Professional Documents

Culture Documents

Spoilage, Rework and Scrap

Spoilage, Rework and Scrap

Uploaded by

Masthura Maimun0 ratings0% found this document useful (0 votes)

3 views27 pagesGreat

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGreat

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views27 pagesSpoilage, Rework and Scrap

Spoilage, Rework and Scrap

Uploaded by

Masthura MaimunGreat

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 27

Spoilage, Rework, and Scrap

© 2009 Pearson Prentice Hall. All rights reserved.

Basic Terminology

Spoilage – units of production, either fully or partially

completed, that do not meet the specifications

required by customers for good units and that are

discarded or sold for reduced prices

© 2009 Pearson Prentice Hall. All rights reserved.

Basic Terminology

Rework – units of production that do not meet the

specifications required by customers but which are

subsequently repaired and sold as good finished

goods

Scrap – residual material that results from

manufacturing a product. Scrap has low total sales

value compared with the total sales value of the

product

© 2009 Pearson Prentice Hall. All rights reserved.

Accounting for Spoilage

Accounting for spoilage aims to determine the

magnitude of spoilage costs and to distinguish

between costs of normal and abnormal spoilage

To manage, control and reduce spoilage costs, they

should be highlighted, not simply folded into

production costs

© 2009 Pearson Prentice Hall. All rights reserved.

Types of Spoilage

Normal Spoilage – is spoilage inherent in a particular

production process that arises under efficient

operating conditions

Management determines the normal spoilage rate

Costs of normal spoilage are typically included as a

component of the costs of good units manufactured

because good units cannot be made without also

making some units that are spoiled

© 2009 Pearson Prentice Hall. All rights reserved.

Types of Spoilage

Abnormal Spoilage – is spoilage that is not inherent

in a particular production process and would not

arise under normal operating conditions

Abnormal spoilage is considered avoidable and controllable

Units of abnormal spoilage are calculated and recorded in

the Loss from Abnormal Spoilage account, which appears as

a separate line item on the income statement

© 2009 Pearson Prentice Hall. All rights reserved.

Process Costing and Spoilage

Units of Normal Spoilage can be counted or not

counted when computing output units (physical or

equivalent) in a process costing system

Counting all spoilage is considered preferable

© 2009 Pearson Prentice Hall. All rights reserved.

Inspection Points and Spoilage

Inspection Point – the stage of the production process

at which products are examined to determine

whether they are acceptable or unacceptable units.

Spoilage is typically assumed to occur at the stage of

completion where inspection takes place

© 2009 Pearson Prentice Hall. All rights reserved.

The Five-Step Procedure for Process Costing

with Spoilage

Step 1: Summarize the flow of Physical Units of

Output – identify both normal and abnormal spoilage

Step 2: Compute Output in Terms of Equivalent

Units. Spoiled units are included in the computation

of output units

© 2009 Pearson Prentice Hall. All rights reserved.

The Five-Step Procedure for Process Costing

with Spoilage

Step 3: Compute Cost per Equivalent Unit

Step 4: Summarize Total Costs to Account For

Step 5: Assign Total Costs to:

1. Units Completed

2. Spoiled Units

3. Units in Ending Work in Process

© 2009 Pearson Prentice Hall. All rights reserved.

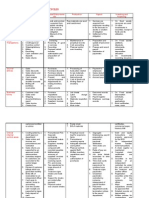

Steps 1 & 2 Illustrated

© 2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5 Illustrated

© 2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2, Illustrated

© 2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5, Illustrated

© 2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2, Illustrated

© 2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5, Illustrated

© 2009 Pearson Prentice Hall. All rights reserved.

Job Costing and Spoilage

Job costing systems generally distinguish between

normal spoilage attributable to a specific job from

normal spoilage common to all jobs

© 2009 Pearson Prentice Hall. All rights reserved.

Job Costing and

Accounting for Spoilage

Normal Spoilage Attributable to a Specific Job: When

normal spoilage occurs because of the specifications

of a particular job, that job bears the cost of the

spoilage minus the disposal value of the spoilage

© 2009 Pearson Prentice Hall. All rights reserved.

Job Costing and

Accounting for Spoilage

Normal Spoilage Common to all Jobs: IN some cases,

spoilage may be considered a normal characteristic of

the production process.

The spoilage is costed as manufacturing overhead

because it is common to all jobs

The Budgeted Manufacturing Overhead Rate includes a

provision for normal spoilage

© 2009 Pearson Prentice Hall. All rights reserved.

Job Costing and

Accounting for Spoilage

Abnormal Spoilage: If the spoilage is abnormal, the

net loss is charged to the Loss From Abnormal

Spoilage account

Abnormal spoilage costs are not included as a part of

the cost of good units produced

© 2009 Pearson Prentice Hall. All rights reserved.

Job Costing and Rework

Three types of rework:

1. Normal rework attributable to a specific job – the

rework costs are charged to that job

2. Normal rework common to all jobs – the costs are

charged to manufacturing overhead and spread,

through overhead allocation, over all jobs

3. Abnormal rework – is charged to the Loss from

Abnormal Rework account that appears on the

income statement

© 2009 Pearson Prentice Hall. All rights reserved.

Accounting for Scrap

No distinction is made between normal and abnormal

scrap because no cost is assigned to scrap

The only distinction made is between scrap

attributable to a specific job and scrap common to all

jobs

© 2009 Pearson Prentice Hall. All rights reserved.

Aspects of Accounting for Scrap

1. Planning & Control, including physical tracking

2. Inventory costing, including when and how it

affects operating income

NOTE: Many firms maintain a distinct

account for scrap costs

© 2009 Pearson Prentice Hall. All rights reserved.

Accounting for Scrap

Scrap Attributable to a Specific Job – job costing

systems sometime trace the scrap revenues to the jobs

that yielded the scrap.

Done only when the tracing can be done in an

economic feasible way

No cost assigned to scrap

© 2009 Pearson Prentice Hall. All rights reserved.

Accounting for Scrap

Scrap Common to all Jobs – all products bear

production costs without any credit for scrap

revenues except in an indirect manner

Expected scrap revenues are considered when setting is

lower than it would be if the overhead budget had not

been reduced by expected scrap revenues

© 2009 Pearson Prentice Hall. All rights reserved.

Accounting for Scrap

Recognizing Scrap at the Time of its Production –

sometimes the value of the scrap is material, and the

time between storing and selling it can be long

The firm assigns an inventory cost to scrap at a

conservative estimate of its net realizable value so that

production costs and related scrap revenues are

recognized in the same accounting period

© 2009 Pearson Prentice Hall. All rights reserved.

© 2009 Pearson Prentice Hall. All rights reserved.

You might also like

- Chapter 19, Modern Advanced Accounting-Review Q & ExrDocument17 pagesChapter 19, Modern Advanced Accounting-Review Q & Exrrlg4814100% (2)

- Chapter 8 AssignmentDocument3 pagesChapter 8 AssignmentThermen DarenNo ratings yet

- Certificates DepositDocument12 pagesCertificates DepositATRNo ratings yet

- Usufruct ReviewerDocument6 pagesUsufruct ReviewerAizaFerrerEbinaNo ratings yet

- Evidencia 5 Summary Export Import Theory V2Document8 pagesEvidencia 5 Summary Export Import Theory V2Sandra Milena100% (3)

- Frank Wood's Business Accounting 1 Twelfth EditionDocument29 pagesFrank Wood's Business Accounting 1 Twelfth EditionEricKHLeaw100% (2)

- Afar 2019Document9 pagesAfar 2019TakuriNo ratings yet

- AFAR-18 (JIT, ABC, FOH - Service Cost Allocation)Document7 pagesAFAR-18 (JIT, ABC, FOH - Service Cost Allocation)Flores Renato Jr. S.No ratings yet

- Ibc ChartsDocument7 pagesIbc Chartspiyush bansalNo ratings yet

- Rice Mill ProjectDocument24 pagesRice Mill Projectbull88% (8)

- Auditing QuestionsDocument10 pagesAuditing Questionssalva8983No ratings yet

- Accounting For Treasury SharesDocument2 pagesAccounting For Treasury SharesCharles Reginald K. Hwang100% (1)

- Kuis Akmen 7D Nur Ikhsan 29Document8 pagesKuis Akmen 7D Nur Ikhsan 29Ikhsan IccankNo ratings yet

- 1st Eval Auditing TheoryDocument9 pages1st Eval Auditing TheoryTong WilsonNo ratings yet

- 203 Principles of Taxation LawDocument182 pages203 Principles of Taxation Lawbhatt.net.in100% (5)

- 02 Audit of Mining Entities PDFDocument12 pages02 Audit of Mining Entities PDFelaine piliNo ratings yet

- Spoilage PPT Ch18Document30 pagesSpoilage PPT Ch18Dayana Noorfitria HalidiputriNo ratings yet

- AT 05 Auditor - S Response To Assessed RiskDocument4 pagesAT 05 Auditor - S Response To Assessed RiskjeromyNo ratings yet

- Week 8Document3 pagesWeek 8Anonymous J0pEMcy5vY100% (1)

- Department of Accountancy: Prepared By: Mohammad Muariff S. Balang, CPA, Second Semester, AY 2012-2013Document22 pagesDepartment of Accountancy: Prepared By: Mohammad Muariff S. Balang, CPA, Second Semester, AY 2012-2013macmac29No ratings yet

- Accounting 3 NotesDocument7 pagesAccounting 3 NotesJudyNo ratings yet

- Cost AccumulationDocument5 pagesCost AccumulationAccounting Files0% (1)

- IT-Audit Team2Document1 pageIT-Audit Team2Von Andrei MedinaNo ratings yet

- Throughput Accounting F5 NotesDocument7 pagesThroughput Accounting F5 NotesSiddiqua KashifNo ratings yet

- Comparison of The Transaction CyclesDocument2 pagesComparison of The Transaction CyclesJN Villacruel AbayariNo ratings yet

- Donors and VatDocument179 pagesDonors and VatGlino ClaudioNo ratings yet

- 19733ipcc CA Vol2 Cp4Document70 pages19733ipcc CA Vol2 Cp4m kumar100% (1)

- MAC Material 2Document33 pagesMAC Material 2Blessy Zedlav LacbainNo ratings yet

- CA5 Accounting For Factory OverheadDocument15 pagesCA5 Accounting For Factory OverheadhellokittysaranghaeNo ratings yet

- Activity 3Document3 pagesActivity 3Alexis Kaye DayagNo ratings yet

- Practice Examination in Auditing TheoryDocument28 pagesPractice Examination in Auditing TheoryGabriel PonceNo ratings yet

- Welcome To The Presentation of The: Group 4Document126 pagesWelcome To The Presentation of The: Group 4Ronald Jason RomeroNo ratings yet

- Managerial Accounting: Job Order CostingDocument75 pagesManagerial Accounting: Job Order Costingsouayeh wejdenNo ratings yet

- Module 12 - Audit ReportingDocument10 pagesModule 12 - Audit ReportingRufina B VerdeNo ratings yet

- HO3 - Cost Concepts and Estimation PDFDocument9 pagesHO3 - Cost Concepts and Estimation PDFPATRICIA PEREZNo ratings yet

- 4) - Are Shares of A Single Foreign Company Issued in The U.S. (ADR or American Depository Receipt)Document8 pages4) - Are Shares of A Single Foreign Company Issued in The U.S. (ADR or American Depository Receipt)mohanraokp2279No ratings yet

- Advanced Accounting Baker Test Bank - Chap003Document37 pagesAdvanced Accounting Baker Test Bank - Chap003donkazoteyNo ratings yet

- Taxation Macmod Capital Gains & LossesDocument2 pagesTaxation Macmod Capital Gains & LossesFaye Cecil Posadas CuramingNo ratings yet

- Programmazione e Controllo Esercizi Capitolo 9Document32 pagesProgrammazione e Controllo Esercizi Capitolo 9Azhar SeptariNo ratings yet

- Chapter 10 Self Test AISDocument5 pagesChapter 10 Self Test AISMichelle100% (1)

- Draft RR Registration EOPT - For Public ConsultationDocument18 pagesDraft RR Registration EOPT - For Public ConsultationGennelyn OdulioNo ratings yet

- Part 2 - Liquidity and Profitability Ratios (Exercises) - Sol 11 Sept 2021Document66 pagesPart 2 - Liquidity and Profitability Ratios (Exercises) - Sol 11 Sept 2021Alyssa PilapilNo ratings yet

- Capital BudgetingDocument4 pagesCapital Budgetingrachmmm0% (3)

- Responsibility AccountingDocument25 pagesResponsibility AccountingAndrew MirandaNo ratings yet

- MAS Handout - Working Capital Management and Financing PDFDocument5 pagesMAS Handout - Working Capital Management and Financing PDFDivine VictoriaNo ratings yet

- Chapter 3-4 QuestionsDocument5 pagesChapter 3-4 QuestionsMya B. Walker0% (1)

- Auditing Chapter 2 ReviewDocument21 pagesAuditing Chapter 2 ReviewYomna AttiaNo ratings yet

- Acc Business Combination NotesDocument118 pagesAcc Business Combination NotesTheresaNo ratings yet

- QUIZ RESULTS For Eilifsen - Auditing & Assurance Services - Chapter 13 - Auditing The Inventory Management Process - Multiple Choice Quiz - Jerichopedragosa@GmailDocument6 pagesQUIZ RESULTS For Eilifsen - Auditing & Assurance Services - Chapter 13 - Auditing The Inventory Management Process - Multiple Choice Quiz - Jerichopedragosa@GmailJericho PedragosaNo ratings yet

- Assignment - Doc - GE02 - Management Accounting - 16022016121047Document13 pagesAssignment - Doc - GE02 - Management Accounting - 16022016121047mahedi hasan100% (1)

- Which Is The Reason Why Entities Are Permitted To Change Accounting PolicyDocument1 pageWhich Is The Reason Why Entities Are Permitted To Change Accounting PolicyCharrey Leigh FormaranNo ratings yet

- ch11 Beams10e TBDocument28 pagesch11 Beams10e TBK. CustodioNo ratings yet

- S06 - Process Costing ProblemsDocument1 pageS06 - Process Costing ProblemsRigel Kent MansuetoNo ratings yet

- Prepared by Coby Harmon University of California, Santa Barbara Westmont CollegeDocument38 pagesPrepared by Coby Harmon University of California, Santa Barbara Westmont Collegee s tNo ratings yet

- Polytechnic University of The Philippines: ST NDDocument10 pagesPolytechnic University of The Philippines: ST NDShania BuenaventuraNo ratings yet

- Chapter 1: The Demand For Audit and Other Assurance ServicesDocument32 pagesChapter 1: The Demand For Audit and Other Assurance Servicessamuel debebeNo ratings yet

- Ex2 Accounting For MaterialsDocument6 pagesEx2 Accounting For MaterialsCHACHACHA100% (1)

- CH 14Document4 pagesCH 14Hoàng HuyNo ratings yet

- (B) Superannuation Standard Choice Form - ShortDocument2 pages(B) Superannuation Standard Choice Form - ShortAnonymous FsIAZZ9llxNo ratings yet

- Hca14 PPT CH07Document39 pagesHca14 PPT CH07Kamlesh ShuklaNo ratings yet

- New and Old Conceptual Framework, Accounting Principles, Accounting Process, PAS 18 - RevenueDocument13 pagesNew and Old Conceptual Framework, Accounting Principles, Accounting Process, PAS 18 - RevenueDennis VelasquezNo ratings yet

- AT L. R. Cabarles/J.M. D. Maglinao Quiz 3 SET A OCTOBER 2019Document2 pagesAT L. R. Cabarles/J.M. D. Maglinao Quiz 3 SET A OCTOBER 2019Paula VillarubiaNo ratings yet

- Advanced FA I - Chapter 02, BranchesDocument137 pagesAdvanced FA I - Chapter 02, BranchesUtban AshabNo ratings yet

- Chapter 1 Test Bank - Booklet PDFDocument10 pagesChapter 1 Test Bank - Booklet PDFjasmineNo ratings yet

- Acctg201 ProcessCostingLectureNotesDocument24 pagesAcctg201 ProcessCostingLectureNotesSophia Marie Eredia FerolinoNo ratings yet

- Spoilage, Rework, and Scrap: © 2012 Pearson Prentice Hall. All Rights ReservedDocument26 pagesSpoilage, Rework, and Scrap: © 2012 Pearson Prentice Hall. All Rights Reservedsaddam khanNo ratings yet

- Spoilage Rework and ScrapDocument21 pagesSpoilage Rework and Scrapabel shimelisNo ratings yet

- Lecture 6 AMA - Spoilage, Rework and ScrapDocument26 pagesLecture 6 AMA - Spoilage, Rework and ScrapNgọcc BảoNo ratings yet

- Module 5Document26 pagesModule 5Eric CauilanNo ratings yet

- DDA Brochure-22!12!2021 CompressedDocument30 pagesDDA Brochure-22!12!2021 CompressedDeepak RanakotiNo ratings yet

- 2660 2021 33 1502 27520 Judgement 15-Apr-2021Document64 pages2660 2021 33 1502 27520 Judgement 15-Apr-2021Richa KesarwaniNo ratings yet

- Santiago Pest Control General Journal For The Month of November 2021 Date 2021 Account Title Debit CreditDocument10 pagesSantiago Pest Control General Journal For The Month of November 2021 Date 2021 Account Title Debit CreditItsRenz YTNo ratings yet

- 1st Sem Economics ProjectDocument11 pages1st Sem Economics ProjectDevendra DhruwNo ratings yet

- Opr 0004 YDocument1 pageOpr 0004 YsrgaurNo ratings yet

- FIZZ 2001 Annual - ReportDocument38 pagesFIZZ 2001 Annual - ReportSteveMastersNo ratings yet

- Book 02Document377 pagesBook 02tazimNo ratings yet

- Internship Report Askari Bank Ltd. 2009Document59 pagesInternship Report Askari Bank Ltd. 2009Imran Mehmood100% (1)

- Navi Mumbai Special Economic Zone (NM Sez) " A Global Sez"Document59 pagesNavi Mumbai Special Economic Zone (NM Sez) " A Global Sez"kc wardhaNo ratings yet

- Basilan Estates Vs CIR Tax Round4Document2 pagesBasilan Estates Vs CIR Tax Round4Angeleeca Sernande CalpitoNo ratings yet

- Transunion Credit Report User Guide: South AfricaDocument8 pagesTransunion Credit Report User Guide: South Africasonal10No ratings yet

- 12 Accounts Imp Ch3Document11 pages12 Accounts Imp Ch3Ashish GangwalNo ratings yet

- SSRN Id3596245 PDFDocument64 pagesSSRN Id3596245 PDFAkil LawyerNo ratings yet

- Bal Sheet (Gail)Document4 pagesBal Sheet (Gail)SuhailNo ratings yet

- 03 - 05 - EBS R12.1 FMS - General Ledger Period Close & ReportingDocument48 pages03 - 05 - EBS R12.1 FMS - General Ledger Period Close & ReportingBhaskarNo ratings yet

- Statement of AccountDocument1 pageStatement of AccountrajivNo ratings yet

- Economic Indicators PBLDocument14 pagesEconomic Indicators PBLMitchelle JosephNo ratings yet

- Lorenz QuestionsDocument4 pagesLorenz QuestionsAhmed ElfeqiNo ratings yet

- Session 11Document15 pagesSession 11Akash HamareNo ratings yet

- Careers in Finance and The Successful Entrepreneur in Business IndustryDocument65 pagesCareers in Finance and The Successful Entrepreneur in Business IndustryJose Federico Frias0% (1)

- KN OW Alex Marchand Dissolving Dollars1Document145 pagesKN OW Alex Marchand Dissolving Dollars1msid22No ratings yet