Professional Documents

Culture Documents

4 Welding Metallurgy-4

Uploaded by

rey0 ratings0% found this document useful (0 votes)

9 views15 pagesCopyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views15 pages4 Welding Metallurgy-4

Uploaded by

reyCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 15

OCEAN ENGINEERING - ITS

Welding Metallurgy

Nur Syahroni, ST., MT., PhD.

Welding Technology & Inspection (MO-141323)

1

Continuous Cooling

Transformation (CCT) Diagram

Welding Technology & Inspection (MO-141323) 2

Continuous Cooling Transformation

(CCT) Diagram

Isothermal heat treatments are

not the most practical

Most heat treatments for steels

involve the continuous cooling of

a specimen to room temperature

An isothermal transformation

(TTT) diagram is valid only for

conditions of constant

temperature,

TTT diagram must be modified

for transformations that occur as

the temperature is constantly

changing, that is called CCT

diagram

CCT diagram is applicable for

the case of welding

carbon steel with 0.76%wt C

Welding Technology & Inspection (MO-141323) 3

Continuous Cooling Transformation

(CCT) Diagram

For eutectoid composition,

normally bainite will not form

because all the austenite will

have transformed to pearlite

Thus, the region representing

the austenite–pearlite

transformation terminates

just below the nose as

indicated by the curve AB

carbon steel with 0.76%wt C

Welding Technology & Inspection (MO-141323) 4

Continuous Cooling Transformation

(CCT) Diagram

For the continuous cooling of

a steel alloy, there exists a

critical quenching rate, which

represents the minimum rate

of quenching that will

produce a totally martensitic

structure

This critical cooling rate,

when included on the

continuous transformation

diagram, will just miss the

nose at which the pearlite

transformation begins

carbon steel with 0.76%wt C

Welding Technology & Inspection (MO-141323) 5

Continuous Cooling Transformation

(CCT) Diagram

Carbon and other alloying

elements also shift the pearlite

(as well as the proeutectoid

phase) and bainite noses to

longer times, thus decreasing

the critical cooling rate

Find the final phases produced

when the AISI 4340 steel is

heated up to eutectoid

temperature and cooled down

to the ambient temparature

with cooling rate as follows:

◦ 0.005oC/s, 0.01oC/s, 0.2oC/s

◦ 5oC/s and 10oC/s

Alloy steel AISI 4340

Welding Technology & Inspection (MO-141323) 6

Continuous Cooling Transformation

(CCT) Diagram

Final microstructures are

resulted from following cooling

rates:

0.005oC/s (very slow)

◦ Ferrite pro-eutectoid + Pearlite

0.01oC/s (rather slow)

◦ Martensite + Ferrite pro-

eutectoid + Pearlite + Bainite

0.2oC/s

◦ Martensite + Ferrite pro-

eutectoid + Bainite

5oC/s

◦ Martensite + Bainite

10oC/s

Alloy steel AISI 4340

◦ Martensite

Welding Technology & Inspection (MO-141323) 7

Mechanical Properties of

Carbon Steels

Welding Technology & Inspection (MO-141323) 8

Mechanical Properties of Carbon Steels

Welding Technology & Inspection (MO-141323) 9

Mechanical Properties of Carbon Steels

Welding Technology & Inspection (MO-141323) 10

Mechanical Properties of Carbon Steels

Because bainitic steels have a

finer structure, they are

generally stronger and harder

than pearlitic ones

They exhibit a desirable

combination of strength and

ductility

Welding Technology & Inspection (MO-141323) 11

Mechanical Properties of Carbon Steels

Martensite is very hard, but

so brittle

To enhance ductility and

toughness of martensite,

tempering can be performed

Temper heat treatment is

carried out by heating

martensite up to the

temperature below eutectoid

(250-650oC) for a specified

time period

By diffusional process,

tempered martensite is

formed by reaction:

Welding Technology & Inspection (MO-141323) 12

Mechanical Properties of Carbon Steels

The microstructure of tempered

martensite consists of extremely

small and uniformly dispersed

cementite particles embedded

within a continuous ferrite Tempering was carried out at 594oC

matrix

This is similar to the

microstructure of spheroidite

except that the cementite

particles are much, much smaller

Tempered martensite may be

nearly as hard and strong as

martensite, but with substantially

enhanced ductility and toughness

Welding Technology & Inspection (MO-141323) 13

Review of Phase Transformations and

Mechanical Properties for Carbon Steels

Welding Technology & Inspection (MO-141323) 14

Review of Phase Transformations and

Mechanical Properties for Carbon Steels

Welding Technology & Inspection (MO-141323) 15

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Structural Analysis ReportDocument62 pagesStructural Analysis ReportNabin AcharyaNo ratings yet

- Masonry Support Systems and LintelsDocument36 pagesMasonry Support Systems and LintelsAchilleas21No ratings yet

- Di Pipes Rate AnalysisDocument32 pagesDi Pipes Rate AnalysisDeepthy VasavanNo ratings yet

- Martensite and The Control of Retained AusteniteDocument6 pagesMartensite and The Control of Retained AusteniteMarcoTulioFonsecaNo ratings yet

- Sae J412 - General Characteristics and Heat Treatments of SteelsDocument26 pagesSae J412 - General Characteristics and Heat Treatments of SteelsDiogo Roesler Melo0% (1)

- Formwork Installation MS.Document3 pagesFormwork Installation MS.Norazmi Mohd NorNo ratings yet

- Installation Guidance For Cement Rotary Kiln (LKB)Document20 pagesInstallation Guidance For Cement Rotary Kiln (LKB)Waka OngetiNo ratings yet

- CATALOG Uniweld-Products TYPE17-2Document13 pagesCATALOG Uniweld-Products TYPE17-2Máy cầm tay Hoàng TrungNo ratings yet

- Ref SA 515Document5 pagesRef SA 515nachoircNo ratings yet

- Amperit Thermal Spray PowdersDocument16 pagesAmperit Thermal Spray PowdersSergeyNo ratings yet

- Alloy and Stainless Steel Forgings (Amendments/Supplements To Astm A 182)Document14 pagesAlloy and Stainless Steel Forgings (Amendments/Supplements To Astm A 182)MunishNo ratings yet

- Tabla de Caracteristicas de Los PlasticosDocument12 pagesTabla de Caracteristicas de Los PlasticosBetty JadueNo ratings yet

- PVC Pipes: Complete PVC Piping SystemDocument2 pagesPVC Pipes: Complete PVC Piping SystemSyed Shariq HassanNo ratings yet

- Clad Metal - PresentationDocument27 pagesClad Metal - PresentationezzataNo ratings yet

- Composite Materials: Contents: - Advantages - Applications - LimitationsDocument23 pagesComposite Materials: Contents: - Advantages - Applications - LimitationsNilesh BhandariNo ratings yet

- Metric Thread - Extended Thread Size RangeDocument17 pagesMetric Thread - Extended Thread Size RangeM DhafinNo ratings yet

- 8x8 Shelter 2.0 Assembly InstructionsDocument23 pages8x8 Shelter 2.0 Assembly InstructionsKevin BlanerNo ratings yet

- Apco Silent Check Valves CSC 640Document8 pagesApco Silent Check Valves CSC 640Julio MorenoNo ratings yet

- Astm C685 C685M 17Document6 pagesAstm C685 C685M 17Alexis MartinezNo ratings yet

- BOQ Rev 1Document8 pagesBOQ Rev 1aris munandarNo ratings yet

- Diktat Praktikum TBK 2021Document71 pagesDiktat Praktikum TBK 2021Muhammad Handika100% (1)

- 19PEB2330Q - Quotation - 60 Line of Air Instrument Supply SystemDocument11 pages19PEB2330Q - Quotation - 60 Line of Air Instrument Supply Systemgusstiawan saputraNo ratings yet

- PET Geogrid SeriesDocument1 pagePET Geogrid Seriessundra0No ratings yet

- SN200-3 2016-05 eDocument7 pagesSN200-3 2016-05 emaik angeloNo ratings yet

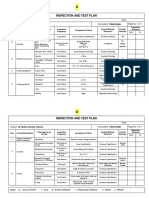

- Inspection and Test Plan ConcreteDocument2 pagesInspection and Test Plan Concreteavikshit yNo ratings yet

- Josam HydrantsDocument9 pagesJosam HydrantsRichPhillipsNo ratings yet

- Possible Role of Tensile Stress in The Etiology of Cervical Erosive Lesions of TeethDocument7 pagesPossible Role of Tensile Stress in The Etiology of Cervical Erosive Lesions of TeethRaul Alfonsin SanchezNo ratings yet

- Austroads Test Methods and Specifications: Code Title IssuedDocument5 pagesAustroads Test Methods and Specifications: Code Title IssuedNaison StanleyNo ratings yet

- Specification Sheet 50100 and TR 571Document2 pagesSpecification Sheet 50100 and TR 571MZY Commercial EnterprisesNo ratings yet

- Molding:: Bulk ContainersDocument9 pagesMolding:: Bulk ContainersRaja PandiNo ratings yet