Professional Documents

Culture Documents

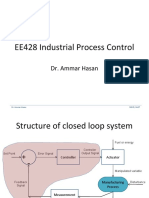

EE428 Industrial Process Control: Dr. Ammar Hasan

Uploaded by

Umer Imran0 ratings0% found this document useful (0 votes)

26 views23 pagesIndustrial Process Control

Original Title

Ch6

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIndustrial Process Control

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views23 pagesEE428 Industrial Process Control: Dr. Ammar Hasan

Uploaded by

Umer ImranIndustrial Process Control

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 23

EE428 Industrial Process Control

Dr. Ammar Hasan

Dr. Ammar Hasan SEECS, NUST

6.14 Motor Nameplate: NEMA

• There are many manufacturers that make the

different types of AC motors

• When producing a motor that will be used in

the United States, manufacturers must comply

with certain standards.

• The regulation agency that establishes and

enforces the required specifications is the

National Electrical Manufacturing Association

(NEMA)

Dr. Ammar Hasan SEECS, NUST

6.14 Motor Nameplate: NEMA

• These standards include:

• Electrical voltage and current ratings

• Dimensions of the mounting bolt holes

• Diameter of the motor shalt

• Distance between the center of the shaft and the

mounting plate.

• Compliance to these standards ensures

interchangability between motors built by

different companies.

Dr. Ammar Hasan SEECS, NUST

The Nameplate

• Electric motors have a metal plate mounted

on the housing.

• Its purpose is to provide pertinent information

about the motor, especially if it becomes

defective and needs to be replaced.

• The data printed on the motor must comply

with NEMA standards.

Dr. Ammar Hasan SEECS, NUST

The Nameplate

Dr. Ammar Hasan SEECS, NUST

Model

• The model number identifies a motor that has

specific operating characteristics.

• It is also a reference tool when using a

manufacturers catalog that has all the

information available about the motor.

• This number is particularly useful when

returning a motor under warranty or for

finding an exact replacement.

Dr. Ammar Hasan SEECS, NUST

Horsepower

• This is the horsepower that the motor is

designed to produce.

• A replacement motor should have the exact

hp rating.

• In an emergency, a motor with a higher

horsepower can be used as a substitute, but

because it would not run at full load, it would

be inefficient.

Dr. Ammar Hasan SEECS, NUST

RPM or Speed

• The speed ofa motor is the rpm at which the-

shaft rotates.

• The number on the nameplate is usually the

nominal no-load speed.

• In this example, it is 3450 rpm.

• If it becomes overloaded, the motor will slow

down to below the rated speed.

• Common rated speeds of AC motors are 1750,

1175, and 890 rpm.

Dr. Ammar Hasan SEECS, NUST

Volts

• This is the voltage at which the motor is designed to

operate.

• Common voltages for single- phase motors are 115 V

and 230 V

• Common voltages for three-phase motors are 230 V

and 460 V

• Less common voltage ratings for motors are 208,

550, 660, and 2300 volts.

• Motors are designed to operate within 10 percent of

their rated voltages to compensate for line losses.

Dr. Ammar Hasan SEECS, NUST

Current

• This value refers to how many amps the motor will

draw from each phase when producing its rated

output power.

• The sample shows two amperage ratings. The higher

value is the current draw when connected to the

lower voltage listed on the nameplate (115 V).

• This information is useful for determining the

required size of the wires, brushes, and contactors

through which current from the supply lines flows.

Dr. Ammar Hasan SEECS, NUST

Frequency

• This value specifies that the motor is designed to

operate at a particular AC frequency.

• Most motors in the United States run at 60 Hz.

Outside the United States, especially in Western

Europe, 50 Hz is the common frequency used.

• Some motors cannot operate at a frequency other

than the one listed on its nameplate.

Dr. Ammar Hasan SEECS, NUST

Duty Rating

• The abbreviation “CONT” in indicates that it is a

continuous duty motor.

• Most motors are designed for continuous output at

their rated power, which means they can run 24

hours per day.

• However, some motors are designed for intermittent

operation, which means there is a certain amount of

time they can run before they need to be shut down

to cool off before resuming operation.

• For example, a motor with the number 20 on the

nameplate, following the heading “Duty,” can

operate for 20 minutes before it must be turned off.

Dr. Ammar Hasan SEECS, NUST

Thermally Protected

• Some motors have a mechanism that protects them

by creating an electrical open if the temperature

rises above a particular level.

• The motor shuts off when this condition occurs.

• Some motors have an automatic reset feature, which

turns the motor back on after it cools off.

• The letter M on the sample nameplate indicates that

the reset mechanism must be reset manually to

resume its operation.

Dr. Ammar Hasan SEECS, NUST

Type

• Motors have design ratings designated by letters. The

most common are the letters A, B, C, and D.

• Each one is determined by the way the motor is

wound, which affects the start and run

characteristics.

• Type A Special

• Type B Normal Starting Torque (Most Common)

• Type C High Starting Torque

• Type D High Starting Torque and High Slip (used for

punch presses)

Dr. Ammar Hasan SEECS, NUST

Service Factor (SF)

• This value indicates if a motor can operate above its

rated horsepower.

• If it has an SF number of 1.0, it cannot operate above

the hp rating listed on the nameplate.

• If it has an SF number of 1.25, for example, it can

produce 1.25 times its rated horsepower without

damage.

• The drawback of running in this condition is that the

efficiency and power factor of the motor will be

lower than when it rims at its rated speed.

Dr. Ammar Hasan SEECS, NUST

Phase (PH)

• This value indicates if the motor is a single-phase or a

three-phase motor.

Dr. Ammar Hasan SEECS, NUST

Power Factor (PF)

• This value indicates the percentage of apparent

power used by the motor.

• All -motors have a power factor, which is affected by

their inductive load.

• A high PF number is desirable.

Dr. Ammar Hasan SEECS, NUST

Ambient Temperature (AMB)

• This value is the maximum temperature of the

surrounding air within which a motor can safely

operate.

• If it is exposed to a higher temperature environment,

it will overheat and become damaged.

• The value on the sample nameplate is 40°C, or 104°F.

• A replacement motor should not have an ambient

temperature rating lower than the one it is replacing.

Dr. Ammar Hasan SEECS, NUST

Insulation Class (INS)

• Motors are constructed with wires that have

insulation materials that can withstand different

temperatures.

• There are four common classes with different

temperature ratings:

• Class A 105°C

• Class B 130°C

• Class C 155°C

• Class D 180°C

Dr. Ammar Hasan SEECS, NUST

Motor Enclosure of Housing (HSG)

• This information indicates the ventilation

requirements of the motor. Examples are as follows:

• Open to Air: This motor has an internal fan that pulls

air from one end and pushes it through the other

end. The term “OPEN” on the sample nameplate

indicates this type of motor housing enclosure.

• Open Drip Proof: A vent is placed at the bottom to

prevent drops of liquid or solids from falling on the

motor at an angle of not greater than 15° vertical.

Dr. Ammar Hasan SEECS, NUST

Motor Enclosure of Housing (HSG)

• Totally Enclosed: This motor is cooled by convection

as an external fan blows air over its housing, and it is

used in dusty, dirty, and corrosive atmospheres.

• EP — Explosion Proof: This motor is used in

hazardous environments that contain gas vapors,

coal dust, or alcohol. Its housing is made to be extra

strong to prevent an internal explosion from igniting

a gas or vapor in the surrounding atmosphere.

Dr. Ammar Hasan SEECS, NUST

NEMA Frame Number

(not mentioned in the book)

• Specifies the different dimensions of the motor

Dr. Ammar Hasan SEECS, NUST

NEMA Frame Number

• Some examples include

Dr. Ammar Hasan SEECS, NUST

You might also like

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Lecture 6Document27 pagesLecture 6Ahmar KhanNo ratings yet

- MAGM 225: Motor Nameplate InformationDocument29 pagesMAGM 225: Motor Nameplate Informationgaruav3512No ratings yet

- Understanding Induction Motor Nameplate InformationDocument9 pagesUnderstanding Induction Motor Nameplate Informationvenkanna.aNo ratings yet

- Induction Motor Nameplate InformationDocument6 pagesInduction Motor Nameplate Informationelectricalrakesh100% (1)

- Induction Motor NameplateDocument5 pagesInduction Motor NameplatepanchalabNo ratings yet

- Nema Motor Nameplate DetailsDocument4 pagesNema Motor Nameplate DetailsBlueQuillNo ratings yet

- Nameplate of InductionDocument6 pagesNameplate of InductionARUNPRASADEEENo ratings yet

- Induction Motor NameplateDocument6 pagesInduction Motor NameplateYudhaMuhamadFauziNo ratings yet

- Placa de Caracteristicas Motor IngDocument25 pagesPlaca de Caracteristicas Motor IngJorge ContrerasNo ratings yet

- 4 Power TransmissionDocument27 pages4 Power TransmissionMehmetNo ratings yet

- Selecting, Operating, and Maintaining Electric Motors: Instructional Materials Service Texas A&M University 8795Document153 pagesSelecting, Operating, and Maintaining Electric Motors: Instructional Materials Service Texas A&M University 8795John Reantaso100% (1)

- Lecture 3Document33 pagesLecture 3Heleana Faye BundocNo ratings yet

- Catalogo Motores NeumaticosDocument34 pagesCatalogo Motores Neumaticosrogelioabril27No ratings yet

- Motors Technical Reference For Electric MotorsDocument78 pagesMotors Technical Reference For Electric Motorschidambaram kasiNo ratings yet

- Electric MotorsDocument6 pagesElectric MotorsRasheed AhamedNo ratings yet

- Airmotor CatalogDocument33 pagesAirmotor CataloghawyegNo ratings yet

- Penjelasan Tentang Motor Nameplate and RatingsDocument10 pagesPenjelasan Tentang Motor Nameplate and RatingsBambangsNo ratings yet

- Understanding The Motor NameplateDocument25 pagesUnderstanding The Motor NameplatevenkatsvNo ratings yet

- Tech Ref. ManualDocument72 pagesTech Ref. Manualgigo_dreamNo ratings yet

- 1.5 Electric MotorsDocument64 pages1.5 Electric MotorsLeojhun PalisocNo ratings yet

- EE428 Industrial Process Control Part 4: Variable Speed DrivesDocument55 pagesEE428 Industrial Process Control Part 4: Variable Speed DrivesRamis AliNo ratings yet

- Module 3 Farm ElectrificationDocument60 pagesModule 3 Farm ElectrificationawancharizzNo ratings yet

- How To Get The Right Electric MotorDocument22 pagesHow To Get The Right Electric MotorRanga VamshiNo ratings yet

- DC Motors ApplicationsDocument4 pagesDC Motors ApplicationsidealparrotNo ratings yet

- Motor Nameplate Information Required by NEMA Standards: 1. Manufacturer's TypeDocument12 pagesMotor Nameplate Information Required by NEMA Standards: 1. Manufacturer's TypeWulan NursyifaNo ratings yet

- Diesel Power PlantDocument34 pagesDiesel Power PlantAnonymous HyOfbJ6100% (1)

- Motor Nameplate InformationDocument29 pagesMotor Nameplate InformationJaishankar PrabhakaranNo ratings yet

- EE428 Industrial Process Control Chapter 9: AC Drives: Dr. Ammar HasanDocument43 pagesEE428 Industrial Process Control Chapter 9: AC Drives: Dr. Ammar HasanRamis AliNo ratings yet

- 2010 Edition Electric Motors and Drives Technical ManualDocument346 pages2010 Edition Electric Motors and Drives Technical ManualWilson Pinacate100% (1)

- Leeson Technical InformationDocument5 pagesLeeson Technical Informationgeorgel1980No ratings yet

- º - The Key Is Inserted Into The Keyway and Pressure-Fit Snugly To Mechanically Connect TheDocument17 pagesº - The Key Is Inserted Into The Keyway and Pressure-Fit Snugly To Mechanically Connect TheVijay KumarNo ratings yet

- Electrical Motors ProtectionsDocument93 pagesElectrical Motors Protectionsdepedromarjan05No ratings yet

- Week 11 - Electric MotorsDocument17 pagesWeek 11 - Electric MotorsSandino Michael Angelo AguilarNo ratings yet

- Basics of Motors & Control PanelDocument59 pagesBasics of Motors & Control PanelPraveen BalakrishnanNo ratings yet

- Engineering Letter: IntegralmotorsforcentrifugalfansDocument4 pagesEngineering Letter: IntegralmotorsforcentrifugalfansjameeloNo ratings yet

- EE428 Industrial Process Control Chapter 7: Servo Motors: Dr. Ammar HasanDocument101 pagesEE428 Industrial Process Control Chapter 7: Servo Motors: Dr. Ammar HasanRamis AliNo ratings yet

- Compressor Drive: Basic Rotary ManualDocument7 pagesCompressor Drive: Basic Rotary ManualElias FernándezNo ratings yet

- Electric Motors: By: Muhammad Azhar HussainDocument28 pagesElectric Motors: By: Muhammad Azhar HussainShaami AtmNo ratings yet

- Understanding Motor Nameplate Information - NEMA vs. IEC StandardsDocument31 pagesUnderstanding Motor Nameplate Information - NEMA vs. IEC StandardsRameez Ali FaridiNo ratings yet

- Know Your Electric Pedestal FansDocument7 pagesKnow Your Electric Pedestal FansAlokojjal BanerjeeNo ratings yet

- Accelerating and Breakdown TorqueDocument44 pagesAccelerating and Breakdown TorqueekonurudinahmadNo ratings yet

- NEMA Standards For Electric MotorsDocument6 pagesNEMA Standards For Electric MotorsRealito BoseNo ratings yet

- How To Read A Motor NameplateDocument8 pagesHow To Read A Motor Nameplateabdulyunus_amirNo ratings yet

- 16-PT5 Durst Pump DrivesDocument5 pages16-PT5 Durst Pump DrivesDiego AlbarracinNo ratings yet

- Cranking SystemsDocument49 pagesCranking SystemsSundar MahalingamNo ratings yet

- Internal Combustion (Ic) Engine Used in Generation of ElectricityDocument46 pagesInternal Combustion (Ic) Engine Used in Generation of ElectricitynatarajansiyerNo ratings yet

- Motor Primer IIIDocument8 pagesMotor Primer IIItristanfernandes2179No ratings yet

- Motor Protection SeminarDocument73 pagesMotor Protection SeminarErstendrain EngNo ratings yet

- AC DC Drives Application ConsiderationDocument8 pagesAC DC Drives Application Considerationvatsalshah24No ratings yet

- Siemens - Motor SpecificationsDocument50 pagesSiemens - Motor SpecificationsArtifoxNo ratings yet

- DG SetDocument42 pagesDG Setgaurang1111No ratings yet

- 14 Motor Soft StarterDocument20 pages14 Motor Soft Starterni60No ratings yet

- Wiring Method & Motor SelectionDocument33 pagesWiring Method & Motor SelectionMahbubul IslamNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsFrom EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Ch17 - Industrial Detection SensorsDocument145 pagesCh17 - Industrial Detection SensorsRamis AliNo ratings yet

- Ch12 - FlowDocument101 pagesCh12 - FlowRamis AliNo ratings yet

- Ch12 - FlowDocument101 pagesCh12 - FlowRamis AliNo ratings yet

- Ch15 - Industrial Process TechniquesDocument135 pagesCh15 - Industrial Process TechniquesRamis AliNo ratings yet

- Ch10 - PressureDocument67 pagesCh10 - PressureRamis AliNo ratings yet

- EE428 Industrial Process Control Chapter 9: AC Drives: Dr. Ammar HasanDocument43 pagesEE428 Industrial Process Control Chapter 9: AC Drives: Dr. Ammar HasanRamis AliNo ratings yet

- EE428 Industrial Process Control: Dr. Ammar HasanDocument27 pagesEE428 Industrial Process Control: Dr. Ammar HasanUmer ImranNo ratings yet

- Ch3 - Lecture 5Document49 pagesCh3 - Lecture 5Umer ImranNo ratings yet

- EE428 Industrial Process Control Part 4: Variable Speed DrivesDocument55 pagesEE428 Industrial Process Control Part 4: Variable Speed DrivesRamis AliNo ratings yet

- EE428 Industrial Process Control: Dr. Ammar HasanDocument110 pagesEE428 Industrial Process Control: Dr. Ammar HasanUmer ImranNo ratings yet

- EE428 Industrial Process Control: Dr. Ammar HasanDocument27 pagesEE428 Industrial Process Control: Dr. Ammar HasanUmer ImranNo ratings yet

- Ch3 - Lecture 5Document49 pagesCh3 - Lecture 5Umer ImranNo ratings yet

- EE428 Industrial Process Control: Slides With Red Background Are Not Included in The SyllabusDocument54 pagesEE428 Industrial Process Control: Slides With Red Background Are Not Included in The SyllabusUmer ImranNo ratings yet

- EE428 Industrial Process Control: Dr. Ammar HasanDocument33 pagesEE428 Industrial Process Control: Dr. Ammar HasanUmer ImranNo ratings yet

- Ch2 - Lecture 4Document22 pagesCh2 - Lecture 4Umer ImranNo ratings yet

- L04 PDFDocument16 pagesL04 PDFUmer ImranNo ratings yet

- Ch1 - Lecture 2Document54 pagesCh1 - Lecture 2Umer ImranNo ratings yet

- L02 PDFDocument17 pagesL02 PDFUmer ImranNo ratings yet

- Ch1 Part 1Document41 pagesCh1 Part 1DanishIshaqNo ratings yet

- L03 PDFDocument21 pagesL03 PDFUmer ImranNo ratings yet

- L01 PDFDocument19 pagesL01 PDFUmer ImranNo ratings yet

- L01 - Entrepreneurship - A Working DefinitionDocument3 pagesL01 - Entrepreneurship - A Working DefinitionUmer ImranNo ratings yet

- Fairchild Power Producs Selection GuideDocument74 pagesFairchild Power Producs Selection GuidevasilmanolovNo ratings yet

- 06 - Weidmuller - Pe and Ie BusbarDocument3 pages06 - Weidmuller - Pe and Ie BusbarharisNo ratings yet

- Avc63-7, Avc63-7D, Avc63-7F Voltage Regulators: Eatures EnefitsDocument2 pagesAvc63-7, Avc63-7D, Avc63-7F Voltage Regulators: Eatures Enefitsraju bonthaNo ratings yet

- PFC Topolojisi Ve SorunlarıDocument114 pagesPFC Topolojisi Ve SorunlarıMehmetDursunNo ratings yet

- Preventa XY2C - XY2CE1A250Document5 pagesPreventa XY2C - XY2CE1A250pardocarr4091No ratings yet

- DS1812Document5 pagesDS1812jnax101No ratings yet

- Helix Electrical Package RevB 9-7-16Document95 pagesHelix Electrical Package RevB 9-7-16casual divertidoNo ratings yet

- Rh31c Zib DatasheetDocument2 pagesRh31c Zib DatasheetWilliam XavierNo ratings yet

- Integration Relay: On-Vehicle InspectionDocument1 pageIntegration Relay: On-Vehicle InspectiondennoNo ratings yet

- Sliver3000 Panel SpecificationsDocument5 pagesSliver3000 Panel SpecificationsembokoNo ratings yet

- Venus User Manual-ENDocument58 pagesVenus User Manual-ENAsif KhanNo ratings yet

- General Electric: InstructionsDocument16 pagesGeneral Electric: Instructionsalex pardoNo ratings yet

- 100S CXXXXXXXDocument3 pages100S CXXXXXXXemersonmarquezveNo ratings yet

- Mto-12!13!8016 BMT App MaintenanceDocument2 pagesMto-12!13!8016 BMT App MaintenanceStephen BridgesNo ratings yet

- Tim Tim IIDocument6 pagesTim Tim IIradiolandiaNo ratings yet

- IEC 60947-5-2-1998 - Low-Voltage Switchgear and Controlgear - Control Circuit Devices and Switching Elements - Proximity Switches (BS EN)Document97 pagesIEC 60947-5-2-1998 - Low-Voltage Switchgear and Controlgear - Control Circuit Devices and Switching Elements - Proximity Switches (BS EN)German Barota BorlagdanNo ratings yet

- GTP - DelCEN 2500 HV - 181224 - R5Document2 pagesGTP - DelCEN 2500 HV - 181224 - R5prekNo ratings yet

- Report On Transformer ManufacturingDocument36 pagesReport On Transformer ManufacturingRaj Moyal89% (57)

- Ee 2022Document9 pagesEe 2022LATIGAR, JEFFERSON 0.No ratings yet

- Data Sheet 3KL8431-3UA00: ModelDocument2 pagesData Sheet 3KL8431-3UA00: Modeliotaathi tNo ratings yet

- Renewable Energy-Based Rural Electrification: The Mini-Grid Experience From IndiaDocument32 pagesRenewable Energy-Based Rural Electrification: The Mini-Grid Experience From IndiaRashmi KrishnanNo ratings yet

- Projeto SolarDocument4 pagesProjeto SolarRaphaelNo ratings yet

- Delta UPS - Agilon Family: Installation & Operation Quick GuideDocument2 pagesDelta UPS - Agilon Family: Installation & Operation Quick GuideBhupinder SinghNo ratings yet

- KBPC DC Drive Series ManualDocument19 pagesKBPC DC Drive Series ManualKBElectronicsincNo ratings yet

- Overhead Design Manual: © ENERGEX 2007 BMS 01613 2.0 Last Update: 15/01/2007Document68 pagesOverhead Design Manual: © ENERGEX 2007 BMS 01613 2.0 Last Update: 15/01/2007Mecmed MomodNo ratings yet

- Beginner Introduction Guide To TubesDocument14 pagesBeginner Introduction Guide To TubesShivaji Rao100% (1)

- Service Manual For The APC Smart - UPS 450 - 700 - 1000 - 1400 UPSDocument44 pagesService Manual For The APC Smart - UPS 450 - 700 - 1000 - 1400 UPSAlexandreRussiSchilive92% (12)

- Mitsubishi v500 VFD Instruction ManualDocument119 pagesMitsubishi v500 VFD Instruction ManualMROstop.com100% (1)

- Negative Sequence & Zero Sequence Reactance PDFDocument6 pagesNegative Sequence & Zero Sequence Reactance PDFviksoniNo ratings yet

- Bee CopDocument30 pagesBee CopARIVOLI SUNDARAMURTHYNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)