0% found this document useful (0 votes)

15 views86 pagesProcurement

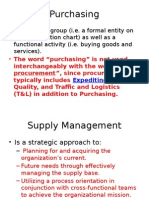

The document provides an overview of inventory and purchasing management, detailing the purchasing function, supply chain management, and the purchasing process. It discusses stock valuation, classification, warehousing types, and inventory control, emphasizing the importance of strategic purchasing in a competitive environment. Additionally, it outlines the skills required for world-class purchasers and presents various warehouse layouts and operations.

Uploaded by

keishamill1977Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

15 views86 pagesProcurement

The document provides an overview of inventory and purchasing management, detailing the purchasing function, supply chain management, and the purchasing process. It discusses stock valuation, classification, warehousing types, and inventory control, emphasizing the importance of strategic purchasing in a competitive environment. Additionally, it outlines the skills required for world-class purchasers and presents various warehouse layouts and operations.

Uploaded by

keishamill1977Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd