0% found this document useful (0 votes)

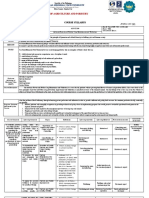

4K views55 pagesFEEDS and FEEDING - FEED FORMULATION

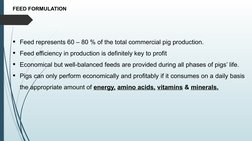

feed represents 60-80% of the total commercial pig production. Animal feeds and feeding Farm animals turn feed into added value products, such as milk, meat and eggs. Balanced feeding promotes the well-being of the livestock, improves the economics of animal production and makes the use of nutrients more efficient so that the environmental effects of production are reduced. hence, economical and well-balanced feeds are provided during all phases of production.

Uploaded by

Jane LabradorCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

4K views55 pagesFEEDS and FEEDING - FEED FORMULATION

feed represents 60-80% of the total commercial pig production. Animal feeds and feeding Farm animals turn feed into added value products, such as milk, meat and eggs. Balanced feeding promotes the well-being of the livestock, improves the economics of animal production and makes the use of nutrients more efficient so that the environmental effects of production are reduced. hence, economical and well-balanced feeds are provided during all phases of production.

Uploaded by

Jane LabradorCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Introduction

- Feed Formulation

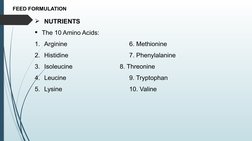

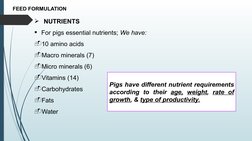

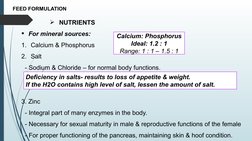

- Nutrients

- Feed Additives

- Supplement & Premixes

- Balancing Ration