Professional Documents

Culture Documents

Booster Compressors

Uploaded by

Raihan Beckham0 ratings0% found this document useful (0 votes)

27 views27 pagesOriginal Title

10625451

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views27 pagesBooster Compressors

Uploaded by

Raihan BeckhamCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 27

Booster Compressors

Why Use a Booster Compressor?

• Supplies high pressure

applications from low pressure

air system

• Avoid purchasing and installing

separate high pressure system Pipeline Testing

• Point of use application

• Alternatives can be expensive

and wasteful

PET Bottle Production

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 2

Booster Compressor Location

Main Air System High Pressure System

(80 – 217 psig) (up to 650 psig)

Compressor Separator Tank Filter Booster High High High

with drain with with compressor pressure pressure pressure

drain drain tank dryer filter

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 3

N-Series Boosters

Model FAD in cfm Motor Power

N 60-G, N153-G 10 to 49 3 to 5 hp

N 253-G – N502-G 37 to 195 10 to 25 hp

N 2001-G 724 50 hp

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 4

N-Series Booster Compressor Features

• Heavy gauge baseplate

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 5

N-Series Booster Compressor Features

• Heavy gauge baseplate

• Anti-vibration pads

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 6

N-Series Booster Compressor Features

• Heavy gauge baseplate

• Anti-vibration pads

• TEFC motor

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 7

N-Series Booster Compressor Features

• Heavy gauge baseplate

• Anti-vibration pads

• TEFC motor

• Aluminum cylinder heads

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 8

N-Series Booster Compressor Features

• Heavy gauge baseplate

• Anti-vibration pads

• TEFC motor

• Aluminum cylinder heads

• High pressure discharge

High

hose with check valve pressure

discharge

hose

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 9

N-Series Booster Compressor Features

• Heavy gauge baseplate

• Anti-vibration pads

• TEFC motor

• Aluminum cylinder heads

• High pressure discharge

hose with check valve

• Inlet filter with drain trap

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 10

N-Series Booster Compressor Features

• Heavy gauge baseplate

• Anti-vibration pads

• TEFC motor

• Aluminum cylinder heads

• High pressure discharge

hose with check valve

• Inlet filter with drain trap

• Enhanced standard starter

panel

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 11

N-Series Booster Compressor Features

• Heavy gauge baseplate

• Anti-vibration pads

• TEFC motor

• Aluminum cylinder heads

• High pressure discharge

hose with check valve

• Inlet filter with drain trap

• Enhanced standard starter

panel

• Low rotational speeds

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 12

Booster Compressor Features

(N 60-G and N 153-G Only)

• Finned copper cooling pipes

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 13

Booster Compressor Features

(N 253-G to N 2001-G)

• Finned copper cooling pipes

• Instrument panel

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 14

Booster Compressor Features

(N 253-G to N 2001-G)

• Finned copper cooling pipes

• Instrument panel

• Air-cooled aftercooler

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 15

Booster Compressor Features

(N 253-G to N 2001-G)

• Finned copper cooling pipes

• Instrument panel

• Air-cooled aftercooler

• Forced lubrication system

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 16

Booster Compressor Features

(N 60-G to N 502-G)

• Sliding manual belt tensioner

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 17

Booster Compressor Features

(N 60-G to N 502-G)

• Sliding manual belt tensioner

• 230/460VAC direct on-line

start

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 18

Booster Compressor Features

(N 2001-G)

• Automatic v-belt tensioner

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 19

Booster Compressor Features

(N 2001-G)

• Automatic v-belt tensioner

• 460VAC wye-delta start

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 20

Booster Compressor Features

(N 2001-G)

• Automatic v-belt tensioner

• 460VAC wye-delta start

• Optional water-cooled

aftercooler

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 21

DN-Series Boosters

Model FAD in cfm Motor Power

DN 22C 175 – 456 30 hp

DN 30C 220 – 409 40 hp

DN 37C 175 – 491 50 hp

DN 45C 385 – 549 60 hp

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 22

DN-Series Boosters

• Max. initial pressure 190 psig

• Max. final pressure 650 psig

• Max. ambient temp 113°F at

4.5:1 compression ratio

• Air-cooled = standard

• Water-cooled = option

• Control cabinet UL508A

• Motors UL approval

• Motors NPE with 1x PT100

sensor

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 23

DN-Series Boosters

Complete machine:

• Enclosure

• Sigma Control 2™

• Starter cabinet

• Factory assembled

• Factory tested

Options:

• Auxiliary heating

• Nitrogen version

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 24

DN-Series Booster Advantages

• Less floor space

• Easy to install

• Excellent accessibility

• Better protection

o SC2

o Sensory array

• Optimized cooling

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 25

How to Size?

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 26

© 2015 Kaeser Compressors, Inc., USA / V1.0 / www.kaeser.com 27

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Marine Piping System PDFDocument233 pagesMarine Piping System PDFNaresh100% (4)

- MK4 To MK5 Upgradation InstructionsDocument27 pagesMK4 To MK5 Upgradation InstructionsAdeel Sajjad Awan60% (5)

- Manual Manifold AmicoDocument46 pagesManual Manifold AmicoFelipe Gagliardi de Paula100% (1)

- Pemisahan Kation Golongan Ii: Kimia AnalisisDocument61 pagesPemisahan Kation Golongan Ii: Kimia AnalisisRaihan BeckhamNo ratings yet

- BoilerDocument51 pagesBoilerRaihan BeckhamNo ratings yet

- BoilerDocument51 pagesBoilerRaihan BeckhamNo ratings yet

- BoilerDocument51 pagesBoilerRaihan BeckhamNo ratings yet

- IchaDocument5 pagesIchaRaihan BeckhamNo ratings yet

- Booklet ProjectDocument50 pagesBooklet ProjectRaihan BeckhamNo ratings yet

- Ali MurtazaDocument3 pagesAli MurtazaRaihan BeckhamNo ratings yet

- Application of ValvesDocument4 pagesApplication of ValvesRevathy Kannan100% (1)

- Applied Bionics in Pumps For Hydrotranport & ProcessDocument61 pagesApplied Bionics in Pumps For Hydrotranport & Processcuriarte14No ratings yet

- Optima EST Manual Ver G2.1Document32 pagesOptima EST Manual Ver G2.1Cory NetoNo ratings yet

- Odoreyes® Technologies, Inc.: Overview of Odorization Systems Kyle WelkerDocument5 pagesOdoreyes® Technologies, Inc.: Overview of Odorization Systems Kyle WelkerMohamed SubkiNo ratings yet

- Valves Used in Fire Protection SystemDocument20 pagesValves Used in Fire Protection SystemrashalNo ratings yet

- Jas-Anz: ISO 9001: 2008 CertifiedDocument12 pagesJas-Anz: ISO 9001: 2008 CertifiedshambhoiNo ratings yet

- Válvula de Cheque - Forbes Marshall Modelo FMDCVDocument2 pagesVálvula de Cheque - Forbes Marshall Modelo FMDCVDennis MendozaNo ratings yet

- 9819 0067 09 Instruction Book Compressor GAR 5 HDocument25 pages9819 0067 09 Instruction Book Compressor GAR 5 HCesar Eduardo100% (1)

- Sullair ST712 PDFDocument72 pagesSullair ST712 PDFBalotileNo ratings yet

- 2021 FMSA Liquid Injection Product CatalogueDocument24 pages2021 FMSA Liquid Injection Product CatalogueEmmanuel Kashala100% (1)

- Operating Instructions - Flowfit CYA27Document68 pagesOperating Instructions - Flowfit CYA27brunotrdNo ratings yet

- Installation, Operation and Maintenance Instructions: Model 3600 API 610 10th Edition (ISO 13709)Document92 pagesInstallation, Operation and Maintenance Instructions: Model 3600 API 610 10th Edition (ISO 13709)José Fernando TerronesNo ratings yet

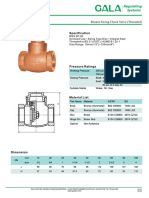

- 4gala - 5451 - Bronze Swing Check ValveDocument1 page4gala - 5451 - Bronze Swing Check ValveAbadimetal UtamaNo ratings yet

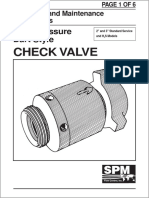

- Dart Valves - Operating & MaintenanceDocument6 pagesDart Valves - Operating & MaintenanceGenard Sabenacio GarciaNo ratings yet

- Valves - PresentationDocument119 pagesValves - Presentationkrahul100% (15)

- Cargo Manual EnvironmentDocument211 pagesCargo Manual EnvironmentAnonymous b68EQR100% (2)

- Chemical Injection PumpsDocument28 pagesChemical Injection PumpsMajid DixonNo ratings yet

- Catálogo Conectores PDFDocument16 pagesCatálogo Conectores PDFJulioNo ratings yet

- OPW AST Catalog - SFLBDocument52 pagesOPW AST Catalog - SFLBGabriel Polanco FossattiNo ratings yet

- Swing Motor PW200 220-7Document7 pagesSwing Motor PW200 220-7Teknik Makina100% (1)

- 29 Hydraulic SystemDocument10 pages29 Hydraulic SystemAlejandro FernandezNo ratings yet

- Section 2 - System ComponentsDocument16 pagesSection 2 - System ComponentsAli OsmanNo ratings yet

- Hydraulic Motors: Concentric ABDocument47 pagesHydraulic Motors: Concentric ABJose RodriguezNo ratings yet

- HPM Catalog PDFDocument8 pagesHPM Catalog PDFTONNo ratings yet

- APT10 and APT14: For Effective Condensate Drainage and RemovalDocument12 pagesAPT10 and APT14: For Effective Condensate Drainage and RemovalwimpievdsNo ratings yet

- HL Series Desiccant Dryer MODELS 90-5000: Operators ManualDocument43 pagesHL Series Desiccant Dryer MODELS 90-5000: Operators ManualLuciusNo ratings yet

- Module 7Document25 pagesModule 7ajmalNo ratings yet