Professional Documents

Culture Documents

Differences in Marine and Land Based Power Generation Application

Uploaded by

Chaitra PmOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Differences in Marine and Land Based Power Generation Application

Uploaded by

Chaitra PmCopyright:

Available Formats

Vessels power system differs a lot in comparison with land power systems.

The main differences are: - Line long; - Compact placement (generation equipment nearby utilization equipment); - One control system and one power system (no sub-systems); - Much less amount of energy transformation. It means that much power is concentrated in a small area. That is why it gives engineering challenge, and requires high accuracy and deep analyses in safety and reliability fields. Marine operation features require choosing and keeping necessary speed and as the result all electric machine is equipped by variable frequency converter.

Comparison of Land Based (Wrtsil 34SF) and Marine (Wrtsil 34DF) Land Reference Conditions Engine Total Barometric pressure 100kPa Air temperature 25C Relative humidity 30% Charge air coolant temperature 25C Marine Reference Conditions Engine Total Barometric pressure 100kPa Air temperature 25C Relative humidity 30% Charge air coolant temperature 25C Operation in inclined position Transverse inclination, permanent(list) 15 Transverse inclination, momentary(roll) 22.5 Longitudinal inclination, permanent(trim) 10 Longitudinal inclination, momentary(pitch) 10

Marine engines have sealed fuel and ignition systems. These features prevent fuel vapour build up in the engine compartment from being ignited by stray ignition sparks. The electrical systems in a marine application are also extremely specialized. In any land based engines, gasoline vapours that accumulate will readily dissipate through the bottom of the engine compartment. However, a boat with its sealed engine compartment does not have that luxury. Therefore, any spark could literally cause a boat to explode. All electrical components in a boat are either completely sealed or specially vented to prevent such a catastrophe. This includes the starter, alternator, distributor, and many other engine electrical components Marine engines need to be stronger because they must sustain high stress levels for long periods of time.

Purpose-built marine engines usually have larger cooling passages than their land-based counterparts.

Specifications of Marine motors (IEEE-45)

A. Above Deck - Totally Enclosed, Cast Iron Construction Only this is what is termed a waterproof motor and requires the following: CORRO-DUTY motor construction with a shaft slinger on the opposite pulley end. Frame surface under conduit box base must be flat to ensure full gasket fit and prevent water entry. Nameplates: "Marine Motor" (Must show full load RPM). In general CORRO-DUTY treatment meets the above deck specification. B. Below Deck - All Enclosures Corrosion treatment - consisting of anti-rust compounds on metal to metal fits, plated hardware, and epoxy painted aluminium parts and air deflectors, stainless steel nameplate, resin and hardener or equivalent on rotor. Nameplate: "Marine Motor" (Must show full load RPM). For boiler room duty - furnish B-1 and B-2 (above). Open and enclosed "U" frames - furnish Class B and Nameplate Class B, 50 C ambient. Open and enclosed "T" frame - furnish Class F and Nameplate Class F, 50C ambient. Explosion-proof - Class I, group D, "U" and "T" frames - furnish Class B and Nameplate Class B 50C ambient with a 65C rise, this may require larger than standard frame on "L" motor. Explosion-proof - Class II, group F and G, "U" and "T" frames - Nameplate Class A, 50 ambient with a 45C rise, this may require larger than standard frame size, such as types "E" and "EA". 4. For normal duty - furnish items B-1 and B-2 (above). Open type - Nameplate 40C ambient. Enclosed type - Nameplate 40C ambient. 5. When enclosed units are required, it is suggested that CORRO-DUTY be supplied subject to insulation and ambient under item 3-c or 3-d. Marine Generators: Marine Generator differs from the ordinary industrial generator in that it is designed and constructed to withstand the moisture and corrosion problems associated with the marine environment. Marine generators do not require self contained cooling systems. They are cooled by

using hydraulic pumps constantly circulating sea water through the generator core. Thus the space consumed by the marine generator is less. To save space and make the construction more cost efficient in DE power systems the generator could be directly connected to the flywheel of the engine or could even be supplied by factory as integrated gensets (e.g. Wrtsil Auxpac gensets). In conventional DE schemes, as electric generator usually synchronous machine is used. Synchronous marine generators have some differences compared with classical ones. Typical marine generator has: - Number of poles: from 4 to 10 (rated rotational speed from 1800 rpm (60Hz) to 600 rpm (50 Hz) respectively) - Excitation: brushless by auxiliary outer pole synchronous generator (DC on the stator, AC induced the rotor windings and then rectifying) placed on the same shaft. - Specific mounting standards (usually designed for the chosen diesel engine); - Cooling systems: (open air (standard with protection IP 23), closed circuit with water cooler (with protection IP44)) Marine Transformer: The most common transformer types which find applications are: - Dry (air insulated, the typical dry transformer for marine application). - Resin insulated - Oil insulated When designing a marine application transformer additional losses and consequently temperature should be taken into account because of a wide range of higher harmonics. Monitoring systems in Marine Power Generation systems: Modern primary engines are equipped by a wide range of monitoring systems and gauges for being able to control the rotating speed, avoiding speed droops, and preventing failures connected with overheating, loosing lubrication pressure, over speeding or turbocharger over speeding. Such an arrangement is an electronic speed control system which is built in and is supplied with engine. This system works directly with an actuator which is adjusting fuel injection. Beside the speed regulation speed control unit compensates droops which occur when load is increasing. Example: Wrtsil Auxpac gensets speed control unit is adjusted at the factory and droop is 4 % at the rated load. Speed droop compensating is important to keep rotation speed constant and consequently generated voltage frequency and brings proper sharing of the load between generators connected in parallel.mm

Marine Automation system: In Marine industry there are two main directions of solutions for automated systems Integrated Automated systems Stand alone automated systems.

Marine automation or vessel control system comprises: 1. Control functions for e.g. HVAC control, cargo and ballast control, emergency shutdown and fire and gas detection, off-loading control, engine control, etc. 2. Power management system (PMS) for handling of generators, black-out prevention, power limitation, load sharing and load shedding. For advanced vessels more sophisticated energy management systems may be used for intelligent power planning and allocation. 3. The operators user interface to the automation system is through the Human-Machine Interface (HMI) with display systems and operator panels, often denoted as operator stations. 4. Centralized computers with scalable CPU processing and I/O capacities, often denoted as controllers or process control stations. 5. Distributed computers or PLCs, typically with local control and interfaces to process and to centralized computers. 6. Communication buses at the different levels of control. 7. Associated cabling, segregation and cable routing. http://www.ivt.ntnu.no/imt/courses/tmr4240/literature/marcyb.pdf

In the beginning PID controllers were used and today are still used in the simpler Dynamic Propulsion systems. But modern controllers use a mathematical model of the ship that is based on a hydrodynamic and aerodynamic description concerning some of the ship's characteristics such as mass and drag. Of course, this model is not entirely correct. The ship's position and heading are fed into the system and compared with the prediction made by the model. This difference is used to update the model by using Kalman filtering technique. For this reason, the model also has input from the wind sensors and feedback from the thrusters. This process is called dead reckoning.

Dead reckoning is the process of calculating one's current position by using a previously determined position, or fix, and advancing that position based upon known or estimated speeds over elapsed time, and course. Electrical Power Generation, Transmission and Distribution Industry- Standards http://www.osha.gov/SLTC/powergeneration/index.html

Engine Room: refers to the machinery spaces of the vessel. To increase the safety and damage survivability of a vessel, the machinery necessary for operations may be segregated into various spaces. The engine room is one of these spaces, and is generally the largest physical compartment of the machinery space. On a large percentage of vessels, ships and boats, the engine room is located near the bottom, and at the rear, end of the vessel, and usually comprises few compartments. This design maximizes the cargo carrying capacity of the vessel and situates the prime mover close to the propeller, minimizing equipment cost and problems posed from long shaft lines. The engine room on some ships may be situated mid-ship, especially on vessels built from

1900 to the 1960s. With the increased use of diesel electric propulsion packages, the engine room(s) may be located well forward, low or high on the vessel, depending on the vessel use. Large engines drive electrical generators that provide power for the ship's electrical systems. Large ships typically have three or more synchronized generators to ensure smooth operation. The combined output of a ship's generators is well above the actual power requirement to accommodate maintenance or the loss of one generator. Position of the Engine room:

Inclination test:

An inclining test is a test performed on a ship to determine its stability, lightship weight and the coordinates of its center of gravity. The test is applied to newly-constructed ships greater than 24m in length, and to ships altered in ways that could affect stability. Inclining test procedures are specified by the International Maritime Organization and other international associations. The metacentric height (GM), which dominates stability, can be estimated from the design, but an accurate value must be determined by an inclining test. The metacentric height (GM) is a measurement of the initial static stability of a floating body. It is calculated as the distance between the centre of gravity of a ship and its metacentre. A larger metacentric height implies greater initial stability against overturning. Metacentric height also has implication on the natural period of rolling of a hull, with very large metacentric heights being associated with shorter periods of roll which are uncomfortable for passengers. Hence, a sufficiently high but not excessively high metacentric height is considered ideal for passenger ships. The inclining test is usually done inshore in calm weather, in still water, and free of mooring restraints to achieve accuracy. The GM position is determined by moving weights transversely to produce a known overturning moment in the range of 1-4 degrees if possible. Knowing the restoring properties (buoyancy) of the vessel from its dimensions and floating position and measuring the equilibrium angle of the weighted vessel, the GM can be calculated.

Leaflet for Inclining test and Lightweight survey http://www.gl-group.com/pdf/Leaflet_for_Inclining_Test.pdf

You might also like

- Cpos Operator ManualDocument316 pagesCpos Operator ManualJuliana Borges0% (1)

- ClassNK - Part H - Electrical InstallationDocument117 pagesClassNK - Part H - Electrical InstallationDimas AnggaNo ratings yet

- Noble Denton Global 1200 Dp2 FmeaDocument80 pagesNoble Denton Global 1200 Dp2 FmeaEra Ya50% (2)

- SINGLE LINE DIAGRAM (H-8001) Rev 2Document13 pagesSINGLE LINE DIAGRAM (H-8001) Rev 2wahyuNo ratings yet

- Alfa Laval Three Screw Pump - Alp Pump Range - Emd00457en PDFDocument6 pagesAlfa Laval Three Screw Pump - Alp Pump Range - Emd00457en PDFMuhd Khir Razani100% (1)

- Vryhof Anchor ManualDocument188 pagesVryhof Anchor ManualSebastianNo ratings yet

- XT0425 Parts ManualDocument105 pagesXT0425 Parts ManualG SNo ratings yet

- GloEn-Patrol Troubleshooting (BWMS)Document114 pagesGloEn-Patrol Troubleshooting (BWMS)NikulNo ratings yet

- GCash OrientationDocument27 pagesGCash OrientationArmiel SarmientoNo ratings yet

- Presentation o Ea 2015 Low Loss ConceptDocument26 pagesPresentation o Ea 2015 Low Loss ConceptWAPP100% (1)

- Achieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABBDocument4 pagesAchieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABByw_oulalaNo ratings yet

- Cathelco ICCP Hull Protection SystemsDocument8 pagesCathelco ICCP Hull Protection SystemsdalianbouriNo ratings yet

- Marine Cable Standards - BATTDocument1 pageMarine Cable Standards - BATTMeleti Meleti MeletiouNo ratings yet

- VR3000 VR3000S Operator's Manual G1Document54 pagesVR3000 VR3000S Operator's Manual G1Miguel PerezNo ratings yet

- Position Reference System (PRS) PDFDocument4 pagesPosition Reference System (PRS) PDFArthur Jay AdajarNo ratings yet

- Digital Gyro STD 22Document4 pagesDigital Gyro STD 22Clarence PieterszNo ratings yet

- L5441T06 Operator Manual (K-Pos DP-11)Document634 pagesL5441T06 Operator Manual (K-Pos DP-11)李志揚No ratings yet

- 3646 STD22 Compact NG001Document58 pages3646 STD22 Compact NG001Nazmi ZulkifliNo ratings yet

- ABB System Project Guide Passenger VesselsDocument268 pagesABB System Project Guide Passenger VesselsSabah AlwanNo ratings yet

- 0907 - A - Support Thruster 5 Year OverhaulsDocument21 pages0907 - A - Support Thruster 5 Year OverhaulsonlyourzNo ratings yet

- Impressed Current SystemDocument71 pagesImpressed Current SystemSergei KurpishNo ratings yet

- Marine Engine Genset Product Guide PDFDocument104 pagesMarine Engine Genset Product Guide PDFRezha Maulana Kusuma A100% (1)

- Autopilot ManualDocument73 pagesAutopilot ManualRyk BroNo ratings yet

- Pre CAS Discussion Questions - Interview.Document9 pagesPre CAS Discussion Questions - Interview.Sowmi DaaluNo ratings yet

- Orca Energy SpecDocument2 pagesOrca Energy SpecHanWee LowNo ratings yet

- Xws 01327 Taha Assalam Annual DP Trial 2018 - Rev.1-MergedDocument102 pagesXws 01327 Taha Assalam Annual DP Trial 2018 - Rev.1-MergedLi Ann ChungNo ratings yet

- STD.22 Parameters DetailsDocument1 pageSTD.22 Parameters DetailsJay SanchaniyaNo ratings yet

- 841 VCB HVF&HVG Catalogue 2012.1Document56 pages841 VCB HVF&HVG Catalogue 2012.1Sergio Ignacio Zurita VargasNo ratings yet

- 700/3000 VA User's Guide: Eaton 9130 UPSDocument98 pages700/3000 VA User's Guide: Eaton 9130 UPSRodrigo Molina ContrerasNo ratings yet

- ALSPA MV3000e: Safety InstructionsDocument115 pagesALSPA MV3000e: Safety Instructionsleebjb100% (1)

- Kongsberg Cjoy Ot Joystick System: Operator ManualDocument208 pagesKongsberg Cjoy Ot Joystick System: Operator ManualBeni SaputraNo ratings yet

- MGPS PDFDocument37 pagesMGPS PDFAlexandra LitaNo ratings yet

- KONGSBERG Fleet PerformanceDocument2 pagesKONGSBERG Fleet Performancec108No ratings yet

- Radascan View Installers GuideDocument63 pagesRadascan View Installers GuideLuana Marchiori100% (1)

- Seatex DPS 102 User's ManualDocument94 pagesSeatex DPS 102 User's ManualilgarNo ratings yet

- Dpcs5723 73m Ahts X 2Document18 pagesDpcs5723 73m Ahts X 2123No ratings yet

- Technical Specification DP SystemDocument48 pagesTechnical Specification DP SystemAjay SinghNo ratings yet

- AvaraDocument10 pagesAvaraElchin SattarovNo ratings yet

- Review of All-Electric and Hybrid-Electric Propulsion Technology For Small VesselsDocument34 pagesReview of All-Electric and Hybrid-Electric Propulsion Technology For Small VesselsFoe AungNo ratings yet

- Inland and Coastal Large Tug (LT) NSN 1925-01-509-7013 (EIC XAG)Document1,008 pagesInland and Coastal Large Tug (LT) NSN 1925-01-509-7013 (EIC XAG)Advocate100% (1)

- 3WL ManualDocument59 pages3WL ManualJuan MoralesNo ratings yet

- IP Rating For Exposed Deck Electric EquipmentDocument5 pagesIP Rating For Exposed Deck Electric EquipmentYouwan LeeNo ratings yet

- Iom1338 2Document127 pagesIom1338 2isaavedracastroNo ratings yet

- VDR HyundaiDocument28 pagesVDR HyundaiDIPIN PNo ratings yet

- Fanbeam: Kongsberg Simrad AS - Training Department ARTEMIS Presentation - Page 1Document6 pagesFanbeam: Kongsberg Simrad AS - Training Department ARTEMIS Presentation - Page 1Edilberto Guerrero Gutierrez0% (1)

- PTD Mega Guard DP Operator Guide Rev3.01.3Document102 pagesPTD Mega Guard DP Operator Guide Rev3.01.3Balaji GunasekaranNo ratings yet

- AP50 Installation PlusDocument142 pagesAP50 Installation PlusPeterJBloomNo ratings yet

- Spring Return and Double Acting Pneumatic Quarter-Turn Actuators For Output Torques To 27,624 LB - inDocument8 pagesSpring Return and Double Acting Pneumatic Quarter-Turn Actuators For Output Torques To 27,624 LB - inThanh Vuong NguyenNo ratings yet

- EM120 Multibeam Echo Sounder Maintenance Manual Rev ADocument274 pagesEM120 Multibeam Echo Sounder Maintenance Manual Rev ADenis Begansky100% (1)

- DP Capability Analysis Operator Manual Rel7 - 1 PDFDocument66 pagesDP Capability Analysis Operator Manual Rel7 - 1 PDFStefan AndrioaeNo ratings yet

- ITrans2 - User Manual - EN - Rev 6.0-UnlockedDocument104 pagesITrans2 - User Manual - EN - Rev 6.0-UnlockedandresNo ratings yet

- Power Management Control of Electrical Propulsion SystemDocument26 pagesPower Management Control of Electrical Propulsion Systemdimitaring100% (1)

- 385603B K-Pos DP (OS) Dynamic Positioning System With Offshore Loading Application Operator Manual (Rel. 8.2.0)Document390 pages385603B K-Pos DP (OS) Dynamic Positioning System With Offshore Loading Application Operator Manual (Rel. 8.2.0)Rodrigo RaonyNo ratings yet

- Product Guide o e w32Document200 pagesProduct Guide o e w32Zia Ur RehmanNo ratings yet

- 70m 120T Bollard Pull 10,800HPDocument1 page70m 120T Bollard Pull 10,800HPMohd ZaidNo ratings yet

- Ld2 Verify DP Operations Manual - Ab-V-ma-00514 - Rev 1cDocument72 pagesLd2 Verify DP Operations Manual - Ab-V-ma-00514 - Rev 1cGleison PrateadoNo ratings yet

- Artemis MK V PDFDocument2 pagesArtemis MK V PDFdeepsea74No ratings yet

- CP Propeller Equipment PDFDocument22 pagesCP Propeller Equipment PDFHtet Myat SoeNo ratings yet

- Smith Berger Shark JawsDocument2 pagesSmith Berger Shark JawsmanjuNo ratings yet

- ElectricalDocument36 pagesElectricalAlvinNo ratings yet

- Quality Related QuestionsDocument22 pagesQuality Related QuestionsHotPriyu OnlyforgalsNo ratings yet

- Airframe Essay QuestionsDocument12 pagesAirframe Essay QuestionsRaul DeonarainNo ratings yet

- Aes MatlabDocument32 pagesAes MatlabbalajithrillerNo ratings yet

- SWIMS Directory of LibrariesDocument17 pagesSWIMS Directory of LibrariessudakshinaroyNo ratings yet

- INTEC 2019 User Manual PDFDocument30 pagesINTEC 2019 User Manual PDFshriramsusindarNo ratings yet

- Ht-Discharge Pipes and Fittings (PPS) : KunststoffeDocument35 pagesHt-Discharge Pipes and Fittings (PPS) : Kunststoffeluis eduardo ramos rebataNo ratings yet

- ABB - AppNotes - 2.2 - 1HC0138868 EN AADocument8 pagesABB - AppNotes - 2.2 - 1HC0138868 EN AADeoudrafNo ratings yet

- Chapter 1 Introduction To PSoCDocument32 pagesChapter 1 Introduction To PSoCtptuyen2246No ratings yet

- Vertical Gas Smoker Fumador de Gas Vertical: Owner'S Manual / Manual Del PropietarioDocument46 pagesVertical Gas Smoker Fumador de Gas Vertical: Owner'S Manual / Manual Del PropietarioJason KarpinskiNo ratings yet

- Blue Solar Charge Controller MPPT: NOT AcceptedDocument12 pagesBlue Solar Charge Controller MPPT: NOT Accepted1382aceNo ratings yet

- A Practical Guide To Machine Vision Lighting - Part IIIDocument4 pagesA Practical Guide To Machine Vision Lighting - Part IIIChai Jien WeiNo ratings yet

- Presentation On Optical Signal To Noise RatioDocument6 pagesPresentation On Optical Signal To Noise RatioReg NdhlovuNo ratings yet

- Vogt Valves: Catalog & Application ManualDocument161 pagesVogt Valves: Catalog & Application ManualAngelique DeanNo ratings yet

- NDT NablDocument3 pagesNDT NablPrabir KumarNo ratings yet

- Ece T 2012 ToppersDocument13 pagesEce T 2012 ToppersRajesh LingamalluNo ratings yet

- Scope of Work Diesel Fuel Tank For The Rifle-Garfield County Regional Airport Fuel Farm IFB-GC-AP-01-14 - Diesel Fuel TankDocument4 pagesScope of Work Diesel Fuel Tank For The Rifle-Garfield County Regional Airport Fuel Farm IFB-GC-AP-01-14 - Diesel Fuel TankMSNo ratings yet

- Sky Spark White PaperDocument7 pagesSky Spark White PaperJohn KablerNo ratings yet

- Government College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusDocument111 pagesGovernment College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusSalma Mehajabeen ShajahanNo ratings yet

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresNo ratings yet

- PhillipsDocument22 pagesPhillipsArthur RodriguezNo ratings yet

- Patrol For Unix and Linux Unix Get StartedDocument112 pagesPatrol For Unix and Linux Unix Get StartedRamesh SharmaNo ratings yet

- IPCR Part 2 2017Document4 pagesIPCR Part 2 2017RommelNo ratings yet

- CRCCDocument13 pagesCRCCGalih SantanaNo ratings yet

- Lighting Layout Power Layout: Single Line Diagram LegendDocument1 pageLighting Layout Power Layout: Single Line Diagram LegendAnieken AyoNo ratings yet

- Normas ISO TelecomunicacionesDocument38 pagesNormas ISO Telecomunicacionesjolao AlmeidaNo ratings yet

- Eminence Deltalite II 2515Document1 pageEminence Deltalite II 2515Suto BandNo ratings yet

- Dilg-Mbcrpp Isf Q2 2023Document2 pagesDilg-Mbcrpp Isf Q2 2023Mallari GabrielNo ratings yet

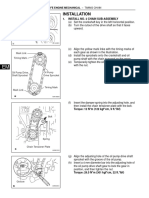

- Sincronizacion de Motor Toyota 2az-FeDocument12 pagesSincronizacion de Motor Toyota 2az-FeWilliams NavasNo ratings yet

- Dodge Journey 2017 - Owner's ManualDocument510 pagesDodge Journey 2017 - Owner's Manualandres camachin100% (1)