Professional Documents

Culture Documents

Computer Aided Quality Control

Uploaded by

harini0 ratings0% found this document useful (0 votes)

18 views16 pagesOriginal Title

CAQC

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views16 pagesComputer Aided Quality Control

Uploaded by

hariniCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 16

Computer Aided Quality Control

Automated Inspection

• Automated inspection can be defined as the automation of one or

more of the steps involved in the inspection procedure.

• There are a number of alternative ways in which automated or semi

automated inspection can be implemented:

1. Automated presentation of parts by an automatic handling system

with a human operator still performing the examination and

decision steps.

2. Automated examination and decision by an automatic inspection

machine, with manual loading (presentation) of parts into the

machine.

3. Completely automated inspection system in which parts

presentation, examination, and decision are all performed

automatically.

Where and When to Inspect

• Inspection can be performed at any of several places in production:

1. Receiving inspection, when raw materials and parts are

received from suppliers.

2. At various stages of manufacture, and

3. Before shipment to the customer.

Off-Line and On-Line Inspection

• The timing of the inspection procedure in relation to the

manufacturing process is an important consideration in quality

control.

• Two alternative situations can be distinguished:

1. Off-line inspection.

2. On-line inspection.

Off-Line Inspection

• Off-line inspection is performed away from the manufacturing

process, and there is generally a time delay between processing and

inspection.

• Manual inspection is common.

On-Line Inspection

• The alternative to off-line inspection is on-line inspection, in which

the procedure is performed when the parts are made, either as

An integral step in the processing or assembly operation, or

Immediately afterward.

• Two on-line inspection procedures can be distinguished:

On-line/in-process.

On-line/post-process.

On-Line/ in-process Inspection

• The is achieved by performing the inspection procedure during the

manufacturing operation.

• As the parts are being made, the inspection procedure is measuring

or gaging the parts simultaneously.

On-Line/ post-process Inspection

• The measurement or gaging procedure is accomplished

immediately following the production process.

Contact vs. Non-contact Inspection Techniques

• Inspection techniques can be divided into two broad categories:

1. Contact Inspection.

2. Non-contact Inspection.

• In contact inspection, physical contact is made between the object

and the measuring or gaging instrument.

• In non-contact inspection no physical contact is made.

Contact Inspection Techniques

• The principal contact technologies are:

Conventional measuring and gaging instruments, manual and

automated.

Coordinate Measuring Machines (CMMs)

Stylus type surface texture measuring machines.

Coordinate Measuring Machines

• A Coordinate Measuring Machine (CMM) is an electromechanical

system designed to perform coordinate metrology.

Coordinate Measuring Machines

Coordinate Measuring Machines

• To accomplish measurements in 3D, a basic CMM is composed of the

following components:

Probe head and probe to contact the workpart suraface.

Mechanical structure that provides motion of the probe in three

Cartesian axes and displacement transducers to measure the

coordinate values of each axis.

CMM Mechanical Structure

(a) Cantilever (b) Moving bridge (c) Fixed bridge

CMM Mechanical Structure

(d) Horizontal Arm (e) Gantry (f ) Column

You might also like

- Computer Aided Quality ControlDocument16 pagesComputer Aided Quality ControlSunil J Raykar76% (17)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Automated Inspection CimsDocument30 pagesAutomated Inspection CimsGomish SharmaNo ratings yet

- Automated InspectionDocument31 pagesAutomated InspectionelkhawadNo ratings yet

- Automated InspectionDocument31 pagesAutomated InspectionVijay Kumar100% (8)

- Automated Inspection: Unit ViDocument45 pagesAutomated Inspection: Unit ViAnonymous surAitMpaNo ratings yet

- Metrology and Quality AssuranceDocument25 pagesMetrology and Quality AssuranceFaisal MaqsoodNo ratings yet

- Subject - Automation Engineering Subject Code - 7ME04 Semester - Seventh Unit No.-06Document13 pagesSubject - Automation Engineering Subject Code - 7ME04 Semester - Seventh Unit No.-06santosh sivarNo ratings yet

- Unit Vi Automated InspectionDocument70 pagesUnit Vi Automated InspectionRajesh ShahNo ratings yet

- Modern Techniques - 6Document51 pagesModern Techniques - 6Abdelrahmam AshrafNo ratings yet

- Inspection Metrology: Mechanical EngineeringDocument21 pagesInspection Metrology: Mechanical EngineeringwhatisnameNo ratings yet

- CAD-CAM Unit-5aDocument14 pagesCAD-CAM Unit-5aSHYAM NANINo ratings yet

- 4th CAMUnitDocument59 pages4th CAMUnitPradeepvenugopalNo ratings yet

- Need of InspectionDocument13 pagesNeed of InspectionPremsagar Ojha OjhaNo ratings yet

- Automated Gauging: Mohan Kumar .B.T PGTE 0202Document13 pagesAutomated Gauging: Mohan Kumar .B.T PGTE 0202Moham'medAlthafAs'lamNo ratings yet

- CAQCDocument20 pagesCAQCANIL DATTATRAYA MANDLIK100% (2)

- Chapter5 Automatic Inspection System CMMDocument9 pagesChapter5 Automatic Inspection System CMMKRISHNA KANT GUPTANo ratings yet

- Unit 4Document30 pagesUnit 4muniraju mNo ratings yet

- Wa0020Document133 pagesWa0020Manoj DhageNo ratings yet

- AutomationDocument12 pagesAutomationPradeep N BNo ratings yet

- Inspection and SQC - NotesDocument10 pagesInspection and SQC - NotesJigar MevadaNo ratings yet

- Unit-7 (CAQC)Document8 pagesUnit-7 (CAQC)Abhishek Saini100% (14)

- Lecture Notes 2 by Prof. Kaushik PalDocument34 pagesLecture Notes 2 by Prof. Kaushik Palrimu tempNo ratings yet

- Computer Aided Quality ControlDocument67 pagesComputer Aided Quality Controlkonankiniranjan1No ratings yet

- Computer Aided Inspection Process Planning SystemDocument14 pagesComputer Aided Inspection Process Planning SystemAtul JainNo ratings yet

- PTC CH7 Intro To CAMDocument30 pagesPTC CH7 Intro To CAMManoj Kumar NayakNo ratings yet

- Advances in Engineering TechnologyDocument14 pagesAdvances in Engineering TechnologyAhmed ElkomyNo ratings yet

- Unit 2-55 Automated Inspection PDFDocument13 pagesUnit 2-55 Automated Inspection PDFLokesh GargNo ratings yet

- Quantity Production Method: Adhesive Bonding. They Form A Joint Between Two Components That Cannot Be EasilyDocument3 pagesQuantity Production Method: Adhesive Bonding. They Form A Joint Between Two Components That Cannot Be EasilyDebaditya DattaNo ratings yet

- Metrology: Production Engineering 2 Code: MEC3202Document58 pagesMetrology: Production Engineering 2 Code: MEC3202sakali aliNo ratings yet

- Quality ControlDocument48 pagesQuality ControlNasif Imtiaz100% (2)

- Cc&a - 4Document51 pagesCc&a - 4Gauri SinghNo ratings yet

- Quality Control - III Unit - V: Operations Management - Semester II Prof - Namita N KumarDocument13 pagesQuality Control - III Unit - V: Operations Management - Semester II Prof - Namita N KumarDeepanshu GoyalNo ratings yet

- Inspection PDFDocument20 pagesInspection PDFSEGU PRATHEEK100% (1)

- Cim Module III-1Document37 pagesCim Module III-1Akash ByjuNo ratings yet

- VT 4Document18 pagesVT 4demoknight tf2No ratings yet

- Cim Module IIIDocument126 pagesCim Module IIIRamees KpNo ratings yet

- The Process of Measurement: - IntroductionDocument24 pagesThe Process of Measurement: - IntroductionJunaid YNo ratings yet

- Quality Control ShopDocument20 pagesQuality Control ShopAshu ThakurNo ratings yet

- Om 1 Special Topics in Operations Management/ Operations Management Chapter 10: Quality ControlDocument2 pagesOm 1 Special Topics in Operations Management/ Operations Management Chapter 10: Quality ControlRoseanne Binayao LontianNo ratings yet

- Low Voltage Switchboards Quality Inspection GuideDocument64 pagesLow Voltage Switchboards Quality Inspection Guideham100% (1)

- CalibrationDocument155 pagesCalibrationdarrel_julio100% (1)

- Measurement: Measurement, Measure - Why? by M.S.NarainDocument58 pagesMeasurement: Measurement, Measure - Why? by M.S.NaraindeepakjothivelNo ratings yet

- ResearchDocument6 pagesResearchcornelius wafulaNo ratings yet

- Quality Control Program For An Apparel Manufacturing Unit: Assignment 2Document12 pagesQuality Control Program For An Apparel Manufacturing Unit: Assignment 2Amrita MitraNo ratings yet

- Inspection and Quality ControlDocument15 pagesInspection and Quality ControlAnurag Goel100% (2)

- Coordinates Measuring Machines (CMM)Document20 pagesCoordinates Measuring Machines (CMM)Muthu RajNo ratings yet

- Need of Inspection-Types and PrinciplesDocument28 pagesNeed of Inspection-Types and PrinciplesVishal KarmakarNo ratings yet

- Maintenance Engg PDFDocument27 pagesMaintenance Engg PDFrahulNo ratings yet

- Lecture 1 - What Is Automation (Printed)Document12 pagesLecture 1 - What Is Automation (Printed)Aung Naing OoNo ratings yet

- Industrial Control SystemsDocument34 pagesIndustrial Control SystemsAmmar OwesNo ratings yet

- Automation Control SystemsDocument68 pagesAutomation Control SystemsAutNo ratings yet

- Plastic Reprocess Machine - Inpection ProcedureDocument1 pagePlastic Reprocess Machine - Inpection ProcedureAthulya PallipurathNo ratings yet

- Lecture 15+16, Quality ControlDocument33 pagesLecture 15+16, Quality ControlMuhammadNo ratings yet

- Chapter 4 Installation Commissioning and Testing in New PlantDocument24 pagesChapter 4 Installation Commissioning and Testing in New PlantMuhd Tasyrif100% (1)

- Regarding Industrial PresentationDocument5 pagesRegarding Industrial PresentationSparsh vatsNo ratings yet

- 1 - Automatic Flow LinesDocument72 pages1 - Automatic Flow LinesAchsah K VijuNo ratings yet

- TQM Unit ADocument33 pagesTQM Unit APooja SinghNo ratings yet

- 08 - Measurements, Inspection Principles and CMMDocument38 pages08 - Measurements, Inspection Principles and CMMBhartendu TavriNo ratings yet

- Corona Virus Government'S DutyDocument14 pagesCorona Virus Government'S DutyhariniNo ratings yet

- SkillsDocument13 pagesSkillshariniNo ratings yet

- UNIT3Document29 pagesUNIT3hariniNo ratings yet

- Unit 4 Important Q&aDocument15 pagesUnit 4 Important Q&ahariniNo ratings yet

- Unit 5 Short Answers: 1. Write Short Notes Wamp? Ans: Wamp For IotDocument21 pagesUnit 5 Short Answers: 1. Write Short Notes Wamp? Ans: Wamp For IothariniNo ratings yet

- Israel PolestheneDocument15 pagesIsrael PolesthenehariniNo ratings yet

- Unit 3 Important Q&aDocument16 pagesUnit 3 Important Q&ahariniNo ratings yet

- Characteristics and Quality AttributesDocument29 pagesCharacteristics and Quality AttributeshariniNo ratings yet

- Chapter 2Document5 pagesChapter 2Anonymous 7qqXzdtLINo ratings yet

- DAAImp QuestionsDocument6 pagesDAAImp QuestionshariniNo ratings yet

- Selenium IDE: Installation Launch The IDEDocument21 pagesSelenium IDE: Installation Launch The IDEhariniNo ratings yet

- HCF & LCMDocument78 pagesHCF & LCMhariniNo ratings yet

- Manual Testing ExamplesDocument17 pagesManual Testing ExampleshariniNo ratings yet

- BST - Important QuestionsDocument1 pageBST - Important QuestionshariniNo ratings yet

- Unit-III Ies Part2Document41 pagesUnit-III Ies Part2hariniNo ratings yet

- Selenium IDE: Installation Launch The IDEDocument21 pagesSelenium IDE: Installation Launch The IDEhariniNo ratings yet

- Manual Testing ExamplesDocument17 pagesManual Testing ExampleshariniNo ratings yet

- Characteristics and Quality AttributesDocument29 pagesCharacteristics and Quality AttributeshariniNo ratings yet

- HCF & LCMDocument78 pagesHCF & LCMhariniNo ratings yet

- Week 3Document2 pagesWeek 3hariniNo ratings yet

- Java Servlets Session - 1: Srikanth ReddyDocument52 pagesJava Servlets Session - 1: Srikanth ReddyhariniNo ratings yet

- Unit-III Ies Part2Document41 pagesUnit-III Ies Part2hariniNo ratings yet

- QQDocument1 pageQQhariniNo ratings yet

- Implementing Bubble Sort AlgorithmDocument6 pagesImplementing Bubble Sort AlgorithmhariniNo ratings yet

- Purpose of Inheritance in C++Document16 pagesPurpose of Inheritance in C++hariniNo ratings yet

- ActivityDocument11 pagesActivityhariniNo ratings yet

- Class Activity QuesDocument4 pagesClass Activity QueshariniNo ratings yet

- CoverletterDocument1 pageCoverletterhariniNo ratings yet

- Val. Trie Data Structure MakesDocument1 pageVal. Trie Data Structure MakeshariniNo ratings yet

- E Book MS 53 - Production and Operations ManagementDocument149 pagesE Book MS 53 - Production and Operations ManagementAravind MoluguNo ratings yet

- About Hemant Urdhwareshe: Fellow of ASQDocument3 pagesAbout Hemant Urdhwareshe: Fellow of ASQKumar AbhishekNo ratings yet

- The Effectiveness of 50 Discount Pricing Strategy of Bread and Pastry Shops in Bonifacio High Street, Bonifacio Global City To The People Living in Taguig CityDocument74 pagesThe Effectiveness of 50 Discount Pricing Strategy of Bread and Pastry Shops in Bonifacio High Street, Bonifacio Global City To The People Living in Taguig CityCedrick Earl ManaliliNo ratings yet

- Eclerx Services LTD: Initiating CoverageDocument25 pagesEclerx Services LTD: Initiating CoverageAjay AroraNo ratings yet

- Media Planning and Buying 20 MARKS 2022 - 23 - Notes For Students With SolutionDocument27 pagesMedia Planning and Buying 20 MARKS 2022 - 23 - Notes For Students With SolutionRiya MishraNo ratings yet

- How Thick Is The Copper On A 1 Oz Copper PCB in MMDocument13 pagesHow Thick Is The Copper On A 1 Oz Copper PCB in MMjackNo ratings yet

- SDM - Logistics Management: CONCOR - Container Corporation of India LTDDocument10 pagesSDM - Logistics Management: CONCOR - Container Corporation of India LTDTanya KhareNo ratings yet

- Economics For Managers (EFM) (4519905)Document20 pagesEconomics For Managers (EFM) (4519905)shivam networkNo ratings yet

- A Comparison of Lifestyle Marketing and Brand Influencer Advertising For Generation Z Instagram Users PDFDocument45 pagesA Comparison of Lifestyle Marketing and Brand Influencer Advertising For Generation Z Instagram Users PDFMaryam KhaliqNo ratings yet

- Single Minute Exchange of Dies: (Set-Up Reduction)Document35 pagesSingle Minute Exchange of Dies: (Set-Up Reduction)Deeksha ShrivastavaNo ratings yet

- Group 3 Operations Management: DinapamaDocument13 pagesGroup 3 Operations Management: DinapamaTimotheus HauwangaNo ratings yet

- Six Sigma Report Out TemplateDocument55 pagesSix Sigma Report Out TemplateWinner#1No ratings yet

- Mahatma Gandhi University Mba Syllabus 2010Document91 pagesMahatma Gandhi University Mba Syllabus 2010Sachu CyriacNo ratings yet

- Chapter 6 - Analysis and ModelingDocument24 pagesChapter 6 - Analysis and ModelingVegi Syam MerkuryNo ratings yet

- Chapter FiveDocument43 pagesChapter FiveKebrie GezahegnNo ratings yet

- A Project Report On Retail Industry in IndiaDocument109 pagesA Project Report On Retail Industry in IndiaPartha PratimNo ratings yet

- Chapter 2 & 3 Visitor Attraction in TourismDocument27 pagesChapter 2 & 3 Visitor Attraction in TourismSharvin NeshNo ratings yet

- Weekly Assignment 7 E.12-3 Chesbrough, Inc., Makes Many of The Components of Its Main Product In-HouseDocument4 pagesWeekly Assignment 7 E.12-3 Chesbrough, Inc., Makes Many of The Components of Its Main Product In-HouseFaradiba100% (1)

- Human Resource OutsourcingDocument21 pagesHuman Resource Outsourcinggurjeetkaur1991No ratings yet

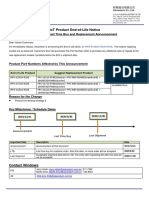

- Product Phase Out Notice IPPC 6152 6172 6192 R2AEDocument1 pageProduct Phase Out Notice IPPC 6152 6172 6192 R2AEguruh anindraNo ratings yet

- The Digital Marketing Handbook Kingsnorth en 44857Document6 pagesThe Digital Marketing Handbook Kingsnorth en 44857valleaxelssonNo ratings yet

- Pressure Die CastingDocument62 pagesPressure Die CastingChetan Nehete100% (2)

- The Influence of Digital Marketing Strategies On Customer's Purchase Intention of Selected Fast-Food RestaurantsDocument14 pagesThe Influence of Digital Marketing Strategies On Customer's Purchase Intention of Selected Fast-Food RestaurantsPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Continuous Improvement Engineer or Lean/Continuous Improvement FDocument3 pagesContinuous Improvement Engineer or Lean/Continuous Improvement Fapi-79152874No ratings yet

- Research TopicDocument2 pagesResearch TopicShubhangi KesharwaniNo ratings yet

- Chapter 1 To 3 MaderazoDocument16 pagesChapter 1 To 3 MaderazoSHERRIE MAE BIJASANo ratings yet

- TOC MDR (Sample)Document17 pagesTOC MDR (Sample)Polosan. JoNo ratings yet

- Gibi Shoes: Case StudyDocument7 pagesGibi Shoes: Case StudyNajera, Hazel JoyNo ratings yet

- Principles of Marketing Promotions DecisionsDocument15 pagesPrinciples of Marketing Promotions DecisionsMehak guptaNo ratings yet

- Hedonic and Functional Brand ImageDocument29 pagesHedonic and Functional Brand Imagealaaelkholi99No ratings yet