandeyNo ratings yet

- SCM - An OverviewDocument50 pagesSCM - An OverviewPooja NagleNo ratings yet

- CH 1 Basic Concepts of SCMDocument43 pagesCH 1 Basic Concepts of SCMbogeloveNo ratings yet

- Supply Chain ManagementDocument12 pagesSupply Chain Managements s s sNo ratings yet

- SCM AssignmntDocument58 pagesSCM AssignmntMasresha TasewNo ratings yet

- Logistics and Supply Chain Management As Competitive Advantage-A StudyDocument13 pagesLogistics and Supply Chain Management As Competitive Advantage-A StudyswatikjmNo ratings yet

- SCM Additional Notes 03Document26 pagesSCM Additional Notes 03Raunak kumar SinghNo ratings yet

- OMGT2085 - Topic01 - Overview of Logistics & Supply Chain ManagementDocument39 pagesOMGT2085 - Topic01 - Overview of Logistics & Supply Chain ManagementMelissa OrtizNo ratings yet

- 1.0 Introduction To Supply Chain Management (SCM)Document69 pages1.0 Introduction To Supply Chain Management (SCM)Anchal BaggaNo ratings yet

- LSCMDocument6 pagesLSCMdevilNo ratings yet

- Introduction To Logistics and Supply Chain Management Notes - Semester 2, 2015Document5 pagesIntroduction To Logistics and Supply Chain Management Notes - Semester 2, 2015renjith r nairNo ratings yet

- Supply ChainmanagementDocument37 pagesSupply Chainmanagementharini yaraganiNo ratings yet

- Strategic Supply Chain ManagemnetDocument17 pagesStrategic Supply Chain ManagemnetmuhammadvaqasNo ratings yet

- Supply Chain ManagementDocument67 pagesSupply Chain ManagementAvijit DindaNo ratings yet

- SCM ReportDocument15 pagesSCM Reportapi-3757629100% (2)

- Shruti Assignment 1Document22 pagesShruti Assignment 1Shruti SuryawanshiNo ratings yet

- Assignment On: Submitted To:Mohit Gupta Sir Submitted By: Akesh KumarDocument10 pagesAssignment On: Submitted To:Mohit Gupta Sir Submitted By: Akesh KumarAkesh GuptaNo ratings yet

- Unit 3: Supply Chain, Purchase and Stores Management: Prepared by Dr. R. ArivazhaganDocument58 pagesUnit 3: Supply Chain, Purchase and Stores Management: Prepared by Dr. R. ArivazhaganSusrii SangitaNo ratings yet

- SCM-Supply Chain Management-Paper PresentationDocument23 pagesSCM-Supply Chain Management-Paper Presentationsb_rameshbabu3283100% (1)

- Supply Chain Management: Prof.G.Purandaran M.Tech (I.I.T-Madras) PGDM (I.I.M-Bangalore)Document63 pagesSupply Chain Management: Prof.G.Purandaran M.Tech (I.I.T-Madras) PGDM (I.I.M-Bangalore)pura_malliNo ratings yet

- Supply Chain: Supply Chain Management Is Primarily Concerned With The Efficient Integration ofDocument24 pagesSupply Chain: Supply Chain Management Is Primarily Concerned With The Efficient Integration ofFavaz PgnNo ratings yet

- OM9 - SupplyChainManagement - NewDocument49 pagesOM9 - SupplyChainManagement - NewJane JasaNo ratings yet

- SCM SummaryDocument47 pagesSCM SummaryEmanuelle BakuluNo ratings yet

- Materials ManagementDocument69 pagesMaterials ManagementproffergaryNo ratings yet

- Supply Chain Management Chapter 3: Logistics and Supply Chains Dr. Pramod MatoliaDocument25 pagesSupply Chain Management Chapter 3: Logistics and Supply Chains Dr. Pramod MatoliaIzzatullah JanNo ratings yet

- Value Supply ChainDocument30 pagesValue Supply ChainAlma AgnasNo ratings yet

- Supply Chain ManagementDocument43 pagesSupply Chain ManagementAbdulAhadNo ratings yet

- Supply Chain and Retail Management 1Document6 pagesSupply Chain and Retail Management 1Akash PataneshvarNo ratings yet

- Kaweesa Strategic SCMDocument45 pagesKaweesa Strategic SCMdavid.kaweesa352No ratings yet

- Supply ChainDocument38 pagesSupply ChainHemant SharmaNo ratings yet

- Supply Chains of The FutureDocument38 pagesSupply Chains of The FutureVishakha JainNo ratings yet

- Supply Chain Management SlidesDocument99 pagesSupply Chain Management SlidesSsemanda Timothy0% (1)

- Logistics Management: Definition: Logistics Is The Process of StrategicallyDocument9 pagesLogistics Management: Definition: Logistics Is The Process of StrategicallyashwinNo ratings yet

- Introduction To Supply Chain ManagementDocument42 pagesIntroduction To Supply Chain Managementsoumyarm942No ratings yet

- SCM 0301 - CSDocument26 pagesSCM 0301 - CSGeorges LolcatsNo ratings yet

- Ch1 Week 1Document101 pagesCh1 Week 1harshmaroo100% (2)

- Sony NX Series PDFDocument62 pagesSony NX Series PDFMaya Tes0% (1)

- Pursuit ManualDocument26 pagesPursuit Manualhunter9903No ratings yet

- Chapter Four Risk Assessment of NLNGDocument8 pagesChapter Four Risk Assessment of NLNGOkePreciousEmmanuelNo ratings yet

- Chapter 19 Malicious LogicDocument16 pagesChapter 19 Malicious LogicAnita Sofia KeyserNo ratings yet

- Kendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14Document8 pagesKendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14ombidasarNo ratings yet

- Unit 9 Computer NetworksDocument8 pagesUnit 9 Computer NetworksDaniel BellNo ratings yet

- Running Head: Digital Storytelling As An Assessment Tool 1Document9 pagesRunning Head: Digital Storytelling As An Assessment Tool 1vifongiNo ratings yet

- Clan Survey Pa 297Document16 pagesClan Survey Pa 297Sahara Yusoph SanggacalaNo ratings yet

- Re InviteDocument16 pagesRe InviteAjay WaliaNo ratings yet

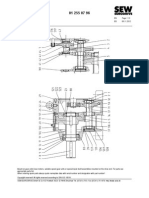

- Parts List 01 255 07 96: Helical Gear Unit R107Document3 pagesParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- Realizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsDocument7 pagesRealizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsLok Bahadur RanaNo ratings yet

- ' ' Shail Ahmad: Privet of India Acres N Inches List of ClientDocument3 pages' ' Shail Ahmad: Privet of India Acres N Inches List of Clientapi-243316402No ratings yet

- Center Pivot Cable / Wire Raintec Span Cable Raintec Motor DropDocument1 pageCenter Pivot Cable / Wire Raintec Span Cable Raintec Motor Drophicham boutoucheNo ratings yet

- LRS Trading StrategyDocument24 pagesLRS Trading Strategybharatbaba363No ratings yet

- Indian Standard: Stationary Valve Regulated Lead Acid Batteries - SpecificationDocument12 pagesIndian Standard: Stationary Valve Regulated Lead Acid Batteries - Specificationmukesh_kht1No ratings yet

- On The Job Winter 2013Document3 pagesOn The Job Winter 2013alanhynesNo ratings yet

- Surface Roughness TesterDocument1 pageSurface Roughness TesterRenju NairNo ratings yet

- Chapter 3: Operating-System StructuresDocument31 pagesChapter 3: Operating-System StructuresDiamond MindglanceNo ratings yet

- 12.turbulent Flow Jan 2015 PDFDocument12 pages12.turbulent Flow Jan 2015 PDFburhanuddinNo ratings yet

- A30050-X6026-X-4-7618-rectifier GR60Document17 pagesA30050-X6026-X-4-7618-rectifier GR60baothienbinhNo ratings yet

- 2 - Way Ball ValvesDocument6 pages2 - Way Ball ValvesFitra VertikalNo ratings yet

- CEN ISO TR 17844 (2004) (E) CodifiedDocument7 pagesCEN ISO TR 17844 (2004) (E) CodifiedOerroc Oohay0% (1)

- CMP Tutorial PDFDocument83 pagesCMP Tutorial PDFMax HaroutunianNo ratings yet

- User Manual For Online Super Market WebsiteDocument3 pagesUser Manual For Online Super Market WebsiteTharunNo ratings yet

- Technical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Document4 pagesTechnical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Yaniss AlgeriaNo ratings yet

- VCEguide 300-360Document25 pagesVCEguide 300-360olam batorNo ratings yet

- Analysis of Business EnvironmentDocument10 pagesAnalysis of Business Environmentrashmi123vaish50% (2)

- SFP Module PDFDocument2 pagesSFP Module PDFMario PatarroyoNo ratings yet

- AcknowledgementDocument4 pagesAcknowledgementPurna GuptaNo ratings yet

- Code PICDocument6 pagesCode PICsongbao527No ratings yet