0% found this document useful (0 votes)

200 views34 pagesThin Film Deposition Techniques Overview

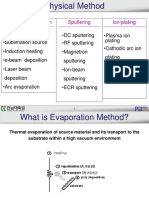

The document discusses various thin film deposition techniques including physical vapor deposition, thermal deposition, e-beam evaporation, sputtering, and pulsed laser deposition. Physical vapor deposition techniques like evaporation and sputtering are used to deposit many thin films in ICs and micromachines. Thermal deposition involves heating a metal source to evaporate or sublime atoms onto a substrate in vacuum. E-beam evaporation uses an electron beam to heat high melting point materials. Sputtering ejects atoms from a target using energetic ions in a plasma. Pulsed laser deposition ablates material from a target using high-power laser pulses.

Uploaded by

Sanjana SCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

200 views34 pagesThin Film Deposition Techniques Overview

The document discusses various thin film deposition techniques including physical vapor deposition, thermal deposition, e-beam evaporation, sputtering, and pulsed laser deposition. Physical vapor deposition techniques like evaporation and sputtering are used to deposit many thin films in ICs and micromachines. Thermal deposition involves heating a metal source to evaporate or sublime atoms onto a substrate in vacuum. E-beam evaporation uses an electron beam to heat high melting point materials. Sputtering ejects atoms from a target using energetic ions in a plasma. Pulsed laser deposition ablates material from a target using high-power laser pulses.

Uploaded by

Sanjana SCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd