Professional Documents

Culture Documents

7 ElectricArcWelding

7 ElectricArcWelding

Uploaded by

raghav_bhatt8817Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 ElectricArcWelding

7 ElectricArcWelding

Uploaded by

raghav_bhatt8817Copyright:

Available Formats

1

Electric Arc Welding

Section 8

Unit 25 & 26

2

ntroduction

A group of fusion welding processes that use an electric arc to

produce the heat required for melting the metal.

Advantages

nexpensive power source

Relatively inexpensive equipment

Welders use standard domestic current.

Portable equipment is available

Process is fast and reliable

Short learning curve

Equipment can be used for multiple functions

Electric arc is about 9,000

o

F

Electric arc welding

ntroduction-cont.

All fusion welding process have thee requirements.

Heat

Shielding

Filler metal

The method used to meet these three requirements is the

primary difference between arc welding processes.

Arc Welding Requirements

Process Heat Shielding

Filler

Material

SMAW

GMAW

Electric

Arc

Electric

Arc

nert Gas

(Flux)

nert Gas

(Cylinder)

Stick

Electrode

Wire

Electrode

n this class you will have the opportunity to use two (2) arc welding

processes:

SMAW

GMAW

5

Eight Additional Electric Arc Welding Processes

1. FCAW

2. GTAW

. SAW

. ESW

5. EGW

6. PAW

7. ASW

Flux Core Arc Welding

Gas Tungsten Arc Welding

Submerged Arc Welding

Electroslag Welding

Electrogas Welding

Plasma Arc Welding

Arc Stud Welding

6

Safe Practices

Welders need protection from:

Arc's rays

Welding fumes

Sparks

Contact with hot metal

7

Arc Welding Power Supplies

The current for arc welder can be supplied by line current or by

an alternator/generator.

The amount of heat is determined by the current flow (amps)

The ease of starting and harshness of the arc is determined by the

electrical potential (volts).

Welding current adjustments can include:

Amperage

Voltage

Polarity

High frequency current

Wave form

8

Arc Welding Power Supplies--cont.

The type of current and the polarity of the welding current are one

of the differences between arc welding processes.

SMAW Constant current (CC), AC, DC+ or DC-

GMAW Constant voltage (CV) DC+ or DC-

GTAW Constant Current (CC) ), AC, DC+ or DC-

9

Twelve (12) Considerations When Selecting

An Arc Welding Power Supply

1. Maximum Amperage

2. Duty cycle

. Amperage range

. Amperage adjustment

mechanism

5. nput power requirements

6. nitial cost and operating cost

7. Size and portability

8. Future needs for a power

supply

9. Available skills

10. Safety

11. Manufacturer's support

12. Open circuit voltage

10

1: Amperage Output

The maximum output of the power supply

determines the thickness of metal that

can be welded before joint beveling is

required.

185 to 225 amps is a common size.

For an individual weld, the optimum

output amperage is determined by the

thickness of the metal, the type of joint,

welding position and type of electrode.

2: Duty cycle

The amount of continuous welding time

a power supply can be used is

determined by the duty cycle of the

power supply.

Duty cycle may be 100%, but usually is

less.

Duty cycle is based on a minute

interval.

Many power supplies have a sloping

duty cycle.

Note in the picture there is a circle

around the 75 amp setting. Why is it

there?

11

What is the most likely outcome of

exceeding a power supply duty cycle?

12

Five Common Output Currents

For Arc Welding

1. AC (Alternating Current)

2. DC (Direct Current)

. ACHF (Alternating Current-High Frequency)

. PC (Pulsed Current)

5. Square wave

1

Arc Welding Electrical Terms

1. Electrical Circuit

2. Direct current (DC)

. Alternating current (AC)

. Ampere

5. Volt

6. Resistance

7. Ohms Law

8. Constant potential

9. Constant current

10. Voltage drop

11. Open circuit voltage

12. Arc voltage

1. Polarity

To understand how an electric arc welder works, you must understand

the following thirteen (1) electrical terms.

1

Electrical Circuit

An electrical circuit is a complete path

for electricity.

Establishing an arc completes an

electric circuit .

15

Alternating Current

Alternating current: The type

of current where the flow of

electrons reverses direction

(polarity) at regular intervals.

Recommended current for

SMAW general purpose

electrodes and flat position.

16

Direct Current

W Direct current: The type

of current where the flow

of electrons (polarity) is in

one direction.

W Controlling the polarity

allows the welder to

influence the location of

the heat.

W When the electrode is

positive (+) DCRP or

DCEP it will be slightly

hotter than the base

metal.

W When the base metal is positive (+),

DCSP or DCEN, the base metal will be

slightly hotter than the electrode.

W DC current is required for GMAW

W t is frequently used for SMAW

17

Ampere

W Amperes: the unit of measure for current flow.

W One ampere is equal to 6.215098c10

18

electrons passing by a point per second.

W Electricity passing through a resistance causes

heat.

W An air gap is a high resistance

W The greater the amperage flowing through the resistance (air

gap)--the greater the heat.

W The electrode also has resistance.

W Excessive amperage for the diameter of the electrode (current

density) over heats the electrode.

W nsufficient amperage for the diameter of electrode makes the

electrode hard to start.

What are the characteristics of an electrode that was used with

excessive current density?

18

Voltage

Voltage is the measure of electromotive

force (Emf).

Emf is measured in units of volts

The voltage at the electrode for SMAW

determines the ease of starting and the

harshness of the arc.

Higher voltage = easier starting.

Starting voltage is called OCV.

Voltage is adjustable in dual control SMAW machines.

Changing the voltage adjusts a GMAW machine for different

metal thickness.

19

Resistance

Def: that characteristic of a material that impedes the flow of an

electrical current.

Measured in units of Ohm's ( )

When an electrical current passes through a resistance heat

(BTU) is produced.

The amount of heat produced is a function of the amount of

resistance (Ohm's) and the amount of current (amps).

s the resistance adjustable in the SMAW process?

20

Ohm's Law

Ohm's law states that, in an electrical

circuit, the current passing through a

material is directly proportional to the

potential difference.

Commonly expressed as:

=

E

R

E = R

Ohm's law also be used to teach a

principle of electrical safety.

Amperage is the harmful portion of

electrical current.

Rearranging Ohm's Law for

amperage shows that amperage

(current flow) is determined by the

voltage divided by the resistance.

The higher the resistance, the less

current that will flow for a given

voltage.

What does this principle

mean for SMAW?

21

Constant Current

W n the normal operation of a transformer as amperage is

increased, the voltage decreases, and vies versa.

W Electrical arc welding power supplies are modified so that either

the voltage or the amperage is relatively constant as the other

factor changes.

W This allows two different types of power supplies:

Constant current

Constant potential

W n a constant current power supply, the current (amperage)

stays relatively constant when the voltage is changed.

W GMAW

W n a constant potential power supply, the voltage stays

relatively constant when the amperage is changed.

W SMAW

22

Constant Current--cont.

W Characteristics of constant current power supply.

W The machine provides a high voltage for striking the arc.

W Open circuit voltage (OCV)

W OCV is not adjustable for most machines

W When the arc is struck the voltage drops to the welding voltage.

W Arc voltage

W Arc voltage varies with the arc length.

W As the welding proceeds the current will not vary much as the

arc length changes.

2

Constant Current-cont.

ncreasing the voltage from 20

to 25 volts (25%) only

decreases the amperage from

11 to 120 Amp (5.8%).

2

Constant Potential

The constant potential power supply is modified to produce a

relatively constant voltage as the amperage changes.

0

10

20

30

40

50

60

70

80

0 50 100 150 200 250

350708

Characteristic of GMAW power supplies.

25

Voltage Drop

Voltage drop is the reduction in voltage in an electrical circuit

between the source and the load.

Primary cause is resistance.

When an excessive voltage drop exists, the electrical circuit will

not perform as designed.

Localized resistance (connection) can cause excessive heat.

Excessive heat can cause component failure.

When extra long welding leads are used, the amperage must be

increased to have the same heat at the weld.

26

Joints, Welds & Positions

Butt

Lap

T

Corner

Edge

Electric arc welding uses the same

five (5) types of joints and five (5)

types of welds and five (5) positions.

Five (5) joints:

27

Joints, Welds & Positions

Five types of welds

1. Surface

2. Groove

. Fillet

. Plug

5. Slot

28

1. Surface Welds

W Surface welds are welds were a material has been applied to the surface

of another material.

May or may not be blended with the work piece.

W Two common applications are for hard

surfacing and padding.

29

2. Groove Welds

Groove welds are used to fuse

the sides or ends of two pieces

of metal.

The primary use of groove

welds is to complete butt joints.

0

. Fillet Welds

Fillet welds have a triangular cross section and are used to fuse

two faces of metal that are at a 90 degree angle to each other.

Lap Joint

Outside Corner T Joint

1

. Plug Welds

Plug welds are used to

attach two surfaces together

when a complete joint is not

required and the design

does not allow for any weld

bead outside the dimensions

of the metal.

The holes can be made with a drill bit or punch.

The weld is completed by establishing the arc on the bottom plate and

then continuing to weld until the hole is full.

2

5. Slot Welds

Slot welds are identical to plug welds except for the shape of the

holes. For slot welds, slots are machined or stamped in the upper

plate.

They are complete the same as plug welds.

Joints, Welds & Positions

Arc Welding Positions

Horizontal

Flat

Vertical Up

Overhead

Vertical Down

Weld Nomenclature

Penetration

Bead

Base metal

Joint Angle

Reinforcement

Bead

Root Face

Excessive

Penetration

Root Opening

5

Weld Nomenclature-cont.

Root

Throat

Face

Toe

Reinforcement

Leg

Leg

Toe

6

Weld Nomenclature-cont.

n multiple pass welds, each pass has a specific function.

Tack Weld

Root Pass

Filler Pass

Cover Pass

A tack weld is used to hold

the joint at the desired gap.

f it is not used, the heat of

the weld will cause the joint

to close.

The filler pass is used to fill in the joint.

A pattern bead or multiple stringer beads will be used.

The root pass is used to fuse the

root of the weld.

f the root pass does not have

adequate penetration, it must be

cut or gouged out before the

weld is completed.

The cover pass isn't used for strength. t is used for appearance and to

fill in surface voids.

7

Bead Patterns

Pattern beads are used

whenever a wider bead is

needed.

Hardsurfacing

Filler pass

Cover pass

Reduce penetration

Common patterns:

Circle

Crescent

Figure 8

8

Weld Defects

A weld defect is any physical characteristic in the completed

weld that reduces the strength and/or affects the appearance of

the weld.

The mark of a good welder is the ability to identify weld defects

and adjust the welding parameters to eliminate them.

Defects that are not visible must be detect by using destructive

or nondestructive testing.

f the defects in a weld exceed the specifications, the weld must

be removed and redone.

Welds are removed by grinding, gouging and cutting.

Eliminating a weld defect is time consuming and expensive --

you must be able to complete the weld correctly the first time.

9

Common Defects and Causes

The depth of the weld

is less than

specifications.

Excessive heat

Excessive speed.

The weld metal is not

completely fused to

base metal or passes

are not completely

fused.

Description Cause(s)

ncorrect angle

ncorrect

manipulation

nsufficient heat

Weld material flows

over, but is not fused

with the base metal.

Slow speed

0

Common Defects and Causes--cont.

Weld bead does not

extend to the

desired depth.

Description Cause(s)

Low heat

Long arc

ncorrect joint design

Small indentions in

the surface of the

weld

Excessive gas in the

weld zone.

Moisture

Rust

Dirt

Accelerated cooling

Small voids

throughout the weld

material.

1

Usually visible cracks

on the surface or

through the weld

Common Defects and Causes--cont.

Description Cause(s)

Accelerated cooling

Constrained joint

Small weld volume

Cracks in the

transition zone

between the weld and

base metal

nduced hydrogen

ncompatible electrode

or wire

Accelerated cooling

Misshapen

and/or uneven

ripples

nconstant speed

ncorrect manipulation

ncorrect welder settings

2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: Instructionsraghav_bhatt8817No ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: Instructionsraghav_bhatt8817No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityraghav_bhatt8817No ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: Instructionsraghav_bhatt8817No ratings yet

- Engineering OptimizationDocument1 pageEngineering Optimizationraghav_bhatt8817No ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: Instructionsraghav_bhatt8817No ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: Instructionsraghav_bhatt8817No ratings yet

- Source and Receiver - pdf2Document200 pagesSource and Receiver - pdf2Loewelyn BarbaNo ratings yet

- Decision Making or Development of Recommendations For Decision MakersDocument4 pagesDecision Making or Development of Recommendations For Decision Makersraghav_bhatt8817No ratings yet

- Product Design and Development (1720809) : 2. Discuss Concept Selection and Evaluation Technique With ExampleDocument1 pageProduct Design and Development (1720809) : 2. Discuss Concept Selection and Evaluation Technique With Exampleraghav_bhatt8817No ratings yet

- Top Down & Bottom UpDocument1 pageTop Down & Bottom Upraghav_bhatt8817No ratings yet

- Sample JD LogisticsDocument3 pagesSample JD Logisticsraghav_bhatt8817No ratings yet

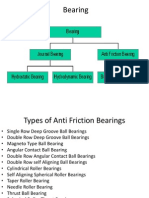

- BearingDocument18 pagesBearingraghav_bhatt8817100% (1)

- J T: Executive in ME D: G: M10 C: Junior Management Cadre R: AssociatesDocument2 pagesJ T: Executive in ME D: G: M10 C: Junior Management Cadre R: Associatesraghav_bhatt8817No ratings yet