Professional Documents

Culture Documents

A Presentation SARQA DKG

A Presentation SARQA DKG

Uploaded by

AshimaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Presentation SARQA DKG

A Presentation SARQA DKG

Uploaded by

AshimaCopyright:

Available Formats

21 CFR Part 11

Electronic Records & Electronic

Signatures

Svend Martin Fransen

Principal Scientist,

QS CRS Quality Services

Novo Nordisk A/S

Contents

• 21CFR11 history

• The important aspects of 21CFR11

• Equivalent requirements in EU legislation

• The Novo Nordisk 21 CFR11 compliance

project

• Examples

• Experiences learned

Slide No. 2 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Contents

• 21CFR11 history

• The important aspects of 21CFR11

• Equivalent requirements in EU legislation

• The Novo Nordisk 21 CFR11 compliance

project

• Examples

• Experiences learned

Slide No. 3 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Why do we have computers?

It has gradually become common knowledge that

knowledge is the most important resource in the

business of the future.

It is the ability to create new knowledge and the ability

to utilize and organize existing knowledge that will be

the primary source for obtaining lasting competitive

advantages.

Peter Holdt Christensen: ”Viden om” – ledelse, viden og

virksomheden

Slide No. 4 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

What is 21CFR11?

• 21CFR = FDA, Code of Federal Regulations

• 21CFR58 = GLP

• 21CFR210 = GMP, Drugs (General)

• 21CFR211 = GMP, Drugs (Finished Pharmaceuticals)

• 21CFR312 = Inv. New drug Application (GCP)

• 21CFR314 = FDA Approval of new drug (GCP)

• 21CFR6xx = GMP, biologics

• 21CFR820 = GMP, Devices

• 21CFR…… = Food, nutrients and cosmetics

• 21CFR11 = Electronic Records; Electronic Signatures

Slide No. 5 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Historic overview

• A wish from the Industry (use of ES)

• FDA:

• Final Draft i 1994

• Final Rule 20.March.1997, effective from 20.Aug.1997

• 4 draft guidelines, ’Glossary of Terms’, ’Validation’, ’Time

stamps’ and ’Maintenance of ER’

• GAMP Part 11 guide, published Nov. 2001 (part 2)

• PDA ”GERM” guide, published Sep. 2002 (part 1)

• PDA ”GERM” guide ’Models’, expected 2003 (part 3)

Slide No. 6 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Contents

• 21CFR11 history

• The important aspects of 21CFR11

• Equivalent requirements in EU legislation

• The Novo Nordisk 21 CFR11 compliance

project

• Examples

• Experiences learned

Slide No. 7 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

21CFR11, Overview

• Substantive rule from 20 August 1997

• Applies to any e-record in any FDA regulated

work including legacy systems

• Criteria for e-records and e-signatures:

• Trustworthy and reliable

• E-signatures = hand-written signatures

• Minimum requirements / fraud prevention

Slide No. 8 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Systems not Applications

• All definitions and

clauses in 21 CFR

Application Instructions,

-software Manuals, etc. 11 refer to

systems

Platform

- hardware Equipment • Application is not

- system SW

mentioned

Computer system Controlled function

• IT part of the GXP

Computer based system

environment.

• Do they know?

Working environment

COMPUTER RELATED SYSTEM

Slide No. 9 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

21 CFR Part 11, Basics

• Electronic records equivalent with paper records

• Storage, retrieval and copying in full retention period

• Submitting to FDA

• Protection of electronic records

• Security (physical and logical)

• Validation

• Audit trail (who did what, when including reason where req.)

• Permission to use of electronic signature

• Equivalent with handwritten signatures

• Name, date and meaning

• Linking of signature to record

• Unique for an individual

Slide No. 10 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

ORA, Compliance Policy Guide

CPG 7153.17 (May 1999)

• Acknowledging ‘not all older systems fully

compliant by Aug 20, 1997’

• ‘firms must take steps to achieve full compliance’

• ‘Regulatory actions based on case by case evaluation’

• ‘FDA auditors should intensify their scrutiny of e-recs’

• Calls for firms to

• have a ‘reasonable timetable’

• ‘promptly modify’ any system not in compliance

• ‘be able to demonstrate progress’

• ‘have procedural controls in place by now’

Slide No. 11 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

FDA 21CFR11 inspection questions

(source: : 21CFR11 Compliance Report, Vol.2, No. 4).

• Who is allowed to input data?

• Who is allowed to change data?

• How can you tell who entered the data?

• How do you know which data had been changed?

• When do you lock down the data input?

• Can you do the following actions?

“Show me some data, show me you can see the history of the data,

show me you control the data life cycle.”

• Is the system validated and are the requirements met?

• Can you show me the results of the validation activities?

• Does the validation include: “Pass/fail, signature, date/time stamp”;

and “objective evidence - screen prints or page printouts with a link

to the direction that generated the output.”?

Slide No. 12 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Earlham College, Warning Letter

• In addition to the above listed violations, our Investigator

noted that the laboratory is using an electronic record

system for processing and storage of data from the

atomic absorption and HPLC instruments that is

• not set up to control the security and data integrity in that the

system is not password controlled,

• there is no systematic back-up provision, and

• there is no audit trail of the system capabilities.

• The system does not appear to be designed and controlled in

compliance with the requirements of 21 CFR, Part 11,

Electronic Records.

Slide No. 13 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Contents

• 21CFR11 history

• The important aspects of 21CFR11

• Equivalent requirements in EU legislation

• The Novo Nordisk 21 CFR11 compliance

project

• Examples

• Experiences learned

Slide No. 14 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

EU

• Annex 11, Computerised Systems

• Personnel

• Validation

• System

• Descriptions and SOP’s

• Change control and configuration management

• Records; entry, storage, retrieval

• Audit trail

• Security and Disaster recovery

• etc.

Slide No. 15 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

PIC/S Draft Guidance

Good Practices for Computerised Systems in

regulated ”GXP” environment

• Computer System Life cycle, incl.

• Electronic Records and Signatures

• Security, and

• Audit trail

• Checklists for Inspection

• Links ISO and IEEE standards, 21CFR11, APV guides,

PDA Technical Reports together

Slide No. 16 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Quote from PIC/S Guide

21. ELECTRONIC RECORDS AND ELECTRONIC SIGNATURES

• 21.1 EC Directive 91/356 sets out the legal requirements for EU

GMP. The GMP obligations include a requirement to maintain a

system of documentation, (Article 9). The main requirements in

Article 9.1 are that documents are clear, legible and up to date, that

the system of documentation makes it possible to trace the history

of manufacture (and testing) of each batch and that the records are

retained for the required time. Article 9.2 envisages that this

documentation may be electronic, photographic or in the form of

another data processing system, rather than written. The main

requirements here being that the regulated user has validated the

system by proving that the system is able to store the data for the

required time, that the data is made readily available in legible form

and that the data is protected against loss or damage.

Slide No. 17 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Draft Proposal for a Commission Directive

(30.Apr.2002)

• Amending Commission Directive 91/356/EEC , Laying Down the

Principles and Guidelines of Good Manufacturing Practice for

Medicinal Products for Human Use

• "When electronic, photographic or other data processing systems

are used instead of written documents, the manufacturer or

importer shall have validated the systems by proving that the data

will be appropriately stored during the anticipated period of storage.

Data stored by these systems shall be made readily available in

legible form and shall be provided on demand to the competent

authorities. For an investigational medicinal product when

electronic, photographic or other data processing systems are used

instead of written documents the manufacturer or importer shall

have validated the systems to maintain the data during the required

period of storage. Data stored by these systems shall be readily

available in legible form and shall be provided on demand to the

competent authorities."

Slide No. 18 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Contents

• 21CFR11 history

• The important aspects of 21CFR11

• Equivalent requirements in EU legislation

• The Novo Nordisk 21 CFR11 compliance

project

• Examples

• Experiences learned

Slide No. 19 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

21CFR11 Compliance Project

• Purpose

• Assist the units/system owners to prioritise the

activities necessary to get in compliance over a

limited period of time.

• Scope

• All Computer Systems within Novo Nordisk that

• generate electronic records covered by regulatory

requirements from FDA,

• including the systems that utilise Electronic

Signatures

Slide No. 20 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Overview of the 21CFR11 compliance project

Development

Product

Supply

Staffs,

Quality, RA

and other

21CFR11 project

No. of systems today = 868 (PS) + 219 (Dev.) + 65 (others) = 1152 systems

(..and more to come)

Slide No. 21 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

21CFR11 Compliance Project

• Tasks

• Secure cGxP for 21CFR11 at Novo Nordisk

• Maintain corporate policy and interpretations

• Responsible for project QAP reporting

• Participate in external groups as NN representatives

• Distribute knowledge to organisation through

• Training (short courses and Site specific)

• Knowledge and guidance database

• Project web page

• Guidelines

Slide No. 22 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Guidance database -web-enabled

Slide No. 23 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Activities in relation to Part 11

1. Identify and register systems (overview)

2. Prioritise systems

3. Evaluate ”high-risk” systems

4. Evaluate ”medium- and low-risk” systems

5. Evaluate corrections/solutions

6. Prepare implementation plan

• ”Quick fixes”

• ”Full compliance, technical and procedural

7. Implement solutions

Slide No. 24 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Prioritisation of systems

Regulatory Risk

• GxP, support systems (20)

Medium risk High risk

• Other GxP critical, systems (11)

Low risk Medium risk

• Non-GxP systems (17)

X

Factor, based on: No. of records generated by the system,

no. of users, frequency of use and system complexity

Slide No. 25 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Gradual achievement of compliance

120

100

80 20 40

Interim solutions

60 20 Phase Technology

2

Procedures

40

20 Phase 60

1 50

20

20

0

Initial State State 2 State 3

Phase 1: Implement Site and system procedures

Phase 2: Technology based solutions, etc.

Slide No. 26 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Deliverables from common workgroups

• Evaluation of the system (gap-analysis) for technical

issues

• Evaluation of possible solutions

• Recommendations and other input from supplier(s)

• Recommended solutions, including

• Draft or example of procedures

• Description of technical solution

• Estimated costs

• Suggested implementation plan

Slide No. 27 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Progress Follow Up

System registration QA System evaluation on Implementation plan

Site

approved track preparation on track

A LL K L

B LL J J

C J J J

D J J K

E J K LLL

F J K K

G J LL L

H J J J

I J J J

J J K K

K LL J K

L LL J J

= On track = Ensure no further delay = Take action to catch up

Slide No. 28 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Examples of Pilot projects in

production area

• Kaye Validator

• SCADA (Fix32)

• Filter testing equipment (PALL)

• Instron (replacement for..)

• PE laboratory equipment (UV/VIS + ..) incl.

replacements for..)

• Usifroid freeze dryer

• BMS (building monitoring systems)

• ...more to come (due to standardisation)

Slide No. 29 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Contents

• 21CFR11 history

• The important aspects of 21CFR11

• Equivalent requirements in EU legislation

• The Novo Nordisk 21 CFR11 compliance

project

• Examples

• Experiences learned

Slide No. 30 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

What can go wrong, will ...

• HPCE (High Pressure Capillary Electrophoresis)

Scenario: Replacement of chromatography

software to Millennium and setting up an archive

installation

• 7 year old software

• HW requirements to PC

• Migration of ER from OS/2 to Win NT

• Indexation of migrated data

• ER on tape stored in safe

• Use of archive installation

• Training of users

• SOPs

Slide No. 31 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Example for remediation

A hardware solution:

• Control power supply to

individual physical entities in

a PC including keyboard

and mouse

• Solution is OS independent

User access is controlled via

Smart card:

• User profiles supported by

pin code on the ZignX

keyboard.

• Logging of access attempts

Further information: http://www.zignx.dk/

Slide No. 32 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Contents

• 21CFR11 history

• The important aspects of 21CFR11

• Equivalent requirements in EU legislation

• The Novo Nordisk 21 CFR11 compliance

project

• Examples

• Experiences learned

Slide No. 33 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Conclusions

• Management commitment pivotal

• Expensive and complex

• Requires highly skilled project management

• Risk-based prioritisation

• FDA enforcement becomes tougher

• and EU is on it’s way (DRAFT PIC/S Guidance)

• Just do it..!

Slide No. 34 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

Problem areas

• Lack of knowledge in the organisation on

• Computer Validation

• 21 CFR Part 11

• Maintenance of computer systems

• Purchase of non-compliant systems are ongoing

• ”Part 11 compliant systems” do not exist

• Administrative controls (= Company policies)

• Procedural controls (= Company SOP’s)

• Technical controls (= Supplier SW controls)

Slide No. 35 • QS CRS Quality Services / Svend Martin Fransen • 03.Oct.2002

You might also like

- CSV Back-UpDocument5 pagesCSV Back-UpAlok Kumar sharmaNo ratings yet

- Validation Vs QualificationDocument1 pageValidation Vs QualificationKiran ChokshiNo ratings yet

- Computer System Validation Basic Documentation PackageDocument5 pagesComputer System Validation Basic Documentation PackageAmer Rahmah0% (1)

- 21CFR, Fette AmericaDocument5 pages21CFR, Fette AmericaleotrevinoNo ratings yet

- Audit Computer SystemsDocument11 pagesAudit Computer SystemsROJI LINANo ratings yet

- A 177 e Records Practice PDFDocument8 pagesA 177 e Records Practice PDFlastrajNo ratings yet

- Electronic Records and Electronic Signatures: BY Poorna Basuri.P M.Pharmacy, I YearDocument61 pagesElectronic Records and Electronic Signatures: BY Poorna Basuri.P M.Pharmacy, I YearPoornaBasuriNo ratings yet

- APIC RSM Auditing - 201802 PDFDocument23 pagesAPIC RSM Auditing - 201802 PDFAl RammohanNo ratings yet

- Software Quality Assurance Notes in Urdu Hindi ExplanationDocument5 pagesSoftware Quality Assurance Notes in Urdu Hindi ExplanationAli RazaNo ratings yet

- Evaluating An ERP For Pharmaceutical Industry: Make Sure That These 11 Questions Are AnsweredDocument2 pagesEvaluating An ERP For Pharmaceutical Industry: Make Sure That These 11 Questions Are Answerednilay1965No ratings yet

- 21 CFR Part11 Req.Document4 pages21 CFR Part11 Req.SupriyaNathRayNo ratings yet

- White Paper Computer System ValidationDocument13 pagesWhite Paper Computer System ValidationErwin MeijboomNo ratings yet

- SageX3 Compliance CFR21Part11Document4 pagesSageX3 Compliance CFR21Part11Diogo CamoesasNo ratings yet

- Aplicabilidad 21CFR11Document6 pagesAplicabilidad 21CFR11Aydee RojasNo ratings yet

- Data Validation, Processing, and Reporting Data ValidationDocument8 pagesData Validation, Processing, and Reporting Data ValidationNaga Ajay Kumar DintakurthiNo ratings yet

- Audit AgendaDocument1 pageAudit AgendaPurushothaman SubramanianNo ratings yet

- 21 CFR Part 11Document8 pages21 CFR Part 11purinaresh85100% (1)

- 21CFR11 Assessment FAQ Metler Toledo STAREDocument51 pages21CFR11 Assessment FAQ Metler Toledo STAREfurqan.malikNo ratings yet

- Auditing Operating Systems Networks: Security Part 1: andDocument24 pagesAuditing Operating Systems Networks: Security Part 1: andAmy RillorazaNo ratings yet

- 5991-8176EN Demystifying Software Validation WhitepaperDocument7 pages5991-8176EN Demystifying Software Validation WhitepaperMykolaNo ratings yet

- Bilgisayarlı SistemlerDocument14 pagesBilgisayarlı Sistemlerttugce29No ratings yet

- Presentation Track Trace Jan 2017Document24 pagesPresentation Track Trace Jan 2017OdunlamiNo ratings yet

- Trackwise Software For Quality Management SystemDocument12 pagesTrackwise Software For Quality Management Systemdeepak upadhyayNo ratings yet

- LIMS For Lasers 2015 User ManualDocument188 pagesLIMS For Lasers 2015 User Manualcharles_0814No ratings yet

- Eres Annex 11 Eu GMP SiemensDocument30 pagesEres Annex 11 Eu GMP SiemenshuykhiemNo ratings yet

- Compiling Usa y FdaDocument36 pagesCompiling Usa y FdaCarlos TservicesNo ratings yet

- Empower 3 EU Annex 11 Compliance Assessment Rev1 November 2019Document12 pagesEmpower 3 EU Annex 11 Compliance Assessment Rev1 November 2019Nur AcarNo ratings yet

- ECA Annex11 CompSysDocument6 pagesECA Annex11 CompSysNitin KashyapNo ratings yet

- System Development Life Cycle (SDLC)Document16 pagesSystem Development Life Cycle (SDLC)Tariq Bezinjo100% (1)

- U R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemDocument66 pagesU R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemSurangaGNo ratings yet

- Empower 3Document4 pagesEmpower 3amgranadosvNo ratings yet

- Software Project ManagementDocument6 pagesSoftware Project ManagementLovekush KewatNo ratings yet

- Computerized Systems Periodic Review: QA Manager - IT ValidationsDocument4 pagesComputerized Systems Periodic Review: QA Manager - IT ValidationsMaruf RasselNo ratings yet

- Selecting, Implementing and Using FDA Compliance Software SolutionsDocument29 pagesSelecting, Implementing and Using FDA Compliance Software SolutionsSireeshaNo ratings yet

- Reg A USP 1058 Analytical Instrument QualificationDocument8 pagesReg A USP 1058 Analytical Instrument QualificationRomen MoirangthemNo ratings yet

- Events Presentations Raci 121126Document22 pagesEvents Presentations Raci 121126mokhtari asmaNo ratings yet

- 1805 Abacus DiagnosticaDocument10 pages1805 Abacus DiagnosticaAnton MymrikovNo ratings yet

- SDS - Software Design SpecificationsDocument14 pagesSDS - Software Design SpecificationsAnitha GrimaldoNo ratings yet

- Impact Assessment FrameworkDocument23 pagesImpact Assessment Frameworkyogeshshivani6914No ratings yet

- Session 14 Train Personnel On CSV and Data Integrity ComplianceDocument36 pagesSession 14 Train Personnel On CSV and Data Integrity ComplianceAl RammohanNo ratings yet

- 21 CFR Part 11 Compliance Assessment: An Oracle White Paper January 2009Document18 pages21 CFR Part 11 Compliance Assessment: An Oracle White Paper January 2009Massimiliano CamilloNo ratings yet

- SRS (Software Requirements Specification) SCLIMSDocument17 pagesSRS (Software Requirements Specification) SCLIMSMelvin Espuerta LotocNo ratings yet

- WHO Validation of Computerized Systems Appendix 5Document21 pagesWHO Validation of Computerized Systems Appendix 5Jocel GómezNo ratings yet

- Vision and Validation White Paper PDFDocument47 pagesVision and Validation White Paper PDFQC SriprasitNo ratings yet

- Standard Operating Procedure: Jodas Expoim Pvt. LTDDocument5 pagesStandard Operating Procedure: Jodas Expoim Pvt. LTDmkm969No ratings yet

- Software Requirements Specification-TMSDocument9 pagesSoftware Requirements Specification-TMSQousain QureshiNo ratings yet

- Logfile 01 2011 Synopsis Annex11 Computer Is Ed SystemsDocument11 pagesLogfile 01 2011 Synopsis Annex11 Computer Is Ed SystemsMohamed SallamNo ratings yet

- Edited Excerpts From Actual 483 Observation Reports by Food and Drug Administration InvestigatorsDocument4 pagesEdited Excerpts From Actual 483 Observation Reports by Food and Drug Administration InvestigatorsMajdi Hasan AyoubNo ratings yet

- VAL 210 Computer Validation Master Plan SampleDocument4 pagesVAL 210 Computer Validation Master Plan SampleSameh MostafaNo ratings yet

- Poster Data IntegrityDocument1 pagePoster Data IntegritySebastian LopezNo ratings yet

- Ftalk-21 CFR PDFDocument34 pagesFtalk-21 CFR PDFGufran AhmadNo ratings yet

- Testing of CSVDocument11 pagesTesting of CSVAbdou SoudakiNo ratings yet

- Standard Operating Procedure: 1. PurposeDocument8 pagesStandard Operating Procedure: 1. PurposeElave SaberNo ratings yet

- Guidelines On Validation - Appendix 5 2Document1 pageGuidelines On Validation - Appendix 5 2nagarajs50No ratings yet

- Risk Profile of The SystemDocument7 pagesRisk Profile of The SystemAbhijeetNo ratings yet

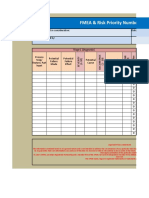

- FMEA & Risk Priority Number (RPN) SheetDocument8 pagesFMEA & Risk Priority Number (RPN) Sheetcasanova mrNo ratings yet

- Overview of Validation Documents and ProjectsDocument5 pagesOverview of Validation Documents and ProjectsMD Fahad MiajiNo ratings yet

- LABWORKS 6.9 Admin GuideDocument534 pagesLABWORKS 6.9 Admin GuideBilla SathishNo ratings yet

- CO - CSA - AgilentDocument19 pagesCO - CSA - AgilentAK Agarwal100% (1)

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Us PharmacopoeiaDocument1 pageUs PharmacopoeiaAshimaNo ratings yet

- MQA203TDocument1 pageMQA203TAshima0% (1)

- Audit For CoatingDocument42 pagesAudit For CoatingAshimaNo ratings yet

- A Presentation SARQA DKGDocument23 pagesA Presentation SARQA DKGAshimaNo ratings yet

- MQA204TDocument30 pagesMQA204TAshimaNo ratings yet

- Gujarat Technological University: Subject Code: Date: 21/05/2018 Subject Name: Time:10:30AM TO 02:30PM Total Marks: 80Document1 pageGujarat Technological University: Subject Code: Date: 21/05/2018 Subject Name: Time:10:30AM TO 02:30PM Total Marks: 80AshimaNo ratings yet

- Gujarat Technological University: M.Pharm Pharmaceutical Quality Assurance Semester: IiDocument2 pagesGujarat Technological University: M.Pharm Pharmaceutical Quality Assurance Semester: IiAshimaNo ratings yet

- Gujarat Technological University: M.Pharm Pharmaceutical Quality Assurance Semester: IiDocument2 pagesGujarat Technological University: M.Pharm Pharmaceutical Quality Assurance Semester: IiAshimaNo ratings yet