Professional Documents

Culture Documents

Energy

Uploaded by

Aman GargCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy

Uploaded by

Aman GargCopyright:

Available Formats

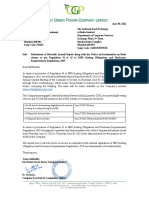

NON CONVENTIONAL ENERGY 1 JAN 3, 2013

Elements Ores Elements Material (alloy)

Ores

Material

Manufacturing Methods

Car

(25C) minerals oxide sulphide Ni,Ti high energy need melting like process to reach this stage with high energy need

Right now only available source is fossil fuel but the main problem is carbon hence it increases the std of living but harms environment too. ENERGY AND STANDARDD OF LIVING Wealth income Quality and availability of employment Class disparity Poverty rate Quality and affordability of housing GDP Inflation rate R=E*N. R= total yearly energy requirement E= per capita energy use per year N= population Standard of living S=f * E f= efficiency of transforming energy in to wealth Hence R = SN/f R/R = S/S + N/N f/f

Neglecting last term With first term 2-5% and second 2-3% R/R is 4-8% which is a very huge number The only way to decrease is increase f/f HOW? Increase use of fossil fuel Increase renewable energy Increase f

NON CONVENTIONAL ENERGY 2 JAN 4, 2013

Si + doping material to produce holes at the atomic level Issues related to conventional source What is ecosystem? It consists of biotic i.e., living organisms and abiotic i.e., non living organisms like pond, lake, ocean, snow, desert, mountains. Humans can also alter ecosystem both positively and negatively. Key factor which is causing the pollution like global warming, acid rain is nothing but CARBON. C, H, N, S, O are main elements in fossil fuel. Natural cycle consists of carbon cycle, nitrogen cycle. CARBON CYCLE. (Refer figure)

CO2 provides life to plants.

L= litter fall major flux of carbon from vegetation to soil

[Type text]

Net change in stored carbon = P-(R+D+H)-O Net effect of ecosystem on atmosphere CO2 = (E+D+O+R)-P Concept to find alternative source of energy is the source which is free from carbon. To reduce E alternate energy comes into picture. Fossil fuel has potential energy to obtain this energy we need combustion. It gives sensible heat.

Fossil Fuel (PE) Combustion with air Sensible heat of POC mCpT & mCO2Cp(T-Tf) POC carryout useful work

POC discharge in surrounding

NON CONVENTIONAL ENERGY 3 JAN 8, 2013

Total Energy Req. Power consumption 2kW/person Renewable energy absorbed by earth 500W/m^2 Harness 4% efficiency and that is 20W/m2 Area of the land is 10m*10m Population density 500 people/Km Hence for 2kW consumption 1000 kW/sq Km 50000 sq m land ~5% land

Solar energy 342 W/m^2 vertical sun at 45 degree sun we get only 242 W/m^2 DIFFERENCE Renewable Source Initial Avg. Intensity Life time Equipment & Capital Cost Environment <= 300 W/m^2 Infinite $1000 per kW Non Renewable Fossil Fuel >=100 kW/m^2 Finite $500 with no norms & $1000 with norms applied Variation & Control Scale Skills Pollution & Environment damage Large Mechanical + Electrical Biomass, Biodiesel, soil error Mechanical only

Scientific Principles of Renewable Energy 1. Energy current (Refer Fig 3.1) 2. End use requirement Periodic variation Wave Hydro Ocean Tidal Biofuel Wind 12 hrs 10 MJ/kg PU0^3 1 year 1 year Hs Re. Height T PHs^2 T PH*Q PT^2 PG*b Cos

3. Quality of supply Renewable Mechanical supplies Tidal power 75%, Hydro 70-90%, Wave 50%, Wind 35% Thermal Biomass, combustion, solar collectors Photon process Photosynthesis, Photovoltaic Cells

Fig. 3.1

NON CONVENTIONAL ENERGY 4 JAN 10, 2013

Technical implications:

Renewable source is dynamic in nature End use requirement & efficiency Matching supply and demand

These all efforts are being done to create LOW CARBON SOCIETY. #Carbon offset #Different models (a) Useful at small level

(b) Negative feedback control. Demand to Supply Very useful in concentrated supply (c) Dynamic characteristics Equipment idle Waste

To stop above energy storage is one of the options. (d) Decoupling local demands by connecting renewable energy resources with grid system.

(e) Feed forward load management control. It is the best strategy to utilise renewable energy. Total load at E~=D

When turbine-generator is used frequency change is a problem. (Other than solar energy) (a) Spill excess energy (b) Storage (c) Load management control These three are applied to all renewable sources.

Hydro energy example

Feed forward load control is very efficient for wind power.

NON CONVENTIONAL ENERGY 6 JAN 15, 2013

Conversion of RER to Electric power: Heat energy to electric power Solar energy Air heating Water heating Fuel cell Electric energy Geothermal Biomass (PE) Combustion Gasification [to convert PE of biomass into gaseous fuel energy] [ to convert C to CO] [if CO2 is made it is loss] Fluid energy KE to mechanical energy [Moving fluid] Hydro Wind Wave Solar air heaters Marine energy [wave + tidal] First generation > Hydro, Biomass, Geothermal Second generation > Solar heating, Wind power, Bioenergy, Photovoltaic Third generation > Biomass gasification, Marine, Advanced geothermal system Fluid consists of liquids and gases. Gases are compressible where as liquids are incompressible. Steady flow Unsteady flow Laminar Turbulent [transfer of energy through fluid packets known as eddies] Differential analysis [microscopic] Integral analysis [macroscopic] [Bernoulli equation: P/g+ z + v2/2g = constant for ideal fluid] and for non ideal fluid add friction Parameter E= 2f*[L/D]2*U2

NON CONVENTIONAL ENERGY 7 JAN 17, 2013

Friction between fluid layers introduces irreversibility and it generates some head loss. Also heat transfer also introduces irreversibility and so head loss.

Friction can happen in: Hydro power Solar heating Ocean thermal energy

Orifice and Venturimeter Que: A venturimeter is installed in an air duct with 0.46 m dia, throat dia = 0.23 m, Q=1.18 m3/s of air at 300 K at pressure of 1.1*10^5 N/m2. Find out maximum pressure drop a manometer can handle.

Now use orifice and we want to measure pressure drop of 50 mm water. Then calculate the diameter of the sharp edge orifice. Que:

Pipe Dia = 100 mm. Install pipe of 50 mm of 0.6 m length as shown in figure. Calculate mass flow rate in terms of P.

HYDROTURBINE Reaction turbine Impulse tubine

Principle of the power generation is P = QgH H = 20m Q = 40 L/s P = 8 kW

The drawback here is we need high H and Q for large power generation. Ha = Total head Ht - frictional loss Hf If I need 100% energy conversion in terms of power then, We need infinite time which is not required as time is important factor. So to maximise power we need to introduce some irreversibility into the system which will cause certain losses to the system. So energy will be dissipated and the surrounding entropy will increase. D = T ds/dt So we define gibbs energy G = H - TS

Reference: Renewable energy conversion, transmission and storage by Bent Sorenson Renewable energy focus handbook

NON CONVENTIONAL ENERGY 8 JAN 18, 2013 Flow rate Q = Volume passing int/t = mean speed u * cross sectional area = u dt

Container fill Float method Weir method [most accurate]

Ha = P/ + v/2g V = Cv 2gHa Discharged head = Cv

[Type text]

[Type text]

Specific speed = jet dia d /wheel pitch dia D v1 = Cv2gH

[Type text]

Que: A small impulse wheel is used to drive a generator of 60Hz.The head is 100 m. Discharge is 40 L/s. Determine a) dia of wheel at the centre line of the bucket and b) speed of the wheel. Cv = 0.98 Assume efficiency 80%.

Que: Test carried out on pelton wheel Head = 27 m at the base of nozzle. Discharge 270 L/s. Dia of jet 123 m. Power developed = 60 kW. Power absorbed in mechanical bearings is 3.5 kW. Determine power loss by the nozzle and due to hydraulic resistance.

NON CONVENTIONAL ENERGY 9 JAN 22, 2013

WIND POWER How it differs from hydro power? Wind to electrical conversion through Electric systems is at certain height Constant wind speed is required KE of wind -> Torque -> Turns turbine

Power Pt = 0.5 Cp A u where Cp is power coefficient u is wind speed = 1.2 kg m-3

Pt/A varies from 10 W/m to 41000 W/m for 2.5 m/s and 40 m/s respectively. Wind energy conversion system consists of Horizontal axis Vertical axis

Rotor - Blades + Supporting Drive train - Shaft + Gear box + Coupling + Mechanical brake and generator Control

[Type text]

Major options available are Number of blades 2 or 3 Rotor orientation Blade material Power control Fixed/Variable rotor speed Gearbox or direct drive generator Synchronous or Induction generator

Wind machine parameters Wind direction relative to blade, lift is preferred on drag

Coefficient of performance Cp = P/(0.5 A U) Speed ratio = R/U Solidity = Blade area /A = Avg chord * Blade length * Number of blades / A

dm/dt = AU P = 0.5AU

P/A = 0.5U

at sea level 15C is 1.225 kg/m

P-bar/A = 0.5 U-bar Ke

[Type text]

where Ke = energy pattern factor = 1/NU-bar * U N = number of hours in a year = 8760

i= 1 to N

Pbar/A < 100 W/m2

= 400 W/m2 > 700 W/m2

Types of wind power Materiological potential depends on available wind source Site potential Technical potential Economic potential Instrumentation potential

= P/RT = 3.4837 P/T P = 101.29 - (0.0011837)z + (4.793*10-7)z2

International standards atmosphere sea level fig2

Statistic techniques P(U) = Probability function Pw(U) = known turbine power curve Capacity factor Cf = Pw-bar/PR = energy actually produced/energy at rated capacity Pw(U) = 0.5 A Cp U where = drive train efficiency = generated power/rated power Rotor power efficiency Cp = Rotor power/Power in wind = P/0.5AU3 = blade tip speed / wind speed = R/U

[Type text]

Uc = characteristic wind velocity = 2Ubar/ (Cp)max = 16/27 X = U/Uc

For D = 18m and Ubar = 6 m/s Pwbar = 38.1 kW

NON CONVENTIONAL ENERGY 10 JAN 23, 2013

HAWM: Horizontal Axis Wind Machine Upwind type Downwind type Shrouded type

VAWM: Vertical Axis Wind Machine Blade top to bottom 30m and 15m wide Failure due to Fatigue failure Rotational torque

[Type text]

Lift force: some parts can move with higher speed than speed of wind Drag force: No component can move with greater speed than speed of wind

What is solidity? High solidity contains large amount of materials. Large torque is generated. e.g., Water pumping

Tip speed ratio = Blade tip speed / Wind speed

[Type text]

[Type text]

Laminar flow Frictionless

A1 = rotor area A0 and A2 enclosure area

F = m*(u0-u2) Pt = F*u1 = m*(u0-u2)u1

Loss of energy Pw = 0.5*m*(u02-u22) Hence,

[Type text]

Equating Pt and Pw we get, u1 = 0.5*(u0+u2)

m = A1u1 Pt = 2A1u12 (u0-u1)

a = interference factor a = (u0-u1)/2u0

Pt = [4a*(1-a) 2]*[0.5A1u03] Pt = 0.5A1u03 Cp Cp = 4a*(1-a)2

NON CONVENTIONAL ENERGY 11 JAN 29, 2013

a = 1/3 for ideal rotor Wind speed at rotor 2/3

uA = uA = 2/3uA A = 2/3 A

uA = uA 2/3uA = 1/3uA 2A = A

Assumption Rotation of wake behind rotor Finite number of blades & associated tip loss Non zero aerodynamic drag

Overall turbine efficiency is function of Rotor power coefficient Mechanical efficiency

[Type text]

What is axial force on the turbine?

NON CONVENTIONAL ENERGY 12 JAN 31, 2013

Fu Design of blade rotor is the only important factor so that it can work beyond the speed of design. Solution: Temporary shut down Decrease the power extraction Design fixed blades Blade pitching or braking

TSR = Vt/u = R/u Small TSR: Air passes Large TSR: works as a solid disc

(TSR: Tip Speed Ratio)

Maximum torque will be at the tip of the blade.

[Type text]

Torque = Fmax * R max = AuR/2

(16) (17)

Torque Coefficient C = /max = R/u max = P/ (18) (19)

Pt = and Pt = Cp P Hence Cp = C Cp = Cpmax C = 0.59/

Que: 1.25 MW rated power at 12 m/s wind speed, rotor diameter 66m, horizontal speed 13.9 to 20.8 rpm

Angular speed range = 2f = 1.46 to 2.18 radians/s v=r = 1.46 to 2.18 * 66/2 = 48.18 to 71.94 m/s = r/v = 4 to 6

[Type text]

Dynamic Matching: can be controlled by angle Power extraction efficiency

If is slow then most of the wind won't be able to detect the rotor blade If is optimum almost all the wind strikes the blade If is very fast vortex shedding will take place

Hence we can say that power extraction efficiency decreases in two ways: Blades are so close together or rotating rapidly Blades have large spacing (low solidity) or rotating slowly

NON CONVENTIONAL ENERGY 13 FEB 1, 2013

Dynamical Matching depends on two timings: tb = 2/n tw = d/u = angular velocity of n blades it depends on size and shape of the blades and wind velocity

For maximum power tb = tw 2/n = d/u (22) Multiply radius on both sides and = R/u

At optimum power extraction = 2/n (R/d) (23) Assume d/R = K = 2/nK From empirical relation K = 1/2 Hence, = 4/n (24)

Que. Wind turbine: 3 blades each 4m long. What distance does the tip of each blade travel in one revolution? If it is rotating at 42 rpm how long does it take to one full revolution? How fast tips move through the air? According to optimal tip speed ratio are these blade moving too fast or slow? Take wind speed approx 6m/s.

[Type text]

At a = 1/3 maximum power extraction At a = 1/2 maximum thrust on turbine At a > 1 reverse thrust, used for braking and landing the aircraft [stalling the blade]

Interaction of wind and foil depends on: Leading edge radius Mean camber-line Trailing edge angle Maximum thickness and thickness distribution

Two types of machines are available: Lift Machines Drag Machine Drag Machine causes: Viscous Unequal Friction Pressure Pitching Moment In all HAWM lift is more than drag.

Stalling:

Combining all the effects like no. of blades, lift, drag on Cp

Momentum Theory We are considering no wake rotation means no angular momentum of air behind rotor. Blade Element Theory We require higher lift and for that blades are slightly twisted and tapered which causes angle of attack increases. Generally twisting is done for power extraction and blade should consists torsional stiffness.

Assumptions: No aerodynamic interaction (ignore radial ow) Coefcient of lift and drag are function of blade shape Relative Wind = Vector sum of [ Wind Velocity at rotor U(1-a) + Wind velocity due to blade rotation] Rotational Component =

Biomass

Inorganic waste Timber Plants Forestry Pulp sludge Black liquor Biological Municipal waste (kitchen, garbage, paper) Plastics Categorised in terms of use: Conventional [agricultural, food] Biomass waste [Derivatives] Plantation biomass [Forestry, Herbaceous, Aquatic, Eucalyptus, Sugarcane, Corn, Rapseed oil, Algae] Moisture content is important for energy calculation. Surface moisture takes away energy while inner/structure moisture generates energy. Biomass dry weight is important and it is the weight of biomass as received - weight of moisture Availability of biomass is very high. Earth has biomass in terms of Forest and Ocean. 1800 billion ton is on ground and 4 billion ton is in ocean. In terms of energy biomass on the ground contributes 3300 EJ. 1E = 10^18 Application of biomass: Energy Feeding Fertiliser

Availability ratio: Agricultural 25% Livestock 12.5% Forestry waste Ind. log 75% Fuel log 25% Wood 100% Biomass characterisation: Constituent Gasication (solid to gaseous conversion) Combustion For gasication and combustion important factors are: Analysis Proximate (it is done for moisture, ash, volatile metal, xed carbon = (100-remaining 3)) Ultimate (C, H, N, O, S, Ash, Moisture) Caloric value Gross CV (HHV) Net CV (LHV) LHV = HHV - latent heat of evaporation Analysis can be reported in different ways: As received Dry basis ( Ash A' = 100/(100-M)A) (A',VM', FC') Dry ash free basis (VM, FC)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Orient Green PowerDocument216 pagesOrient Green PowerReTHINK INDIANo ratings yet

- Assignment Environemt 9Document3 pagesAssignment Environemt 9le phucNo ratings yet

- Project On Solar Power Air CompressorDocument34 pagesProject On Solar Power Air CompressorDivya Venkat80% (5)

- Proposal For Research Work at Iit Indore: ProjectsDocument2 pagesProposal For Research Work at Iit Indore: ProjectsAman GargNo ratings yet

- Material Simulation of Polymers Containing Spherical StructuresDocument6 pagesMaterial Simulation of Polymers Containing Spherical StructuresAman GargNo ratings yet

- Cc3100 Boost User Guide Swru371Document21 pagesCc3100 Boost User Guide Swru371Aman GargNo ratings yet

- Paper - Sensors 12 11505 PDFDocument22 pagesPaper - Sensors 12 11505 PDFAman GargNo ratings yet

- Advanced Javascript, 3rd EditionDocument617 pagesAdvanced Javascript, 3rd Editionprmohanty08100% (1)

- Ab-409 1 enDocument36 pagesAb-409 1 enAman GargNo ratings yet

- Godrej Consumer ProductsDocument2 pagesGodrej Consumer ProductsAman GargNo ratings yet

- JaquarDocument2 pagesJaquarAman GargNo ratings yet

- Maruti SuzukiDocument2 pagesMaruti SuzukiAman GargNo ratings yet

- HSILDocument2 pagesHSILAman GargNo ratings yet

- Indian OilDocument2 pagesIndian OilAman GargNo ratings yet

- Tutorial - 3Document2 pagesTutorial - 3Aman GargNo ratings yet

- Market: Third BUSINES Superbrands-2010-Final 6/1/11 12:38 PM Page 74Document2 pagesMarket: Third BUSINES Superbrands-2010-Final 6/1/11 12:38 PM Page 74Aman GargNo ratings yet

- HDFC LifeDocument2 pagesHDFC LifeAman GargNo ratings yet

- CompressorsDocument10 pagesCompressorsAman GargNo ratings yet

- Crompton GreavesDocument2 pagesCrompton GreavesAman GargNo ratings yet

- EdelweissDocument2 pagesEdelweissAman GargNo ratings yet

- Market: Third BUSINES Superbrands-2010-Final 6/1/11 12:15 PM Page 10Document2 pagesMarket: Third BUSINES Superbrands-2010-Final 6/1/11 12:15 PM Page 10Aman GargNo ratings yet

- History: Third BUSINES Superbrands-2010-Final 6/1/11 12:17 PM Page 20Document2 pagesHistory: Third BUSINES Superbrands-2010-Final 6/1/11 12:17 PM Page 20Aman GargNo ratings yet

- Blue DartDocument2 pagesBlue DartAman GargNo ratings yet

- Stirling CycleDocument3 pagesStirling CycleRon QuerubinNo ratings yet

- Otto CycleDocument5 pagesOtto CycleSaraju NandiNo ratings yet

- 2 Carnot CycleDocument6 pages2 Carnot CyclecaptainhassNo ratings yet

- Blue StarDocument2 pagesBlue StarAman GargNo ratings yet

- 4 Ericsson CycleDocument2 pages4 Ericsson CyclecaptainhassNo ratings yet

- 7 Limited Pressure CycleDocument4 pages7 Limited Pressure CyclecaptainhassNo ratings yet

- Introduction To Gas Power CyclesDocument3 pagesIntroduction To Gas Power CyclesJoseph SajanNo ratings yet

- 9 Atkinson CycleDocument3 pages9 Atkinson CyclecaptainhassNo ratings yet

- Nptel - Ac.in Courses IIT-MADRAS Applied Thermodynamics Module 4 6 AsdcDocument4 pagesNptel - Ac.in Courses IIT-MADRAS Applied Thermodynamics Module 4 6 AsdcSanjeev PrakashNo ratings yet

- 4.10 Brayton Cycle (Simple Gas Turbine Cycle) :: Fig.4.10. Brayton Cycle On P-V and T-S DiagramDocument3 pages4.10 Brayton Cycle (Simple Gas Turbine Cycle) :: Fig.4.10. Brayton Cycle On P-V and T-S DiagrammominjeelaniNo ratings yet

- Performance Analysis of A PV Grid-Connected System at The Universidade Nacional Timor Lorosa'eDocument111 pagesPerformance Analysis of A PV Grid-Connected System at The Universidade Nacional Timor Lorosa'eHmaedNo ratings yet

- General Layout of Madhyamaheshwar SHP (3X5 MW)Document1 pageGeneral Layout of Madhyamaheshwar SHP (3X5 MW)krishbistNo ratings yet

- Awarded Solar Grid 20160630Document16 pagesAwarded Solar Grid 20160630International Home DecorsNo ratings yet

- The Passage Below Is Accompanied by A Set of Questions. Choose The Best Answer To Each QuestionDocument98 pagesThe Passage Below Is Accompanied by A Set of Questions. Choose The Best Answer To Each Questionmayank patelNo ratings yet

- Energy From Tides and Waves: Dana Word, Chris Webber, Lacey Doucet, Bekah BeallDocument13 pagesEnergy From Tides and Waves: Dana Word, Chris Webber, Lacey Doucet, Bekah BeallRahul NampalliwarNo ratings yet

- Solarking: Brackets For Solar Photovoltaic Power Hot-Dip 5%Al-Zn/Al-Mg-Zn Coated Steel ForDocument16 pagesSolarking: Brackets For Solar Photovoltaic Power Hot-Dip 5%Al-Zn/Al-Mg-Zn Coated Steel ForJah KuNo ratings yet

- PDFDocument232 pagesPDFAhmad KalbounahNo ratings yet

- Project Sustainable Design Management: Methodology For Sustainable Solutions (BIM Book)Document47 pagesProject Sustainable Design Management: Methodology For Sustainable Solutions (BIM Book)Nhan DoNo ratings yet

- Syllabus of ME476-Fall2020Document9 pagesSyllabus of ME476-Fall2020HussamNo ratings yet

- Aqa Gcse Science Command Words1Document19 pagesAqa Gcse Science Command Words1Wong Weng SonNo ratings yet

- GinerELX ESMCDocument12 pagesGinerELX ESMCBjorn FejerNo ratings yet

- A National Vision Smart Grids KoreaDocument10 pagesA National Vision Smart Grids KoreaAlan Edu RojasNo ratings yet

- Biorefining of Biomass To BiofuelsDocument382 pagesBiorefining of Biomass To Biofuelsthalassophilia100% (1)

- Linear Fresnel Re Ector (LFR) : June 2020Document11 pagesLinear Fresnel Re Ector (LFR) : June 2020Madhur Bain SinghNo ratings yet

- Wmu 2013 - PPT - FinalDocument103 pagesWmu 2013 - PPT - FinalRochdi BahiriNo ratings yet

- Iha 2018 Hydropower Status Report 4Document53 pagesIha 2018 Hydropower Status Report 4Wilsonfeng WangNo ratings yet

- Report 1Document17 pagesReport 1Francis MokogwuNo ratings yet

- Reserve Power: Res Opzv BatteriesDocument8 pagesReserve Power: Res Opzv BatteriesJayson EnrileNo ratings yet

- Northern Biogas IM USD OCT2019Document31 pagesNorthern Biogas IM USD OCT2019David LeongNo ratings yet

- REI 2019 Show Directory - Third Cut-MinDocument419 pagesREI 2019 Show Directory - Third Cut-Minmahajan.gouravNo ratings yet

- A Study On Consumer Awareness and Adoption of Green Banking PractisesDocument67 pagesA Study On Consumer Awareness and Adoption of Green Banking PractisesArdra SabuNo ratings yet

- Module 1 SEP-Ktunotes - inDocument24 pagesModule 1 SEP-Ktunotes - inmujeebNo ratings yet

- Exelon 2020: A Low Carbon RoadmapDocument30 pagesExelon 2020: A Low Carbon RoadmapjennabushNo ratings yet

- Gill Wilkins Technology Transfer For Renewable Energy Overcoming Barriers in Developing CountriesDocument256 pagesGill Wilkins Technology Transfer For Renewable Energy Overcoming Barriers in Developing CountriesmshameliNo ratings yet

- 3kVA Quote Jeff (Pylontech Battery)Document1 page3kVA Quote Jeff (Pylontech Battery)az PhillipsNo ratings yet

- Community Energy: Planning, Development and Delivery, UK Edition, by Michael King and Rob Shaw, 2010Document42 pagesCommunity Energy: Planning, Development and Delivery, UK Edition, by Michael King and Rob Shaw, 2010Randall WestNo ratings yet