Hybrid Layouts

Hybrid Layouts

Hybrid layouts modify and/or combine

some aspects of product and process

layouts.

Examples:

Group technology & manufacturing cells used in Just-inTime manufacturing

Grocery stores

Three hybrid layouts:

Cellular layouts (presented by Maria Roig)

Flexible manufacturing systems

Barnes)

(presented by Brian

�Hybrid Layouts: Cellular

layouts

Cellular layouts group dissimilar

machines into work centers

(called cells) that process families

of parts with similar shapes or

requirements.

Combines the flexibility of a process layout with

the efficiency of a product layout.

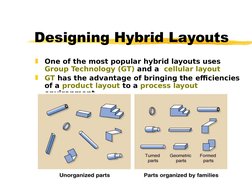

�Designing Hybrid Layouts

One of the most popular hybrid layouts uses

Group Technology (GT) and a cellular layout

GT has the advantage of bringing the efficiencies

of a product layout to a process layout

environment

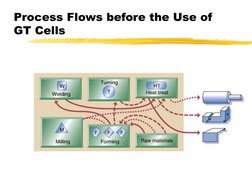

�Process Flows before the Use of

GT Cells

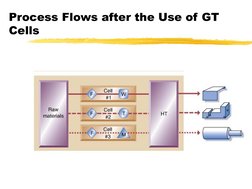

�Process Flows after the Use of GT

Cells

�Hybrid Layouts: Cellular

layouts

Characteristics of the process:

Cells are arranged in relation to each other so that material

movement is minimized.

Large machines that cannot be split among cells are

located near to the cells that use them (point of use)

The layout of machines within each cell resembles a small

assembly line.

Adjustments can be used to arrange the machines within

the cell.

Computer programs can be used to locate cells.

�Hybrid Layouts: Cellular

layouts

Example:

Machines are grouped by function into four distinct

departments.

Component parts manufactured in the process layout

section of the factory are later assembled into a finished

product on the assembly line.

The parts follow different flow paths through the shop.

Three representative routings, for parts A, B, and C.

Workers are skilled within a single department and can

operate more than one machine at a time.

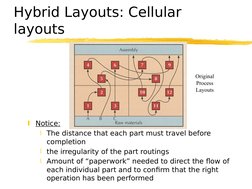

�Hybrid Layouts: Cellular

layouts

Original

Process

Layouts

Notice:

The distance that each part must travel before

completion

the irregularity of the part routings

Amount of paperwork needed to direct the flow of

each individual part and to confirm that the right

operation has been performed

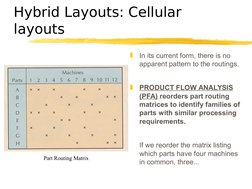

�Hybrid Layouts: Cellular

layouts

In its current form, there is no

apparent pattern to the routings.

PRODUCT FLOW ANALYSIS

(PFA) reorders part routing

matrices to identify families of

parts with similar processing

requirements.

Part Routing Matrix

If we reorder the matrix listing

which parts have four machines

in common, three...

�Hybrid Layouts: Cellular

layouts

Revised Layout with Three Cells

Part Routing Matrix Reordered to Highlight Cells

�Hybrid Layouts: Cellular

layouts

Advantages:

Reduced material handling

and transit time

Reduced setup time

Reduced work-in-process

inventory

Better use of human

resources

multifunctional workers

Easier to control

Easier to automate

Disadvantages:

Inadequate part families

Poorly balanced cells

Expanded training and

scheduling of workers

Increased capital investment

�Types of Layout - Example

Manufacturing Cell

Animated Picture

�Types of Layout - Example

Manufacturing Cell

An example of a hybrid layout

�Types of Layout - Example

Automated Manufacturing Cell

An example of a hybrid layout

�Types of Layout - Example

Flexible Manufacturing Cell

An example of a hybrid layout

�Types of Layout - Example

Manufacturing Cell

An example of a hybrid layout

�Types of Layout - Example

Automated Manufacturing Cell

An example of a hybrid layout

�Types of Layout - Example

Flexible Manufacturing Cell

An example of a hybrid layout

�Types of Layout

Work Cell, Focused Work Center, and

Focused Factory

Work Cell

Assembly or Production line-oriented arrangement of

machines and personnel in what is ordinarily a processoriented facility. Cells can be formed on a temporary

basis.

Example: job shop with rearranged machinery and

personnel to produce 30 unique control panels

Focused Work

Center

A permanent assembly-line-oriented arrangement of

machines and personnel in what is ordinarily a processoriented facility

Example: manufacturing of pipe brackets at a

shipyard

Focused Factory A permanent facility to produce a product or component

in a product-oriented facility

Example: a plant to produce window mechanisms for

automobiles

�Principles of a Good Layout

Manufacturing

Straight-line Flow Pattern when possible

Backtracking kept to a Minimum

Predictable Production Time

Little In-process materials storage

Open Floor plans so everyone can see what is going

on

Bottlenecks under control

Workstations close together

Minimum of material handling

Easy adjustment to changing conditions

�New Trends in Manufacturing

Layouts

Designed for quality and flexibility

Ability to quickly shift to different product

models or to different production rates

Cellular layout within larger process layouts

Automated material handling

U-shaped production lines use to better

accomplish flow control

More open work areas with fewer walls,

partitions, or other obstacles

Smaller and more compact factory layouts

Less space provided for storage of inventories

throughout the layout

�Wrap-up

Attaining Lean Production

Focus on inventory reduction

Build systems that help employees

Reduce space requirements

Develop close relationships with suppliers

Educate suppliers

Eliminate all but value-added activities

Develop the workforce

Make jobs more challenging

Set sights on perfection!