Professional Documents

Culture Documents

Eor Storage Reservoirs

Uploaded by

manish.74170 ratings0% found this document useful (0 votes)

11 views15 pagesEnhnced oil recovery storage in reservoirs

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEnhnced oil recovery storage in reservoirs

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views15 pagesEor Storage Reservoirs

Uploaded by

manish.7417Enhnced oil recovery storage in reservoirs

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 15

CO2 Enhanced Oil Recovery

and Storage in Reservoirs

CHE384-Energy Technology and Policy

Xi Chen

Nov. 19th, 2007

EOR-Background

Primary recovery

Natural pressure, 10% OOIP

Secondary recovery

Injection of water or gas, 20-40% OOIP

Tertiary or enhanced oil recovery

Aiming at recovery of 30%-60% OOIP

Categories of EOR

Thermal recovery

Steam flooding, ~50% of EOR production

Chemical injection

Polymer/water flooding, <1%

Gas injection ~50%

immiscible flooding: CH4, N2

miscible flooding : CO2

Ult. Recovery

Process Utilization Lecture notes

% OOIP

Miscible 10-15 10 MCF/bbl

from

Immiscible 5-10 10 MCF/bbl Dr. Larry W. Lake

EOR by CO2 flooding

Advantages of CO2 flooding

Dense fluid over much of the range of pressure

and temperature in reservoirs

Low MMP (minimum miscibility pressure) and

high miscibility with oil

Low mutual solubility with water

Low cost and abundance

Naturally occuring source

Environmental benefit if industrial CO2 is used

and stored in reservoirs

Capture and sequestration of CO2 from combustion

of fossil fuel

Source: Oil & Gas Journal

206,000 barrels per day in 2004 = 4% of the Nation’s total.

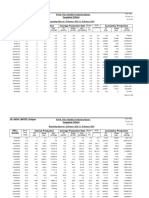

Screening criteria for application

of CO2 miscible flood

Gozalpour, “CO2 EOR and Storage in Oil Reservoirs”, 2005,

Oil & Gas Science and Technology – Rev. IFP,

Vol. 60 (2005), No. 3, pp. 537-546

Optimum reservoir parameters and weighting factors

for ranking oil reservoirs suitable for CO2 EOR

Rivas, O. et al. (1992) Ranking Reservoirs for Carbon Dioxide

Flooding Processes.

Technical challenge

Poor sweep efficiency

Gravity override

Mobility contrast

Reservoir heterogeneity

CO2 related problem

Corrosion on facilities

Solid deposition in reservoir formation

Well spacing

Greater spacing causes sweep efficiency reduction

CO2 mobility control

Foam

mixed surfactants as foaming agent

Thickening agent

Fluorinated compound or polymer (good

solubility in CO2)

Chemical gels

In-situ gelation of polymer to lower

permeability

CO2 Storage in Reservoirs

Most favorable site for storage

Dense webs of seismic and well for long-

term trap

Surface and subsurface infrastructure

readily converted for CO2 distribution and

injection

Less costly

CO2 Storage in Reservoirs

CO2 capacity of a reservoir:

Theoretically, equal to the volume

previously occupied by the produced oil

and water

Other factor: Water invasion, gravity

segregation, reservoir heterogeneity and

CO2 dissolution

Reservoir type, depth, size and safety of

CO2 storage

Economics

Cost of CO2 from different sources:

Naturally occuring CO2: $14/t

Pure anthropogenic CO2 from chemical plant: $18/t

Capture and processing of CO2 from coal fired plant: $18-54/t

Lako, P. (2002) Options for CO2 Sequestration and Enhanced

Fuel Supply.

CO2 utilization efficiency: 4~8 Mscf/bbl (0.2~0.5t/bbl)

Transportation cost: $0.5~1.2/Mscf

Operation cost: $2-3/bbl

Economical even at a oil price of $40/bbl.

CO2 storage credit ($2.5/Mscf) makes it more

economical for producers.

Summary

Combination of CO2 EOR and storage in

reservoirs provides a bridge between

reducing greenhouse gases from industrial

waste streams and the beneficial use of CO2

injection for increasing oil and gas recovery.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Discover Your Life PathDocument0 pagesDiscover Your Life PathypraviNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Numerology - Numbers Past and Present With The Lo Shu Square PDFDocument54 pagesNumerology - Numbers Past and Present With The Lo Shu Square PDFifhul2179% (14)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- By Ramanand Roll-PE16M005 M. Tech. Petroleum Iit MadrasDocument20 pagesBy Ramanand Roll-PE16M005 M. Tech. Petroleum Iit Madrasmanish.7417No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- By Ramanand Roll-PE16M005 M. Tech. Petroleum Iit MadrasDocument20 pagesBy Ramanand Roll-PE16M005 M. Tech. Petroleum Iit Madrasmanish.7417No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hall PlotDocument3 pagesHall Plotmanish.7417No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 4 Pab1033 Pcb1033 Reservoir Rock and Fluid PropertiesDocument15 pages4 Pab1033 Pcb1033 Reservoir Rock and Fluid PropertiesMohammad M. Lil-jivaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Interval Production Average Production Rate Cumulative ProductionDocument3 pagesInterval Production Average Production Rate Cumulative Productionmanish.7417No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Bourdet vs. Additional Derivatives: In/heshammokhtaraliDocument11 pagesBourdet vs. Additional Derivatives: In/heshammokhtaralimanish.7417No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Water InjectionDocument15 pagesWater InjectionWaleed El-azabNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Input: Table-1: EOR Screening of NHK027 Block As Per SPE-12069 Min Score 5Document2 pagesInput: Table-1: EOR Screening of NHK027 Block As Per SPE-12069 Min Score 5manish.7417No ratings yet

- The Stratigraphic Method: A Structured Approach To History-Matching Complex Simulation ModelsDocument8 pagesThe Stratigraphic Method: A Structured Approach To History-Matching Complex Simulation ModelsAlejandro Duvan Lopez RojasNo ratings yet

- 33 Pcb1033 Reservoir Rock and Fluid PropertiesDocument22 pages33 Pcb1033 Reservoir Rock and Fluid Propertiesmanish.7417No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- ECLIPSE How To Request Grid Output For Specific Cells in A ModelDocument1 pageECLIPSE How To Request Grid Output For Specific Cells in A Modelmanish.7417No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ECLIPSE How To Request Grid Output For Specific Cells in A ModelDocument1 pageECLIPSE How To Request Grid Output For Specific Cells in A Modelmanish.7417No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- TreadmillDocument2 pagesTreadmillmanish.7417No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Classic Water Flooding Predictive ModelsDocument28 pagesClassic Water Flooding Predictive Modelsjohndo30% (1)

- TreadmillDocument2 pagesTreadmillmanish.7417No ratings yet

- Alternative Methodology To Avoid Convergence Problems Caused For WELDRAW KeywordDocument3 pagesAlternative Methodology To Avoid Convergence Problems Caused For WELDRAW Keywordmanish.7417No ratings yet

- By Ramanand Roll-PE16M005 M. Tech. Petroleum Iit MadrasDocument20 pagesBy Ramanand Roll-PE16M005 M. Tech. Petroleum Iit Madrasmanish.7417No ratings yet

- Tech Reservoir MBE Mat BalDocument12 pagesTech Reservoir MBE Mat BalPerry SegereNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Co 2 ExercisesDocument15 pagesCo 2 Exercisesmanish.7417No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Petrel Reservoir EngineeringDocument31 pagesPetrel Reservoir Engineeringmanish.7417No ratings yet

- 4 Methods For Any TreatmentDocument1 page4 Methods For Any Treatmentmanish.7417No ratings yet

- Carbon Capture and Storage MechanismsDocument10 pagesCarbon Capture and Storage Mechanismsmanish.7417No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- S3 Control Quick GuideDocument24 pagesS3 Control Quick Guidemanish.7417No ratings yet

- Pge 361Document89 pagesPge 361egv2000No ratings yet

- SPE/WPC/AAPG joint definitions of petroleum resourcesDocument1 pageSPE/WPC/AAPG joint definitions of petroleum resourcesmanish.7417No ratings yet

- Gullfaks Sorreservoirsimulationmodelrev 1Document22 pagesGullfaks Sorreservoirsimulationmodelrev 1manish.7417No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Presentations TipsDocument21 pagesPresentations Tipsapi-253601657No ratings yet

- Labor Law - Durabuilt Vs NLRCDocument1 pageLabor Law - Durabuilt Vs NLRCEmily LeahNo ratings yet

- The Communistic Societies of The United StatesFrom Personal Visit and Observation by Nordhoff, Charles, 1830-1901Document263 pagesThe Communistic Societies of The United StatesFrom Personal Visit and Observation by Nordhoff, Charles, 1830-1901Gutenberg.org100% (2)

- Bitcoin Dicebot Script WorkingDocument3 pagesBitcoin Dicebot Script WorkingMaruel MeyerNo ratings yet

- Listing Eft 2022Document22 pagesListing Eft 2022Farhan AimanNo ratings yet

- Corporation Law - Atty. Zarah Villanueva (Case List)Document3 pagesCorporation Law - Atty. Zarah Villanueva (Case List)leizzhyNo ratings yet

- Mill Test Certificate: Run Date 21/12/2021 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 21/12/2021 OR0019M - JAZ User ID E1037RakeshParikhNo ratings yet

- Liquidity RatioDocument3 pagesLiquidity RatioJodette Karyl NuyadNo ratings yet

- HR McqsDocument12 pagesHR McqsHammadNo ratings yet

- Marico's Leading Brands and Targeting StrategiesDocument11 pagesMarico's Leading Brands and Targeting StrategiesSatyendr KulkarniNo ratings yet

- MEC 1st Year 2020-21 EnglishDocument16 pagesMEC 1st Year 2020-21 EnglishKumar UditNo ratings yet

- EdpDocument163 pagesEdpCelina SomaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ralph & Eileen Swett Foundation - Grant ApplicationDocument8 pagesRalph & Eileen Swett Foundation - Grant ApplicationRafael Kieran MondayNo ratings yet

- Lesson 6 Global DividesDocument5 pagesLesson 6 Global DividesRachel VillasisNo ratings yet

- Indian Railways Project ReportDocument27 pagesIndian Railways Project Reportvabsy4533% (3)

- SEC Application of Perkins Coie TWB Investment Partnerships SEC 2008Document6 pagesSEC Application of Perkins Coie TWB Investment Partnerships SEC 2008Beverly TranNo ratings yet

- Proforma LocDocument3 pagesProforma LocPooja MohiteNo ratings yet

- Supplier Selection: A Green Approach With Carbon Footprint MonitoringDocument8 pagesSupplier Selection: A Green Approach With Carbon Footprint Monitoringamit_hoodaNo ratings yet

- Women Welfare Schemes of Himachal Pradesh GovtDocument4 pagesWomen Welfare Schemes of Himachal Pradesh Govtamitkumaramit7No ratings yet

- Caution against sharing access to our websiteDocument23 pagesCaution against sharing access to our websiteramshere2003165No ratings yet

- Data 73Document4 pagesData 73Abhijit BarmanNo ratings yet

- How High Would My Net-Worth Have To Be. - QuoraDocument1 pageHow High Would My Net-Worth Have To Be. - QuoraEdward FrazerNo ratings yet

- CBRMDocument14 pagesCBRMSurajSinghalNo ratings yet

- Urbanization and Rural-Urban Migration: Theory and PolicyDocument42 pagesUrbanization and Rural-Urban Migration: Theory and PolicyJunaid AhmedNo ratings yet

- Mortgage 2 PDFDocument5 pagesMortgage 2 PDFClerry SamuelNo ratings yet

- Capital Budgeting Project Instruction RubricDocument3 pagesCapital Budgeting Project Instruction RubricSunil Kumar0% (1)

- CRM ProcessDocument9 pagesCRM ProcesssamridhdhawanNo ratings yet

- Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E Ticketing Service Electronic Reservation Slip (Personal User)Anonymous Pog15DNo ratings yet

- ERUMGROUP 2019 - General PDFDocument20 pagesERUMGROUP 2019 - General PDFAlok KaushikNo ratings yet

- Lead Dev Talk (Fork) PDFDocument45 pagesLead Dev Talk (Fork) PDFyosiamanurunNo ratings yet

- Informative FinalDocument7 pagesInformative FinalJefry GhazalehNo ratings yet