Professional Documents

Culture Documents

Electrical Work Practices

Electrical Work Practices

Uploaded by

elzerafin2080Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Work Practices

Electrical Work Practices

Uploaded by

elzerafin2080Copyright:

Available Formats

ELECTRICAL WORK

PRACTICES

Hazardous (Classified) Locations

Electrical Safety Work Practices

Work Practice Selection and Use

Equipment Use

Personal Protection Safeguards.

Introduction

This module is based on 29

CFR 1910 Subpart S and

covers electrical work

requirements designed to

minimize potential accidents.

The Occupational Safety and

Health Administration’s

(OSHA) standards were

developed to cover electrical

system parts an employee

would normally use or contact.

In general, all equipment

should be de-energized before

an employee works on it.

Otherwise, protective

equipment and insulated tools

are required.

12/08/21 © 2003 Seton Identification Products 2

Objectives

At the end of the Electrical Work Practices

module, you should be able to:

Identify hazardous locations

Define proper safety related work practices

Define safeguards for personal protection.

12/08/21 © 2003 Seton Identification Products 3

Hazardous (Classified)

Locations

Hazardous (classified)

locations present a real

threat to worker safety.

They are areas where a

potential for explosion and

fire exist due to the

presence of flammable:

Gases

Vapors

Finely pulverized dusts

Ignitable fibers or flyings.

The Hazardous (Classified)

Locations section is based

on 29 CFR 1910.307.

12/08/21 © 2003 Seton Identification Products 4

Hazardous (Classified)

Locations

It presents a description of

and the requirements for

working in hazardous

(classified) locations.

This section covers the

topics listed on the left.

29 CFR 1910.307 is based

on the National Electrical

Code (NEC), NFPA 70.

12/08/21 © 2003 Seton Identification Products 5

Causes

Hazardous locations can

be found in most

workplaces.

A hazardous (classified)

location may result from the

normal processing of

certain volatile chemicals,

gases, grains, etc., or it

may result from accidental

failure of storage systems

for these materials.

12/08/21 © 2003 Seton Identification Products 6

Causes

It is also possible that a

hazardous location may

occur when volatile

solvents or fluids, used in a

normal maintenance

routine, vaporize to form an

explosive atmosphere.

Each room, section, or

area shall be considered

individually when

determining hazardous

classification.

12/08/21 © 2003 Seton Identification Products 7

Precaution

Despite the hazards of a

location, every precaution

must be taken to guard

against ignition of the

atmosphere.

Certainly no open flames are

permitted in these locations.

Electric equipment capable of

igniting flammable materials or

gases shall not be used,

unless measures are taken to

prevent hazardous conditions

from developing.

There are many ways in which

electrical equipment can act

as a source of ignition in a

hazardous location:

12/08/21 © 2003 Seton Identification Products 8

Precaution

Switches, circuit breakers,

motor starters, contactors,

plugs, and receptacles all

release arcs and sparks as

contacts open and close

during normal operation

Lighting fixtures and motors

are classified as "heat

producing". They will become

a source of ignition if their

surface temperature exceeds

the ignition temperature of the

flammable material or gas

An abnormality or failure in an

electrical system, such as the

failure of insulation, can

release sparks, arcs, or heat.

12/08/21 © 2003 Seton Identification Products 9

Wiring Installation

It is important to have an

awareness of the problems

that electrical equipment and

wiring create when they are

located in hazardous

(classified) locations because

several OSHA standards

require the installation of

electrical wiring and

equipment in these locations.

Most of these locations are

defined in the "Hazardous

(Classified) Locations" module

available from the "Hazardous

Materials" selection on the

main menu.

12/08/21 © 2003 Seton Identification Products 10

Electrical Safety Work

Practices- Introduction

Any location with electrical

equipment creates

dangerous working

conditions.

OSHA Safety Related Work

Practice standards for

general industry were

developed to protect

employees from the

electrical hazards to which

they may be exposed even

when equipment is in

compliance with the

installation requirements of

Subpart S. Electrical.

12/08/21 © 2003 Seton Identification Products 11

Electrical Safety Work

Practices- Introduction

OSHA Safety-Related

Work Practice standards

for general industry,

1910.331 - .399, are

performance-oriented

regulations that

complement the existing

electrical installation

standards

12/08/21 © 2003 Seton Identification Products 12

Electrical Safety Work

Practices- Introduction

These work-practice

standards include

requirements for:

Work performed on or

near exposed energized

and de-energized parts of

electric equipment

Use of electrical protective

equipment

Safe use of electric

equipment.

The topics covered are

listed to the left

12/08/21 © 2003 Seton Identification Products 13

Electrical Safety Work

Practices - Scope

The provisions of 1910.331

designate the scope of safety-

related work practices based on

an employee’s classification as

qualified or unqualified.

A qualified employee is an

employee with training in avoiding

electrical hazards when working

near exposed energized parts

while an unqualified employee has

little or no training in this area.

Both qualified and unqualified

employees are covered by the

standard when working on, near,

or with the following installations:

12/08/21 © 2003 Seton Identification Products 14

Electrical Safety Work

Practices - Scope

Premises Wiring - Installations of

electric conductors and equipment

within or on buildings or other

structures, and on other premises

such as yards, carnivals, parking

lots, and industrial substations

Wiring for Connections to Supply -

Installations of conductors that

connect to the supply of electricity

Other Wiring - Installations of

other outside conductors on the

premises

Optical Fiber Cable - Installations

of optical fiber cable where such

installations are made along with

electric conductors.

12/08/21 © 2003 Seton Identification Products 15

Electrical Safety Work

Practices - Scope

Any unqualified employee

working on, near, or with the

following installations are

covered by standard

1910.331:

Generation, transmission,

and distribution installations

located in buildings used for

such purposes or located

outdoors

Communications installations

containing communications

equipment to the extent that

the work is covered under

OSHA standard 1910.268

12/08/21 © 2003 Seton Identification Products 16

Electrical Safety Work

Practices - Scope

Installations in vehicles such

as ships, watercraft, railway

rolling stock, aircraft, or

automotive vehicles other

than mobile homes and

recreational vehicles

Railway installations used for

generation, transformation,

transmission, or distribution

of power used exclusively for

operation of rolling stock or

installations of railways used

exclusively for signaling and

communication purposes.

Qualified employees are not

covered by standard 1910.331

when working on the above

four installations.

12/08/21 © 2003 Seton Identification Products 17

Electrical Safety Work

Practices - Descriptions

Employees covered by

standard 1910.331 must

follow the safe work

practices listed here:

Keep a prescribed distance

from exposed energized

lines

Avoid the use of electric

equipment when the

employee or the equipment

is wet

Lockout and tag equipment

which is de-energized for

maintenance

12/08/21 © 2003 Seton Identification Products 18

Electrical Safety Work

Practices - Descriptions

Use electrical protective

devices such as:

Rubber gloves and rubber

mats to insulate against

live parts

Live-line tools which

provide a means of

manipulating live parts

from a distance. Live-line

tools must also insulate

workers from live parts.

The protective capabilities

of equipment is dependent

on proper manufacturing

and maintenance.

12/08/21 © 2003 Seton Identification Products 19

Differentiation with CFR

1910.147

It is important to understand

the distinction between OSHA

Standards 1910.331 - .399

and OSHA Standard

1910.147, Control of

Hazardous Energy

(Lockout/Tagout).

The lockout/tagout standard

(1910.147) helps safeguard

employees from hazardous

energy while they are

performing servicing or

maintenance on machines and

equipment.

12/08/21 © 2003 Seton Identification Products 20

Differentiation with CFR

1910.147

Standard 1910.147 covers

electrical energy sources, but

it specifically excludes

"exposure to electrical hazards

from work on, near, or with

conductors or equipment in

electrical utilization

installations," which is covered

by Subpart S, Electrical.

Thus, the lockout/tagout

standard does not cover

electrical hazards associated

with conductors, and only

defines requirements for

electrical machinery and

equipment that are covered by

this lockout standard.

12/08/21 © 2003 Seton Identification Products 21

Training

29 CFR 1910.332 describes

training requirements for

employees who face a risk of

electric shock that is not

reduced to a safe level by the

electrical installation

requirements of 1910.303 - .

308.

Employees in occupations

exposed to electric shock risk

must be trained. Click on the

term below to see a list of

occupations that require such

training.

Occupations Exposed to Elec

tric Shock Risk

12/08/21 © 2003 Seton Identification Products 22

Training

With the exception of

electricians and welders,

workers do not need to be

trained if their work or the work

of those they supervise does

not bring them close enough

to exposed parts of electric

circuits operating at 50 volts or

more to ground for a hazard to

exist.

The training required by this

section shall be of the

classroom or on-the-job type.

The degree of training

provided shall be determined

by the risk to the employee.

12/08/21 © 2003 Seton Identification Products 23

Training

Employees shall be trained in

safety-related work practices

required by 1910.331-.355 that

pertain to their respective job

assignments.

In addition, unqualified

employees who are covered

by the scope of this standard

shall also be trained in any

electrically related safety

practices not specifically

addressed by 1910.331 - .335,

but which are necessary for

their safety.

12/08/21 © 2003 Seton Identification Products 24

Training

At a minimum, qualified

persons shall be trained in and

familiar with the:

Skills and techniques

necessary to distinguish

exposed live parts from other

parts of electric equipment

Skills and techniques

necessary to determine the

nominal voltage of exposed

live parts

Clearance distances

specified in this standard and

the corresponding voltages to

which the qualified person

will be exposed.

12/08/21 © 2003 Seton Identification Products 25

Quiz Question:

Hazardous (classified) locations are

areas where employees are in danger

of electric shock.

True

False

12/08/21 © 2003 Seton Identification Products 26

Quiz Question:

The lockout/tagout standard

(1910.147) covers electrical hazards

associated with conductors and

equipment.

True

False

12/08/21 © 2003 Seton Identification Products 27

Selection and Use of Work

Practices - Introduction

The Selection and Use of

Work Practices section, based

on standard 1910.333, covers

employees working on or near

the topics listed on the left.

In general, safety-related work

practices shall be used to

prevent employees from being

shocked by equipment which

may be energized.

Specific safety-related work

practices shall be consistent

with the associated electrical

hazards as described in this

section.

12/08/21 © 2003 Seton Identification Products 28

Exposed De-energized Parts

Live parts to which an

employee may be exposed

shall be de-energized before

the employee works on or

near them. However, de-

energizing is not required if it:

Introduces additional or

increased hazards

Is infeasible due to equipment

design or operational limits

Contains live parts that

operate at less than 50 volts to

ground and does not increase

the risk of electrical burns or

explosion due to electric arcs.

12/08/21 © 2003 Seton Identification Products 29

Exposed De-energized Parts

While any employee is

exposed to contact with de-

energized fixed electric

equipment or circuits, the

circuits energizing the parts

shall be locked out, tagged, or

both.

De-energized conductors and

electric equipment parts that

have not been tagged shall be

treated as energized parts.

Click below to review the

proper lock out/tagging

procedures.

Lock Out/Tagging Procedure

s

12/08/21 © 2003 Seton Identification Products 30

Exposed Energized Parts

Sometimes equipment cannot be

de-energized due to operational

limits, equipment design, or risk of

increased hazards.

Only qualified persons may work

on electric circuit parts or

equipment that have not been de-

energized under the procedures of

standard 1910.333.

12/08/21 © 2003 Seton Identification Products 36

Exposed Energized Parts

Qualified persons shall be capable

of working safely on energized

circuits and shall be familiar with:

Proper use of special

precautionary techniques

Personal protective equipment

Insulating and shielding materials

Insulated tools.

To protect employees working on

exposed live parts, safety-related

work practices shall be used.

Such work practices protect

employees against contact with

energized circuit parts directly with

any part of their body or indirectly

through a conductive object.

12/08/21 © 2003 Seton Identification Products 37

Exposed Energized Parts

If work is to be performed near overhead lines, the lines shall

be de-energized and grounded, unless other protective

measures are provided before work is started.

If the lines are to be de-energized, arrangements to de-

energize and ground the lines shall be made with the operator

or controller of the electric circuits involved.

If protective measures such as guarding, isolating, or

insulating are provided, these precautions shall prevent

employees from contacting lines directly with any body part or

conductive materials, tools, or equipment.

The closest an unqualified person may come to an

unguarded, energized overhead line is 10 feet plus 4 inches

for every 10 kV over 50 kV. This rule also applies to any

conductive material with which he or she is in contact.

12/08/21 © 2003 Seton Identification Products 38

Exposed Energized Parts

The closest a qualified person and the longest conductive

material he or she possesses may come to an unguarded,

energized overhead line is designated in Table S-5 of

1910.333(c)(3)(ii), unless certain insulation requirements are

met.

The closest any part of a vehicle or mechanical equipment

that is capable of being elevated may come to an unguarded,

energized overhead line is 10 feet plus 4 inches for every 10

kV over 50 kV. However, the standard outlines situations

where the clearance can be reduced for elevated equipment.

12/08/21 © 2003 Seton Identification Products 39

Exposed Energized Parts

Energized parts, conductive

materials, and equipment that

are in contact with any part of

an employee's body shall be

handled in a manner that will

prevent them from contacting

exposed energized conductors

or circuit parts.

If an employee must handle

long dimensional conductive

objects (such as ducts and

pipes) in areas with exposed

live parts, the employer shall

institute work practices (such

as the use of insulation,

guarding, and material

handling techniques) which

will minimize the hazard.

12/08/21 © 2003 Seton Identification Products 40

Exposed Energized Parts

Conductive articles of jewelry

and clothing may not be worn

if they might contact exposed

energized parts, unless they

are rendered non-conductive

by covering, wrapping, or

other insulating means.

12/08/21 © 2003 Seton Identification Products 41

Exposed Energized Parts

Where live parts present an

electrical contact hazard,

employees may not perform

housekeeping duties at

distances close enough for

possible contact unless

adequate safeguards (such as

insulating equipment or

barriers) are provided.

Electrically conductive

cleaning materials may not be

used in proximity to energized

parts unless procedures are

followed which will prevent

electrical contact.

12/08/21 © 2003 Seton Identification Products 42

Exposed Energized Parts

If a portable ladder is to be

used where the employee or

ladder could contact exposed

energized parts, the ladder

shall have non-conductive

siderails.

Only a qualified person

following the requirements of

this section may defeat an

electrical safety interlock, and

then only temporarily while he

or she is working on the

equipment.

The interlock system shall be

returned to its operable

condition when the work is

completed.

12/08/21 © 2003 Seton Identification Products 43

Exposed Energized Parts

Employees may not enter

spaces containing exposed

energized parts unless

illumination is provided that

enables the employees to

perform the work safely.

Where lack of illumination or

an obstruction precludes

observation of the work to be

performed, employees may

not perform tasks near

exposed energized parts.

Employees may not reach

blindly into areas which may

contain energized parts.

12/08/21 © 2003 Seton Identification Products 44

Quiz Question:

De-energized equipment must be

locked out.

True

False

12/08/21 © 2003 Seton Identification Products 45

Quiz Question:

The closest an unqualified employee

may come to an overhead line is 10

feet plus:

6 inches for every 10 kV over 50 kV

8 inches for every 10 kV over 50 kV

10 inches for every 10 kV over 50 kV

4 inches for every 10 kV over 50 kV

12/08/21 © 2003 Seton Identification Products 46

Equipment Use -

Introduction

The Equipment Use section is

based on 29 CFR 1910.334. It

describes the topics listed on

the left.

Proper use of equipment is at

the core of maintaining worker

and equipment safety.

Equipment that is transported

and used in different locations

is susceptible to improper use,

because each new location

presents different hazards that

must be assessed.

12/08/21 © 2003 Seton Identification Products 47

Portable Electric Equipment

Portable electric equipment

requirements apply to cord-

and plug-connected

equipment including

flexible cord sets

(extension cords).

The requirements include

the following.

12/08/21 © 2003 Seton Identification Products 48

Portable Electric Equipment

Portable cord- and plug-

connected equipment and

flexible cord sets shall be

visually inspected for external

defects and for evidence of

possible internal damage

before use on any shift. If the

equipment and extension

cords remain connected once

they are put in place and are

not exposed to damage, they

do not need to be visually

inspected until they are

relocated. Defective or

damaged items shall be

removed from service until

repaired.

12/08/21 © 2003 Seton Identification Products 49

Portable Electric Equipment

Portable equipment shall be

handled carefully to prevent

damage. Flexible electric

equipment cords may not be

used for raising or lowering the

equipment nor should they be

fastened with staples or

otherwise hung in such a

fashion that could damage the

outer jacket or insulation.

Locking-type connectors shall

be properly secured after

connection.

12/08/21 © 2003 Seton Identification Products 50

Portable Electric Equipment

Portable electric equipment

and flexible cords used in

highly conductive work

locations or in job locations

where employees are likely

to contact water or

conductive liquids, shall be

approved for those

locations.

Employees' hands may not

be wet when plugging and

unplugging flexible cords

and cord- and plug-

connected equipment, if

energized equipment is

involved.

12/08/21 © 2003 Seton Identification Products 51

Portable Electric Equipment

Energized plug and

receptacle connections

may be handled only with

insulating protective

equipment if the connection

could provide a conducting

path to the employee's

hand.

12/08/21 © 2003 Seton Identification Products 52

Portable Electric Equipment

When a flexible cord is used with

grounding-type equipment, the

cord shall contain an equipment

grounding conductor.

Attachment plugs and receptacles

may not be connected or altered in

a manner which would prevent

proper continuity of the equipment

grounding conductor at the point

where plugs are attached to

receptacles. Additionally, these

devices may not be altered to

allow the grounding pole of a plug

to be inserted into slots intended

for connection to the current-

carrying conductors.

Adapters which interrupt the

continuity of the equipment

grounding connection may not be

used.

12/08/21 © 2003 Seton Identification Products 53

Test Instruments and

Equipment

Testing instruments and equipment are

subject to damage much like other

portable equipment.

Since test instruments are utilized in

different work environments, they are

prone to misuse.

The following regulations for their use

and handling were developed.

Only qualified persons may perform

testing work on electric circuits or

equipment.

12/08/21 © 2003 Seton Identification Products 54

Test Instruments and

Equipment

Test instruments and equipment and

all associated test leads, cables, power

cords, probes, and connectors shall be

visually inspected for external defects

and damage before the equipment is

used.

If there is a defect or evidence of

damage that might expose an

employee to injury, the defective or

damaged item shall be removed from

service, and it will not be used until

necessary repairs and tests to render

the equipment safe have been made.

Test instruments and equipment and

their accessories shall be rated for the

circuits and equipment to which they

will be connected and shall be

designed for the environment in which

they will be used.

12/08/21 © 2003 Seton Identification Products 55

Electric Power and Lighting

Circuits

Equipment should only be used

for its designated purpose.

Load rated switches, circuit

breakers, or other devices

specifically designed as

disconnecting means shall be

used for the opening, reversing, or

closing of circuits under load

conditions.

Cable connectors not of the load-

break type, fuses, terminal lugs,

and cable splice connections may

not be used for such purposes,

except in an emergency.

12/08/21 © 2003 Seton Identification Products 56

Electric Power and Lighting

Circuits

After a circuit is de-energized by a

circuit protective device, the circuit

may not be manually re-energized

until it has been determined that

the equipment and circuit can be

safely energized.

The repetitive manual re-closing of

circuit breakers or re-energizing of

charged circuits through replaced

fuses is prohibited.

Overcurrent protection of circuits

and conductors may not be

modified, even on a temporary

basis, beyond that allowed in

standard 1910.304(e), the

installation safety requirements for

overcurrent protection.

12/08/21 © 2003 Seton Identification Products 57

Personnel Protection

Safeguards - Introduction

The Safeguards for Personal

Protection section, based on

standard 1910.335, describes the

proper use and maintenance of

protective equipment to ensure the

safety of employees working in the

area of energized electrical

equipment.

The topics covered are listed to

the left.

In general, employees working in

areas where there are potential

electrical hazards shall be

provided with, and shall use,

electrical protective equipment

that is appropriate for the specific

parts of the body to be protected

and for the work to be performed.

12/08/21 © 2003 Seton Identification Products 58

Use of Personal Protective

Equipment

Employees shall wear non-

conductive head protection

wherever there is a danger of

head injury from electric shock

or burns due to contact with

exposed energized parts.

Employees shall wear

protective equipment for the

eyes or face wherever there is

danger of injury to the eyes or

face from electric arcs or

flashes or from flying objects

resulting from electrical

explosion.

12/08/21 © 2003 Seton Identification Products 59

Use of Personal Protective

Equipment

Protective equipment shall be

maintained in a safe, reliable

condition and shall be

periodically inspected or

tested, as required by

1910.137.

If the insulating capability of

protective equipment may be

subject to damage during use,

the insulating material shall be

protected. (For example, an

outer covering of leather is

sometimes used for the

protection of rubber insulating

material.)

12/08/21 © 2003 Seton Identification Products 60

General Protective Equipment

and Tools

It is not enough to use insulated personal protection equipment when working

near energized conductors or circuit paths.

General tools or handling equipment must also be insulated if the tools could

come in contact with energized electric parts.

Fuse handling equipment, insulated for the circuit voltage, shall be used to

remove or install fuses when the fuse terminals are energized.

Ropes and handlines used near exposed energized parts shall be non-

conductive.

Protective shields, protective barriers, or insulating materials shall be used to

protect each employee from shock, burns, or other electrically-related injuries

while that employee is working near exposed energized parts which might be

accidentally contacted or where dangerous electric heating or arcing might

occur.

When normally enclosed live parts are exposed for maintenance or repair,

they shall be guarded to protect unqualified persons from contact with the live

parts.

If the insulating capability of insulated tools or handling equipment is subject

to damage, the insulating material shall be protected.

12/08/21 © 2003 Seton Identification Products 61

Alerting Techniques

Employees should be warned

about hazards which could

cause injury due to electric

shock, burns, or failure of

electric equipment parts by the

following techniques:

Safety signs and tags -

Safety signs, safety symbols,

or accident prevention tags

shall be used where

necessary to warn

employees about electrical

hazards which may endanger

them, as required by

standard 1910.145

12/08/21 © 2003 Seton Identification Products 62

Alerting Techniques

Barricades - Barricades shall

be used in conjunction with

safety signs where it is

necessary to prevent or limit

employee access to work

areas exposing employees to

uninsulated energized

conductors or circuit parts.

Conductive barricades may

not be used where they might

cause an electrical contact

hazard

Attendants - If signs and

barricades do not provide

sufficient warning and

protection from electrical

hazards, an attendant shall

be stationed to warn and

protect employees.

12/08/21 © 2003 Seton Identification Products 63

Quiz Question:

Portable plug- and cord-connected

equipment shall be inspected before

every shift, unless they are not moved

nor subject to damage.

True

False

12/08/21 © 2003 Seton Identification Products 64

Quiz Question:

Only qualified employees may perform

tests on electric circuits or equipment.

True

False

12/08/21 © 2003 Seton Identification Products 65

Quiz Question:

Personal protection equipment must be:

Maintained in a safe reliable location

Used whenever an employee is near electric

equipment

Worn to protect eyes and heads at all times

Periodically inspected or tested

Supplied by the employer

12/08/21 © 2003 Seton Identification Products 66

Summary

During this module we have discussed the

scope and philosophy of Subpart E of the

OSHA standard and presented issues and

requirements for:

Electrical Safety Related Work Practices

Selection and Use of Work Practices

Working On or Near Energized Parts

Equipment Use

Personal Protection Safeguards

12/08/21 © 2003 Seton Identification Products 67

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Detector de Humo Fotoelectrico CONV 71 - 55Document4 pagesDetector de Humo Fotoelectrico CONV 71 - 55heberthNo ratings yet

- 3.02 Components and Parameters of TransistorsDocument2 pages3.02 Components and Parameters of TransistorsVamsiMadupuNo ratings yet

- Terminal BoxesDocument2 pagesTerminal BoxesZdelvin ZainudinNo ratings yet

- OPen Collector and Tri State GateDocument19 pagesOPen Collector and Tri State GateJaydip FadaduNo ratings yet

- TW 14792Document2 pagesTW 14792crisplebeuNo ratings yet

- Ecc 2Document6 pagesEcc 2Reshmi BaisNo ratings yet

- BUT70W: High Power NPN TransistorDocument4 pagesBUT70W: High Power NPN Transistor3jos3aNo ratings yet

- SCC 86587 TPV IPB Repair Instructions v1.0Document6 pagesSCC 86587 TPV IPB Repair Instructions v1.0sonic-esNo ratings yet

- Physics Investigatory Project UpdatedDocument18 pagesPhysics Investigatory Project Updatedjohhnysins1978No ratings yet

- Catálogo EZ-LightDocument4 pagesCatálogo EZ-Lightbrunonunes2010No ratings yet

- INU Hardware ManualDocument212 pagesINU Hardware Manualjuan_set8822No ratings yet

- Loa24 171B27Document11 pagesLoa24 171B27prihharmanto antokNo ratings yet

- BisturiDocument42 pagesBisturiajcneto82No ratings yet

- Electrical Engineering Portal - Com StarDelta Motor StarterDocument9 pagesElectrical Engineering Portal - Com StarDelta Motor StarterRicardo A VergaraNo ratings yet

- Diff - Op Amp PDFDocument5 pagesDiff - Op Amp PDFPoonam mirkaleNo ratings yet

- LED RGB Controller: User ManualDocument1 pageLED RGB Controller: User ManualUltraLEDsNo ratings yet

- Pressure Transmitter For Air and Water Applications: Type MBS 1900Document4 pagesPressure Transmitter For Air and Water Applications: Type MBS 1900chandras20No ratings yet

- Article Testing The State of High Voltage Insulation Hummel ENUDocument6 pagesArticle Testing The State of High Voltage Insulation Hummel ENUarnenylundNo ratings yet

- Silicon NPN Power Transistors: Inchange Semiconductor Product SpecificationDocument3 pagesSilicon NPN Power Transistors: Inchange Semiconductor Product Specificationtonny lethantNo ratings yet

- Ia T 3 Two Marks Q & ADocument2 pagesIa T 3 Two Marks Q & ARAMESH BABU EEENo ratings yet

- A Wide Compensation Ranged Hybrid Statcom With Low DC - Link Voltage PDFDocument7 pagesA Wide Compensation Ranged Hybrid Statcom With Low DC - Link Voltage PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design CRITERIA Report SAUDDocument13 pagesDesign CRITERIA Report SAUDahmed fouadNo ratings yet

- Q Automat CatalogueDocument2 pagesQ Automat CatalogueAlHadiPutroNo ratings yet

- Daf Cf65 Cf75 Cf85 To Chassis 0e621376 Electrical Wiring DiagramDocument20 pagesDaf Cf65 Cf75 Cf85 To Chassis 0e621376 Electrical Wiring Diagraminez100% (45)

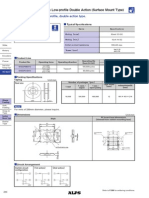

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuNo ratings yet

- Medidores Hipot DCDC HAEFELY - HD100-Series - SPECDocument2 pagesMedidores Hipot DCDC HAEFELY - HD100-Series - SPECArturo mendozaNo ratings yet

- PY600AC Sliding Gate Opener User ManualDocument20 pagesPY600AC Sliding Gate Opener User ManualJose Gregorio Pantaleon Anaya0% (1)

- System Fault Level Calculation 15MW AADocument5 pagesSystem Fault Level Calculation 15MW AAerkamlakar2234No ratings yet

- Laser Security SystemDocument18 pagesLaser Security SystemDipin Preet SinghNo ratings yet

- Varistor 275l40Document1 pageVaristor 275l40marisafrescoNo ratings yet