Professional Documents

Culture Documents

Steel Frame Construction-1

Uploaded by

JC0 ratings0% found this document useful (0 votes)

6 views18 pagesCopyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views18 pagesSteel Frame Construction-1

Uploaded by

JCCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 18

STEEL FRAME CONSTRUCTION

Learning Objectives

Become acquainted with drawings prepared for

structural steel buildings

Describe the procedure for fabricating and erecting the

structural steel frame of a building

Be familiar with the fastening techniques used to join

structural steel members

Learning Objectives (cont’d.)

Describe fire-protection procedures for structural steel

members required by building codes

Discuss steel framing systems using manufactured

components

Steel Frame Construction

Utilize skeleton frame construction in which walls,

floors, and roof are supported by a structural

framework of steel beams, columns, girders, and

related structural elements

Steel frames are strong, lightweight, and durable

structures

Conducted according to the Code of Standard Practice

for Structural Steel Buildings and Bridges (AISC 303-

10)

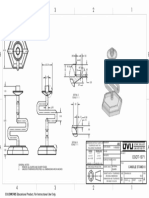

FIGURE 17.1 STEEL-FRAMED BUILDINGS UTILIZE A SKELETON FRAME

OF WALLS, FLOORS, AND ROOF, SUPPORTED BY A STRUCTURAL

FRAMEWORK OF STEEL BEAMS, COLUMNS, AND GIRDERS.

Structural Steel Drawings

Engineering design drawings

Indicate type of construction

Shop drawings

Contain necessary information for fabrication of each

member

Erection plans

Assembly drawings used on-site to direct placement of

each member in its desired location

The Steel Frame

The members making up a steel frame are joined with

metal connections and riveted, bolted, or welded

Connections transmit vertical (shear) forces and bending

moments (rotational forces) from one member to the

other

Frame Stability

The Steel Frame (cont’d.)

Steel Frame Connections

Simple Connections

Moment Connections

Riveted Connections

Bolted Connections

Welded Connections

The Steel Frame (cont’d.)

The Erection Process

Steel erection is considered one of the most dangerous of all

construction activities.

Necessary to ensure safety during steel erection

Finished members are delivered on-site in the order in which

they are needed during erection

The Steel Frame (cont’d.)

Decking

Metal Decking

Composite decking

Concrete Decking

FIGURE 17.35 COMPOSITE DECKING SERVES AS A

FORM FOR A CONCRETE FLOOR OR ROOF SLAB.

The Steel Frame (cont’d.)

Pre-Engineered Metal Building Systems

Complete building system that has been engineered and

fabricated to specifications

Common types of pre-engineered buildings available include:

Welded rigid frame

Truss type

Post-and-beam

Sloped roof

Other Steel Construction System

Pre-fabricated steel truss components used for:

Roof trusses

Open-web joists

Space frames

Coplanar (forces operating in the same plane)

assembly of structural members joined at their ends

Tensile Structures

Framed using high-strength cables of cold drawn steel

suspended between supporting members and secured

with cable stays

Span large distances in almost unlimited number of

shapes and curvatures

Light-Gauge Steel Framing

Formed from flat cold-rolled pieces of carbon steel

Gauge thicknesses from No. 12 - No. 20

Shape form

Single steel sheet

Several forms shape-welded

Nailable and non-nailable types

Fire Protection of the Steel

Frame

Structural steel is an incombustible material that will not

melt even during a building fire

However, when subjected to sustained extreme heat its

properties, including strength, are affected

This can lead to steel column and beam failure during a

prolonged fire

Fire Protection of the Steel

Frame

To protect a building’s occupants and structural integrity,

codes require coating certain steel frames with a fire-

resistant material

Materials used include concrete, tile, brick, stone, gypsum

board, gypsum blocks, fire-resistant plasters, sprayed-on

mineral fibers, intumescent fire-retarding coatings, liquids,

and flame shields

Figure 17.47 Cementitious materials

are sprayed on steel frames to provide

fire protection.

You might also like

- 1300 2-3 ConnectionsDocument31 pages1300 2-3 ConnectionsJCNo ratings yet

- 1300 2-1 CutsDocument18 pages1300 2-1 CutsJCNo ratings yet

- Lesson 2-1 Cuts - Copes, Blocks, & Strips: Paul Mcmullin, Se, PHDDocument18 pagesLesson 2-1 Cuts - Copes, Blocks, & Strips: Paul Mcmullin, Se, PHDJCNo ratings yet

- 1300 2-2 ReactionsDocument13 pages1300 2-2 ReactionsJCNo ratings yet

- 1300 3-4 1300 ERECTION DwgsDocument9 pages1300 3-4 1300 ERECTION DwgsJCNo ratings yet

- S&P S&P: EGDT1100 OwnerDocument2 pagesS&P S&P: EGDT1100 OwnerJCNo ratings yet

- EGDT 1300 1-6 Checking & RFIDocument9 pagesEGDT 1300 1-6 Checking & RFIJCNo ratings yet

- WS10-Chapter 28 Structural Components of Framed ConstructionDocument2 pagesWS10-Chapter 28 Structural Components of Framed ConstructionJCNo ratings yet

- WS5-Chapter 18 Floor Plan LayoutDocument2 pagesWS5-Chapter 18 Floor Plan LayoutJCNo ratings yet

- Egdt 1100Document2 pagesEgdt 1100JCNo ratings yet

- Egdt 1020 Midterm Exam Rev - ADocument2 pagesEgdt 1020 Midterm Exam Rev - AJCNo ratings yet

- EGDT 1300 1-5 Erectability & SafetyDocument25 pagesEGDT 1300 1-5 Erectability & SafetyJCNo ratings yet

- WS13-Chapter 35 Foundation Plan LayoutDocument2 pagesWS13-Chapter 35 Foundation Plan LayoutJC0% (1)

- Drawing Problem InstructionsDocument3 pagesDrawing Problem InstructionsJCNo ratings yet

- 8 - Chapter 11-1Document33 pages8 - Chapter 11-1JCNo ratings yet

- Sample File: I P T 10 H EDocument56 pagesSample File: I P T 10 H EJCNo ratings yet

- WS3-Chapter 10 Room Relationships and SizesDocument2 pagesWS3-Chapter 10 Room Relationships and SizesJCNo ratings yet

- WS1-Chapter 11 Exterior Design FactorsDocument2 pagesWS1-Chapter 11 Exterior Design FactorsJCNo ratings yet

- Supplement 1 (Project Standards)Document2 pagesSupplement 1 (Project Standards)JCNo ratings yet

- WS4-Chapter 16 Floor Plan SymbolsDocument2 pagesWS4-Chapter 16 Floor Plan SymbolsJCNo ratings yet

- Entrance 1 Aerobics 6Document2 pagesEntrance 1 Aerobics 6JCNo ratings yet

- WS2-Chapter 09 Guidelines and Codes That Affect DesignDocument2 pagesWS2-Chapter 09 Guidelines and Codes That Affect DesignJCNo ratings yet

- Assignment 12Document1 pageAssignment 12JCNo ratings yet

- EGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyDocument1 pageEGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyJCNo ratings yet

- EGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyDocument1 pageEGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyJCNo ratings yet

- CLUB-01: Club House Club BuildingDocument1 pageCLUB-01: Club House Club BuildingJCNo ratings yet

- EGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyDocument1 pageEGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyJCNo ratings yet

- Assignment 12Document1 pageAssignment 12JCNo ratings yet

- EGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyDocument1 pageEGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyJCNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fms RailwayDocument34 pagesFms RailwayRohayah Che Amat100% (2)

- Codes For HomeownersDocument521 pagesCodes For HomeownersNitsugaNo ratings yet

- Integrated Design Project 2Document50 pagesIntegrated Design Project 2Donothan SookrajNo ratings yet

- House 2Document1 pageHouse 2luis figueroaNo ratings yet

- Cement ConsuptionDocument12 pagesCement ConsuptionMAULIK RAVALNo ratings yet

- List of Major Bridges in WBDocument13 pagesList of Major Bridges in WBChhandak BiswasNo ratings yet

- From Bauhaus To M - (H) Ouse - The Concept of The Ready-Made and The Kit-Built House by Paul J. ArmstrongDocument9 pagesFrom Bauhaus To M - (H) Ouse - The Concept of The Ready-Made and The Kit-Built House by Paul J. Armstrongshazwan_88No ratings yet

- Palm Hills PDFDocument13 pagesPalm Hills PDFishansri7776873No ratings yet

- (Spec) Steel Truss Bridge (NMHEP)Document37 pages(Spec) Steel Truss Bridge (NMHEP)S RastogiNo ratings yet

- Realsun New Home Furniture Catalogue 2020-08Document49 pagesRealsun New Home Furniture Catalogue 2020-08Metin BalıNo ratings yet

- IPC04 Monthly Quantity and Cost Report - 16 March 2023 - CmlindeDocument92 pagesIPC04 Monthly Quantity and Cost Report - 16 March 2023 - CmlindeMochammad Shofiyul humamNo ratings yet

- Table of Contents MF04Document31 pagesTable of Contents MF04hgogoriyaNo ratings yet

- KAZAKHSTAN's ARCHITECTURE OF THE 21st CENTURY BEGINNING TRENDS OF FORMS EVOLUTION - The Album of Typical Examples by Dr. Konstantin I.Samoilov, 2016Document104 pagesKAZAKHSTAN's ARCHITECTURE OF THE 21st CENTURY BEGINNING TRENDS OF FORMS EVOLUTION - The Album of Typical Examples by Dr. Konstantin I.Samoilov, 2016Konstantin SamoilovNo ratings yet

- Concrete Construction Article PDF - Fire Ratings of Masonry Walls PDFDocument3 pagesConcrete Construction Article PDF - Fire Ratings of Masonry Walls PDFChua Kwee HowNo ratings yet

- Architecture PPT ReportDocument44 pagesArchitecture PPT ReportJohnMichael Palmiano EsplanaNo ratings yet

- Library - Sheet1 PDFDocument99 pagesLibrary - Sheet1 PDFrushab tatedNo ratings yet

- Zero-Force Members: Determine The in The Plane TrussDocument37 pagesZero-Force Members: Determine The in The Plane TrussÖmer faruk SilNo ratings yet

- Chimney Breast Removals: Building Control Advice Sheet BC14Document2 pagesChimney Breast Removals: Building Control Advice Sheet BC14Kiri TNo ratings yet

- Cameron Residences - Official Project Brief - 080719Document47 pagesCameron Residences - Official Project Brief - 080719neil dNo ratings yet

- Directory of ConstructionDocument39 pagesDirectory of ConstructionAbdulkadir Al-OthiamNo ratings yet

- B.Des (Interior Design) (Curriculum & Syllabus 2010) 4 Year Degree ProgramDocument37 pagesB.Des (Interior Design) (Curriculum & Syllabus 2010) 4 Year Degree ProgramchaitanyaomronNo ratings yet

- Snag ListDocument4 pagesSnag ListUjjwal AhujaNo ratings yet

- DBH Guide For Building Work Consent Not Required PDFDocument60 pagesDBH Guide For Building Work Consent Not Required PDFbenra1No ratings yet

- Landmark Case StudyDocument56 pagesLandmark Case StudyNguyễn ViệtNo ratings yet

- Adobeconstruct 19 NeubDocument34 pagesAdobeconstruct 19 NeublailanuitNo ratings yet

- Timber Frame & Wood Frame DesignDocument30 pagesTimber Frame & Wood Frame Designmokhtar yasserNo ratings yet

- DSR 2016 in Ms ExcelDocument749 pagesDSR 2016 in Ms ExcelsaravananNo ratings yet

- Daily WorkDocument184 pagesDaily WorkMahmoudFarhatNo ratings yet

- Solar Space Heating and Cooling 3Document17 pagesSolar Space Heating and Cooling 3puviin varmanNo ratings yet

- Muppa Villa No 230 Rev EstimationDocument2 pagesMuppa Villa No 230 Rev Estimationsrinivas pNo ratings yet