Professional Documents

Culture Documents

6 Stroke Engine

6 Stroke Engine

Uploaded by

Kumar SahebCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Stroke Engine

6 Stroke Engine

Uploaded by

Kumar SahebCopyright:

Available Formats

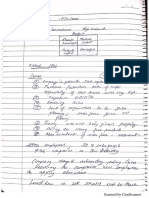

ABSTRACT

Modern world thrives on heat energy used in

different forms.

Automobile industries is ever-growing industry.

95% of the automobile run on IC engines which are

powered by fossil fuels.

Aim of thermal is to convert the heat energy to

mechanical energy.

Efficiency of automobile is 30%.

Paper describes the potential IC engine.

To meet tomorrows challenges.

INTRODUCTION

Otto cycle theoretically represents best option for an

IC engine cycle.

Fuel energy is converted to heat at constant volume ,

when fluid is at maximum compression.

Two technical modifications in 4-stroke to 6-stroke.

Six stroke engines captures the wasted heat from the

4-stroke Otto cycle , creates steam and cools engine

by providing free power stroke.

Developed by BRUCE CROWER and MALCOLM

BEARE.

WORKING OF A 4-STROKE ENGINE

Fuel/air valves opens the piston moves down , which

draws air and fuel into the chamber.

Valve closes as the piston moves back up , putting

the air/fuel mixture under pressure.

Mixture is then ignited , causing a small explosion.

Exhaust valves opens the piston moves back up once

again , pushing the by products of the fuel explosion

out of the chamber. This leaves the piston back in its

starting position ready for another cycle.

BRUCE CROWERS 6STROKE ENGINE

Four stroke engine after the exhaust stroke again the

suction stroke take place.

Engine has some heat energy left in it , which is not

utilized.

To cool, the engine radiator is used.

The engine harnesses normally waste heat energy by

creating steam inside the combustion chamber.

Engine runs on normal 4-stroke engine followed by

steam stroke and extra stroke.

BEARE DUAL OPPOSED

PISTON 6-_STROKE ENGINE

6-stroke BEARE HEAD simply replaces the

conventional 4- stroke engine cylinder head.

The BEARE HEAD utilizes an overhead short stroke

Crank shaft and piston arrangement which open and

closes inlet and exhaust ports leading through the upper

cylinder liner.

The technology combines a 4-stroke engine bottom end

with an opposite piston in the head working half the

cylindrical rate of the bottom piston.

Head piston works in a ported cylinder closely

resembling 2-stroke, thus 4+2=6.

Engine increases both torque and power output , better

fuel economy , cleaner burning with reduced emissions.

Amount of power\torque generated by 35%.

WORKING

After the exhaust cycles out of the chamber, rather than

squirting more fuel and air into the chamber, his design

injects ordinary water. Inside the extremely hot chamber, the

water immediately turns to steam expanding to 1600 times

its volume which forces the piston down for a second power

stroke. Another exhaust cycle pushes the steam out of the

chamber, and then the six-stroke cycle begins again.

It appears to be quite innovative, despite the previous usage

of water injection, which was to hold down combustion

temperatures to avoid melting the engine. The WWII

airplanes that used the water injection often used two stages

of turbo charging, complete with an intercooler between the

stages to limit the temperature rise.

WORKING OF BEARE DUAL

OPPOSED PISTON 6-STROKE

ENGINE

Combustion chamber volume : 100 cc

Main head:

Bore

:

115 mm

Stroke

:

96.3 mm

Swept volume :

1000cc

Beare head:

Bore

Stroke

:

Swept volume

:

75 mm

56.5 mm

:

250 cc

VOLUME-ANGLE 4-STROKE

FOR 6-STROKE

PRESSURE- VOLUME FOR OTTO

CYCLE

PRESSURE-VOLUME FOR DUAL

CYCLE

COMPARISON B\W 4 AND 6STROKE

PERFORMANCE AND

ECONOMY

Beare Head 6 Stroke Engine is thermodynamically more efficient,

because the change in volume of the Beare Engine Power Stroke is

greater than the intake, compression, & exhaust strokes.

The compression ratio of the Beare Dual Piston Engine can be

greatly increased because of the absence of hot spots in the

combustion chamber.

The Beare Engines rate of change in volume during the critical

combustion period is less than in a conventional 4stroke.

The absence of valves within the combustion chamber allows

greater Beare Engine design freedom.

A one-piece Beare Engine casting from crankshaft to upper shaft

becomes feasible. No head gasket needed, cheaper to tool and

produce.

ADVANTAGES

ADVANTAGES OF BEARE DUAL OPPOSED PISTON

6-STROKE ENGINE

The net result is,

Power/torque increases of 35% (conservative)

Simpler and less expensive manufacturing and tooling.

Reduction of cylinder head reciprocating parts.

Lower maintenance costs due to less wearing parts

(Beare cylinder head)

Longer service intervals possible due to lower operating

temperatures recorded.

CONCLUSION

The world now thrives on fossil fuels, but it is an

exhaustible resource. We humans will surely move to an

age where there will be no fossil fuel left for

consumption and we must try to postpone it by using the

available fossil fuel efficiently, so that we can prepare

ourselves to face that era.

The two engines discussed in the above paper promises

to use the available fossil fuel in an efficient manner.

The engines may have some flaws in it which can be

eliminated as time progresses. We are sure that these

engines will rule the future.

REFERENCE

www.sixstroke.com

Beare Technology Six stroke engine - Air-cooled

opposed-piston rotary- & reed-valve 90 V-twin.

Accessed June 2007

Lyons, Pete. "Inside Bruce Crowers Six-Stroke Engine",

Auto Week, Feb 23, 2006. Retrieved on 2007-06-22.

QUERIES

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 19PGP177 Session10 PDFDocument5 pages19PGP177 Session10 PDFHafis SayedNo ratings yet

- 19PGP177 Session12 PDFDocument4 pages19PGP177 Session12 PDFHafis SayedNo ratings yet

- 19PGP177 Session11 PDFDocument5 pages19PGP177 Session11 PDFHafis SayedNo ratings yet

- 19PGP177 Session13 PDFDocument3 pages19PGP177 Session13 PDFHafis SayedNo ratings yet

- 19PGP177 Session6 PDFDocument6 pages19PGP177 Session6 PDFHafis SayedNo ratings yet

- 19PGP177 Session7 PDFDocument4 pages19PGP177 Session7 PDFHafis SayedNo ratings yet

- 19PGP177 Session4 PDFDocument5 pages19PGP177 Session4 PDFHafis SayedNo ratings yet

- 19PGP177 Session9 PDFDocument4 pages19PGP177 Session9 PDFHafis SayedNo ratings yet

- 19PGP177 Session8 PDFDocument5 pages19PGP177 Session8 PDFHafis SayedNo ratings yet

- 19PGP177 Session11 PDFDocument5 pages19PGP177 Session11 PDFHafis SayedNo ratings yet

- 19PGP177 Session5 PDFDocument5 pages19PGP177 Session5 PDFHafis SayedNo ratings yet

- 19PGP177 Session13 PDFDocument3 pages19PGP177 Session13 PDFHafis SayedNo ratings yet

- 19PGP177 Session14 PDFDocument5 pages19PGP177 Session14 PDFHafis SayedNo ratings yet

- 19PGP177 Session6Document6 pages19PGP177 Session6Hafis SayedNo ratings yet

- 19PGP177 Session10 PDFDocument5 pages19PGP177 Session10 PDFHafis SayedNo ratings yet

- 19PGP177 Session2 PDFDocument3 pages19PGP177 Session2 PDFHafis SayedNo ratings yet

- 19PGP177 Session12 PDFDocument4 pages19PGP177 Session12 PDFHafis SayedNo ratings yet

- 19PGP177 Session8 PDFDocument5 pages19PGP177 Session8 PDFHafis SayedNo ratings yet

- 19PGP177 Session7 PDFDocument4 pages19PGP177 Session7 PDFHafis SayedNo ratings yet

- 19PGP177 Session9 PDFDocument4 pages19PGP177 Session9 PDFHafis SayedNo ratings yet

- 19PGP177 Session5Document5 pages19PGP177 Session5Hafis SayedNo ratings yet

- 19PGP177 Session1 PDFDocument3 pages19PGP177 Session1 PDFHafis SayedNo ratings yet

- 19PGP177 Session4Document5 pages19PGP177 Session4Hafis SayedNo ratings yet

- 19PGP177 Session20 PDFDocument2 pages19PGP177 Session20 PDFHafis SayedNo ratings yet

- 19PGP177 Session3Document3 pages19PGP177 Session3Hafis SayedNo ratings yet

- 19PGP177 Session1Document2 pages19PGP177 Session1Hafis SayedNo ratings yet

- 19PGP177 Session19 PDFDocument3 pages19PGP177 Session19 PDFHafis SayedNo ratings yet

- 19PGP177 Session17 PDFDocument3 pages19PGP177 Session17 PDFHafis SayedNo ratings yet

- 19PGP177 Session18 PDFDocument5 pages19PGP177 Session18 PDFHafis SayedNo ratings yet

- 19PGP177 Session8Document5 pages19PGP177 Session8Hafis SayedNo ratings yet