Professional Documents

Culture Documents

Hoiit

Uploaded by

MunavirFirozOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hoiit

Uploaded by

MunavirFirozCopyright:

Available Formats

7-1

Design of Work Systems

Operations Management

BUMG 3107

Faculty of Business

Instructor: Dr. Suresh Subramoniam

LECTURE 8

7-2

Design of Work Systems

Job Design

Job design involves specifying the content and

methods of job

What will be done

Who will do the job

How the job will be done

Where the job will be done

Ergonomics is the incorporation of human factors

in the design of the workplace.

7-3

Design of Work Systems

Design of Work Systems

Specialization- Work that concentrates on some

aspect of product or service

Behavioral Approaches to Job Design

Teams

Methods Analysis

Motions Study

Working conditions

7-4

Design of Work Systems

Job Design Success

Successful Job Design must be:

Carried out by experienced personnel with

the necessary training and background

Consistent with the goals of the

organization

In written form

Understood and agreed to by both

management and employees

7-5

Design of Work Systems

Specialization in Business: Advantages

Table 7.1

For Management:

For Labor:

1. Simplifies training 1. Low education and

2. High productivity

3. Low wage costs

skill requirements

2. Minimum

responsibilities

3. Little mental effort

needed

7-6

Design of Work Systems

Disadvantages

Table 7.1

For Management:

For Labor:

1. Difficult to motivate

quality

1. Monotonous work

2. Limited opportunities

for advancement

2. Worker dissatisfaction,

possibly resulting in

3. Little control over work

absenteeism, high

4. Little opportunity for

turnover, disruptive

self-fulfillment

tactics, poor attention

to quality

7-7

Design of Work Systems

Behavioral Approaches to Job Design

Job Enlargement

Job Rotation

Giving a worker a larger portion of the total task by horizontal

loading. Eg. Making a worker responsible for sequence of

activities instead of one activity.

Workers periodically exchange jobs. This broadens their

learning experience. Helps fill up gaps during absence of other

workers.

Job Enrichment

Increasing responsibility for planning and coordination tasks, by

vertical loading. Eg. Stock clerks handling reordering of goods

at supermarkets

7-8

Design of Work Systems

Motivation and Trust

Motivation

Influences quality and productivity

Contributes to work environment

Trust between management & workers

Influences productivity and employeemanagement relations

More responsibility is entrusted with the worker

only when the trust is more

7-9

Design of Work Systems

Teams

Benefits of teams

Higher quality

Higher productivity

Greater worker satisfaction

Self-directed teams

Groups of empowered to make certain

changes in their work process

7-10

Design of Work Systems

Methods Analysis

Methods analysis

Analyzing how a job gets done

Begins with overall analysis

Moves to specific details

7-11

Design of Work Systems

Methods Analysis

The need for methods analysis can come

from a number of different sources:

Changes in tools and equipment

Changes in product design

or new products

Changes in materials or procedures

Governmental regulations

Other factors (e.g. accidents, quality

problems)

7-12

Design of Work Systems

Methods Analysis Procedure

1.

2.

3.

4.

5.

6.

7.

Identify the operation to be studied. Eg.

Jobs with high labor content, unsafe ,

frequently done

Get employee input

Study and document on current method

Analyze the job

Propose new methods

Install new methods

Follow-up to ensure improvements have

been achieved

7-13

Design of Work Systems

Analyzing the Job

Flow process chart (Fig. 7.2)

Chart used to examine the overall sequence

of an operation by focusing on movements

of the operator or flow of materials

Worker-machine chart (Fig. 7.3)

Chart used to determine portions of a work

cycle during which an operator and

equipment are busy or idle

Requisition made by department head

Put in pick-up basket

To accounting department

Account and signature verified

Amount approved by treasurer

Amount counted by cashier

Amount recorded by bookkeeper

Petty cash sealed in envelope

Petty cash carried to department

Petty cash checked against requisition

Receipt signed

Petty cash stored in safety box

ge

Stor

a

Del

ay

ion

ect

Ins

p

Details of Method

en t

ANALYST PAGE

Job Requisition of petty cash D. Kolb 1 of 2

vem

FLOW PROCESS CHART

Mo

Figure 7-2

tion

Design of Work Systems

Op

era

7-14

7-15

Design of Work Systems

Motion Study

Motion study is the systematic

study of the human motions used

to perform an operation.

7-16

Design of Work Systems

Motion Study Techniques

Motion Study is the systematic study of human

motions used to perform an operation.

Motion study principles - guidelines for designing

motion-efficient work procedures

Analysis of therbligs - basic elemental motions

into which a job can be broken down. Eg. Search,

select, grasp, hold, transport, release load

Micromotion study - use of motion pictures and

slow motion to study motions that otherwise

would be too rapid to analyze

Charts SIMO Chart Fig. 7.4

7-17

Design of Work Systems

Motion study principles

A.

Use of human body

- Both hands must begin, accomplish simultaneously and must not be idle

- Motion of hands must be symmetrical

- Continuous curved motion is preferable than straight line motion with

sharp turn

B. Arrangement and conditions of work place

- Fixed location for all tools and material to avoid therbligs in search and

select

- Gravity bins should be used to reduce reach and move times

C. The design of tools and equipment

- All levers handles and control devices must be readily accessible with the

required mechanical advantage

- Parts must be held by fixtures

7-18

Design of Work Systems

Developing Work Methods

1.

2.

3.

4.

5.

Eliminate unnecessary motions

Combine activities

Reduce fatigue

Improve the arrangement of the workplace

Improve the design of tools and equipment

7-19

Design of Work Systems

Working Conditions

T e m p e ra tu re &

H u m id it y

I llu m in a t io n

V e n t ila t io n

C o lo r

7-20

Design of Work Systems

Working Conditions (contd)

Noise & Vibration

Work Breaks

Safety

Causes of Accidents

7-21

Design of Work Systems

Work Measurement

Determines how long it will take to do a job

Standard time- The amount of time it

takes a qualified worker to complete a

specified task, working at a sustainable rate

using given methods, tools and equipment,

raw materials and workplace arrangement.

Stopwatch time study- Development of

time standards based on observations of

one worker taken over number of cycles

7-22

Design of Work Systems

Determination of number of cycles

Example on Page 317

Number of cycles of observation = n = [(z.s) / (a.x)]2

where s= standard deviation of the sample time

a= desired accuracy percentage

x= sample mean of time

z= Number of normal deviations needed for

desired confidence, eg., z=90% confidence

then z= 1.65

Alternatively

Number of cycles of observation = n = [(z.s) / (e)]2

where e = maximum acceptable error in time units

7-23

Design of Work Systems

Determination of Standard Time

1. Determine observed time (OT) = xi / n

where x= recorded time, n= no. of observations

2. Normal time (NT)= OT x PR

where PR= performance rating

3. Standard Time = NT x AF

where AF= Allowance Factor

AFjob= (1+A) where A is allowance based on job time

AFworkday= 1/(1-A) where A is allowance based on work day time

7-24

Design of Work Systems

Standard elemental times

Time standards derived from a firms historical time

data

7-25

Design of Work Systems

Predetermined Time standards

Published data based on extensive research standard

elemental times.

Advantages:

-Based on large no. of workers under controlled

conditions;

-Analyst not required to make performance rating;

-No disruption of operation;

-Standards can be established even before a job is

done;

Basic measurement unit is Time Measurement Unit

(TMU) which is .0006 minute or the wink of an eye

7-26

Design of Work Systems

Work Sampling

Technique for estimating the proportion of time that

a worker or machine spends on various activities

and idle time

7-27

Design of Work Systems

Example on Page 323

The manager of a supermarket chain tries to find proportion of time stock

clerk spend making price changes on previously marked merchandise.

The manager wants a 98% confidence that the resulting estimate will be

within 5% of the true value. What sample size should he use?

2

z

n p (1 p )

e

z No. of standard deviations

e Percentage error allowed from true value

n Sample size

7-28

Design of Work Systems

Example contd.

Z 2.33

e 0.05 . Take the following for

the true proportion as follows

p 0.5

Revise value of p to new value after

20 observations. Recalculate " n"

7-29

Design of Work Systems

Compensation

Time-based system

Compensation based on time an employee

has worked during a pay period

Output-based (incentive) system

Compensation based on the amount of output

an employee produces during a pay period

7-30

Design of Work Systems

Form of Incentive Plan

Accurate

Easy to apply

Consistent

Easy to understand

Fair

7-31

Design of Work Systems

Compensation

Individual Incentive Plans, piece rate

Group Incentive Plans, profit sharing

Knowledge-Based Pay System, based on

training undergone and skill levels

Management Compensation, top executive

pay based on success of the company

You might also like

- 1039 CassiniDocument24 pages1039 CassiniMunavirFirozNo ratings yet

- CommunicationDocument35 pagesCommunicationMunavirFirozNo ratings yet

- Chapter 7Document11 pagesChapter 7Muhammad AsharNo ratings yet

- CommunicationDocument35 pagesCommunicationMunavirFirozNo ratings yet

- Nagoor Kani Control SystemsDocument209 pagesNagoor Kani Control SystemsAnonymous eWMnRr70q71% (35)

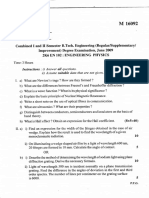

- 2K6 en 102, June 2009Document2 pages2K6 en 102, June 2009MunavirFirozNo ratings yet

- 2K6 en 102 - Apr. 2011Document2 pages2K6 en 102 - Apr. 2011MunavirFirozNo ratings yet

- Kozhikode Train Time PDFDocument1 pageKozhikode Train Time PDFMunavirFirozNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Functional Approach To Challenging Behaviour ResizeDocument37 pagesFunctional Approach To Challenging Behaviour ResizeElectra ZenNo ratings yet

- Human Resource Management - IntroductionDocument25 pagesHuman Resource Management - IntroductionFozail AhmadNo ratings yet

- HRM Participative ManagementDocument23 pagesHRM Participative ManagementAditya SawantNo ratings yet

- A Study On Time Office Management AT MYLAN Laboratories LTD, Unit-8, VizianagaramDocument86 pagesA Study On Time Office Management AT MYLAN Laboratories LTD, Unit-8, VizianagaramRaghuram AravalliNo ratings yet

- M.A. Applied PsychologyDocument56 pagesM.A. Applied PsychologyHappyMinds7No ratings yet

- Teaching English To Senior Citizens - The EFL Teacher As A Course Developer and A Reflective PractitionerDocument17 pagesTeaching English To Senior Citizens - The EFL Teacher As A Course Developer and A Reflective PractitionerEducationdavid100% (1)

- Secondary 2a Assessment 1Document22 pagesSecondary 2a Assessment 1api-533984328No ratings yet

- Mental Toughness Chapter 1-3Document27 pagesMental Toughness Chapter 1-3Bent Tong100% (2)

- Professional Skills and Abilities of Effective TeachersDocument3 pagesProfessional Skills and Abilities of Effective Teachersapi-350475725No ratings yet

- 5 6251157094955745737 PDFDocument165 pages5 6251157094955745737 PDFAmit SinghNo ratings yet

- LO1 Hospitality Consumer Behavior and InsightDocument64 pagesLO1 Hospitality Consumer Behavior and InsightSangeeta GotameNo ratings yet

- Training Key Managerial Skills For New Managers and SupervisorsDocument4 pagesTraining Key Managerial Skills For New Managers and SupervisorsBMG TrainingNo ratings yet

- FunctionDocument7 pagesFunctionChukka KeerthiNo ratings yet

- Case Study 4Document1 pageCase Study 4lumiradut50% (2)

- ABE Level 5 UMAO Syllabus v2Document7 pagesABE Level 5 UMAO Syllabus v2Immanuel LashleyNo ratings yet

- Veterinary Animal Husbandry Extension Education PDFDocument12 pagesVeterinary Animal Husbandry Extension Education PDFPriye Obomanu100% (1)

- Group 2 - Section B - MPPO ProjectDocument18 pagesGroup 2 - Section B - MPPO ProjectSam SamNo ratings yet

- Alberto Sample: Profiles Sales AssessmentDocument14 pagesAlberto Sample: Profiles Sales AssessmentValaki MimiNo ratings yet

- Delegation PDFDocument5 pagesDelegation PDFPauline IntiaNo ratings yet

- 4 A 10Document15 pages4 A 10Elieza Mae Dionisio BautistaNo ratings yet

- Vol. 4 Issue 4 Full PDFDocument80 pagesVol. 4 Issue 4 Full PDFISHANT SINGH BHADAURIYANo ratings yet

- Chapter 9Document9 pagesChapter 9ahmedNo ratings yet

- G11 Campos Research Proposal Group 1Document48 pagesG11 Campos Research Proposal Group 1remar rubindiazNo ratings yet

- Green Skinner Time MGT 2005Document17 pagesGreen Skinner Time MGT 2005SunnyNo ratings yet

- Assignment WorkDocument67 pagesAssignment WorksandeepNo ratings yet

- Consumer Behavior - AppleDocument33 pagesConsumer Behavior - AppleNavin1990100% (1)

- Maslow TheoryDocument6 pagesMaslow TheoryJen7778No ratings yet

- PB - The Hopeful RomanticDocument3 pagesPB - The Hopeful Romanticm888braun0% (1)

- Nature of Human Behavior: The People-Organization RelationshipDocument49 pagesNature of Human Behavior: The People-Organization RelationshipMaricel MelgarNo ratings yet

- Organizational BehaviourDocument371 pagesOrganizational Behaviourbalakalees100% (1)