Professional Documents

Culture Documents

Taguchi

Taguchi

Uploaded by

Sk Shankar0 ratings0% found this document useful (0 votes)

7 views17 pagesOriginal Title

taguchi

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views17 pagesTaguchi

Taguchi

Uploaded by

Sk ShankarCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 17

MIG Welding

Manufacturing and Materials

Processes

(GMAW) MIG Welding

Gas Metal Arc Welding (GMAW) is

frequently referred to as MIG welding.

MIG welding is a commonly used high

deposition rate welding process.

Wire is continuously fed from a spool.

MIG welding is therefore referred to as a

semiautomatic welding process.

MIG Welding Benefits

All position capability

Higher deposition rates than SMAW

Less operator skill required

Long welds can be made without

starts and stops

Minimal post weld cleaning is

required

MIG Welding Shielding

Gas

The shielding gas, forms the arc

plasma, stabilizes the arc on the

metal being welded, shields the arc

and molten weld pool, and allows

smooth transfer of metal from the

weld wire to the molten weld pool.

The primary shielding

gasses used are:

Argon

Argon – 95% to 5% Oxygen

Argon – 75% to 25% CO2

Argon/Helium

CO2 is also used in its pure form in

some MIG welding processes. However,

in some applications the presence of

CO2 in the shielding gas may adversely

affect the mechanical properties of the

weld.

Welding Parameters and

Techniques

Welding current

Wire electrode extension

Welding voltage

Arc travel speed

WELDING CURRENT

The welding current is the electrical

amperage in the power system as the

weld is being made.

welding current is directly related to wire-

feed speed (if the wire extension beyond

the guide tip is constant). As the wire-feed

speed is varied, the welding current will

vary in the same direction. In other

words, an increase (or decrease) in the

wire-feed speed will cause an increase (or

decrease) of the current.

WIRE ELECTRODE

EXTENSION

Wire extension or ”stick-out” is the

distance between the last point of

electrical contact, usually the end of

the contact tip, and the end of the

wire electrode.

WIRE ELECTRODE

EXTENSION

Controlling tip-to-work distance is

important. Long extensions result in

excess weld metal being deposited

with low arc heat. This can cause

poor bead shape and low

penetration. In addition, as the tip-

to-work distance increases, the arc

becomes less stable.

WELDING VOLTAGE

voltage setting directly controls the

arc length.

In addition, a certain range is

required to maintain arc stability at

any given welding current level.

ARC TRAVEL SPEED

As the material thickness increases,

the travel speed must be lowered.

For a given material thickness and

joint design, as the welding current is

increased, so is the arc travel speed.

The converse is also true.

Higher welding speeds are attainable

by using the forehand welding

technique.

WELDING TECHNIQUES

Torch Position

Split the angle (90 degrees = 45 degree

split)

5 degree rake

Good Voltage to Voltage to Too Fast Too Slow

Weld High Low

Less Stick

Out

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WELD-A Welding Guide For Beginners - Beginner Welding GuideDocument11 pagesWELD-A Welding Guide For Beginners - Beginner Welding GuidepeterNo ratings yet

- Welding Consumable ChartDocument2 pagesWelding Consumable ChartAfetNo ratings yet

- LIGHTDocument29 pagesLIGHTDevrathNo ratings yet

- Westinghouse 1979 Large Lamp CatalogDocument52 pagesWestinghouse 1979 Large Lamp CatalogAlan MastersNo ratings yet

- High Intensity Discharge Lamps: Prepared byDocument34 pagesHigh Intensity Discharge Lamps: Prepared byRiwel YumulNo ratings yet

- TVL Smaw11 Q1 M 12Document8 pagesTVL Smaw11 Q1 M 12Earl Christian BonaobraNo ratings yet

- 1st TRANCHE SCHOLARSHIPDocument1 page1st TRANCHE SCHOLARSHIPJekBrionesNo ratings yet

- CRM # 4044662347 (Zpec # 5)Document1 pageCRM # 4044662347 (Zpec # 5)Mohammad MushtaqNo ratings yet

- Gas Tungsten Arc WeldingDocument1 pageGas Tungsten Arc WeldingabhibawaNo ratings yet

- Learners Achievement Monitoring ReportDocument2 pagesLearners Achievement Monitoring ReportEm Boquiren Carreon100% (1)

- Spaulding Lighting Huntington I Spec Sheet 8-84Document2 pagesSpaulding Lighting Huntington I Spec Sheet 8-84Alan MastersNo ratings yet

- Lincoln Procedure Handbook of Arc WeldingDocument896 pagesLincoln Procedure Handbook of Arc WeldingJosué Rodríguez Díaz100% (12)

- Training Program - SudanDocument4 pagesTraining Program - SudanKhalid HafezNo ratings yet

- Consent 1Document2 pagesConsent 1Fatima MacabagoNo ratings yet

- Gas Discharge TubesDocument16 pagesGas Discharge TubesYdnar Dale GanzonNo ratings yet

- Wide-Lite Ballast Tech. Data Bulletin 1987Document4 pagesWide-Lite Ballast Tech. Data Bulletin 1987Alan MastersNo ratings yet

- Dielectric BreakdownDocument8 pagesDielectric BreakdownPranjal RathoreNo ratings yet

- High and Lower Pressure Sodium LampDocument2 pagesHigh and Lower Pressure Sodium LampJohn Paul LiwaliwNo ratings yet

- Tugas 02 - 1106069992Document11 pagesTugas 02 - 1106069992Reinol SianturiNo ratings yet

- Asme PQR Gtaw P8Document12 pagesAsme PQR Gtaw P8Boran YelkenciogluNo ratings yet

- ITT American Electric Price List 5-73Document36 pagesITT American Electric Price List 5-73Alan MastersNo ratings yet

- Havells CFL Light PDFDocument4 pagesHavells CFL Light PDFsunilpradhan.76No ratings yet

- NGK NTK Catálogo Motocicletas 2016-2017Document372 pagesNGK NTK Catálogo Motocicletas 2016-2017ysmael romeroNo ratings yet

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Document11 pagesCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruNo ratings yet

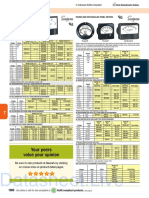

- Datasheet - Live: ANALOG (2%)Document85 pagesDatasheet - Live: ANALOG (2%)vinoth RajaNo ratings yet

- Welding Calculator BOHLERDocument7 pagesWelding Calculator BOHLERKhamdi AfandiNo ratings yet

- Marco HID Architectural Downlighting Catalog 1991Document88 pagesMarco HID Architectural Downlighting Catalog 1991Alan MastersNo ratings yet

- Barangay Skills Need Survey Form 2-TADIAN MUNICIPALITYDocument230 pagesBarangay Skills Need Survey Form 2-TADIAN MUNICIPALITYshell liwagNo ratings yet

- Arc Welding - Introduction and FundamentalsDocument30 pagesArc Welding - Introduction and FundamentalsDanem HalasNo ratings yet

- KObelco Rods 202-209Document4 pagesKObelco Rods 202-209dedikartiwa_dkNo ratings yet