Professional Documents

Culture Documents

Cutting Tool and Materia

Cutting Tool and Materia

Uploaded by

krunal panchal0 ratings0% found this document useful (0 votes)

6 views12 pagesOriginal Title

cutting tool and materia

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views12 pagesCutting Tool and Materia

Cutting Tool and Materia

Uploaded by

krunal panchalCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 12

Cutting tool and

Cutting tool material

• 1 : Tool materials

• 2 : Types of tool materials

Tool materials

• In order for a machining operation to

produced at a fast rate with minimum tool

and machining cost thr cutting tool material

must satisfy certain basic reqirements . The

more important of these requirements are

given below.

• 1 : Hot hardness

• 2 : Wear resistance

• 3 : Toughness

• 4 : low friction

• 5 : Thermal conductivity

• 6 : Cost

1 : Hot hardness

• This represents the capacity of the tool to

retain its cutting ability and hardness at the

high temperature developed at the chip tool

interface

2 : Wear resistance

• The life of the tool is determined by the wear

developed on its cutting face due to motion of

the chip and on its flank due to contact with

the machined surface

3 : Toughness

• Toughness is necessary to enable the tool to

withstand cutting forces , to absorb shock and

to prevent the chipping of the cutting edge.

4 : Low friction

• The co efficient of friction between the tool

material and the chip should be low . This is

important for the reducing tool forces ,

keeping chip tool interface temperature low.

5: thermal conductivity

• A material with a high thermal conductivity

can conduct heat away from the chip tool

interface faster.

6: Cost

• This incudes the cost of material , cost of

grinding and the cost of replacement when

the tool is worm out .

Types of Tool Material

• 1 : Carbon tool steels

• 2 : High speed steels

• 3 : Cast Non ferrous alloys

• 4 : Carbides

• 5 : Ceramics

• 6 : Diamond

1 : Carbon tool steels

• carbon tool steel contain carbon in amount

ranging from 0.90 to 1.20 percent

• cutting tools of carbon steels are limited to

slow speeds and light duty work

• THANK YOU

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Checklist Equipment Layout DesignDocument4 pagesChecklist Equipment Layout Designkrunal panchalNo ratings yet

- General Plot Plan Development PhilosophyDocument5 pagesGeneral Plot Plan Development Philosophykrunal panchalNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

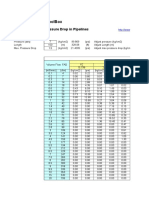

- The Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesDocument6 pagesThe Engineering Toolbox: Compressed Air - Pressure Drop in Pipelineskrunal panchalNo ratings yet

- E90°/E180° IN Inch E90°/E180° IN MM E90° LR C/C Spacing in MM E90° SR C/C Spacing in MMDocument1 pageE90°/E180° IN Inch E90°/E180° IN MM E90° LR C/C Spacing in MM E90° SR C/C Spacing in MMkrunal panchalNo ratings yet