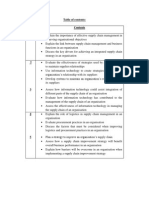

Professional Documents

Culture Documents

Introduction To Strategic Supply Chain M

Uploaded by

Waqas Shakir0 ratings0% found this document useful (0 votes)

5 views21 pagesStrategic supply chain managment notes

Original Title

Introduction_to_Strategic_Supply_Chain_M

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStrategic supply chain managment notes

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views21 pagesIntroduction To Strategic Supply Chain M

Uploaded by

Waqas ShakirStrategic supply chain managment notes

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 21

Introduction to Strategic

Supply Chain Management

By:- Israr K. Raja

Islamabad, Pakistan

Tactical, Operational and Strategic supply

chain

Supply chain management operates at three levels:

Strategic Level

Tactical Level

Operational Level.

Strategic Supply Chain

At the strategic level, company management makes high-level strategic

supply chain decisions that are relevant to whole organizations.

The decisions that are made with regards to the supply chain should

reflect the overall corporate strategy that the organization is following.

The strategic supply chain processes that management has to decide

upon will cover the breadth of the supply chain.

These include

Product development,

Customers,

Manufacturing,

Inventory

Vendors,

Logistics.

Product Development

Product Development

Product Development

Senior Management has to define a strategic direction

when considering the products that the company

should manufacture and offer to their customers.

As product cycles mature or products sales decline,

management has to make strategic decisions to

develop and introduce new versions of existing

products into the marketplace, rationalize the current

product offering, or whether develop a new range of

products and services.

Product Development

These strategic decisions may include

The need to acquire another company or

Sell existing businesses.

However, when making these strategic product

development decisions, the overall objectives of the

firm should be the determining factor.

Customers

At the strategic level, a company has to identify the

customers for its products and services.

When company management makes strategic

decisions on the products to manufacture, they need

to then identify the key customer segments

where company marketing and advertising will be

targeted.

Identify the key customer segments

Manufacturing/Facilities

At the strategic level, manufacturing decisions define

the manufacturing infrastructure and technology that

is required.

Based on high-level forecasting and sales estimates,

the company management has to make strategic

decisions on how products will be manufactured.

Manufacturing/Facilities

The decisions can require new manufacturing

facilities to be built or to increase production at

existing facilities.

The overall company objectives include moving

manufacturing overseas, then the decisions may lean

towards using subcontracting and third party logistics.

As environmental issues influence corporate policy to

a greater extent, this may influence strategic supply

chain decisions with regards to manufacturing.

Inventory

Inventory is key to profitability.

Inventory velocity turns assets into profits.

The faster inventory turns, the greater the profitability.

Inventory is the key issue to supply chain management

success.

Customers demand that their orders be shipped

complete, accurate and on-time.

That means having the right inventory at the right

place at the right time.

Suppliers

Company management has to decide on the strategic

supply chain policies with regards to suppliers.

Reducing the purchasing spend for a company can

directly relate to an increase in profit and strategically

there are a number of decisions that can be made to

obtain that result.

Leveraging the total company’s purchases over many

businesses can allow company management to select

strategic global suppliers who offer the greatest

discounts.

Suppliers

But these decisions have to correspond with the

overall company objectives

If a company has adopted policies on quality, then

strategic decisions on suppliers will have to fall within

the overall company objective.

Logistics

As well as strategic decisions on manufacturing

locations, the logistics function is key to the success of

the supply chain.

Order fulfilment is an important part of the supply

chain and company management needs to make

strategic decisions on the logistics network.

The design and operation of the network have a

significant influence on the performance of the supply

chain.

Logistics

Strategic decisions are required in

warehouses, distribution centers which transportation

modes should be used.

If the overall company objectives identify the use of

more third party subcontracting, the company may

strategically decide to use third-party

logistics companies in the supply chain.

Strategic Supply Chain Management

Strategic decisions determine the overall direction of

company’s supply chain.

They should be made in conjunction with the

companies overall objectives and not biased towards

any particular product or regional location.

These high-level decisions can be refined, as required,

to the specific needs of the company at the lower levels

which allow for tactical and operational supply chain

decisions to be made.

Conclusion

The primary and overriding goal of any supply chain is

to make sure a company is delivering the orders its

customers want when its customers want those orders

- and accomplish this by spending as little money as

possible.

Only by lowering costs and improving performance

can a supply chain be truly optimized.

When a supply chain is managed at the operational,

tactical and strategic levels - it has the best chance of

helping its company reach its goals.

Conclusion

When strategic supply chain is optimized, a company

is delivering what its customers want, when its

customers want it - and spending as little money as

possible getting that done.

You might also like

- Introduction To Strategic Supply Chain Management: By:-Israr K. Raja Islamabad, PakistanDocument21 pagesIntroduction To Strategic Supply Chain Management: By:-Israr K. Raja Islamabad, PakistanMufti AliNo ratings yet

- Supply Chain Management (SCM) Is The Management of A Network ofDocument5 pagesSupply Chain Management (SCM) Is The Management of A Network ofshubham666666No ratings yet

- Supply Chain Strategy Is A Long-Range Plan For The Design and OngoingDocument4 pagesSupply Chain Strategy Is A Long-Range Plan For The Design and OngoingDương Xuân NamNo ratings yet

- Think and Supply Any Product: Unlocking Success Through Strategic Product SourcingFrom EverandThink and Supply Any Product: Unlocking Success Through Strategic Product SourcingNo ratings yet

- Strategic Supply Chain Management and Logistics-120626131827-Phpapp01Document15 pagesStrategic Supply Chain Management and Logistics-120626131827-Phpapp01awais04100% (1)

- Why Implement A Logistics Strategy?: What Is Involved in Developing A Logistic Strategy?Document4 pagesWhy Implement A Logistics Strategy?: What Is Involved in Developing A Logistic Strategy?SoorajKrishnanNo ratings yet

- Operation and Supply Chain StrategiesDocument12 pagesOperation and Supply Chain StrategiesAvisekh KumarNo ratings yet

- Supply-Chain MGMT NotesDocument40 pagesSupply-Chain MGMT Notesakshay26100% (4)

- SCM-Supply Chain Management-Paper PresentationDocument23 pagesSCM-Supply Chain Management-Paper Presentationsb_rameshbabu3283100% (1)

- Sum Chap Chap 1: Huymi Chap 2: Chap 3: Chap 4: Thủy Chap 5: Hằng Chap 6: My Chap 7: Nhi Chap 8: HàDocument30 pagesSum Chap Chap 1: Huymi Chap 2: Chap 3: Chap 4: Thủy Chap 5: Hằng Chap 6: My Chap 7: Nhi Chap 8: HàDương Xuân NamNo ratings yet

- Supply Chain StrategiesDocument10 pagesSupply Chain StrategiesEthan Jeremy ParedesNo ratings yet

- Operations MDocument35 pagesOperations MPriyanshu RajNo ratings yet

- The Supply Chain Strategy and Corporate StrategyDocument31 pagesThe Supply Chain Strategy and Corporate StrategyR-jayVenturilloNo ratings yet

- Unit-12, Supply Chain Management MD Abdur Rouf, St. Id.-OCL1052Document11 pagesUnit-12, Supply Chain Management MD Abdur Rouf, St. Id.-OCL1052S M Abdur RoufNo ratings yet

- Hitachi Key IssuesDocument12 pagesHitachi Key IssuesKirti SrivastavaNo ratings yet

- Cap 1&2Document23 pagesCap 1&2Hellen QFNo ratings yet

- Strategic Sourcing: CIT End Term Project Report OnDocument21 pagesStrategic Sourcing: CIT End Term Project Report Onnavyapurwar100% (1)

- Operations and Supply StrategiesDocument5 pagesOperations and Supply StrategiesTanu Trivedi100% (1)

- Operations and Supply Chain JUNE 2022Document11 pagesOperations and Supply Chain JUNE 2022Rajni KumariNo ratings yet

- Supply Chain Performance: Achieving Strategic Fit andDocument47 pagesSupply Chain Performance: Achieving Strategic Fit andvaibhavs_100950% (2)

- 3 - Supply Chain ManagementDocument15 pages3 - Supply Chain ManagementGurpreet BansalNo ratings yet

- 3 - Supply Chain ManagementDocument13 pages3 - Supply Chain ManagementGurpreet BNo ratings yet

- Aligning Supply Chain Strategy With Business StrategiesDocument5 pagesAligning Supply Chain Strategy With Business StrategiesEddy MusyokaNo ratings yet

- What Is A Supply ChainDocument13 pagesWhat Is A Supply ChaindudyonesNo ratings yet

- 07 Supply-Chaiscn Operating ModelDocument6 pages07 Supply-Chaiscn Operating ModelAbhishek GangwarNo ratings yet

- Supply Chain Management ProjectDocument22 pagesSupply Chain Management ProjectYogita NarangNo ratings yet

- Bullent PointsDocument6 pagesBullent PointsSaraNo ratings yet

- Thi SCMDocument30 pagesThi SCMDương Xuân NamNo ratings yet

- L7 Prodqua-1Document2 pagesL7 Prodqua-1Catherine AborNo ratings yet

- Om0012 - Supply Chain ManagementDocument6 pagesOm0012 - Supply Chain ManagementSolved AssignMents100% (1)

- Supply Chain Strategy Lecture 3Document13 pagesSupply Chain Strategy Lecture 3Waqas ShakirNo ratings yet

- Operations Management 1 - BeaDocument27 pagesOperations Management 1 - BeaBea Renela Gabinete ConcepcionNo ratings yet

- Mb0044 Unit 03 SLMDocument22 pagesMb0044 Unit 03 SLMRahul ReddyNo ratings yet

- UNIT-4 Supply Chain Management (SCM) : Key TakeawaysDocument13 pagesUNIT-4 Supply Chain Management (SCM) : Key TakeawaysThakur RudreshwarNo ratings yet

- Lecture 2 - Supply Chain Performance Achieveing Strategic Fit and ScopeDocument28 pagesLecture 2 - Supply Chain Performance Achieveing Strategic Fit and ScopeNadine AguilaNo ratings yet

- Viclee Video 31 - 3Document6 pagesViclee Video 31 - 3Nguyễn Đăng HiếuNo ratings yet

- Operations StrategyDocument26 pagesOperations Strategysulabhagarwal1985No ratings yet

- Supply Chain Activities / Functions of A CompanyDocument6 pagesSupply Chain Activities / Functions of A CompanyAhmed Afridi Bin FerdousNo ratings yet

- 4 Operations SrtrategyDocument37 pages4 Operations SrtrategyRosni ShahNo ratings yet

- OM and Strategic PlanningDocument20 pagesOM and Strategic PlanningPhooto StoridgeNo ratings yet

- Corperate StrategyDocument3 pagesCorperate StrategySaba AsimNo ratings yet

- Master of Business Administration-MBA Semester 3 ' Supply Chain" Specialization SC0009-Supply Chain Cost Management - 4 Credits Assignment (60 Marks)Document8 pagesMaster of Business Administration-MBA Semester 3 ' Supply Chain" Specialization SC0009-Supply Chain Cost Management - 4 Credits Assignment (60 Marks)mreenal kalitaNo ratings yet

- Supply Chain ManagementDocument33 pagesSupply Chain ManagementRa BiNo ratings yet

- Engineering ManagementDocument19 pagesEngineering Managementveil davidNo ratings yet

- SCLM NewDocument2 pagesSCLM NewSoorajKrishnanNo ratings yet

- Chapter 16 - Strategic Challenges and Change For Supply ChainsDocument26 pagesChapter 16 - Strategic Challenges and Change For Supply ChainsArmanNo ratings yet

- SCM Unit IDocument10 pagesSCM Unit Imba departmentNo ratings yet

- Invstigacion OrlandoDocument8 pagesInvstigacion OrlandoYolanda GarzaNo ratings yet

- Supply Chain Management (SCM)Document47 pagesSupply Chain Management (SCM)sean buenaventura100% (1)

- What Is Strategy and Why Is It Important?Document43 pagesWhat Is Strategy and Why Is It Important?yadav poonamNo ratings yet

- Redited Remedies SCMDocument25 pagesRedited Remedies SCMneha lasiyalNo ratings yet

- Opman SoftDocument72 pagesOpman SoftEllen MaskariñoNo ratings yet

- Supply Chain ManagementDocument5 pagesSupply Chain ManagementŠ Òű VïķNo ratings yet

- International Logistics and Supply Chain Management-SolvedDocument14 pagesInternational Logistics and Supply Chain Management-SolvedAssignment HuntNo ratings yet

- MGMT 314 Tutorial 2Document16 pagesMGMT 314 Tutorial 2Lini VargheseNo ratings yet

- POM Notes PreparationDocument24 pagesPOM Notes PreparationP. Akthar SulthanaNo ratings yet

- Module 2.1Document7 pagesModule 2.1ParalogityNo ratings yet

- Supply Chain Strategy Lecture 3Document13 pagesSupply Chain Strategy Lecture 3Waqas ShakirNo ratings yet

- Supply Chain Course OutlineDocument4 pagesSupply Chain Course OutlineWaqas ShakirNo ratings yet

- Naila Shakir Eco 401Document4 pagesNaila Shakir Eco 401Waqas ShakirNo ratings yet

- Supply Chain Strategy Lecture 4Document36 pagesSupply Chain Strategy Lecture 4Waqas ShakirNo ratings yet

- Student ID Number: Submission Coversheet (All Programmes)Document39 pagesStudent ID Number: Submission Coversheet (All Programmes)WilliamArugaNo ratings yet

- Gasoline Usage SurveyDocument16 pagesGasoline Usage SurveyWaqas ShakirNo ratings yet

- Gasoline Usage SurveyDocument16 pagesGasoline Usage SurveyWaqas ShakirNo ratings yet

- Smoking and Pregnancy, BT20145.EditedDocument9 pagesSmoking and Pregnancy, BT20145.EditedWaqas ShakirNo ratings yet

- Nursing Assingment 23april 2300Hrs StartedDocument14 pagesNursing Assingment 23april 2300Hrs StartedWaqas ShakirNo ratings yet

- Smoking and Pregnancy, BT20145.EditedDocument9 pagesSmoking and Pregnancy, BT20145.EditedWaqas ShakirNo ratings yet

- Smoking and Pregnancy, BT20145.EditedDocument9 pagesSmoking and Pregnancy, BT20145.EditedWaqas ShakirNo ratings yet

- Smoking and Pregnancy, BT20145.EditedDocument9 pagesSmoking and Pregnancy, BT20145.EditedWaqas ShakirNo ratings yet

- Smoking and Pregnancy, BT20145.EditedDocument9 pagesSmoking and Pregnancy, BT20145.EditedWaqas ShakirNo ratings yet

- Smoking and Pregnancy, BT20145.EditedDocument9 pagesSmoking and Pregnancy, BT20145.EditedWaqas ShakirNo ratings yet

- Combating Money Laundering and The Financing of TeDocument110 pagesCombating Money Laundering and The Financing of TeWaqas ShakirNo ratings yet

- Ajzen, Icek. (1991) The Theory of Planned BehaviorDocument33 pagesAjzen, Icek. (1991) The Theory of Planned BehaviorrafaelfdhNo ratings yet

- Pran RFL ReportDocument17 pagesPran RFL ReportAnita Khan33% (3)

- Vinayak Pandla Nbs (Bank of Baroda)Document19 pagesVinayak Pandla Nbs (Bank of Baroda)Vinayak PandlaNo ratings yet

- H030TR PDF EngDocument5 pagesH030TR PDF EngKa CiNo ratings yet

- Revised Booking - Confirmation - EBKG06645778Document4 pagesRevised Booking - Confirmation - EBKG06645778Ribeiro Eugenio SardenhaNo ratings yet

- Lec 1 2 3 International AccDocument38 pagesLec 1 2 3 International AccMariam AbdelalimNo ratings yet

- Lesson Two:: Prepared and Compiled by Gerry S. PeñaDocument22 pagesLesson Two:: Prepared and Compiled by Gerry S. PeñawonuNo ratings yet

- Preparation of Annual Accounts GuidelineDocument23 pagesPreparation of Annual Accounts Guidelinenancy amooNo ratings yet

- Google Finance Investment TrackerDocument13 pagesGoogle Finance Investment TrackerSwaraj NayseNo ratings yet

- DCF Case StudyDocument17 pagesDCF Case StudyVivekananda RNo ratings yet

- Docu Robeco Sustainability Risk PolicyDocument25 pagesDocu Robeco Sustainability Risk PolicyDiana IrimescuNo ratings yet

- Logistical Challenges of Warehousing and TransportingDocument5 pagesLogistical Challenges of Warehousing and Transportingiamcheryl2098No ratings yet

- Statement of Realization and LiquidationDocument2 pagesStatement of Realization and LiquidationSherilyn BunagNo ratings yet

- Janet Wooster Owns A Retail Store That Sells New andDocument2 pagesJanet Wooster Owns A Retail Store That Sells New andAmit PandeyNo ratings yet

- DN No 710 H K SERVICES - MANDYADocument3 pagesDN No 710 H K SERVICES - MANDYAGangaraju T CNo ratings yet

- Citi Bank Card PaymentsDocument6 pagesCiti Bank Card PaymentsMohd AtNo ratings yet

- Goodyear AnalysisDocument2 pagesGoodyear AnalysisSakshi ShardaNo ratings yet

- Marketing Management: - Physical DistributionDocument20 pagesMarketing Management: - Physical Distributiondivyansh tanejaNo ratings yet

- 02 Insurance Law Case List - Updated (ALS 4D)Document2 pages02 Insurance Law Case List - Updated (ALS 4D)Malcolm CruzNo ratings yet

- Excise Tax SummaryDocument40 pagesExcise Tax SummaryHeva AbsalonNo ratings yet

- FA2 Mock 3 ExamDocument12 pagesFA2 Mock 3 ExamRameen ChNo ratings yet

- Ecogreen Pharmacy Retail Chain SoftwareDocument12 pagesEcogreen Pharmacy Retail Chain SoftwareShivam Pathak50% (2)

- 13 Mbfi - at - 191104 PDFDocument2 pages13 Mbfi - at - 191104 PDFAkshayNo ratings yet

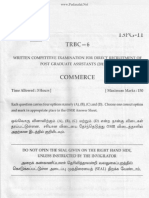

- 2013 PG TRB Commerce q1Document49 pages2013 PG TRB Commerce q1julie jasmineNo ratings yet

- Financial Maths Test 2020Document6 pagesFinancial Maths Test 2020Liem HuynhNo ratings yet

- NAAWAN COMMUNITY RURAL BANK vs. CADocument2 pagesNAAWAN COMMUNITY RURAL BANK vs. CAmark anthony mansuetoNo ratings yet

- Lecture - Chapter 2Document2 pagesLecture - Chapter 2maria ronoraNo ratings yet

- CMA Inter GR I (Cost Accounting) TheoryDocument25 pagesCMA Inter GR I (Cost Accounting) TheoryManav JainNo ratings yet

- Duke Cannon Inv 88607Document2 pagesDuke Cannon Inv 88607api-609272624No ratings yet

- Quant Checklist 382 by Aashish Arora For Bank Exams 2023Document111 pagesQuant Checklist 382 by Aashish Arora For Bank Exams 2023ritikraj569No ratings yet

- Peter Drucker: Father of Post-War Management ThinkingDocument12 pagesPeter Drucker: Father of Post-War Management Thinkingamit chavaria100% (1)