Professional Documents

Culture Documents

Lubr Dil T M Baq

Uploaded by

Dilnaz Tegispay0 ratings0% found this document useful (0 votes)

7 views5 pagesOriginal Title

lubr dil t m baq

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views5 pagesLubr Dil T M Baq

Uploaded by

Dilnaz TegispayCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 5

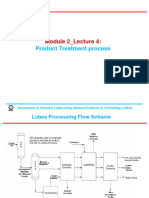

The production process consists of the following steps:

• Distillation: the process of removing the components at a very low and

very high boiling point.

• Removal of aromatics: It leaves the lubricating oil behind with a high

proportion of saturated hydrocarbons, and improves its viscosity index and

stability.

• Dewaxing: It removes candles and controls the low temperature properties

of the lubricant.

FROM RE-REFINING OF USED LUBRICANTS

The waste lubricant, through the contamination undergone during use, it

become unsuitable for lubrication due to the presence of impurities and other

products or due to the loss of its original properties. Re-refining separates

water, oil and asphalt products and through distillation it restores the

lubricating oil as in the refining process.

The produced base lubricant is blended with chemical additives to produce

lubricants for all uses, it is used, and at the end of its lifecycle it is collected

and re-treated by the refinery and thus the lifecycle of the lubricant starts

again…

Application of lubricants

• Lubricants are widely used in industries including automotive, aerospace,

construction, chemical, or textile industries to ensure the smooth

functioning of their machinery and equipment.

• It also used to reduce friction between parts in contact. Depending on the

type, lubricants also perform various other functions such as heat

regulation, power transmission, as well as reducing oxidation and

preventing corrosion.

You might also like

- Soap Manufacturing TechnologyFrom EverandSoap Manufacturing TechnologyLuis SpitzRating: 4 out of 5 stars4/5 (6)

- Week 9Document27 pagesWeek 9Muhammad Suleman AttariNo ratings yet

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Re-Refining of Used Lube OilsDocument23 pagesRe-Refining of Used Lube OilsJaydeep TayadeNo ratings yet

- LUBE Oil AssignmentDocument6 pagesLUBE Oil Assignmentkhansasultan333No ratings yet

- 4.0 TreatmentDocument15 pages4.0 TreatmentAlhaj MassoudNo ratings yet

- Module2 Lect4Document28 pagesModule2 Lect4srirajgirish7No ratings yet

- PSPT - Unit - 5 NotesDocument30 pagesPSPT - Unit - 5 Notessandys8754No ratings yet

- Petroleum LectureDocument14 pagesPetroleum LectureAmer ShaierNo ratings yet

- Lubri Oil Additives PDFDocument47 pagesLubri Oil Additives PDFTejas PatelNo ratings yet

- Petroleum RefiningDocument22 pagesPetroleum RefiningNoor Taha ALkarbalaiNo ratings yet

- STP Present Used Lube Oil Re-Refining 25anniversaryDocument89 pagesSTP Present Used Lube Oil Re-Refining 25anniversaryEng D A MaxNo ratings yet

- The HyLubeDocument4 pagesThe HyLubeZahoor Hussain RanaNo ratings yet

- Solvent DewaxingDocument14 pagesSolvent Dewaxingابوالحروف العربي ابوالحروفNo ratings yet

- Solvent Extraction in RefineryDocument16 pagesSolvent Extraction in RefineryFalcon CollegeRaja JangNo ratings yet

- Refining of Used Lube OilDocument89 pagesRefining of Used Lube OilAadarsh MouryaNo ratings yet

- An-Najah National University Chemical Engineering DepartmentDocument53 pagesAn-Najah National University Chemical Engineering DepartmentAmarjeet YadavNo ratings yet

- Palm Oil RefiningDocument10 pagesPalm Oil Refiningharrison_sNo ratings yet

- LubesDocument2 pagesLubesPeyman SazandehchiNo ratings yet

- Introduction of Used Oil Re-RefiningDocument21 pagesIntroduction of Used Oil Re-RefiningAkhil TiwariNo ratings yet

- Classification of Liquid Lubricants-NotesDocument11 pagesClassification of Liquid Lubricants-Notesleebrown21082003No ratings yet

- Solvent Extraction Process in RefineryDocument5 pagesSolvent Extraction Process in RefineryBariya AnjaliNo ratings yet

- Information Technology Services ControlsDocument12 pagesInformation Technology Services ControlsMohammed AliraqiNo ratings yet

- Lube RefineryDocument20 pagesLube RefineryRajNo ratings yet

- Used Lube RecyclingDocument62 pagesUsed Lube RecyclingBharat SharmaNo ratings yet

- Re-Refining of Used Lube Oil: Presented By-M.tech PLE BatchDocument30 pagesRe-Refining of Used Lube Oil: Presented By-M.tech PLE BatchKhageshwar RongkaliNo ratings yet

- Assignment-2 (UCH850 - 101601010) PDFDocument7 pagesAssignment-2 (UCH850 - 101601010) PDFarpit thukralNo ratings yet

- Lube Oil: Oil Refining and Petrochemical Application Note 8.03.01 Lube Oil Refining Process 1Document3 pagesLube Oil: Oil Refining and Petrochemical Application Note 8.03.01 Lube Oil Refining Process 1Jimmy CuongNo ratings yet

- Thermopac Process Engineering LLPDocument3 pagesThermopac Process Engineering LLPAkshay ThermopacNo ratings yet

- Mr. Daramola AsssignmentDocument2 pagesMr. Daramola AsssignmentVictorNo ratings yet

- Waste Oil RefiningDocument6 pagesWaste Oil RefiningJohn simpson100% (1)

- Review Paper A Study of Purify The Used Oil Exploitation AcidclayDocument3 pagesReview Paper A Study of Purify The Used Oil Exploitation AcidclaymeetNo ratings yet

- Seminar by Gajanan R. Hange ROLL NO:B-22: Guide: Prof S. R. KulkarniDocument17 pagesSeminar by Gajanan R. Hange ROLL NO:B-22: Guide: Prof S. R. Kulkarniنزار خيرNo ratings yet

- Poliflock For Oil GeneralDocument7 pagesPoliflock For Oil GeneralSaad KhalidNo ratings yet

- Edible Oil ProcessingDocument22 pagesEdible Oil ProcessingSivamani Selvaraju100% (1)

- CPT4Document5 pagesCPT4daddarioalexander01No ratings yet

- 08 - Vegetable Oil RefiningDocument39 pages08 - Vegetable Oil Refiningwaleed chNo ratings yet

- Process For Refining of Used Lubricating OilDocument8 pagesProcess For Refining of Used Lubricating OilSubrata Banerjee100% (2)

- Crude Oil ProcessingDocument19 pagesCrude Oil ProcessingYinka OlatunjiNo ratings yet

- Crude DistillationDocument22 pagesCrude DistillationKritagyaNo ratings yet

- Oil Refinery Processes and Basic ApplicationsDocument58 pagesOil Refinery Processes and Basic ApplicationsAwais839100% (1)

- Chapter No. 20Document11 pagesChapter No. 20hananNo ratings yet

- Chemicals: MixingDocument4 pagesChemicals: Mixingمحمدرفیع احمدیانNo ratings yet

- Lube Assist Technical InformationDocument5 pagesLube Assist Technical InformationsergeiivanNo ratings yet

- Oleochem Chap 1Document47 pagesOleochem Chap 1lolahonez100% (4)

- Dewaxing ProcessesDocument19 pagesDewaxing ProcessesMahi FatimaNo ratings yet

- Hydrofinishing Slides For Refining PresentationDocument1 pageHydrofinishing Slides For Refining PresentationYudhisthira100% (1)

- Dewaxing ProcessDocument12 pagesDewaxing Processnavya.cogni21No ratings yet

- PetrocDocument20 pagesPetrocgundogan21No ratings yet

- LUB Oil RefiningDocument2 pagesLUB Oil RefiningGarry SandhuNo ratings yet

- SOR Re-Refining ProcessDocument16 pagesSOR Re-Refining ProcessShyam YadavNo ratings yet

- 25 Hylube ProcessDocument2 pages25 Hylube Processramonchang100% (1)

- Chapter 2.2 Soybean Oil Rev1Document35 pagesChapter 2.2 Soybean Oil Rev1Rathish RagooNo ratings yet

- DeodorisasiDocument28 pagesDeodorisasiDeska RizkiNo ratings yet

- Recycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsDocument6 pagesRecycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsTuribio SunnyNo ratings yet

- Ch8 Refinery ProcessesDocument46 pagesCh8 Refinery Processesفرح100% (1)

- T Cosmetic Creams 2016 USDocument4 pagesT Cosmetic Creams 2016 USidon'tgiveachogiwaNo ratings yet

- Chapter 3 Wax Processing and PurificationDocument40 pagesChapter 3 Wax Processing and Purificationjiva100% (8)

- Bio Energy Presentation of Bio FuelDocument31 pagesBio Energy Presentation of Bio FuelDeep GreyNo ratings yet