Traditional Inventory System

Brijesh Patel

�Definition

Inventory can be defined as a physical resource that a firm

holds in stock with the intent of selling it or transforming it

into a more valuable state.

There are many types of inventory:

Raw

Materials

Works-in-Process

Finished

Goods

�Definition

Traditional inventory systems attempt to solve the inventory

management

dilemma

through

better

forecasting,

improvements in the order point / order quantity process, or by

adjusting safety stock levels.

However, order quantities, safety stock and lead time represent

only a minority of the sources of inventory problems.

�Objectives

Improve customer service

Economies of production

Transportation savings

Hedge against future

To maintain independence of supply chain

�Basic Features

Agreements

Agreement with supplier was basic part of traditional system

where focus was to avoid payment full price for incoming

inventory in advance.

It also involves demanding price contracts and discounts in

exchange of consistent orders for specific periods.

Today most of the interaction with suppliers is done in real

time with the on go payment options with suppliers as well as

delivery agents.

Manual monitoring of stock level

Simple eye assessment when a store manager would stand in the middle of store and

based on visual observations, decide which items are short in inventory and need

replenishment.

The system was also based on manual calculations being made on stock level using

Fixed Order Quantity

Inventory Storage

Large spaces were needed in warehouses to store inventory as at that time large

inventory only meant good delivery and service to customers.

Order placement

Orders were placed manually on a telephone, fax, mail, etc. unlike the modern

technology driven systems where integrated software system takes care of placing

and processing orders without employee input.

�Classification Of Inventory

ABC

HML

XYZ

VED

FSN

SDE

SOS

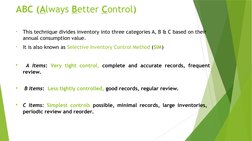

�ABC (Always Better Control)

This technique divides inventory into three categories A, B & C based on their

annual consumption value.

It is also known as Selective Inventory Control Method (SIM)

A Items: Very tight control, complete and accurate records, frequent

review.

B Items: Less tightly controlled, good records, regular review.

C Items: Simplest controls possible, minimal records, large inventories,

periodic review and reorder.

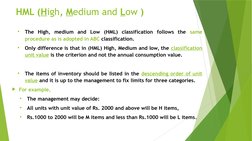

�HML (High, Medium and Low )

The High, medium and Low (HML) classification follows the same

procedure as is adopted in ABC classification.

Only difference is that in (HML) High, Medium and low, the classification

unit value is the criterion and not the annual consumption value.

The items of inventory should be listed in the descending order of unit

value and it is up to the management to fix limits for three categories.

For example,

The management may decide:

All units with unit value of Rs. 2000 and above will be H items,

Rs.1000 to 2000 will be M items and less than Rs.1000 will be L items .

�XYZ

On the basis of value of inventory stored

X High Value

Y Medium value

Z Least value

Aimed to identify items which are extensively

stocked.

�FSN (Fast, Slow and Non)

Classification depends on the pattern of issues from stores

F Fast moving

S Slow moving

N Non Moving

It helps to avoid investments in non moving or slow items.

If there are no issues of an item during the period, it is N item.

Then up to certain limit, say 10-15 issues in the period, the item is S item

The items exceeding such limit of no. of issues during the period are F items.

The period of consideration & the limiting number of issues vary from organization

to organization.

�SDE (Scare, Difficult and Easy)

Analysis is based upon the availability of items and is very useful in

the context of scarcity of supply

S refers to scarce items, generally imported, and those which

are in short supply.

D refers to difficult items, which are available indigenously but

are difficult items to procure.

E refers to items which are easy to acquire and which are

available in the local markets.

�VED (Vital , Essential and Desirable)

VED classification is based on the criticality of the inventories.

Vital items Its shortage may cause havoc & stop the work in organization.

They are stocked adequately to ensure smooth operation.

Essential items - Here, reasonable risk can be taken. If not available, the

plant does not stop; but the efficiency of operations is adversely affected

due to expediting expenses. They should be sufficiently stocked to ensure

regular flow of work.

Desirable items Its non availability does not stop the work because they

can be easily purchased from the market as & when needed.

�S-OS

Raw materials especially for agriculture units

S Seasonal

OS Off seasonal

�EOQ (Economic Order Quantity)

EOQ or Fixed Order Quantity system is the technique of ordering

materials whenever stock reaches the reorder point.

Economic order quality deals when the cost of procurement and

handling of inventory are at optimum level and total cost is

minimum.

In this technique, the order quantity is larger than a single

periods requirement so that ordering costs & holding costs

balance out.

�Assumptions

Demand for the product is constant

Lead time is constant

Price per unit is constant

Inventory carrying cost is based on average inventory

Ordering costs are constant per order

All demands for the product will be satisfied (no back

orders)

�EOQ Model

Annual Cost

Holding Cost

Order Quantity

�EOQ Model

Annual Cost

Holding Cost

Order (Setup) Cost

Order Quantity

�EOQ Model

Annual Cost

Total Cost Curve

Holding Cost

Order (Setup) Cost

Order Quantity

�EOQ Model

Annual Cost

Total Cost Curve

Holding Cost

Order (Setup) Cost

Optimal

Order Quantity (Q*)

Order Quantity

�EOQ Formula Derivation

D=

C=

Q=

S=

I =

H=

Annual demand (units)

Cost per unit ($)

Order quantity (units)

Cost per order ($)

Holding cost (%)

Holding cost ($) = I x C

Total cost =

inv carry cost

Average inventory

units = Q / 2

$

= (Q / 2) x C

Cost to carry

average inventory = (Q / 2) x I x C

= (Q /2) x H

order cost

Take the 1st derivative:

d(TC)/d(Q) =

Number of Orders = D / Q

Ordering costs

= S x (D / Q)

(Q/2) x I x C + S x (D/Q)

(I x C) / 2

- (D x S) / Q

To optimize: set d(TC)/d(Q) = 0

DS/ Q = IC / 2

Q/DS = 2 / IC

Q= (DS x 2 )/ IC

Q = sqrt (2DS / IC)

�Economic Order Quantity

2 D S

EOQ

H

D=

S=

C=

I =

H=

Annual demand (units)

Cost per order ($)

Cost per unit ($)

Holding cost (%)

Holding cost ($) = I x C

�Problems

Poor execution

Poor communication

Poor decision-making

Poor execution, communication and decision making, coupled with

advanced inventory management systems leads to a vicious cycle,

ultimately reducing sales, profit margins and customer loyalty.

�Thank You