Professional Documents

Culture Documents

Maximum Hypothesis in A Plastic Deformation

Uploaded by

karthigeyan0 ratings0% found this document useful (0 votes)

8 views10 pagesOriginal Title

Maximum Hypothesis in a Plastic Deformation.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views10 pagesMaximum Hypothesis in A Plastic Deformation

Uploaded by

karthigeyanCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 10

• When metals are being stressed in tension at relatively low

levels, the applied stress is linearly proportional to the

induced strain, i.e. elastic deformation.

• The relationship between the applied stress and the strain

being induced.

What is Plastic Deformation?

• Plastic deformation is a process in which permanent

deformation is caused by a sufficient load.

• It produces a permanent change in the shape or size of a

solid body without fracture, resulting from the application of

sustained stress beyond the elastic limit.

What happens during plastic deformation?

• When a sufficient load is applied to a metal or other

structural material, it will cause the material to change shape.

• A temporary shape change that is self-reversing after the

force is removed, so that the object returns to its original

shape.

What is slip in plastic deformation?

• Slip is the prominent mechanism of plastic deformation in metals.

• It involves sliding of blocks of crystal over one other along definite

crystallographic planes, called slip planes.

• It is analogous to a deck of cards when it is pushed from one end.

• Slip occurs when shear stress applied exceeds a critical value.

Causes of Deformation

• Deformation is caused by stress

• The scientific term for force applied to a certain area.

• Stresses on rocks can stem from various sources, such as

changes in temperature or moisture, shifts in the Earth's

plates, sediment buildup or even gravity.

Deformation Process

• A forming operation is one in which the shape of a metal

sample is altered by plastic deformation.

• Forming processes include stamping, rolling, extrusion and

forging, where deformation is induced by external

compressive forces or stresses exceeding the yield stress of

the material.

Maximum Hypothesis on Plastic Deformation.

• Under tensile stress, plastic deformation is characterized by a

strain hardening region and a necking region and finally,

fracture.

• During strain hardening the material becomes stronger

through the movement of atomic dislocations.

• During necking, the material can no longer withstand the

maximum stress and the strain in the specimen rapidly

increases.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Ams - Metallography of SpecimenDocument8 pagesAms - Metallography of SpecimenkarthigeyanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- First PartDocument9 pagesFirst PartkarthigeyanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

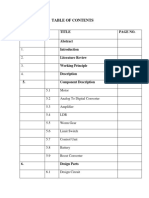

- NO. Title Page No. Literature Review Working Principle Description 5. Component DescriptionDocument2 pagesNO. Title Page No. Literature Review Working Principle Description 5. Component DescriptionkarthigeyanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- NO. Title Page No. Literature Review Working Principle Description 5. Component DescriptionDocument2 pagesNO. Title Page No. Literature Review Working Principle Description 5. Component DescriptionkarthigeyanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Light Sensor: Karthigeyan.R R18MDD05 M.Tech-Machine Design Mechatronic Product DesigDocument11 pagesLight Sensor: Karthigeyan.R R18MDD05 M.Tech-Machine Design Mechatronic Product DesigkarthigeyanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Light Sensor: Karthigeyan.R R18MDD05 M.Tech-Machine Design Mechatronic Product DesigDocument11 pagesLight Sensor: Karthigeyan.R R18MDD05 M.Tech-Machine Design Mechatronic Product DesigkarthigeyanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)