Professional Documents

Culture Documents

The Coffee Supply Chain

Uploaded by

Phanindra SaiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Coffee Supply Chain

Uploaded by

Phanindra SaiCopyright:

Available Formats

12/08/2012

The coffee supply chain

The coffee supply chain

Description of the Coffee Supply Chain The coffee supply chain is here briefly described using its different life cycle phases: - agricultural phase (cultivation of green coffee), - roasted coffee production phase, - additional processing phase, - transport and distribution phase, - consumption phase, - waste management phase. The agricultural phase includes the cultivation of green coffee with different treatments such as soil management, fertilization, pest treatment and harvesting. Each of these treatments can be exploited in different ways depending on cultivation practices (conventional or organic), typology of plantation (shaded or sunlight crops; monoculture or polyculture crops), harvesting method (manual or mechanized), etc. After the harvesting, coffee beans can be processed in two different ways following the dry method or the wet one: - the dry method (also called the natural method) is the oldest and simplest one and it is used for about 90% of the Arabica coffee produced in Brazil, most of the coffees produced in Ethiopia, Haiti and Paraguay, as well as for some Arabicas produced in India and Ecuador; also almost all Robustas are processed by this method. It is not practical in very rainy regions, where the humidity of the atmosphere is too high or where it rains frequently during harvesting. The dry method involves the following steps: sorting and cleaning - the harvested cherries are usually sorted and cleaned, to separate the unripe, overripe and damaged cherries and to remove dirt, soil, twigs and leaves; this can be done by hand or by flotation in washing channels; drying - the coffee cherries are spread out in the sun and turned by hand for 3-4 weeks; in larger plantation a machine-drying can be used after the coffee has been pre-dried in the sun for a few days; hulling an hulling machine removes all the outer layers of the dried cherry (skin and pulp). The solid wastes generated (skin and pulp) are used as fuel for thermal applications; storage - after hulling dried green beans are stored and remain in this form until shortly before export. - the wet method (also called the washed method) requires the use of specific equipment and substantial quantities of water and the coffee produced by this method is usually regarded as being of better quality and commands higher prices. It is generally used for Arabica coffees (with the exception of those produced in Brazil and the Arabica-producing countries mentioned above as users of the dry method) and it is rarely used for Robustas. The wet method involves the following steps: sorting and cleaning - it can be done by washing the cherries in tanks filled with flowing water; pulping this is done by a machine which squeezes the cherries between two serrated metal plates so that the skin and the pulp of the fruit are detached from the seed. The mucilage-coated seeds and fruit skins (with pulp) are separated into different streams. The skin and pulp are carried away in a stream of flowing water and the pulp (solid waste used as animal feed or fertilizer after a composting process) is separated from the waste water (pulp water) that can join the wastewater stream or recovered in the pulping process. The beans, enclosed in their mucilaginous parchment covering, are sent to the next stage; washing (mucilage removing) - because the pulping is done by mechanical means it normally leaves some residual flesh as well as the sticky mucilage adhering to the parchment surrounding the beans which has to be completely removed to avoid contamination of the coffee beans by products resulting from the degradation of the mucilage. There are five different methods of removing this mucilage (natural fermentation, chemical methods, warm water soaking, enzymatic fermentation, attrition), but the most popular one combine fermentation and attrition. The beans are placed in large fermentation tanks in which the mucilage is broken down by natural enzymes until it is dispersible, when it can be washed away. For most coffees mucilage removal takes between 24 and 36 hours, depending on the temperature, thickness of the mucilage layer and concentration of the enzymes. When the fermentation is complete, the coffee is thoroughly washed with clean water in tanks or in special washing machines; drying - to reduce the moisture of the washed coffee it is dried either in the sun, in a mechanical dryer, or by a combination of the two. The use of hot-air drying machines becomes necessary to speed up the process in large plantations where, at the peak of the harvesting period, there might be much more coffee than can be effectively dried on the terraces. However, the process must be carefully controlled to achieve satisfactory and economical drying without any damage to quality; storage - after drying, the wet-processed coffee, or parchment coffee as it is commonly known, is stored and remains in this form until shortly before export.

ww2.unime.it/emaf/index.php?view=article&id=57%3Afiliera-caffe&tmpl=component&print=1&layou 1/4

12/08/2012

The coffee supply chain

The production phase includes the coffee processing and packing stage. Coffee processing includes the following steps: storing, cleaning and weighting; roasting; cooling; blending; grinding. The only waste of this phase is the parchment layer that still cover the bean removed with the use of a mechanical process. Sometimes coffee powder may be subjected to different processes to develop product varieties (additional processing phase) such as instant coffee manufacture or decaffeinated coffee. These processes may be done in the same firms or in other manufacturing companies. The packaging step includes many different types of primary and secondary packaging for roast coffee (aluminium cans, paper filters, etc) depending on the choices of the company. The transport and distribution phase includes all the transport activities, related to raw materials, by-products, wastes depending on production capacity and localization of firms, and distribution of the product in the sell market at a local, regional, national or international level, depending on the strategy and production capacity of the firm. Especially transport from coffee growers to roasting companies (generally of other countries) is very relevant in this phase. Transport activities can occur also elsewhere in the life cycle (other than where already mentioned), either between any two subsequent life-cycle stages or within a given stage, depending on the site-specific means of processing and the level of supply-chain integration. The consumption phase, in the case of roasted coffee, cannot be considered as an insignificant stage in a life cycle perspective, because the product consumption need further preparations or treatments that involve energy consumption. Nevertheless, the consumption step is very difficult to measure and/or estimate because it depends on so many different factors: consumer nationality and tastes (the amounts of coffee and water used to make French coffee and Italian espresso differ greatly) or the type and brand of coffee machine used (in particular for energy consumption) amongst others and these differences are highly significant (30%). The waste management phase (end of life) includes the procedures for treatment of packaging wastes (cardboard boxes, coffee chaff, coffee grounds, etc.). This phase can also have great impacts on the environment depending on the chosen method of waste management (for example, reuse, recycling, landfilling, etc).

ww2.unime.it/emaf/index.php?view=article&id=57%3Afiliera-caffe&tmpl=component&print=1&layou

2/4

12/08/2012

The coffee supply chain

References - The International Coffee Organization (ICO) www.ico.org.

ww2.unime.it/emaf/index.php?view=article&id=57%3Afiliera-caffe&tmpl=component&print=1&layou 3/4

12/08/2012

The coffee supply chain

- Salomone R., 2003, Life Cycle Assessment applied to coffee production: investigating environmental impacts to aid decision making for improvements at company level, in Food, Agriculture & Environment, Vol. 1(2), 295-300. Chanakya H.N., De Alwis A.A.P.. 2004, Environmental issues and management in primary coffee processing, in Process Safety and Environmental Protection, 82(B4), 291-300.

back

ww2.unime.it/emaf/index.php?view=article&id=57%3Afiliera-caffe&tmpl=component&print=1&layou

4/4

You might also like

- Coffee ProductionDocument6 pagesCoffee ProductionXara XinnirahNo ratings yet

- Proceso AguaDocument139 pagesProceso AguaKevin VillacisNo ratings yet

- Ecological Processing of Coffee at The Farm Level (Cenifcafe) - Mechanical Demucilation SectionsDocument12 pagesEcological Processing of Coffee at The Farm Level (Cenifcafe) - Mechanical Demucilation SectionsJenny PabonNo ratings yet

- Coffe ProductionsDocument5 pagesCoffe ProductionscoteNo ratings yet

- Training Manual ECXDocument47 pagesTraining Manual ECXAbenzer MulugetaNo ratings yet

- TechnoServe Wet Mill Processing GuideDocument70 pagesTechnoServe Wet Mill Processing GuideMahider AnberbirNo ratings yet

- By Your Best UnderstandingDocument12 pagesBy Your Best Understandingthanh3445thanhNo ratings yet

- Coffee ProductionDocument9 pagesCoffee Productionbaurm1qmtNo ratings yet

- Planting. Coffee Is A Crop That Mostly Grows On Tropical and Subtropical Climates. Usually, TheseDocument8 pagesPlanting. Coffee Is A Crop That Mostly Grows On Tropical and Subtropical Climates. Usually, Theseimo konsensyaNo ratings yet

- Us 20150017270Document10 pagesUs 20150017270Edwin Revelo CeballosNo ratings yet

- Challenges 07 00019Document22 pagesChallenges 07 00019Luis Antonio Castañeda BaltazarNo ratings yet

- Activity 1-4 (Midterms)Document75 pagesActivity 1-4 (Midterms)Arnel SisonNo ratings yet

- Chemical Process TechnologyDocument19 pagesChemical Process TechnologysepticmoneyNo ratings yet

- Cash Crop Technology-1Document195 pagesCash Crop Technology-1Food science and technologyNo ratings yet

- Erl INTRODUCTIONDocument21 pagesErl INTRODUCTIONKerwin Codiaman MartinezNo ratings yet

- Intro Coffee DryingDocument20 pagesIntro Coffee Dryingandi aflahNo ratings yet

- Jurnal Anggia (Eng)Document12 pagesJurnal Anggia (Eng)RifkyNo ratings yet

- Thesis Edit and CriticDocument76 pagesThesis Edit and CriticReden LopezNo ratings yet

- Instant Coffee - Glucose and XyloseDocument20 pagesInstant Coffee - Glucose and Xyloseiguacu.qadNo ratings yet

- Starch Protein Potatoes B RR 10-11-0003Document12 pagesStarch Protein Potatoes B RR 10-11-0003Nilesh B ChaudhariNo ratings yet

- Composicao Da CascaDocument11 pagesComposicao Da CascaJuliana RezendeNo ratings yet

- Coffee Production: Coffee Production Is The Industrial Process of Converting The Raw FruitDocument8 pagesCoffee Production: Coffee Production Is The Industrial Process of Converting The Raw FruitJeffrey BasabeNo ratings yet

- Coffee Production ProcessDocument20 pagesCoffee Production ProcessCamille Dela CruzNo ratings yet

- Ijanu2019 Article CoffeeProcessingWastewaterTreaDocument11 pagesIjanu2019 Article CoffeeProcessingWastewaterTreaYohannes HaileNo ratings yet

- Production, Composition, and Application of Coffee and Its Industrial ResiduesDocument12 pagesProduction, Composition, and Application of Coffee and Its Industrial ResiduesEdwin WirghoNo ratings yet

- Introduction To CassavaDocument43 pagesIntroduction To Cassavajames agboNo ratings yet

- Production, Composition, and Application of Coffee and Its Industrial ResiduesDocument13 pagesProduction, Composition, and Application of Coffee and Its Industrial ResiduesErica González de Torres100% (1)

- Processes and Factors Influences The Quality of Industrial Chocolate Manufacturin1Document8 pagesProcesses and Factors Influences The Quality of Industrial Chocolate Manufacturin1Arslan KhanNo ratings yet

- Coffee 33Document52 pagesCoffee 33Merera TesfayeNo ratings yet

- Coffee Fermentation and MicrobiotaDocument13 pagesCoffee Fermentation and MicrobiotaLael IsazaNo ratings yet

- A Kinetic Study of The Enzymatic Hydrolysis of Cassava StarchDocument6 pagesA Kinetic Study of The Enzymatic Hydrolysis of Cassava StarchInternational Journal of Science and Engineering Investigations100% (2)

- 10 11648 J Ijfet 20220601 12Document10 pages10 11648 J Ijfet 20220601 12Andrés Felipe Bahamón MonjeNo ratings yet

- Tea and CoffeeDocument30 pagesTea and CoffeeSarah DayNo ratings yet

- Aceite Esencial de NaranjaDocument41 pagesAceite Esencial de NaranjaJuan David JuanchoNo ratings yet

- Stages of BioprocessingDocument8 pagesStages of BioprocessingMd Shahjalal Sagor0% (1)

- Coffee Industry OverviewDocument8 pagesCoffee Industry OverviewYan Lin KyawNo ratings yet

- Cassava RefineryDocument16 pagesCassava RefineryÁngeles HerreraNo ratings yet

- Mechanization of Cacao ProcessingDocument33 pagesMechanization of Cacao Processingjha escoria100% (2)

- Dry Coffee Processing ProposalDocument13 pagesDry Coffee Processing ProposalMekonnen Kassahun100% (4)

- Palm Oil ProcessingDocument26 pagesPalm Oil Processingsamruddhi84No ratings yet

- Fruits Washing & SanitationDocument43 pagesFruits Washing & SanitationMuhammad RamzanNo ratings yet

- Technological Steps For Processing of Fruit Juices Without PulpDocument15 pagesTechnological Steps For Processing of Fruit Juices Without PulpbhaleshNo ratings yet

- Small-Scale Coffee Processing: Agricultural and Botanical AspectsDocument8 pagesSmall-Scale Coffee Processing: Agricultural and Botanical Aspectsanakarylle100% (1)

- Fermentation 03 00024Document8 pagesFermentation 03 00024Bashar MelhemNo ratings yet

- Bahasa Inggris Ii "Process of Production in A Company": Oleh: Ni Putu Diah Pitriani (18103044)Document5 pagesBahasa Inggris Ii "Process of Production in A Company": Oleh: Ni Putu Diah Pitriani (18103044)kadek suwarNo ratings yet

- Sugar Process 2003Document7 pagesSugar Process 2003pacoto livingstoneNo ratings yet

- Background of The StudyDocument73 pagesBackground of The StudyCable PadcalNo ratings yet

- Africa Codes of Practice For Shea Kernel and Shea ButterDocument13 pagesAfrica Codes of Practice For Shea Kernel and Shea Butterdissentor100% (1)

- Topic 4Document8 pagesTopic 4Nur BatrisyiaNo ratings yet

- Process of Production of Coffee Expo 2018Document12 pagesProcess of Production of Coffee Expo 2018Rafael RuizNo ratings yet

- 10 Steps To Produce CoffeeDocument6 pages10 Steps To Produce CoffeeAllan ArthurNo ratings yet

- ASAGsdfs-03-0676 SDFDocument6 pagesASAGsdfs-03-0676 SDFeranda bandaraNo ratings yet

- Improving The Operation of A Commercial Mango Dryer: Donald G. Mercer PHD PengDocument12 pagesImproving The Operation of A Commercial Mango Dryer: Donald G. Mercer PHD PengDavid RudiantoNo ratings yet

- Performance Task in Entrepreneurship: Submitted byDocument7 pagesPerformance Task in Entrepreneurship: Submitted byPaula Patrisha RoxasNo ratings yet

- Manufacturing Process of Potato FlakesDocument5 pagesManufacturing Process of Potato FlakesandreaNo ratings yet

- Flash Bio Thermo Extraction - What Can It Do For You? - by Paul BaggioDocument3 pagesFlash Bio Thermo Extraction - What Can It Do For You? - by Paul BaggioTheBeverageFoodGroupNo ratings yet

- Secretarialcommunicationok1 090408015508 Phpapp02Document28 pagesSecretarialcommunicationok1 090408015508 Phpapp02lumissima1766No ratings yet

- Banking and Financial Abbreviations - Gr8AmbitionZ PDFDocument7 pagesBanking and Financial Abbreviations - Gr8AmbitionZ PDFPhanindra SaiNo ratings yet

- Fractions Decials Percents Cheat SheetDocument2 pagesFractions Decials Percents Cheat SheetPhanindra SaiNo ratings yet

- Formula Reference Sheet Formulas For Area (A) and Circumference (C) ShapeDocument2 pagesFormula Reference Sheet Formulas For Area (A) and Circumference (C) ShapePhanindra SaiNo ratings yet

- Mahesh Edible Oil Industries LimitedDocument12 pagesMahesh Edible Oil Industries LimitedPhanindra SaiNo ratings yet

- Mahesh Edible Oil Industries LimitedDocument12 pagesMahesh Edible Oil Industries LimitedPhanindra SaiNo ratings yet

- Unit I - Introduction To Financial Institutions and MarketsDocument22 pagesUnit I - Introduction To Financial Institutions and MarketsPhanindra SaiNo ratings yet

- Annualreport 07 08Document87 pagesAnnualreport 07 08Phanindra SaiNo ratings yet

- City Focus - VizagDocument3 pagesCity Focus - VizagPhanindra SaiNo ratings yet

- FeasibilityDocument16 pagesFeasibilityRavi TejaNo ratings yet

- CarbohydratesDocument10 pagesCarbohydratesshajmalikNo ratings yet

- PigmenDocument78 pagesPigmenPranay MeskarNo ratings yet

- Directions: During Reading, Annotate For The Following QuestionsDocument2 pagesDirections: During Reading, Annotate For The Following QuestionsBrody DukeNo ratings yet

- Feedback Mechanism LabDocument5 pagesFeedback Mechanism LabBeverly Carballo - Moguel0% (1)

- Food Culture of Kansai and Kanto5Document12 pagesFood Culture of Kansai and Kanto5Hans Morten Sundnes100% (1)

- Name: - Date: - Grade/Section - ScoreDocument2 pagesName: - Date: - Grade/Section - Scorerovie avenidoNo ratings yet

- Group 2 - Cuisine - Food Cost FormDocument10 pagesGroup 2 - Cuisine - Food Cost Formaira mikaela ruazolNo ratings yet

- (Updated) The Berry Farming Guide - Work in Progress Guides - PokeMMO PDFDocument34 pages(Updated) The Berry Farming Guide - Work in Progress Guides - PokeMMO PDFAndre KastorNo ratings yet

- Garden and Lawn Seeds 1920Document108 pagesGarden and Lawn Seeds 1920jdgplpaNo ratings yet

- Final-Ppt For Proposal DefenseDocument29 pagesFinal-Ppt For Proposal DefensezyfranciscoNo ratings yet

- MC Donald'S Gets Health Conscious: Presented byDocument32 pagesMC Donald'S Gets Health Conscious: Presented byPranjil KumarNo ratings yet

- San (Yi Hyosek) GNDocument13 pagesSan (Yi Hyosek) GNChoi DongYiNo ratings yet

- Royal TulipDocument23 pagesRoyal TulipSanchit PawarNo ratings yet

- Top 10 Business Opportunities Marijuana IndustryDocument8 pagesTop 10 Business Opportunities Marijuana IndustryhkhalsaNo ratings yet

- Sz. FamilyDocument3 pagesSz. FamilyCrisileen Jhoy SantosNo ratings yet

- A Brief History of The Early PhilippinesDocument45 pagesA Brief History of The Early PhilippinesRye SanNo ratings yet

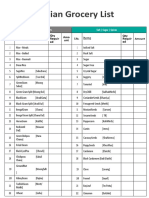

- Indian Grocery List: Items ItemsDocument4 pagesIndian Grocery List: Items ItemsToday's world50% (2)

- Hotel CodeDocument24 pagesHotel CodeJairus Narvasa0% (2)

- Thinking About Complementary and Alternative Med PPL With CancerDocument13 pagesThinking About Complementary and Alternative Med PPL With CancerTaranisaNo ratings yet

- PIDA - Inception ReportDocument270 pagesPIDA - Inception ReportTrevor T ParazivaNo ratings yet

- Biochemical EngineeringDocument35 pagesBiochemical EngineeringMark Wechenje0% (2)

- Contamination ControlDocument5 pagesContamination ControlPadmanabhan DhanasekaranNo ratings yet

- The Ants' Party: Find, Circle and WriteDocument3 pagesThe Ants' Party: Find, Circle and WriteLucas Raul CuezzoNo ratings yet

- ConditioningDocument21 pagesConditioningjason marsh100% (3)

- Food Production NotesDocument66 pagesFood Production NotesSunil BholaNo ratings yet

- Operations Retail Big BazaarDocument21 pagesOperations Retail Big BazaarRushadIrani100% (1)

- History of Toothbrushes and ToothpastesDocument15 pagesHistory of Toothbrushes and ToothpastesShams SNo ratings yet

- Detailed Lesson Plan in English 1Document3 pagesDetailed Lesson Plan in English 1Kathleen BorjaNo ratings yet

- Waste SegregationDocument10 pagesWaste SegregationFaye Y. SantiagoNo ratings yet

- The Effects of Undernutrition On-2Document8 pagesThe Effects of Undernutrition On-2Rachel Ann CINCONIEGUENo ratings yet

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (35)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (65)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldFrom EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldRating: 4 out of 5 stars4/5 (595)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (699)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- When the Sahara Was Green: How Our Greatest Desert Came to BeFrom EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeRating: 4.5 out of 5 stars4.5/5 (6)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraFrom EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraRating: 3 out of 5 stars3/5 (10)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)