100% found this document useful (1 vote)

2K views53 pagesStevenson Chapter 13 - Inventory Management

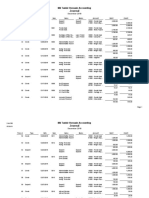

Here are the steps to solve this EPQ example problem:

* Annual demand = 48,000 wheels

* Production rate (p) = 800 wheels/day

* Usage rate (u) = 48,000 wheels/year / 240 days/year = 200 wheels/day

* Setup cost (S) = $45

* Carrying cost (H) = $1 per wheel/year

* Economic run size (Qp) = √(2*D*S)/(H*(p-u))

= √(2*48,000*$45)/($1*(800-200)) = 3,000 wheels

* Minimum total annual cost = Qp*H/2

Uploaded by

Sium Adnan Khan 1511153030Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

2K views53 pagesStevenson Chapter 13 - Inventory Management

Here are the steps to solve this EPQ example problem:

* Annual demand = 48,000 wheels

* Production rate (p) = 800 wheels/day

* Usage rate (u) = 48,000 wheels/year / 240 days/year = 200 wheels/day

* Setup cost (S) = $45

* Carrying cost (H) = $1 per wheel/year

* Economic run size (Qp) = √(2*D*S)/(H*(p-u))

= √(2*48,000*$45)/($1*(800-200)) = 3,000 wheels

* Minimum total annual cost = Qp*H/2

Uploaded by

Sium Adnan Khan 1511153030Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd